-

Vim li cas semi-insulating SiC dhau conductive SiC?

Semi-insulating SiC muaj kev tiv thaiv ntau dua, uas txo cov dej ntws tawm hauv cov khoom siv hluav taws xob siab thiab cov khoom siv siab. Conductive SiC yog qhov tsim nyog rau cov ntawv thov uas xav tau hluav taws xob conductivity. -

Cov wafers puas tuaj yeem siv rau kev loj hlob epitaxial?

Yog lawm, cov wafers no yog epi-npaj thiab optimized rau MOCVD, HVPE, los yog MBE, nrog rau kev kho deg thiab tsis xws luag tswj kom zoo dua epitaxial txheej. -

Koj ua li cas kom wafer huv si?

Chav kawm-100 cov txheej txheem ntxuav, ntau theem ultrasonic tu, thiab cov ntim ntim ntim nitrogen lav tias cov wafers tsis muaj kab mob, cov khoom seem, thiab micro-scratches. -

Lub sij hawm ua ntej rau kev txiav txim yog dab tsi?

Cov qauv feem ntau xa tuaj tsis pub dhau 7-10 hnub ua haujlwm, thaum kev txiav txim ntau lawm feem ntau xa tuaj hauv 4-6 lub lis piam, nyob ntawm seb qhov loj me thiab kev cai tshwj xeeb. -

Koj puas tuaj yeem muab cov qauv kev cai?

Yog lawm, peb tuaj yeem tsim kev cai substrates hauv ntau yam duab xws li lub qhov rais planar, V-grooves, spherical lo ntsiab muag, thiab lwm yam.

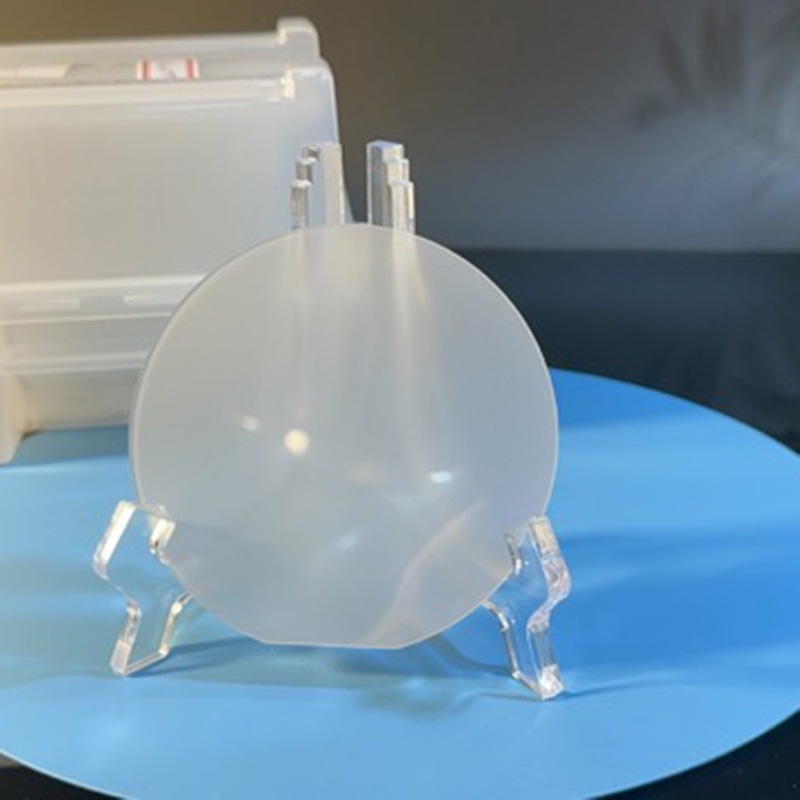

Semi-Insulating Silicon Carbide (SiC) Substrate High-Purity Rau Ar Glasses

Daim duab qhia ntxaws

Khoom Muag Khoom ntawm Semi-Insulating SiC Wafers

ur High-Purity Semi-Insulating SiC Wafers yog tsim los rau cov khoom siv hluav taws xob siab tshaj plaws, RF/microwave Cheebtsam, thiab kev siv optoelectronic. Cov wafers no yog tsim los ntawm high-quality 4H- los yog 6H-SiC ib leeg siv lead ua, siv ib tug refined Physical Vapor Transport (PVT) txoj kev loj hlob, ua raws li kev sib sib zog nqus nyiaj annealing. Cov txiaj ntsig yog wafer nrog cov khoom zoo hauv qab no:

-

Ultra-High Resistivity: ≥1 × 10¹² Ω·cm, zoo txo cov dej ntws tawm hauv cov khoom siv hluav taws xob siab.

-

Wide Bandgap (~ 3.2 eV): Ua kom muaj kev ua tau zoo nyob rau hauv qhov kub-kub, qhov chaw siab, thiab hluav taws xob-intensive ib puag ncig.

