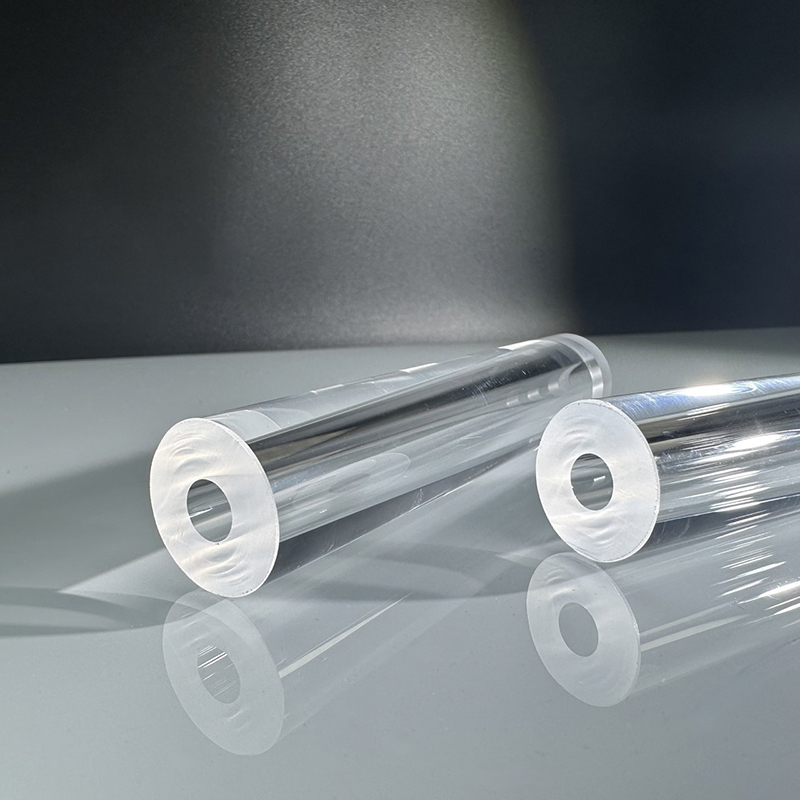

Sapphire Square Blank Substrate - Optical, Semiconductor, thiab Test Wafer

Daim duab qhia ntxaws

Txheej txheem cej luam ntawm Sapphire Square Blank Substrate

Lub sapphire square blank substrate, raws li tau piav nyob rau hauv daim duab, yog ib tug high-purity ib leeg-crystal aluminium oxide (Al₂O₃) tivthaiv tsim rau siv nyob rau hauv advanced kho qhov muag engineering, semiconductor ntaus ntawv manufacturing, thiab precision khoom kuaj. Renowned rau nws cov khoom tshwj xeeb ntawm lub cev thiab tshuaj lom neeg, sapphire tau dhau los ua ib qho ntawm cov khoom siv tseem ceeb tshaj plaws hauv kev lag luam uas xav tau kev ua haujlwm siab, ruaj khov, thiab kev ua haujlwm kho qhov muag. Ua los ntawm cov txheej txheem siv lead ua sophisticated, xws li Kyropoulos (KY), Heat Exchange Method (HEM), lossis Czochralski (CZ) cov txheej txheem, cov square blanks yog tsim los ua kom tau raws li cov qauv zoo tshaj plaws.

Cov yam ntxwv tseem ceeb ntawm Sapphire Square Blank Substrate

Sapphire yog ib qho uniaxial, anisotropic siv lead ua nrog cov qauv hexagonal lattice, muab kev sib xyaw ua ke ntawm cov khoom siv dag zog, thermal stability, thiab tshuaj tiv thaiv. Nrog rau Mohs hardness ntsuam xyuas ntawm 9, sapphire yog thib ob tsuas yog pob zeb diamond nyob rau hauv cov nqe lus ntawm khawb tsis kam, kom ntseeg tau tshwj xeeb ntev ntev txawm nyob rau hauv abrasive industrial tej yam kev mob. Nws cov ntsiab lus melting siab tshaj 2000 ° C, tso cai rau kev ua tau zoo nyob rau hauv qhov chaw kub kub, thaum nws qhov tsis tshua muaj dielectric poob ua rau nws nyiam cov khoom siv rau RF thiab cov ntawv siv hluav taws xob ntau zaus.

Nyob rau hauv qhov chaw kho qhov muag, sapphire nthuav tawm dav dav kis tau los ntawm kev sib sib zog nqus ultraviolet (~ 200nm) los ntawm pom mus rau nruab nrab-infrared (~ 5000nm), nrog rau qhov zoo tshaj plaws optical homogeneity thiab qis birefringence thaum ua kom zoo. Cov khoom no ua rau sapphire square blanks indispensable nyob rau hauv optics-intensive teb xws li laser tshuab, photonics, spectroscopy, thiab imaging.

