Pob zeb diamond-Copper Composite Thermal Management Materials

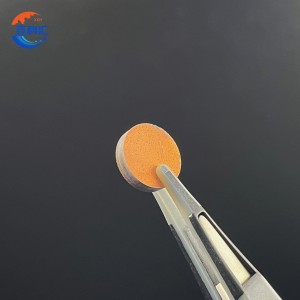

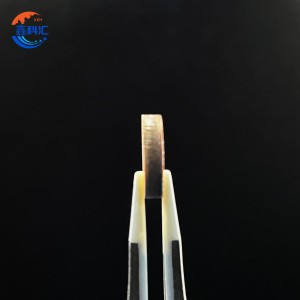

Daim duab qhia ntxaws

Khoom Taw Qhia

CovPob zeb diamond-Copper Composite (Cu-Diamond)yog ibultra-high-kev ua haujlwm thermal tswj cov khoomuas ua ke nrog lub ntiaj teb cov khoom siv hluav taws xob zoo tshaj plaws -pob zeb diamond- nrog superior hluav taws xob thiab mechanical zog ntawmtooj liab.

Tsim los rau cov khoom siv hluav taws xob thiab cov khoom siv hluav taws xob, qhov sib xyaw no ua tiav qhov sib npaug tshwj xeeb ntawmhuab cua thermal conductivity, tswj tau thermal expansion, thiabmechanical stability, ua kom txhim khu kev lag luam txawm nyob rau hauv qhov xav tau tshaj plaws thermal ib puag ncig.

Tsis zoo li cov pa tooj liab, tungsten, lossis molybdenum-raws li substrates, Pob zeb diamond-Copper composites xamus txog ob zaug ntawm thermal conductivitythaum txo qhov hnyav, ua rau lawv nyiam xaiv rausemiconductor ntim, laser tshuab, aerospace electronics, thiab high-power LED modules.

Txoj Cai Khoom Siv

Nyob rau hauv lub plawv ntawm composite lus dagpob zeb diamond haisuniformly embedded nyob rau hauv ibtooj liab matrix.

Txhua pob zeb diamond particle ua raws li lub dab dej micro cua sov, sib kis tau sai, thaum lub tooj liab matrix xyuas kom muaj hluav taws xob conduction thiab kev ua haujlwm ruaj khov.

Los ntawm cov txheej txheem tsim khoom qib siab - suav nrognqus infiltration, tshuaj txheej txheej, thiabLub teeb plasma sintering (SPS)- ib tug muaj zog thiab ruaj khov interface daim ntawv cog lus yog tsim, guaranteeing ntev kev cia siab nyob rau hauv tas li thermal cycling.

Technical Highlights

| | |

|---|---|

| | |

| | |

| | |

| | |

| | |

Daim ntawv thov

-

High-Power Semiconductor Modules(IGBT, MOSFET, RF & microwave pob)

-

Laser Diodes thiab Optoelectronic Devices

-

Aerospace thiab Defense Cooling Systems

-

High-performance LED Thaum tshav kub kub Spreaders

-

IC thiab CPU Kub Sinks rau Advanced Computing

-

Fais fab Amplifiers thiab Optical Communication Equipment

Vim li cas thiaj xaiv Pob Zeb Diamond-Copper Composite?

Vimkub tseem ceeb.

Nyob rau hauv lub era ntawm miniaturization thiab siab zog ceev, tswj cov cua sov zoo txhais lub neej thiab kev ua tau zoo ntawm txhua yam khoom.

Cu-Diamond composite xyuas kom meej:

-

Cov cuab yeej siv tau ntev dua

-

Txhim khu kev ua haujlwm ruaj khov

-

Txhim kho zog efficiency

-

Txo thermal qaug zog

FAQ ntawm Quartz Glasses

Q1: Puas yog Cu-Pob Zeb Composites tuaj yeem hloov kho rau cov ntaub ntawv tshwj xeeb nti?

Yog lawm. Cov pob zeb diamond ntim feem thiab CTE tuaj yeem raug kho kom haum rau Si, GaN, lossis SiC-raws li cov khoom siv.

Q2: Puas yuav tsum tau metallization ua ntej soldering?

Yog lawm. Surface metallization (Ni/Au, Ti/Ni/Au) raug pom zoo kom ua kom muaj kev sib raug zoo thiab kev ua haujlwm thermal tsawg.

Q3: Nws ua li cas nyob rau hauv high-frequency los yog pulsed cua sov tej yam kev mob?

Pob zeb diamond lub tshav kub kis tau zoo ua kom muaj qhov sib npaug ntawm qhov kub thiab txias, ua rau nws zoo tagnrho rau cov khoom siv hluav taws xob ntau thiab cov mem tes-loaded.

Q4: Dab tsi yog qhov kev ua haujlwm siab tshaj plaws?

Lub composite tseem ruaj khov mus txog600 ° Cnyob rau hauv inert los yog lub tshuab nqus tsev ib puag ncig, nyob ntawm seb lub txheej thiab kev sib txuas lus interface.

Txog Peb

XKH tshwj xeeb hauv kev tsim cov thev naus laus zis, tsim khoom, thiab muag cov iav tshwj xeeb kho qhov muag thiab cov ntaub ntawv siv lead ua tshiab. Peb cov khoom siv kho qhov muag khoom siv hluav taws xob, khoom siv hluav taws xob, thiab tub rog. Peb muab Sapphire optical Cheebtsam, xov tooj ntawm tes lens npog, Ceramics, LT, Silicon Carbide SIC, Quartz, thiab semiconductor siv lead ua wafers. Nrog cov kws tshaj lij thiab cov cuab yeej siv niaj hnub, peb ua tau zoo hauv kev ua cov khoom lag luam uas tsis yog tus qauv, aiming los ua ib qho khoom siv optoelectronic high-tech enterprise.