High-Precision Ib Sab Polishing Khoom

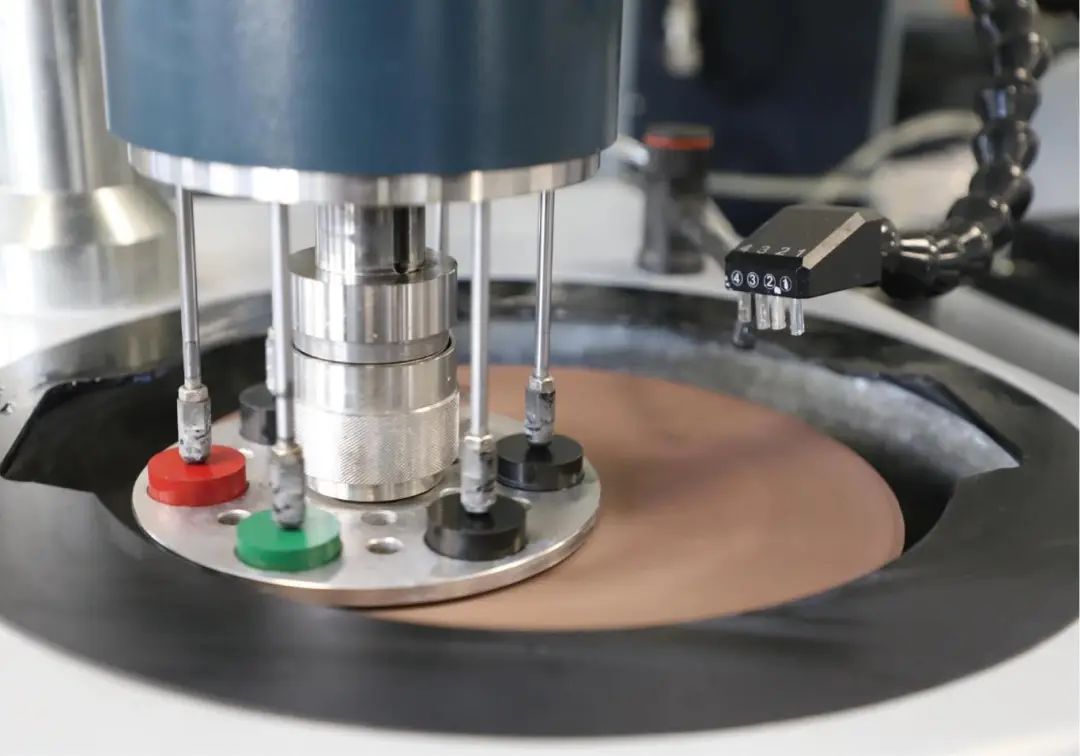

Yees duab ntawm Cov Khoom Siv Ib Sab Polishing

Qhia txog Cov Khoom Siv Hauv Ib Sab Polishing

Lub tshuab polishing ib leeg yog ib qho tshwj xeeb ntawm cov cuab yeej tsim los rau kev ua tiav ntawm cov ntaub ntawv nyuaj thiab nkig. Nrog rau kev loj hlob sai ntawm kev lag luam semiconductor, optoelectronics, optical Cheebtsam, thiab cov khoom siv siab heev, kev thov rau cov khoom siv polishing high-precision thiab high-efficiency polishing tau ua sai heev. Lub tshuab polishing ib leeg siv cov kev sib txheeb ntawm cov polishing disc thiab cov phaj ceramic los ua kom lub siab tsis sib xws ntawm qhov chaw ua haujlwm, ua kom zoo tshaj plaws thiab zoo li daim iav tiav.

Tsis zoo li cov tsoos ob sab polishing tshuab, ib leeg-sab polishing tshuab muaj kev yooj yim dua los tuav ntau qhov sib txawv thiab thicknesses ntawm wafers lossis substrates. Qhov no ua rau nws tsim tshwj xeeb rau kev ua cov ntaub ntawv xws li silicon wafers, silicon carbide, sapphire, gallium arsenide, germanium flakes, lithium niobate, lithium tantalate, thiab optical iav. Qhov tseeb ua tiav nrog cov khoom siv no ua kom ntseeg tau tias cov txheej txheem ua tau raws li cov kev cai nruj ntawm microelectronics, LED substrates, thiab kev ua haujlwm siab optics.

