Cov Khoom Siv Hluav Taws Xob rau Sapphire / Ceramics / Marble Cov Khoom Siv hauv Vertical / Kab rov tav / Multi-Wire Txiav

Daim duab qhia ntxaws

Cov Khoom Siv Txheej Txheem thiab Cov Nqi Tseem Ceeb

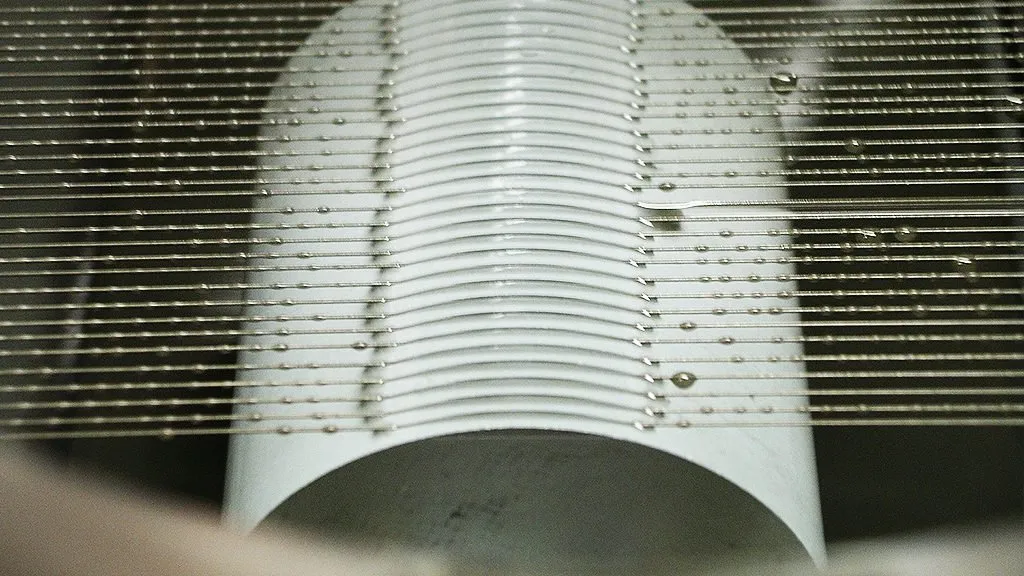

Lub Hlau Saw Tshuab yog cov cuab yeej txiav cov cuab yeej siv siab ceev uas siv lub pob zeb diamond xaim. Nws tsim cov cuab yeej txiav tau yooj yim los ntawm kev txhim kho pob zeb diamond abrasives rau hauv cov hlau hlau los ntawm electroplating lossis resin bonding, ua kom muaj txiaj ntsig zoo ntawm cov khoom siv hardness thiab high-brittleness. Nws cov txiaj ntsig tseem ceeb nyob hauv kev ua tiav high-precision, tsis tshua muaj kev puas tsuaj, thaum txhim kho cov khoom siv thiab kev ua haujlwm zoo. Nws yog tshwj xeeb tshaj yog haum rau cov ntaub ntawv xws li sapphire, ceramics, thiab marble, uas yog nyuaj rau ib txwm ua txoj kev.

Cov yam ntxwv ntawm kev ua cov khoom siv thiab cov lus qhia siv

| Yam ntxwv Dimension | Sapphire | Ceramics | Marble |

| Cov yam ntxwv tseem ceeb | Ultra-siab hardness (Mohs 9), siab brittleness | High hardness, siab brittleness, siab elastic modulus | Cov khoom tsis sib xws, muaj cov ntsiab lus nyuaj xws li quartz |

| Kev Sib Tw | Yooj yim rau tawg thiab ntug chipping | Txiav saum npoo nws yooj yim rau microcracks | Yooj yim rau kev txiav tsis sib xws thiab ntug chipping |

| Qhov tseem ceeb Metrics | Nto roughness tuaj yeem tswj tau rau Ra <0.5μm | Ua raws li kev txiav txim siab saum npoo, txo cov microcracks | High txiav efficiency, tiaj tus slab nto |

| Main Application Directions | LED substrates, optical qhov rais daim hlau, semiconductor ntaus ntawv substrates | Electronic ceramic substrates, ntim cov ntaub ntawv, cov qauv ceramics | Architectural hniav slabs, countertops, carving crafts |

