Cov ntsiab lus

1. Kev hloov pauv thev naus laus zis: Kev nce ntawm Silicon Carbide thiab nws cov kev sib tw

2. TSMC's Strategic Shift: Exiting GaN and Betting on SiC

3. Cov khoom sib tw: Qhov Irreplaceability ntawm SiC

4. Daim Ntawv Thov Scenario: Thermal Management Revolution in AI Chips thiab Next-Gen Electronics

5. Cov Kev Sib Tw Yav Tom Ntej: Kev Sib Tw Kev Lag Luam thiab Kev Lag Luam

Raws li TechNews, kev lag luam thoob ntiaj teb semiconductor tau nkag mus rau lub sijhawm uas tau tsav los ntawm kev txawj ntse txawj ntse (AI) thiab kev ua haujlwm siab (HPC), qhov twg thermal tswj tau tshwm sim los ua lub hauv paus tseem ceeb cuam tshuam rau kev tsim cov chips thiab cov txheej txheem tawg. Raws li cov txheej txheem ntim qib siab zoo li 3D stacking thiab 2.5D kev koom ua ke txuas ntxiv ua kom cov nti ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom tsis tuaj yeem ua tau raws li qhov xav tau thermal flux. TSMC, lub ntiaj teb cov thawj coj wafer foundry, tau teb rau qhov kev sib tw no nrog cov khoom siv ua haujlwm loj: siab puag 12-nti ib leeg-crystal silicon carbide (SiC) substrates thaum maj mam tawm hauv kev lag luam gallium nitride (GaN). Qhov kev txav no tsis tsuas yog qhia txog kev rov ua dua tshiab ntawm TSMC cov khoom siv lub tswv yim tab sis kuj tseem qhia txog qhov kev tswj xyuas thermal tau hloov pauv li cas los ntawm "kev txhawb nqa thev naus laus zis" mus rau "kev sib tw tseem ceeb."

Silicon Carbide: Tshaj Tawm Hluav Taws Xob Hluav Taws Xob

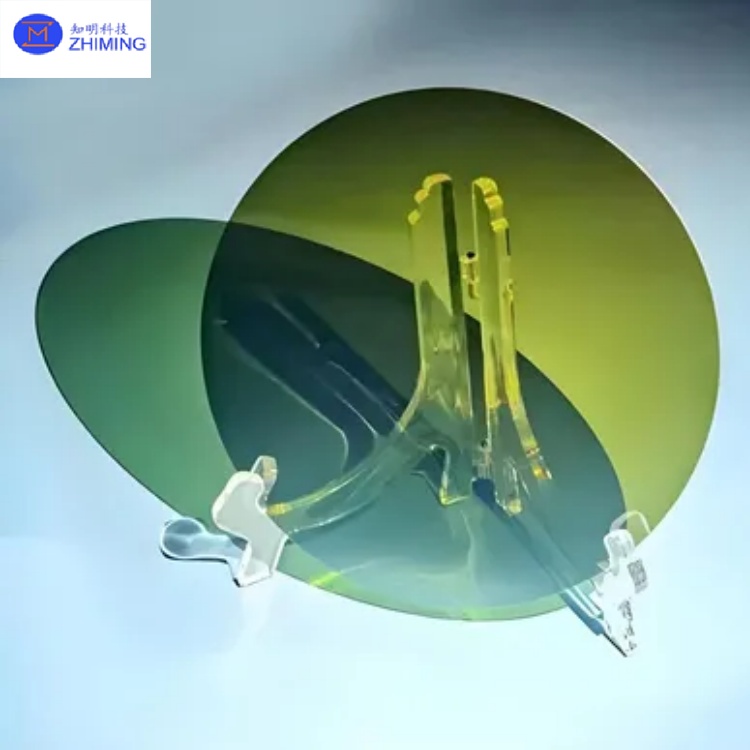

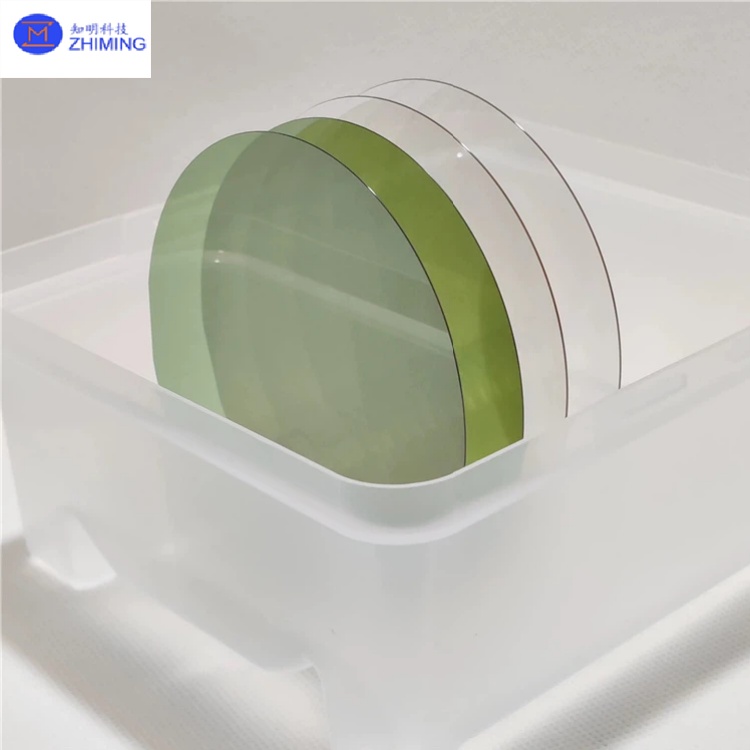

Silicon carbide, renowned rau nws dav bandgap semiconductor zog, tau ib txwm siv nyob rau hauv high-efficiency fais fab hluav taws xob xws li hluav taws xob tsheb inverters, muaj lub cev muaj zog tswj, thiab tauj dua tshiab zog infrastructure. Txawm li cas los xij, SiC lub peev xwm nthuav dav dhau qhov no. Nrog rau qhov tshwj xeeb thermal conductivity ntawm kwv yees li 500 W / mK - deb tshaj cov pa ceramic substrates xws li txhuas oxide (Al₂O₃) los yog sapphire -SiC tam sim no npaj los daws cov teeb meem thermal ntawm cov ntawv thov siab.

