HPSI SiC Wafer ≥90% Transmittance Optical Qib rau AI / AR tsom iav

Kev Taw Qhia Core: Lub luag haujlwm ntawm HPSI SiC Wafers hauv AI / AR Glasses

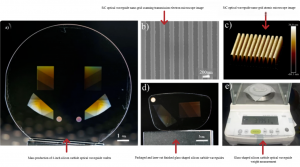

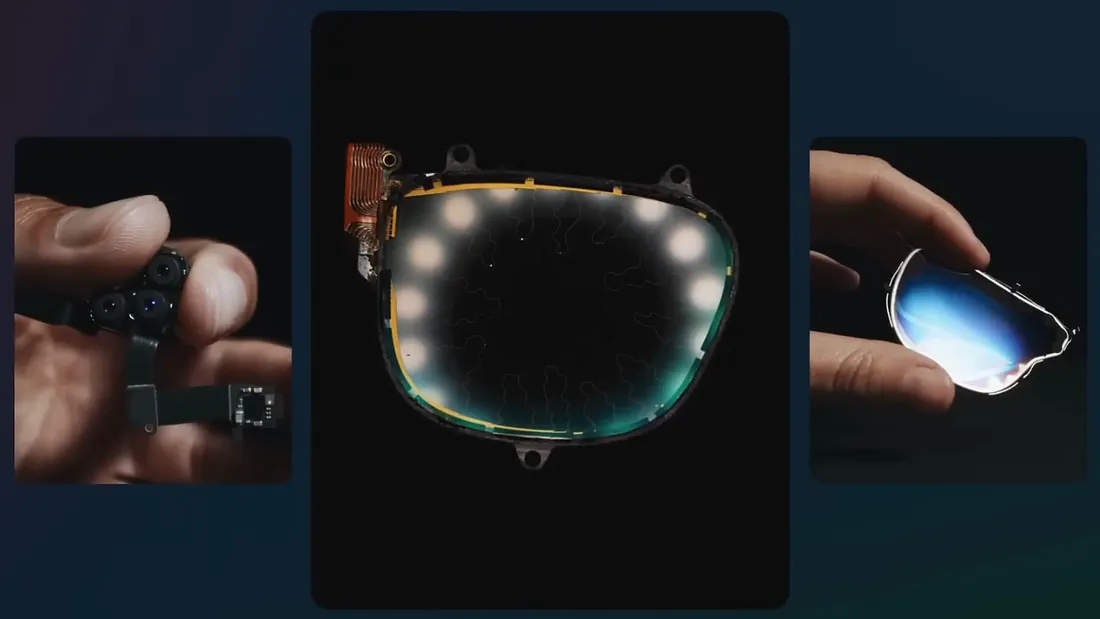

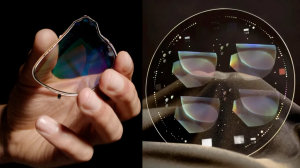

HPSI (High-Purity Semi-Insulating) Silicon Carbide wafers yog cov wafers tshwj xeeb uas muaj kev tiv thaiv siab (> 10⁹ Ω·cm) thiab tsis tshua muaj qhov tsis xws luag. Hauv AI / AR tsom iav, lawv feem ntau yog cov khoom siv hauv cov khoom siv rau cov khoom siv kho qhov muag pom kev sib txawv, hais txog cov khoom siv kho qhov muag uas cuam tshuam nrog cov khoom siv kho qhov muag nyob rau hauv cov nqe lus ntawm daim ntawv nyias-thiab-teeb, tshav kub dissipation, thiab kev ua haujlwm kho qhov muag. Piv txwv li, AR tsom iav siv SiC waveguide lo ntsiab muag tuaj yeem ua tiav qhov dav dav ntawm qhov pom (FOV) ntawm 70 ° - 80 °, thaum txo qhov tuab ntawm ib txheej txheej lo rau tsuas yog 0.55mm thiab qhov hnyav rau tsuas yog 2.7g, ua kom muaj kev nplij siab thiab pom kev zoo.

Cov yam ntxwv tseem ceeb: Yuav ua li cas SiC Cov Khoom Siv Ua Rau AI / AR Glasses Tsim

High Refractive Index thiab Optical Performance Optimization

- SiC's refractive index (2.6–2.7) yog ze li ntawm 50% siab dua li cov iav tsoos (1.8–2.0). Qhov no tso cai rau cov txheej txheem waveguide thinner thiab ntau dua, nthuav dav FOV. Lub siab refractive Performance index kuj pab txo qis "cov nyhuv zaj sawv" uas muaj nyob rau hauv diffractive waveguides, txhim kho cov duab purity.

Exceptional Thermal Management Peev Xwm

- Nrog lub thermal conductivity siab li 490 W / m·K (ze rau ntawm tooj liab), SiC tuaj yeem sai sai dissipate cua sov tsim los ntawm Micro-LED zaub modules. Qhov no tiv thaiv kev ua haujlwm tsis zoo lossis kev laus ntawm cov cuab yeej vim qhov kub thiab txias, ua kom lub neej ntev roj teeb thiab ruaj khov siab.