Tsom ntsoov rau Txoj Cai Ua Haujlwm

Lub hauv paus ntsiab lus ntawm kev ua haujlwm tseem ceeb ntawm cov khoom siv hlau pom yog siv cov hlau tsis tu ncua uas txuas nrog cov pob zeb diamond abrasives uas grinds cov khoom los ntawm kev ua haujlwm siab. Lub hom phiaj ntawm txoj cai no txawv ntawm cov khoom sib txawv:

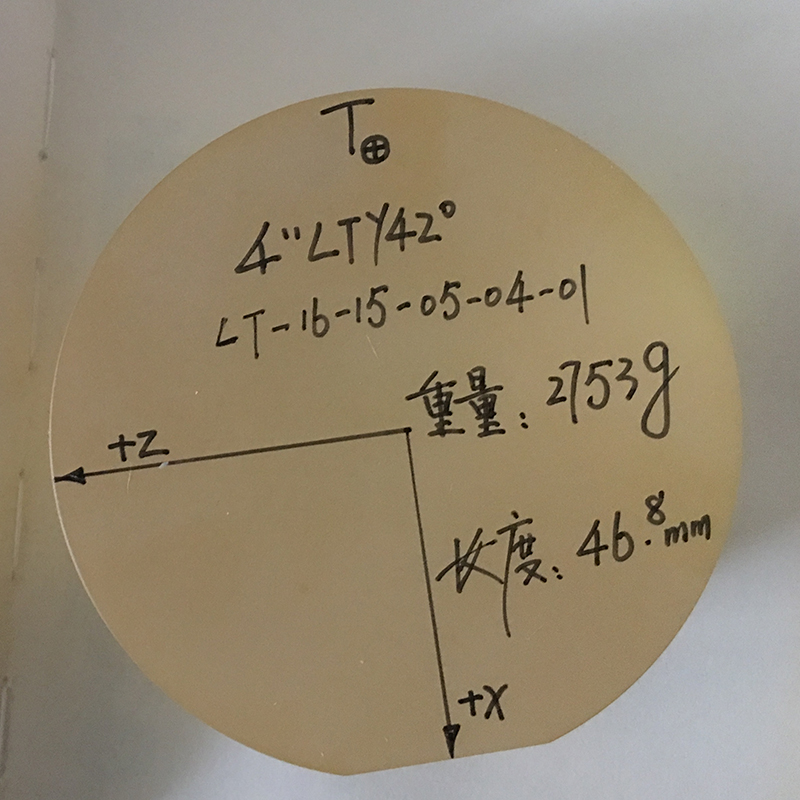

- uaSapphire:Qhov tseem ceeb yog nyob rau hauv kev tswj hwm ntawm kev txiav tsis zoo (xws li xaim ceev, pub tus nqi, nro) kom tsis txhob tawg ntawm cov khoom siv. Piv txwv li, siv lub pob zeb diamond hlau nrog ib txoj kab uas hla ntawm 0.7 hli, ntawm qhov ceev ntawm 20m / s, pub tus nqi ntawm 0.5mm / min, thiab nro quab yuam ntawm 50N, tuaj yeem ua tiav qhov chaw txiav nrog roughness hauv qab 0.5μm.