Advantage ntawm Ib Sab Polishing Khoom

Tus tsim lub tswv yim ntawm ib leeg-sab polishing tshuab hais txog kev ruaj ntseg, precision, thiab efficiency. Lub cev tseem ceeb ntawm lub tshuab feem ntau yog ua los ntawm cam khwb cia thiab forged steel, uas muab cov neeg kho tshuab ruaj khov thiab txo qis kev vibration thaum ua haujlwm. Cov khoom lag luam zoo thoob ntiaj teb tau txais kev pom zoo rau cov txheej txheem tseem ceeb xws li kev sib hloov tsav, kev xa hluav taws xob, thiab kev tswj hwm, kom ntseeg tau tias kev ua tau zoo thiab kev ua haujlwm ntev.

Lwm qhov txiaj ntsig tseem ceeb nyob hauv nws qhov kev ua haujlwm humanized interface. Niaj hnub nimno ib leeg-sab polishing tshuab yog nruab nrog ntse tswj vaj huam sib luag, tso cai rau cov neeg ua haujlwm kho cov txheej txheem ceev xws li polishing ceev, siab, thiab kev sib hloov. Qhov no ua rau cov txheej txheem ua tau zoo dua qub, uas yog qhov tseem ceeb rau kev lag luam uas qhov sib xws yog qhov tseem ceeb.

Los ntawm qhov kev xav ntawm cov txheej txheem versatility, cov cuab yeej tuaj yeem ua kom haum rau ntau qhov ntau thiab tsawg ntawm machining, feem ntau ntawm 50mm txog 200mm lossis loj dua, nyob ntawm tus qauv. Kev sib hloov ntawm cov polishing disc feem ntau poob ntawm 50 txog 80 rpm, thaum lub zog ntsuas nws txawv ntawm 11kW mus rau ntau tshaj 45kW. Nrog xws li ib tug dav spectrum ntawm configurations, cov neeg siv yuav xaiv ib tug qauv uas zoo tshaj plaws haum lawv cov kev xav tau ntau lawm, txawm rau kev tshawb fawb-scale chaw soj nstuam los yog rau loj-scale industrial ntau lawm.

Tsis tas li ntawd, cov qauv siab heev muaj ntau lub taub hau polishing, synchronized los ntawm servo hluav taws xob tswj tshuab. Qhov no xyuas kom meej tias txhua lub taub hau polishing muaj qhov nrawm nrawm thaum lub sijhawm ua haujlwm, yog li txhim kho ob qho tib si ua haujlwm zoo thiab tawm los. Tsis tas li ntawd, lub tshuab ua kom txias thiab kub tswj kev sib xyaw ua ke rau hauv lub tshuab lav kev ruaj ntseg thermal, uas yog ib qho tseem ceeb thaum cuam tshuam nrog cov khoom siv hluav taws xob.

Lub tshuab polishing ib leeg sawv cev yog ib qho tseem ceeb ntawm cov khoom tsim khoom nyob rau hauv niaj hnub era ntawm high technology. Nws kev sib xyaw ua ke ntawm kev tsim kho tshuab zoo, kev tswj xyuas ntse, ntau yam khoom siv sib xws, thiab kev ua tiav zoo tshaj plaws ua rau nws yog ib qho cuab yeej tseem ceeb rau cov tuam txhab thiab cov koom haum tshawb fawb uas yuav tsum tau muaj qhov tseeb ntawm cov ntaub ntawv siab heev.

Khoom nta ntawm ib leeg-Side Polishing khoom

-

Kev ruaj ntseg siab: Lub tshuab lub cev yog cam khwb cia thiab forged los xyuas kom meej cov txheej txheem rigidity thiab zoo heev ua hauj lwm stability.

-

Precision Cheebtsam: International-qib bearings, motors, thiab hluav taws xob tswj units lav lub neej ntev kev pab cuam thiab txhim khu kev qha kev ua tau zoo.