Mechanical Strength thiab Durability

- SiC muaj Mohs hardness ntawm 9.5 (thib ob nkaus xwb rau pob zeb diamond), muab qhov tshwj xeeb khawb tsis kam, ua rau nws zoo tagnrho rau cov neeg siv khoom siv iav. Nws qhov roughness tuaj yeem tswj tau rau Ra < 0.5 nm , kom ntseeg tau tias tsis tshua muaj kev sib kis thiab cov teeb pom kev zoo sib xws hauv waveguides.

Hluav taws xob khoom Compatibility

- HPSI SiC's resistivity (> 10⁹ Ω·cm) pab tiv thaiv cov teeb liab cuam tshuam. Nws kuj tseem tuaj yeem ua cov khoom siv hluav taws xob muaj txiaj ntsig zoo, ua kom lub zog tswj hwm lub zog hauv AR tsom iav.

Cov Lus Qhia Tseem Ceeb rau Daim Ntawv Thov

Core Optical Cheebtsam rau AI / AR Glasses

- Diffractive Waveguide Lenses : SiC substrates yog siv los tsim ultra-thin optical waveguides txhawb nqa loj FOV thiab tshem tawm cov nyhuv zaj sawv.

- Qhov rai Phaj thiab Prisms: Los ntawm kev txiav thiab polishing, SiC tuaj yeem ua tiav rau hauv cov qhov rais tiv thaiv lossis kho qhov muag prisms rau AR tsom iav, txhim kho lub teeb xa tawm thiab hnav tsis kam.

Daim ntawv thov txuas ntxiv hauv Lwm cov teb

- Fais fab Electronics : Siv nyob rau hauv high-frequency, high-power scenarios zoo li tshiab zog tsheb inverters thiab industrial motor tswj.

- Quantum Optics : Ua haujlwm ua tus tswv tsev rau cov chaw xim, siv hauv cov substrates rau quantum kev sib txuas lus thiab cov khoom siv ntsuas.

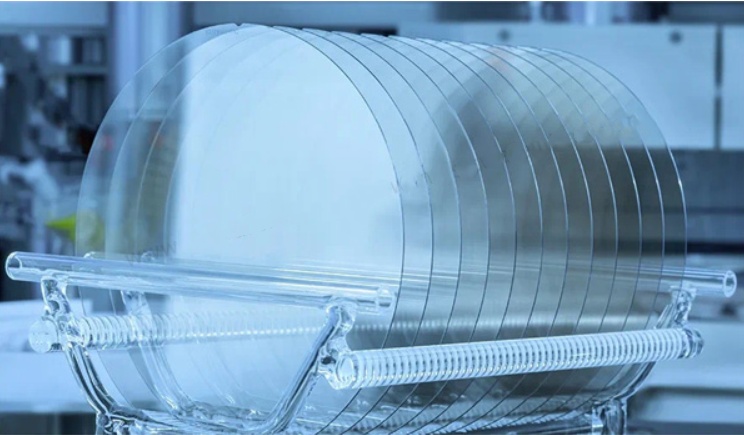

4 nti & 6 nti HPSI SiC Substrate Specification Sib piv

| Parameter | Qib | 4-nti substrate | 6-nti substrate |

| Txoj kab uas hla | Qib Z / D Qib | 99.5mm-100.0 hli | 149.5 hli - 150.0 hli |

| Poly-type | Qib Z / D Qib | 4H | 4H |

| Thickness | Z Qib | 500 μm ± 15 μm | 500 μm ± 15 μm |

| D Qib | 500 μm ± 25 μm | 500 μm ± 25 μm | |

| Wafer Orientation | Qib Z / D Qib | Ntawm axis: <0001> ± 0.5° | Ntawm axis: <0001> ± 0.5° |

| Micropipe ntom ntom | Z Qib | ≤ 1 cm² | ≤ 1 cm² |

| D Qib | ≤ 15 cm² | ≤ 15 cm² | |

| Kev tiv thaiv | Z Qib | ≥ 1E10 Ω·cm | ≥ 1E10 Ω·cm |

| D Qib | ≥ 1E5 Ω·cm | ≥ 1E5 Ω·cm | |

| Thawj Txoj Kev Ncaj Ncees | Qib Z / D Qib | (10-10) ± 5.0° | (10-10) ± 5.0° |

| Primary Flat Length | Qib Z / D Qib | 32.5 hli ± 2.0 hli | Ntsig |

| Secondary Flat Length | Qib Z / D Qib | 18.0 hli ± 2.0 hli | - |

| Ntug Exclusion | Qib Z / D Qib | 3 hli | 3 hli |

| LTV / TTV / Hneev / Warp | Z Qib | ≤ 2.5 μm / ≤ 5 μm / ≤ 15 μm / ≤ 30 μm | ≤ 2.5 μm / ≤ 6 μm / ≤ 25 μm / ≤ 35 μm |