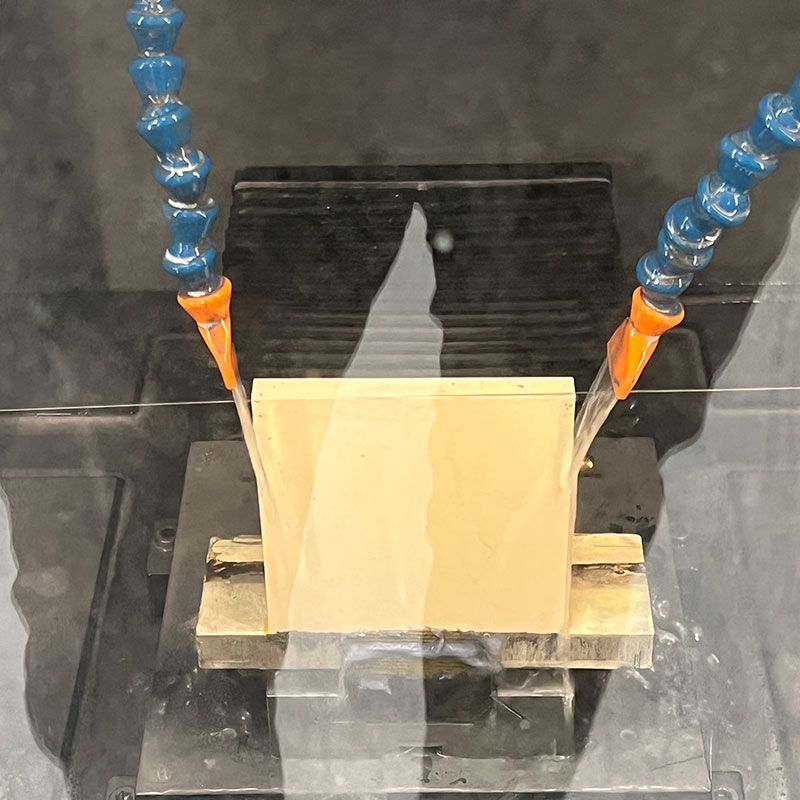

- uaCeramics:Nws yog ib qho tsim nyog los kov yeej lawv cov hardness siab thiab brittleness. Kev sib tsoo ntawm cov pob zeb diamond hlau pom tuaj yeem txo qhov kev ntxhov siab thaum txiav, txo qhov kev pheej hmoo ntawm micro-crack tiam. Nws cov txheej txheem ua haujlwm zoo ib yam li kev sib tsoo, tab sis txoj kev abrasive particle txoj kev sib txawv.

- uaMarble:Vim lub pob zeb tsis sib xws, lub pob zeb diamond hlau pom yuav tsum muaj kev hloov tau zoo thiab muaj peev xwm tshem tawm nti. Niaj hnub nimno high-speed hlau saws tuaj yeem ua tiav cov hlau nrawm mus txog 2000 meters ib feeb thiab tuaj yeem hloov kho qhov txiav tsis zoo rau pob zeb sib txawv hardness los ntawm cov tshuab ntse.

Cov txheej txheem nthuav dav thiab cov teebmeem

| Khoom siv | Thaiv Txiav / Slabbing | Hla Txiav / Trimming | Multi-Wire Txiav |

| uaSapphire | Qhov cuam tshuam:Nqaim kerf (tuaj yeem ncav cuag 0.55mm), nto roughness controllable hauv qab 1 micrometer, zoo txo cov khoom poob thiab ua haujlwm tom qab. uaTxoj kev:Txiav siv lead ua ingots rau hauv nyias slices rau ua LED substrates, thiab lwm yam. | Qhov cuam tshuam:ceev txiav ceev; 2-inch inch sapphire pas nrig tuaj yeem txiav hauv 0.5 teev. Txoj kev:Siv rau truncating ingots los yog ua ntej shaping. | uaCov nyhuv:Tau ib txhij txiav ib tug loj tus naj npawb ntawm nyias slices, zoo heev txhim kho kev ua hauj lwm efficiency rau cov ntaub ntawv xws li silicon wafers; sliced nto muaj zoo zoo thiab uniform thickness. |

| Ceramics | uaCov nyhuv:Zoo zoo txiav nto, tsawg ntug kev puas tsuaj, haum rau kev npaj cov txheej txheem-me me hluav taws xob ceramic substrates. uaTxoj kev:Siv los txiav cov blanks ceramic rau hauv substrates ntawm cov duab thiab qhov ntau thiab tsawg. | uaCov nyhuv:Haum rau kev txiav tshwj xeeb-zoo li ceramic Cheebtsam, muab siab txiav yooj. Txoj kev:Ua tiav machining lossis profile txiav ntawm cov khoom siv ceramic. | uaCov nyhuv:Haum rau high-volume txiav ntawm uniform ceramic Cheebtsam, siab ntau lawm efficiency. uaTxoj kev:Txiav nrog ntau cov xov hlau ib txhij, haum rau kev tsim khoom loj. |

| Marble | uaCov nyhuv:High txiav efficiency, tiaj tus slab nto, tso lub hauv paus zoo rau kev sib tsoo thiab polishing tom ntej. uaTxoj kev:Txiav cov khoom thaiv loj rau hauv slabs. | uaCov nyhuv:Yuav siv tau rau thaiv shaping, loj slab faib, hloov mus rau ntau yam kev xav tau. uaTxoj kev:Trimming los yog trimming pob zeb slabs. | uaCov nyhuv:Ib qho kev txiav tuaj yeem tsim ntau cov slabs loj, kev ua haujlwm siab ntau lawm, zoo slab uniformity, haum rau loj-scale project yuav tsum. |