AI Accelerators thiab Thermal Crisis

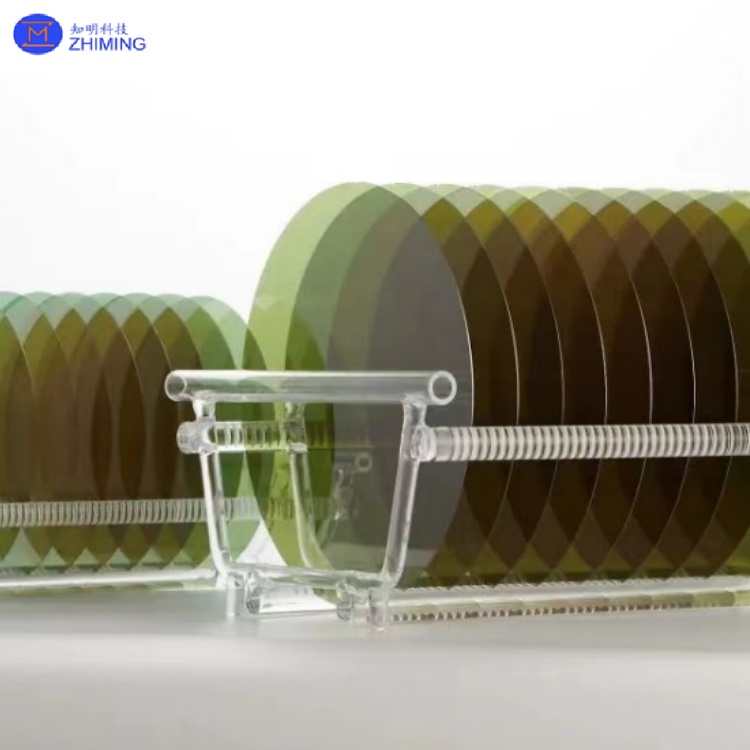

Kev loj hlob ntawm AI accelerators, data center processors, thiab AR ntse tsom iav tau ua rau muaj kev txwv ntau dua thiab kev tswj xyuas thermal. Hauv cov khoom siv hnav, piv txwv li, cov khoom siv microchip nyob ze ntawm lub qhov muag xav tau cov thermal tswj kom muaj kev nyab xeeb thiab ruaj khov. Leveraging nws lub xyoo caum ntawm kev txawj ntse nyob rau hauv 12-nti wafer fabrication, TSMC yog nce mus rau loj-thaj chaw ib leeg-crystal SiC substrates los hloov cov tsoos ceramics. Lub tswv yim no ua rau muaj kev sib koom ua ke rau hauv cov kab tsim khoom uas twb muaj lawm, sib npaug cov txiaj ntsig thiab cov nqi zoo yam tsis tas yuav tsum tau ua tiav kev tsim khoom.

Kev Sib Tw Txuj Ci thiab Kev Tsim Kho Tshiabua

uaSiC lub luag haujlwm hauv Advanced Ntim

- 2.5D Integration:Chips yog mounted ntawm silicon los yog organic interposers nrog luv luv, zoo teeb liab txoj kev. Thaum tshav kub kub dissipation cov nyom ntawm no feem ntau yog kab rov tav. ua

- 3D Integration:Vertically stacked chips ntawm through-silicon vias (TSVs) los yog hybrid bonding ua tiav ultra-siab interconnect ceev tab sis fim exponential thermal siab. SiC tsis tsuas yog ua haujlwm raws li cov khoom siv hluav taws xob tsis zoo xwb tab sis kuj sib koom ua ke nrog cov kev daws teeb meem zoo li pob zeb diamond lossis kua hlau los ua "hybrid cooling" systems.

uaStrategic Exit los ntawm GaN

Beyond Automotive: SiC's New Frontiers

- Conductive N-hom SiC:Ua raws li cov thermal kis hauv AI accelerators thiab cov txheej txheem ua haujlwm siab.

- Insulating SiC:Ua haujlwm li interposers hauv chiplet tsim, ntsuas hluav taws xob sib cais nrog thermal conduction.

Cov kev tsim kho tshiab no tso SiC ua cov khoom siv hauv paus rau kev tswj xyuas thermal hauv AI thiab cov ntaub ntawv chaw chips.

uaCov khoom toj roob hauv pes

TSMC's 12-nti wafer kev txawj ntse txawv nws ntawm cov neeg sib tw, ua kom muaj kev xa tawm sai ntawm SiC platforms. Los ntawm kev siv cov cuab yeej cuab tam uas twb muaj lawm thiab cov khoom ntim qib siab zoo li CoWoS, TSMC lub hom phiaj los hloov cov khoom zoo rau hauv cov txheej txheem thermal daws teeb meem. Ib yam li ntawd, kev lag luam loj xws li Intel tau ua qhov tseem ceeb rau kev xa hluav taws xob rov qab thiab thermal-power co-tsim, underscoring lub ntiaj teb hloov mus rau thermal-centric innovation.

Post lub sij hawm: Sep-28-2025