Kev tsim khoom thiab kev ua haujlwm

Txhua lub sapphire square blank substrate tau dhau los ua cov txheej txheem tsim khoom nruj, pib nrog high-purity raw alumina hmoov raug tswj hwm kev loj hlob ntawm cov khoom siv kub kub. Tom qab cov khoom siv lead ua loj hlob tuaj, nws yog qhov taw qhia meej (feem ntau C-plane (0001), A-plane (11-20), lossis R-plane (1-102)) kom haum rau cov ntawv thov tshwj xeeb. Cov siv lead ua yog ces hlais rau hauv cov square blanks nrog pob zeb diamond-coated saws, ua raws li precision lapping kom ua tiav thickness uniformity. Rau kev siv kho qhov muag thiab semiconductor, qhov chaw tuaj yeem polished rau atomic-theem smoothness, ntsib stringent flatness, parallelism, thiab deg roughness specifications.

Qhov Zoo Tshaj Plaws

-

Optical Transparency zoo- Kev sib kis dav dav los ntawm UV rau IR ua rau nws zoo tagnrho rau cov qhov rais kho qhov muag, cov kab noj hniav laser, thiab cov npog npog.

-

Superior Mechanical Strength- Siab compressive zog, tawg toughness, thiab khawb kuj ua kom lub neej ntev nyob rau hauv ib puag ncig kev ntxhov siab.

-

Thermal & Chemical Stability-Resistant rau thermal shock, kub siab, thiab aggressive chemicals, tswj kev ncaj ncees thaum lub sij hawm semiconductor ua thiab hnyav ib puag ncig raug.

-

Precise Dimensional Control- Ua tiav cov thickness kam rau ua nyob rau hauv ± 5µm thiab nto flatness mus txog λ / 10 (ntawm 632.8nm), tseem ceeb rau photolithography thiab wafer daim ntawv thov.

-

Ntau yam- Tsim nyog rau ntau yam kev siv xws li cov khoom siv kho qhov muag, epitaxial kev loj hlob substrates, thiab tshuab kuaj wafers.

Daim ntawv thov

-

Kev siv kho qhov muag: Siv raws li qhov rais, cov ntxaij lim dej, laser nce nruab nrab tuav, tiv thaiv npog rau sensors, thiab photonics substrates vim nws qhov muag pom tseeb thiab durability.

-

Semiconductor Substrates: Ua lub hauv paus tseem ceeb rau GaN-raws li LEDs, hluav taws xob hluav taws xob (SiC-on-sapphire qauv), RF cov khoom siv, thiab microelectronic circuits, qhov twg thermal conductivity thiab tshuaj tiv thaiv yog qhov tseem ceeb.

-

Cov Khoom Siv Xeem thiab Dummy Wafers: Feem ntau ua hauj lwm raws li kev sim substrates nyob rau hauv semiconductor fabrication kab, siv rau tshuab calibration, txheej txheem simulation, thiab endurance xeem ntawm etching, deposition, los yog cov khoom soj ntsuam.

-

Kev Tshawb Fawb Txog Kev Tshawb Fawb: Qhov tseem ceeb hauv kev sim teeb tsa uas xav tau inert, pob tshab, thiab mechanically ruaj khov platforms rau optical, hluav taws xob, thiab cov ntaub ntawv kawm.

FAQ

Q1: Dab tsi yog qhov zoo ntawm kev siv square sapphire dawb paug hla ib puag ncig wafer?

A: Square blanks muab qhov chaw siv tau ntau tshaj plaws rau kev txiav, kev tsim khoom, lossis kev sim tshuab, txo cov khoom pov tseg thiab nqi.

Q2: sapphire substrates puas tuaj yeem tiv taus qhov chaw ua haujlwm semiconductor?

A: Yog, sapphire substrates tswj kev ruaj ntseg nyob rau hauv qhov kub thiab txias, plasma etching, thiab tshuaj kho mob ntau yam hauv semiconductor fabrication.

Q3: Puas yog kev taw qhia saum npoo tseem ceeb rau kuv daim ntawv thov?

A: Yog lawm. C-plane sapphire yog dav siv rau GaN epitaxy hauv LED ntau lawm, thaum A-plane thiab R-dav hlau orientations yog nyiam rau cov kev siv kho qhov muag lossis piezoelectric.

Q4: Cov blanks no puas muaj nrog cov txheej txheem kev cai?

A: Yog lawm, cov tshuaj tiv thaiv kev cuam tshuam, dielectric, lossis cov txheej txheem hluav taws xob tuaj yeem siv los ua kom tau raws li cov kev xav tau tshwj xeeb kho qhov muag lossis hluav taws xob.

Txog Peb

XKH tshwj xeeb hauv kev tsim cov thev naus laus zis, tsim khoom, thiab muag cov iav tshwj xeeb kho qhov muag thiab cov ntaub ntawv siv lead ua tshiab. Peb cov khoom siv kho qhov muag khoom siv hluav taws xob, khoom siv hluav taws xob, thiab tub rog. Peb muab Sapphire optical Cheebtsam, xov tooj ntawm tes lens npog, Ceramics, LT, Silicon Carbide SIC, Quartz, thiab semiconductor siv lead ua wafers. Nrog cov kws tshaj lij thiab cov cuab yeej siv niaj hnub, peb ua tau zoo hauv kev ua cov khoom lag luam uas tsis yog tus qauv, aiming los ua ib qho khoom siv optoelectronic high-tech enterprise.