-

Exceptional Thermal conductivity:> 4.9 W / cm·K, muab cov cua sov kom zoo hauv kev siv hluav taws xob siab.

-

Superior Mechanical Strength: Nrog rau Mohs hardness ntawm 9.0 (thib ob xwb rau pob zeb diamond), tsis tshua muaj thermal expansion, thiab muaj zog tshuaj stability.

-

Atomically Smooth ntoRa <0.4 nm thiab qhov tsis xws luag <1 / cm², zoo tagnrho rau MOCVD / HVPE epitaxy thiab micro-nano fabrication.

Muaj Qhov Loj: Cov qauv loj muaj xws li 50, 75, 100, 150, thiab 200 mm (2 "–8"), nrog rau kev cai diameters txog li 250 mm.

Thickness Ntau: 200-1,000 μm, nrog kev kam rau siab ± 5 μm.

Kev tsim cov txheej txheem ntawm Semi-Insulating SiC Wafers

High-Purity SiC hmoov npaj

-

Pib Khoom: 6N-qib SiC hmoov, purified siv ntau theem nqus sublimation thiab thermal kev kho mob, kom ntseeg tau tias tsis muaj hlau paug (Fe, Cr, Ni < 10 ppb) thiab tsawg kawg nkaus polycrystalline inclusions.

Hloov kho PVT Ib Leeg-Crystal Loj hlob

-

Ib puag ncig: Ze-nqus (10⁻³–10⁻² Torr).

-

KubGraphite crucible rhuab mus rau ~ 2,500 ° C nrog kev tswj thermal gradient ntawm ΔT ≈ 10-20 ° C / cm.

-

Gas Flow & Crucible Design: Tailored crucible thiab porous separators xyuas kom meej vapor faib thiab suppress pliaj nucleation.

-

Dynamic Feed & Rotation: Lub sij hawm ntxiv ntawm SiC hmoov thiab siv lead ua-qhib kev sib hloov ua rau muaj qhov sib txawv tsawg (<3,000 cm⁻²) thiab kev taw qhia 4H / 6H zoo ib yam.

Deep-Level Compensation Annealing

-

Hydrogen Anneal: Ua nyob rau hauv H₂ huab cua ntawm qhov kub ntawm 600-1,400 ° C kom qhib cov cuab yeej sib sib zog nqus thiab txhim kho cov khoom siv hauv nruab nrab.

-

N/Al Co-Doping (Yeem): Kev koom ua ke ntawm Al (acceptor) thiab N (tus pub) thaum lub sij hawm kev loj hlob lossis kev loj hlob tom qab CVD los tsim cov khub pub dawb-cov neeg txais khoom ruaj khov, kev tsav tsheb tsis zoo.

Precision Slicing & Multi-Stage Lapping

-

Pob zeb diamond-hlau sawing: wafers hlais mus rau ib lub thickness ntawm 200-1,000 μm, nrog kev puas tsuaj tsawg kawg nkaus thiab kev kam rau siab ntawm ± 5 μm.

-

Lapping txheej txheem: Sequential coarse-rau-nplua pob zeb diamond abrasives tshem tawm kev puas tsuaj, npaj lub wafer rau polishing.

Tshuaj Mechanical Polishing (CMP)

-

Polishing Media: Nano-oxide (SiO₂ lossis CeO₂) slurry hauv cov tshuaj alkaline me me.

-

Txheej txheem tswj: Low-stress polishing minimizes roughness, ua tiav RMS roughness ntawm 0.2-0.4 nm thiab tshem tawm micro-scatches.

Thaum kawg ntxuav & ntim

-

Ultrasonic ntxuav: Cov txheej txheem ntxuav ntau theem (cov kuab tshuaj organic, cov tshuaj acid / hauv paus, thiab cov dej deionized yaug) hauv chav kawm-100 qhov chaw huv.

-

Sealing & Ntim: wafer ziab nrog nitrogen tshem tawm, ntim rau hauv cov hnab ntim khoom tiv thaiv nitrogen thiab ntim rau hauv cov thawv tiv thaiv zoo li qub, kev co-dampening txheej thawv.

Specifications ntawm Semi-Insulating SiC Wafers

| Product Performance | Qib P | Qib D |

|---|---|---|

| kuv. Crystal Parameters | kuv. Crystal Parameters | kuv. Crystal Parameters |

| Crystal Polytype | 4H | 4H |

| Refractive Index ib | > 2.6 @589nm | > 2.6 @589nm |

| Absorption Rate a | ≤0.5% @450-650nm | ≤1.5% @450-650nm |

| MP Transmittance ib (Uncoated) | ≥66.5% | ≥66.2% |

| Haze a | ≤ 0.3% | ≤ 1.5% |

| Polytype suav nrog a | Tsis pub | Thaj tsam ≤ 20% |

| Micropipe ntom ntom a | ≤ 0.5 / cm² | ≤ 2 / cm² |

| Hexagonal Void ib | Tsis pub | N/A |

| Faceted Inclusion a | Tsis pub | N/A |

| MP Inclusion a | Tsis pub | N/A |

| II. Mechanical Parameters | II. Mechanical Parameters | II. Mechanical Parameters |