| D Qib | ≤ 10 μm / ≤ 15 μm / ≤ 25 μm / ≤ 40 μm | ≤ 5 μm / ≤ 15 μm / ≤ 40 μm / ≤ 80 μm | |

| Roughness | Z Qib | Polish Ra ≤ 1 nm / CMP Ra ≤ 0.2 nm | Polish Ra ≤ 1 nm / CMP Ra ≤ 0.2 nm |

| D Qib | Polish Ra ≤ 1 nm / CMP Ra ≤ 0.2 nm | Polish Ra ≤ 1 nm / CMP Ra ≤ 0.5 nm | |

| Ntug Cracks | D Qib | Cov cheeb tsam ≤ 0.1% | Qhov ntev ≤ 20 mm, ib leeg ≤ 2 mm |

| Polytype Areas | D Qib | Cov cheeb tsam ≤ 0.3% | Qhov ntau thiab tsawg ≤ 3% |

| Visual Carbon Inclusions | Z Qib | Qhov ntau thiab tsawg ≤ 0.05% | Qhov ntau thiab tsawg ≤ 0.05% |

| D Qib | Cov cheeb tsam ≤ 0.3% | Qhov ntau thiab tsawg ≤ 3% | |

| Silicon Surface Scratches | D Qib | 5 tso cai, txhua ≤1mm | Qhov ntev ≤ 1 x inch |

| Ntug Chips | Z Qib | Tsis muaj kev tso cai (dav thiab qhov tob ≥0.2mm) | Tsis muaj kev tso cai (dav thiab qhov tob ≥0.2mm) |

| D Qib | 7 tso cai, txhua ≤1mm | 7 tso cai, txhua ≤1mm | |

| Threading Screw Dislocation | Z Qib | - | ≤ 500 cm² |

| Ntim | Qib Z / D Qib | Multi-wafer Cassette lossis Ib Lub Thawv Wafer | Multi-wafer Cassette lossis Ib Lub Thawv Wafer |

XKH Cov Kev Pabcuam: Kev Tsim Kho Kev Tsim Kho thiab Kev Ua Haujlwm Zoo

XKH lub tuam txhab muaj peev xwm sib koom ua ke los ntawm cov khoom siv raw mus rau cov khoom tiav, npog tag nrho cov saw ntawm SiC substrate kev loj hlob, slicing, polishing, thiab kev cai ua. Cov kev pabcuam tseem ceeb muaj xws li:

- Material Diversity:Peb tuaj yeem muab ntau hom wafer xws li 4H-N hom, 4H-HPSI hom, 4H / 6H-P hom, thiab 3C-N hom. Resistivity, thickness, thiab orientation tuaj yeem hloov kho raws li qhov xav tau.

- uaFlexible Size Customization:Peb txhawb nqa wafer ua los ntawm 2-nti mus rau 12-nti diameters, thiab tseem tuaj yeem ua cov qauv tshwj xeeb xws li square pieces (xws li 5x5mm, 10x10mm) thiab prisms tsis xwm yeem.

- Optical-Qib Precision Control:Wafer Tag Nrho Thickness Variation (TTV) tuaj yeem khaws cia ntawm <1μm, thiab nto roughness ntawm Ra <0.3 nm, ua tau raws li cov kev cai nano-theem flatness rau cov khoom siv waveguide.

- Rapid Market Teb:Cov qauv kev lag luam sib xyaw ua kom muaj kev hloov pauv ntawm R & D mus rau ntau lawm, txhawb txhua yam los ntawm kev txheeb xyuas me me mus rau cov khoom xa tuaj loj (lub sijhawm ua haujlwm feem ntau 15-40 hnub).

FAQ ntawm HPSI SiC Wafer

Q1: Vim li cas HPSI SiC suav tias yog cov khoom siv zoo tshaj plaws rau AR waveguide lo ntsiab muag?

A1: Nws lub siab refractive Performance index (2.6–2.7) ua rau nyias nyias, ua haujlwm zoo dua cov qauv waveguide uas txhawb nqa qhov loj ntawm kev pom (piv txwv li, 70°–80°) thaum tshem tawm "cov nyhuv zaj sawv".

Q2: HPSI SiC txhim kho thermal tswj hauv AI/AR tsom iav li cas?

A2: Nrog rau cov thermal conductivity txog 490 W / m·K (ze rau tooj liab), nws ua tau zoo dissipates cua sov los ntawm cov khoom xws li Micro-LEDs, kom ntseeg tau ruaj khov thiab ntev lub neej ntawm cov cuab yeej.

Q3: Qhov zoo ntawm kev ua haujlwm ntev npaum li cas HPSI SiC muab rau cov iav tsom iav?

A3: Nws qhov tshwj xeeb hardness (Mohs 9.5) muab kev tiv thaiv khawb zoo dua, ua rau nws ruaj khov rau kev siv txhua hnub hauv cov neeg siv khoom qib AR tsom iav.