-

Cov qauv yooj yim: Muaj nyob rau hauv ntau lub series (305, 36D, 50D, 59D, thiab X62 S59D-S) kom tau raws li ntau haiv neeg yuav tsum tau ua.

-

Humanized Interface: Ib qho yooj yim-rau-siv vaj huam sib luag nrog cov chaw rau polishing tsis, ua kom ceev daim ntawv qhia hloov.

-

Ua kom txias txias: Integrated water-cooled systems nrog precision kub sensors kom ruaj khov polishing tej yam kev mob.

-

Multi-Head Synchronization: Servo hluav taws xob tswj xyuas kom synchronized ceev ntawm ntau lub taub hau polishing kom zoo ib yam.

Technical Specifications ntawm ib leeg-Side Polishing khoom

| Qeb | Yam khoom | 305 Series | 36D Series | 50D Series | 59D Series |

|---|---|---|---|---|---|

| Polishing Disc | Txoj kab uas hla | 8 20mm | 9 14mm | 12 82mm | 1 504mm |

| Ceramic phaj | Txoj kab uas hla | 305mm ua | 360 hli | 4 85mm | 5 76mm |

| Optimum Machining | Workpiece Loj | 50-100 hli | 50-150 hli | 150-200 hli | 200 hli |

| Hwj chim | Main Tsav | 11 kWm | 11 kWm | 18.5 kW tsi | 30 kWm |

| Rotation Rate | Polishing Disc | 80rpm ua | 65rpm ua | 65rpm ua | 50rpm ua |

| Qhov Loj (L × W × H) | — | 1920 × 1125 × 1680 hli | 1360 × 1330 × 2799 hli | 2334 × 1780 × 2759 hli | 1900 × 1900 × 2700 hli |

| Tshuab hnyav | — | 2000 kg | 3500 kg ib | 7500kg ib | 1 1826kg |

| Yam khoom | Parameter | Khoom siv |

|---|---|---|

| Txoj kab uas hla ntawm Main Polishing Disc | Φ1504 × 40 hli | SUS 410 |

| Txoj kab uas hla ntawm Polishing Disc (Lub taub hau) | Φ576 × 20 hli | SUS 316 |

| Max Ceev ntawm Main Polishing Disc | 60rpm ua | — |

| Max Ceev ntawm Upper Throwing Head | 60rpm ua | — |

| Tus naj npawb ntawm Polishing taub hau | 4 | — |

| Qhov Loj (L × W × H) | 2350 × 2250 × 3050 hli | — |

| Khoom hnyav | 12 ib t | — |

| Max Siab Ntau Yam | 50-500 ± kg | — |

| Tag Nrho Lub Hwj Chim Tag Nrho Lub Tshuab | 45 kW ua | — |

| Loading Capacity (ib lub taub hau) | 8 h / φ 150 mm (6 ") lossis 5 h / φ 200 mm (8") | — |

