Cov Lus Qhia

1. Cov hom phiaj tseem ceeb thiab qhov tseem ceeb ntawm kev ntxuav wafer

2. Kev soj ntsuam kev sib kis thiab cov txheej txheem Advanced Analytical

3.Txoj kev tu siab tshaj plaws thiab cov txheej txheem kev ua haujlwm

4.Technical Implementation and Process Control Essentials

5. Yav Tom Ntej Trends thiab Innovative Directions

6. XKH End-to-End Solutions thiab Service Ecosystem

Kev ntxuav wafer yog txheej txheem tseem ceeb hauv kev tsim khoom semiconductor, txawm tias cov kab mob atomic-theem tuaj yeem ua rau cov cuab yeej ua tau zoo lossis tawm los. Cov txheej txheem ntxuav feem ntau muaj ntau yam kev tshem tawm ntau yam kab mob, xws li cov organic residues, metallic impurities, hais, thiab haiv neeg oxides.

1. Lub Hom Phiaj ntawm Wafer Cleaning

- Tshem tawm cov kab mob organic (xws li, photoresist residues, ntiv tes).

- Tshem tawm cov hlau tsis huv (xws li Fe, Cu, Ni).

- Tshem tawm cov pa paug paug (piv txwv li, plua plav, silicon fragments).

- Tshem tawm cov oxides ib txwm muaj (xws li SiO₂ txheej tsim thaum raug huab cua).

2. Qhov tseem ceeb ntawm Rigorous Wafer Cleaning

- Ua kom cov txheej txheem siab tawm los thiab kev ua haujlwm ntawm cov cuab yeej.

- Txo qhov tsis xws luag thiab wafer seem tus nqi.

- Txhim kho qhov zoo thiab sib xws.

Ua ntej yuav siv tshuaj ntxuav tes, nws yog ib qho tseem ceeb rau kev ntsuam xyuas cov kab mob uas twb muaj lawm. Kev nkag siab txog hom, qhov loj me, thiab qhov chaw nyob ntawm qhov chaw ntawm cov kab mob ntawm qhov chaw wafer optimizes ntxuav chemistry thiab cov khoom siv hluav taws xob.

3. Advanced Analytical Techniques for Contamination Assessment

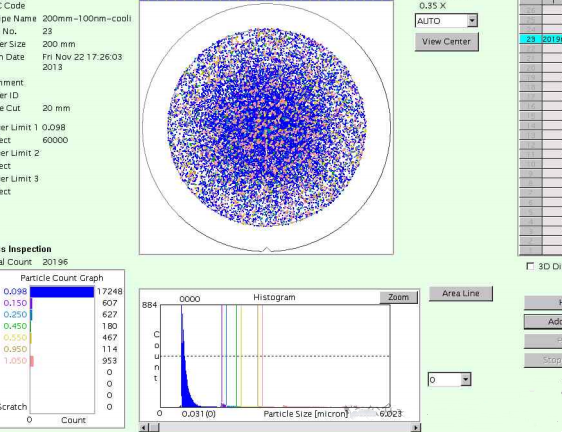

3.1 Surface Particle Analysis

- Cov txee tshwj xeeb siv cov khoom siv laser tawg lossis lub zeem muag hauv computer los suav, qhov loj, thiab daim ntawv qhia cov khib nyiab.

- Lub teeb tawg siv sib cuam tshuam nrog qhov loj me me li kaum ntawm nanometers thiab qhov ntom ntom qis li 0.1 particles / cm² .

- Calibration nrog cov qauv kom ntseeg tau kho vajtse. Kev kuaj ua ntej thiab tom qab ntxuav validate tshem tawm efficiency, tsav kev txhim kho.

3.2 Elemental Surface Analysis

- Cov txheej txheem deg-rhiab heev txheeb xyuas qhov muaj pes tsawg leeg.

- X-ray Photoelectron Spectroscopy (XPS/ESCA): Txheeb xyuas cov tshuaj lom neeg hauv lub xeev los ntawm irradiating lub wafer nrog X-rays thiab ntsuas emission electrons.