Core Parameter Table ntawm Hlau Pom Khoom

| Lub npe parameter | Parameter ntsuas |

| Main Lub cev muaj zog | 11KW-75KW TSI |

| Hlau Ceev | 0-40 (m / s) ceev |

| Max. Hlau Length | 20-150 m |

| Fais fab mov | Standard: Peb-theem, 380V, 50Hz |

| Taug kev Motor Power | 0.75KW - 1.5KW TSI |

| Lub kaum sab xis tig | 360 ° (Kev tswj hluav taws xob) |

| Tswj | Automatic / phau ntawv ua haujlwm. Qee cov qauv siv CNC lossis PLC tswj tshuab. |

| Tso cai ua haujlwm kub | -15 ℃ ~ + 40 ℃ |

XKH Service cog lus

Peb tau cog lus los muab cov neeg siv khoom siv dav hlau pom cov cuab yeej daws teeb meem thiab kev txhawb nqa thev naus laus zis, leveraging qhov zoo ntawm kev lag luam thiab kev lag luam:

- Customized khoom:Muab cov phiaj xwm xaim pom cov cuab yeej xaiv thiab teeb tsa cov tswv yim raws li cov ntaub ntawv tshwj xeeb cov neeg siv khoom thiab cov khoom xav tau.

- Txheej txheem Optimization Support:Qhia txiav txiav cov kev paub dhau los rau cov khoom sib txawv los pab cov neeg siv khoom hauv kev ua kom cov txheej txheem txiav, txhim kho kev txiav thiab cov khoom zoo.

- uaTechnical Support thiab Training:Muab cov cuab yeej ua haujlwm, kev saib xyuas, thiab lwm yam kev cob qhia kom ntseeg tau tias cov neeg siv khoom tuaj yeem siv cov cuab yeej ua haujlwm tau zoo.

- Txhim khu kev ntseeg tom qab-muag Guarantee:Tsim kom muaj kev pabcuam tomqab muag tiav kom teb tau sai rau cov neeg siv khoom xav tau, muab cov khoom seem txhawb nqa thiab kho cov kev pabcuam.

FAQ ntawm Hlau Saw Khoom

Q1: Dab tsi yog cov khoom siv saw hlau?

A1: Cov hlau pom yog cov cuab yeej txiav uas siv cov pob zeb diamond-coated hlau txav ntawm kev kub ceev kom hlais los ntawm cov ntaub ntawv nyuaj, nkig xws li sapphire, ceramics, thiab marble nrog cov khib nyiab tsawg.

Q2: Cov ntaub ntawv twg tuaj yeem txiav cov hlau zoo?

A2: Hlau saws yog zoo tagnrho rau kev ua sapphire, quartz, ceramics, marble, silicon carbide, thiab lwm yam nyuaj, nkig ntaub ntawv vim lawv siab precision thiab txo txoj kev pheej hmoo ntawm tawg.

Q3: Dab tsi yog qhov txawv ntawm ntau cov hlau thiab ib leeg-xaim txiav?

A3: Multi-wire txiav siv ntau cov xov hlau los hlais cov blocks loj rau hauv ntau lub hlais ib txhij, txhawb kev ua haujlwm rau ntau lawm, thaum ib leeg-xaim txiav yog haum rau me me, txiav txiav.ua

Q4: Dab tsi ntawm kev txiav qhov tseeb tuaj yeem ua tiav?

A4: High-precision hlau saws tuaj yeem ua tiav qhov tseeb hauv ± 10μm, ua rau lawv tsim nyog rau kev tsim khoom semiconductor wafers thiab cov khoom siv kho qhov muag.

Q5: Kuv yuav ua li cas thiaj xaiv cov hlau pom zoo rau kuv qhov project?

A5: Xaiv raws li cov khoom siv hardness, qhov project scale (xws li, ntau-xaim rau loj-ntim slab ntau lawm), thiab yuav tsum tau precision, thaum tseem xyuas kom meej lub tshuab muaj stability thiab ib tug nruj tswj system.