Daim Ntawv Thov Ntau Yam Khoom Siv Ib Sab Polishing

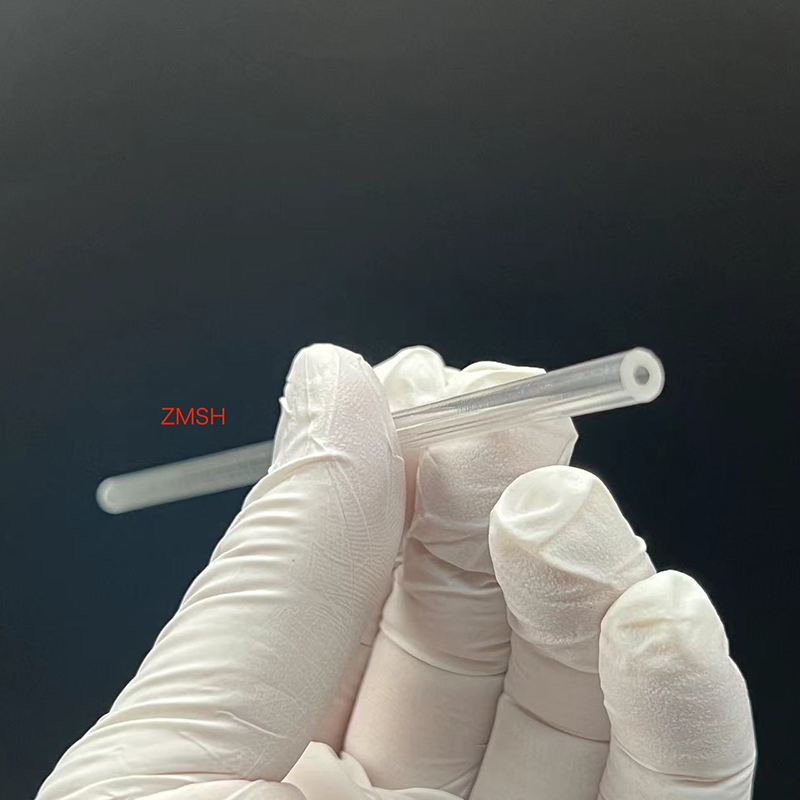

Lub tshuab yog tsim rauib sab polishingntawm ntau yam khoom tawv thiab nkig, suav nrog:

-

Silicon wafers rau cov khoom siv semiconductor

-

Silicon carbide rau hluav taws xob hluav taws xob thiab LED substrates

-

Sapphire wafers rau optoelectronics thiab saib crystals

-

Gallium arsenide rau kev siv hluav taws xob ntau zaus

-

Germanium flakes rau infrared optics

-

Lithium niobate thiab lithium tantalate rau piezoelectric Cheebtsam

-

Cov iav substrates rau precision optics thiab cov khoom siv sib txuas lus

Cov Lus Nug Nquag (FAQ) ntawm Cov Khoom Siv Sab Hauv Ib Sab Polishing

Q1: Cov ntaub ntawv dab tsi tuaj yeem ua tus txheej txheem ntawm ib sab polishing?

Lub tshuab yog tsim rau silicon wafers, sapphire, silicon carbide, gallium arsenide, iav, thiab lwm yam ntaub ntawv nkig.(Keywords: polishing tshuab, brittle cov ntaub ntawv)

Q2: Dab tsi yog qhov ntau thiab tsawg polishing disc muaj?

Nyob ntawm cov series, polishing discs muaj li ntawm 820 hli mus rau 1504 hli inch.(Keywords: polishing disc, tshuab loj)

Q3: Dab tsi yog qhov kev sib hloov ntawm polishing disc?

Kev sib hloov tus nqi sib txawv ntawm 50 mus rau 80 rpm, nyob ntawm tus qauv.(Keywords: kev sib hloov tus nqi, polishing ceev)

Q4: Yuav ua li cas tswj qhov system txhim kho polishing zoo?

Lub tshuab siv servo hluav taws xob tswj rau synchronized lub taub hau kev sib hloov, kom ntseeg tau tias lub siab sib xws thiab ruaj khov.(Keywords: tswj qhov system, polishing taub hau)

Q5: Dab tsi yog qhov hnyav thiab hneev taw ntawm lub tshuab?

Tshuab hnyav li ntawm 2 tons mus rau 12 tons, nrog hneev taw ntawm 1360 × 1330 × 2799 mm thiab 2350 × 2250 × 3050 mm.(Keywords: tshuab hnyav, qhov ntev)

Txog Peb

XKH tshwj xeeb hauv kev tsim cov thev naus laus zis, tsim khoom, thiab muag cov iav tshwj xeeb kho qhov muag thiab cov ntaub ntawv siv lead ua tshiab. Peb cov khoom siv kho qhov muag khoom siv hluav taws xob, khoom siv hluav taws xob, thiab tub rog. Peb muab Sapphire optical Cheebtsam, xov tooj ntawm tes lens npog, Ceramics, LT, Silicon Carbide SIC, Quartz, thiab semiconductor siv lead ua wafers. Nrog cov kws tshaj lij thiab cov cuab yeej siv niaj hnub, peb ua tau zoo hauv kev ua cov khoom lag luam uas tsis yog tus qauv, aiming los ua ib qho khoom siv optoelectronic high-tech enterprise.