- Glow Discharge Optical Emission Spectroscopy (GD-OES): Sputters ultra-thin surface layers sequentially while analyzing emitted spectra to txiav txim siab qhov tob-dependent elemental muaj pes tsawg leeg.

- Cov kev txwv tsis pub ncav cuag qhov chaw ib lab (ppm), qhia kev xaiv cov tshuaj ntxuav tu zoo.

3.3 Morphological Contamination Analysis

- Scanning Electron Microscopy (SEM) : Captures high-resolution dluab los nthuav tawm cov kab mob 'cov duab thiab nam piv, qhia adhesion mechanisms (chemical vs. mechanical).

- Atomic Force Microscopy (AFM): Maps nanoscale topography kom muaj nuj nqis particle qhov siab thiab txhua yam khoom.

- Focused Ion Beam (FIB) Milling + Transmission Electron Microscopy (TEM): Muab kev pom sab hauv ntawm cov kab mob faus.

4. Advanced Cleaning Methods

Thaum cov kuab tshuaj ntxuav tau zoo tshem tawm cov kab mob organic, cov txheej txheem qib siab ntxiv yog xav tau rau cov khoom siv tsis zoo, cov hlau seem, thiab cov kab mob ionic:

ua

4.1 RCA Ntxuav

- Tsim los ntawm RCA Laboratories, txoj kev no siv cov txheej txheem da dej dual kom tshem tawm cov kab mob polar.

- SC-1 (Standard Clean-1): Tshem tawm cov pa phem thiab cov khoom siv sib xyaw ntawm NH₄OH, H₂O₂, thiab H₂O(piv txwv li, 1: 1: 5 piv ntawm ~ 20 ° C). Ua ib txheej nyias silicon dioxide.

- SC-2 (Standard Clean-2): Tshem tawm cov hlau tsis huv siv HCl, H₂O₂, thiab H₂O(piv txwv li, 1: 1: 6 piv ntawm ~ 80 ° C). Leaves ib tug passivated nto.

- Sib npaug kev huv nrog kev tiv thaiv saum npoo.

ua

4.2 Ozone Purification

- Immerses wafers hauv ozone-saturated deionized dej (O₃/H₂O).

- Ua tau zoo oxidizes thiab tshem tawm cov organics yam tsis muaj kev puas tsuaj rau lub wafer, tawm hauv cov tshuaj lom neeg passivated nto.