| Txoj kab uas hla | 150.0 hli + 0.0 hli / -0.2 hli | 150.0 hli + 0.0 hli / -0.2 hli |

| Surface Orientation | {0001} ± 0.3° | {0001} ± 0.3° |

| Qhov Loj Loj Loj | Ntsig | Ntsig |

| Secondary Flat Length | Tsis muaj lub tiaj tiaj | Tsis muaj lub tiaj tiaj |

| Notch Orientation | <1-100> ± 2° | <1-100> ± 2° |

| Lub kaum ntse ntse | 90 ° + 5 ° / -1 ° | 90 ° + 5 ° / -1 ° |

| Notch Qhov tob | 1 hli ntawm ntug +0.25 hli / -0.0 hli | 1 hli ntawm ntug +0.25 hli / -0.0 hli |

| Kev kho saum npoo | C-face, Si-face: Chemo-Mechanical Polishing (CMP) | C-face, Si-face: Chemo-Mechanical Polishing (CMP) |

| Wafer Ntug | Chamfered (hli) | Chamfered (hli) |

| Nto Roughness (AFM) (5μm x 5μm) | Si-ntsej muag, C-ntsej muag: Ra ≤ 0.2 nm | Si-ntsej muag, C-ntsej muag: Ra ≤ 0.2 nm |

| Thickness ib (Tropel) | 500.0 μm ± 25.0 μm | 500.0 μm ± 25.0 μm |

| LTV (Tropel) (40mm x 40mm) a | ≤ 2 m | ≤ 4 m |

| Total Thickness Variation (TTV) a (Tropel) | ≤ 3 m | ≤ 5 μm |

| Bow (Tus Nqi Tsis Muaj) a (Tropel) | ≤ 5 μm | ≤ 15 hli |

| Warp a (Tropel) | ≤ 15 hli | ≤ 30 μm |

| III ib. Surface Parameters | III ib. Surface Parameters | III ib. Surface Parameters |

| Chip / Notch | Tsis pub | ≤ 2 pcs, txhua qhov ntev thiab dav ≤ 1.0 hli |

| Scratch ib (Si-face, CS8520) | Tag nrho qhov ntev ≤ 1 x Diameter | Tag nrho qhov ntev ≤ 3 x Dia |

| Particle a (Si-face, CS8520) | ≤ 500 pcs | N/A |

| Txhaum | Tsis pub | Tsis pub |

| Kev kis kab mob a | Tsis pub | Tsis pub |

Cov ntawv thov tseem ceeb ntawm Semi-Insulating SiC Wafers

-

High-Power Electronics: SiC-based MOSFETs, Schottky diodes, thiab cov khoom siv hluav taws xob rau cov tsheb hluav taws xob (EVs) tau txais txiaj ntsig los ntawm SiC qhov kev ua haujlwm qis thiab muaj peev xwm ua haujlwm siab.

-

RF thiab Microwave: SiC qhov kev ua haujlwm siab thiab kev tiv thaiv hluav taws xob yog qhov zoo tagnrho rau 5G puag-chaw nres tsheb amplifiers, radar modules, thiab kev sib txuas lus satellite.

-

Optoelectronics: UV-LEDs, xiav-laser diodes, thiab photodetectors siv atomically smooth SiC substrates rau uniform epitaxial loj hlob.

-

Ib puag ncig zoo heev Sensing: SiC qhov kev ruaj ntseg ntawm qhov kub siab (> 600 ° C) ua rau nws zoo meej rau cov sensors nyob rau hauv ib puag ncig hnyav, nrog rau cov roj turbines thiab nuclear detectors.

-

Aerospace & Kws muaj txuj ci: SiC muaj kev ruaj khov rau hluav taws xob hluav taws xob hauv satellites, missile systems, thiab aviation electronics.

-

Kev tshawb fawb Advanced: Kev daws teeb meem rau quantum suav, micro-optics, thiab lwm yam kev tshawb fawb tshwj xeeb.

FAQs

Txog Peb

XKH tshwj xeeb hauv kev tsim cov thev naus laus zis, tsim khoom, thiab muag cov iav tshwj xeeb kho qhov muag thiab cov ntaub ntawv siv lead ua tshiab. Peb cov khoom siv kho qhov muag khoom siv hluav taws xob, khoom siv hluav taws xob, thiab tub rog. Peb muab Sapphire optical Cheebtsam, xov tooj ntawm tes lens npog, Ceramics, LT, Silicon Carbide SIC, Quartz, thiab semiconductor siv lead ua wafers. Nrog cov kws tshaj lij thiab cov cuab yeej siv niaj hnub, peb ua tau zoo hauv kev ua cov khoom lag luam uas tsis yog tus qauv, aiming los ua ib qho khoom siv optoelectronic high-tech enterprise.