uaPhau ntawv

1. Cov Ntsiab Lus Tseem Ceeb thiab Kev Ntsuas

2. Kev ntsuas ntsuas

3. Cov ntaub ntawv ua thiab yuam kev

4. Cov txheej txheem cuam tshuam

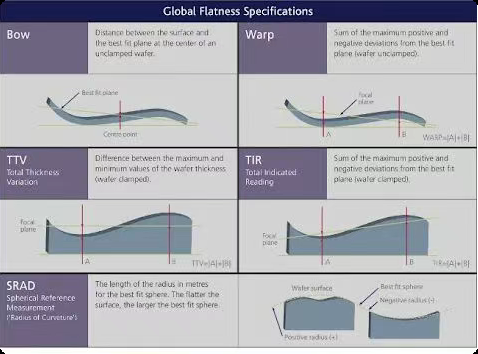

Hauv kev tsim khoom semiconductor, lub thickness uniformity thiab nto flatness ntawm wafers yog qhov tseem ceeb cuam tshuam rau cov txheej txheem yield. Cov ntsiab lus tseem ceeb xws li Tag Nrho Thickness Variation (TTV), Hneev (arcuate warpage), Warp (global warpage), thiab Microwarp (nano-topography) ncaj qha cuam tshuam rau qhov tseeb thiab ruaj khov ntawm cov txheej txheem tseem ceeb xws li photolithography tsom, tshuaj kho tshuab polishing (CMP), thiab nyias zaj duab xis deposition.

Core Concepts thiab Metrics

TTV (Tag nrho Thickness Variation).

Warp

Warp ntsuas qhov siab tshaj plaws ntawm qhov siab tshaj plaws-rau-kiv qhov sib txawv thoob plaws txhua qhov chaw saum npoo txheeb ze rau lub dav hlau siv, ntsuas lub wafer tag nrho flatness nyob rau hauv lub xeev dawb.

Kev ntsuas ntsuas

1. TTV Measurement Methods

- Dual-Surface Profilometry

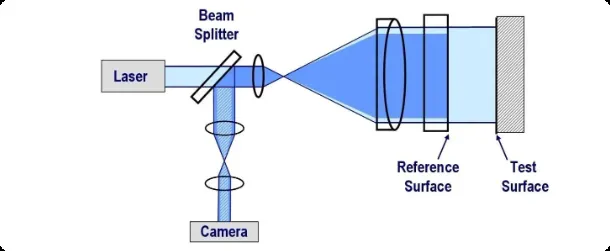

- Interferometry Cov Lus Qhia:Siv cov kev cuam tshuam kev cuam tshuam ntawm lub dav hlau siv thiab lub wafer nto. Haum rau qhov chaw du tab sis txwv los ntawm qhov loj-curvature wafers.

- Dawb Lub Teeb Scanning Interferometry (SWLI):Ntsuas qhov siab siab ntawm cov hnab ntawv uas tsis tshua muaj sib xws. Siv tau rau cov txheej txheem zoo li tab sis txwv los ntawm kev siv tshuab scanning ceev.

- Confocal Methods:Ua tiav cov kev daws teeb meem sub-micron los ntawm pinhole lossis dispersion cov qauv. Qhov zoo tshaj plaws rau qhov chaw ntxhib los yog translucent tab sis qeeb vim qhov ntsuas los ntawm taw tes.

- Laser Triangulation:Cov lus teb nrawm tab sis ua rau qhov tseeb poob los ntawm qhov sib txawv ntawm qhov sib txawv.

- Transmission / Reflection Coupling

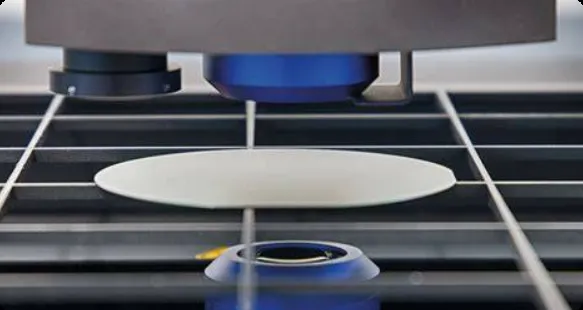

- Dual-Head Capacitance Sensors: Symmetric tso ntawm sensors ntawm ob sab ntsuas thickness li T = L – d₁ – d₂ (L = puag ncig deb). Ceev tab sis rhiab heev rau cov khoom siv.

- Ellipsometry / Spectroscopic Reflectometry: Txheeb xyuas cov teeb meem teeb meem sib cuam tshuam rau nyias zaj duab xis tuab tab sis tsis haum rau TTV ntau.