ua

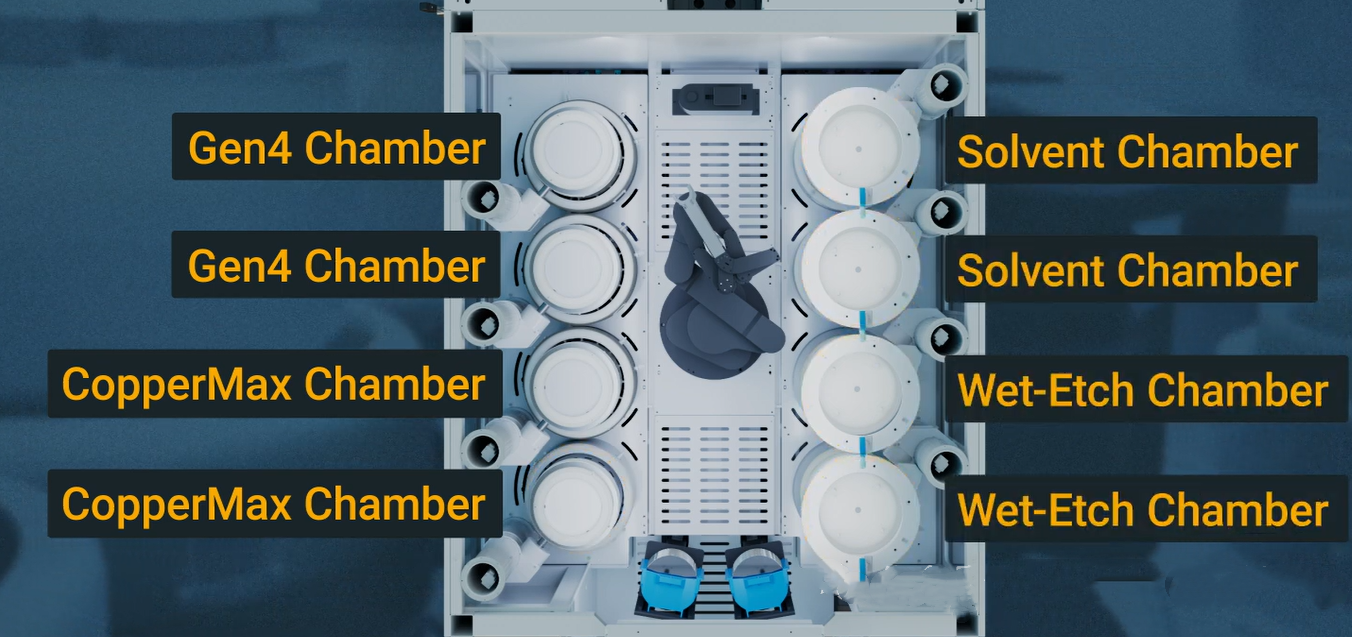

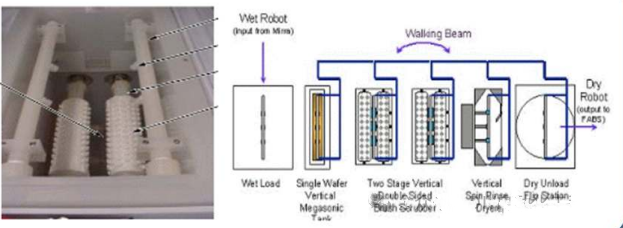

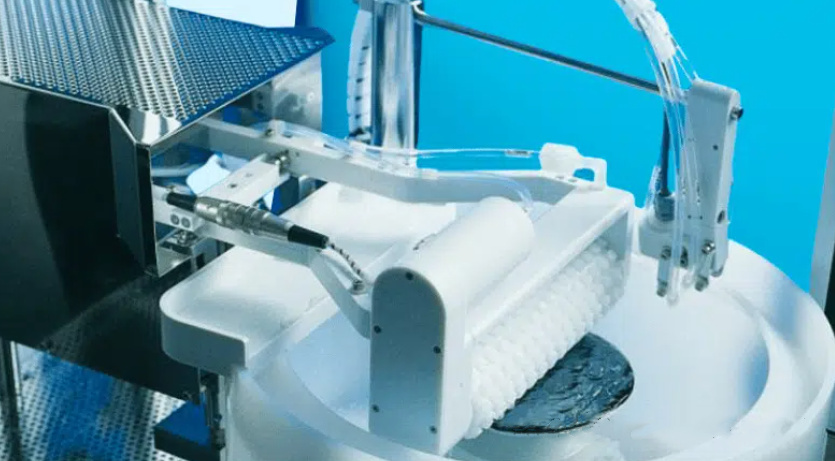

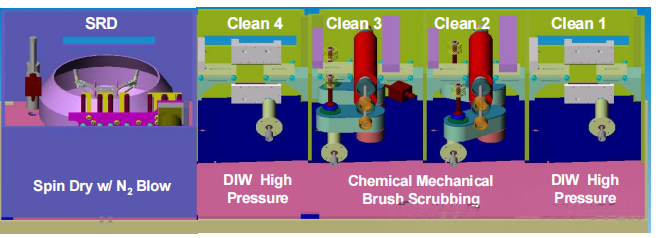

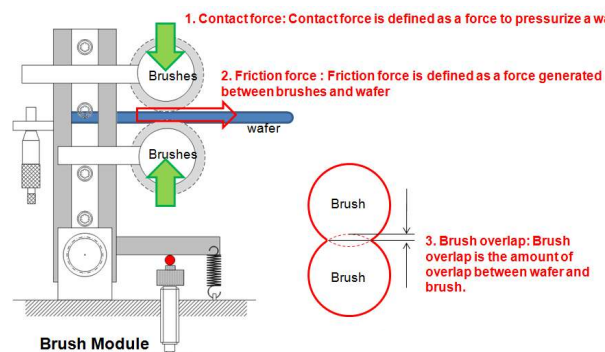

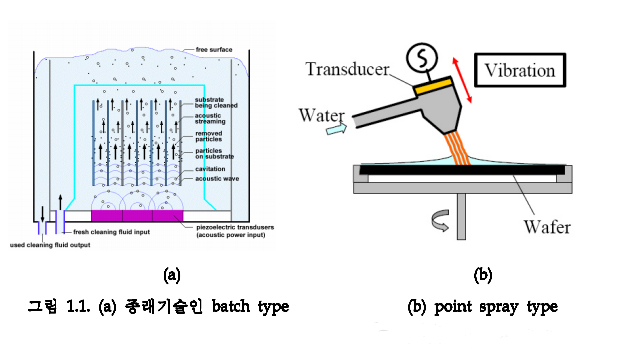

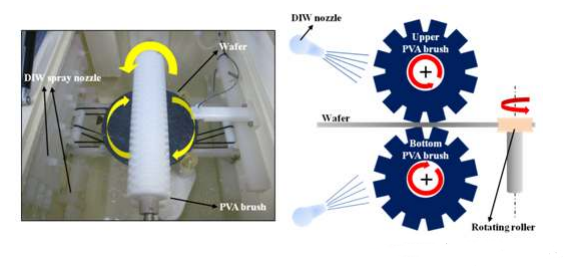

4.3 Megasonic Ntxuavua

- Siv lub zog ultrasonic zaus (feem ntau 750-900 kHz) ua ke nrog cov kev daws teeb meem.

- Tsim cov npuas cavitation uas tshem tawm cov kab mob. Penetrates complex geometries thaum txo kev puas tsuaj rau cov qauv me me.

4.4 Cryogenic Cleaning

- Ceev ceev wafers txias rau qhov kub thiab txias, brittling cov kab mob.

- Tom qab rinsing los yog maj mam txhuam tshem tawm loosened hais. Tiv thaiv recontamination thiab diffusion rau saum npoo.

- Cov txheej txheem ceev, qhuav nrog kev siv tshuaj tsawg tsawg.

Xaus:

Raws li lub tuam txhab ua lag luam thoob ntiaj teb kev daws teeb meem, XKH tau tsav los ntawm kev tsim kho thev naus laus zis thiab cov neeg siv khoom xav tau kom xa cov kev pabcuam kawg-rau-kawg encompassing cov khoom siv high-end, wafer fabrication, thiab precision tu . Peb tsis tsuas yog muab cov khoom siv hluav taws xob thoob ntiaj teb lees paub (xws li cov tshuab lithography, etching systems) nrog cov kev daws teeb meem tab sis kuj tseem muaj cov thev naus laus zis thev naus laus zis - suav nrog RCA tu, ozone purification, thiab megasonic tu - kom ntseeg tau atomic-theem cleanliness kev ua haujlwm zoo rau kev tsim khoom thiab kev tsim khoom. Leveraging cov pab pawg neeg teb ceev ceev thiab cov kev pabcuam ntse, peb muab kev txhawb nqa zoo xws li kev teeb tsa thiab cov txheej txheem kev ua kom zoo rau kev saib xyuas, txhawb cov neeg siv khoom kom kov yeej cov kev cov nyom thiab nce mus rau qhov siab dua thiab kev txhim kho semiconductor. Xaiv peb rau kev sib tw dual-yeej ntawm kev txawj ntse thiab kev lag luam tus nqi.

Post lub sij hawm: Sep-02-2025