2. Hneev thiab Warp Ntsuas

- Multi-Probe Capacitance Arrays : Khaws cov ntaub ntawv qhov siab tag nrho ntawm cov theem huab cua rau kev tsim kho 3D sai.

- Structured Light Projection: High-speed 3D profileing siv kho qhov muag shaping.

- Low-NA Interferometry : High-resolution nto mapping tab sis kev co-sensitive.

3. Microwarp Kev Ntsuas

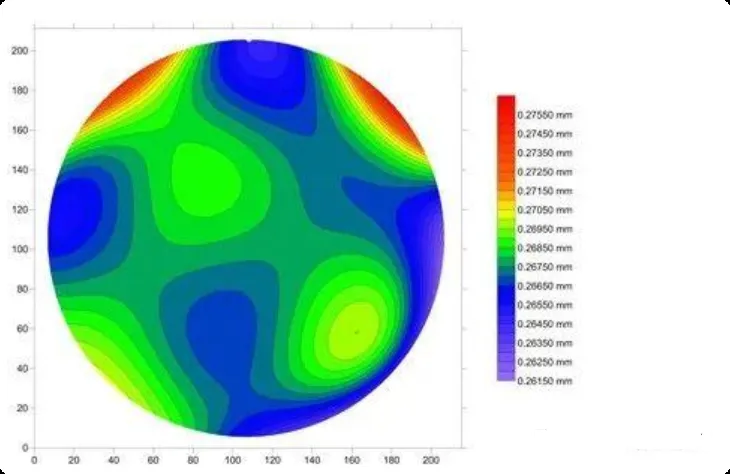

- Spatial Frequency Analysis:

- Tau txais high-resolution nto topography.

- Compute power spectral density (PSD) ntawm 2D FFT.

- Siv cov ntxaij lim dej bandpass (piv txwv li, 0.5–20 mm) kom cais cov wavelengths tseem ceeb.

- Xam RMS lossis PV qhov tseem ceeb los ntawm cov ntaub ntawv lim.

- Nqus Chuck Simulation:Mimic tiag tiag-lub ntiaj teb clamping teebmeem thaum lithography.

Cov ntaub ntawv ua thiab yuam kev Sources

Processing Workflow

- TTV:Txhim kho pem hauv ntej / nraub qaum ntawm qhov chaw sib koom ua ke, suav cov thickness sib txawv, thiab rho tawm cov txheej txheem tsis raug (piv txwv li, thermal drift).

- uaHneev / Warp:Haum LSQ dav hlau rau qhov siab cov ntaub ntawv; Hneev = nruab nrab point residual, Warp = ncov-rau-valley residual.

- uaMicrowarp:Lim spatial frequencies, suav txheeb cais (RMS/PV).

Key yuam kev Sources

- Environmental Factors:Kev co (tseem ceeb rau interferometry), huab cua turbulence, thermal drift.

- Sensor txwv:Lub suab nrov (interferometry), wavelength calibration yuam kev (confocal), cov lus teb ntawm cov khoom siv (capacitance).

- Wafer tuav:Edge exclusion misalignment, motion theem inaccuracies nyob rau hauv stitching.

Impact on Process Criticality

- Lithography:Hauv zos microwarp txo DOF, ua rau CD variation thiab overlay yuam kev. ua

- CMP:Thawj TTV qhov tsis sib xws ua rau tsis muaj qhov sib xws ntawm polishing siab. ua

- Kev Ntsuam Xyuas Kev Nyuaj Siab:Hneev/Warp evolution qhia thermal/mechanical stress cwj pwm. ua

- Ntim:Ntau TTV tsim voids hauv kev sib txuas lus sib txuas.

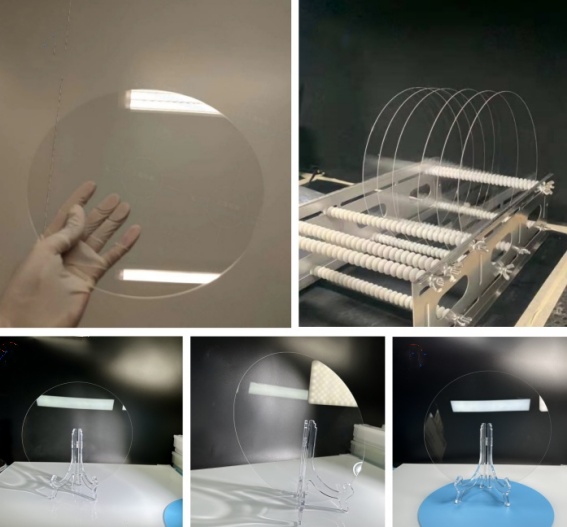

XKH's Sapphire Wafer

Post lub sij hawm: Sep-28-2025