SICOI (Silicon Carbide ntawm Insulator) Wafers SiC Film ON Silicon

Daim duab qhia ntxaws

Qhia txog Silicon Carbide ntawm Insulator (SICOI) wafers

Silicon Carbide ntawm Insulator (SICOI) wafers yog lwm tiam neeg semiconductor substrates uas sib xyaw ua ke ntawm lub cev thiab hluav taws xob zoo tshaj ntawm silicon carbide (SiC) nrog cov yam ntxwv ntawm kev sib cais hluav taws xob zoo ntawm cov txheej txheem insulating, xws li silicon dioxide (SiO₂) lossis silicon nitride (Si₂). Ib tug raug SICOI wafer muaj ib tug nyias epitaxial SiC txheej, intermediate insulating zaj duab xis, thiab ib tug txhawb nqa substrate, uas yuav ua tau silicon los yog SiC.

Cov qauv hybrid no yog tsim los ua kom tau raws li qhov xav tau ntawm cov khoom siv hluav taws xob siab, siab zaus, thiab cov khoom siv hluav taws xob kub. Los ntawm kev koom ua ke ib txheej insulating, SICOI wafers txo cov kab mob parasitic thiab txo cov dej ntws tawm, yog li ua kom muaj kev ua haujlwm ntau dua, ua haujlwm zoo dua, thiab txhim kho kev tswj xyuas thermal. Cov txiaj ntsig no ua rau lawv muaj txiaj ntsig zoo hauv cov haujlwm xws li lub tsheb hluav taws xob, 5G kev sib txuas lus hauv kev sib txuas lus, aerospace systems, advanced RF electronics, thiab MEMS sensor technologies.

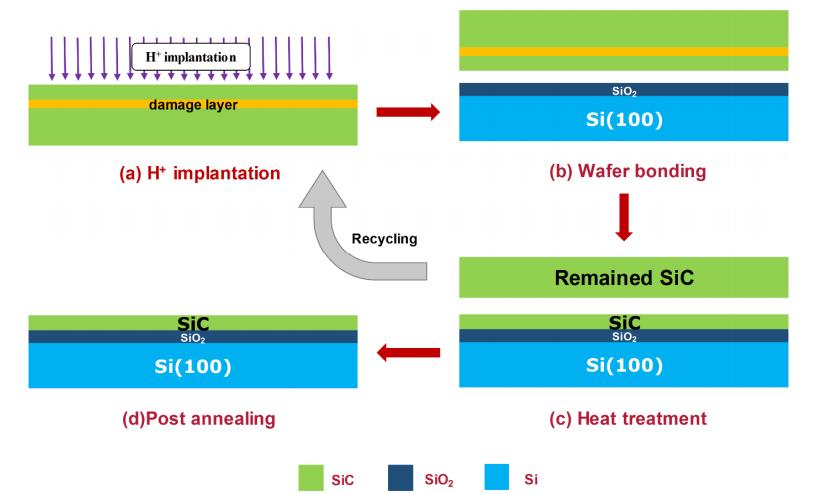

Txoj Cai Tsim Khoom ntawm SICOI Wafers

SICOI (Silicon Carbide ntawm Insulator) wafers yog tsim los ntawm kev tshaj lijwafer bonding thiab thinning txheej txheem:

-

SiC Substrate Loj hlob- Cov khoom siv zoo ib leeg-crystal SiC wafer (4H / 6H) yog npaj ua cov khoom pub dawb.

-

Insulating Txheej Txheej- Ib zaj duab xis insulating (SiO₂ lossis Si₃N₄) yog tsim los ntawm cov cab kuj wafer (Si lossis SiC).

-

Wafer Bonding- Lub SiC wafer thiab cov cab kuj wafer yog sib koom ua ke nyob rau hauv qhov kub thiab txias los yog kev pab plasma.

-

Thinning & Polishing- SiC pub dawb wafer yog thinned mus rau ob peb micrometers thiab polished kom ua tiav qhov atomically du nto.

-

Kev soj ntsuam zaum kawg- Ua tiav SICOI wafer raug kuaj rau cov thickness uniformity, nto roughness, thiab rwb thaiv tsev kev ua tau zoo.

Los ntawm txoj kev no, anyias active SiC txheejnrog cov khoom siv hluav taws xob zoo heev thiab cov khoom siv thermal yog ua ke nrog cov yeeb yaj kiab insulating thiab kev txhawb nqa substrate, tsim kom muaj kev ua tau zoo tshaj plaws rau lub zog tiam tom ntej thiab cov khoom siv RF.

Qhov tseem ceeb ntawm SICOI Wafers

| Feature Qeb | Cov yam ntxwv | Cov txiaj ntsig tseem ceeb |

|---|---|---|

| Khoom siv | 4H / 6H-SiC active txheej + insulating zaj duab xis (SiO₂ / Si₃N₄) + Si los yog SiC cab kuj | Ua kom muaj zog hluav taws xob sib cais, txo cov kab mob cuam tshuam |

| Cov khoom hluav taws xob | Lub zog tawg siab (> 3 MV / cm), tsis tshua muaj dielectric poob | Optimized rau high-voltage thiab high-frequency ua haujlwm |

| Thermal Properties | Thermal conductivity txog 4.9 W / cm·K, ruaj khov tshaj 500 ° C | Cov cua kub zoo, kev ua haujlwm zoo heev nyob rau hauv hnyav thermal loads |

| Mechanical Properties | Hardness heev (Mohs 9.5), qis coefficient ntawm thermal expansion | Robust tiv thaiv kev ntxhov siab, txhim kho cov cuab yeej ua haujlwm ntev |

| Nto Zoo | Ultra-smooth nto (Ra <0.2 nm) | Txhawb nqa tsis xws luag-dawb epitaxy thiab txhim khu kev qha ntaus ntawv fabrication |

| Rwb thaiv tsev | Resistivity> 10¹⁴ Ω·cm, tsis tshua muaj to tam sim no | Txhim khu kev ua haujlwm hauv RF thiab cov ntawv thov kev sib cais siab |

| Loj & Customization | Muaj nyob rau hauv 4, 6, thiab 8-nti hom; SiC thickness 1-100 μm; rwb thaiv tsev 0.1-10 μm | Saj zawg zog tsim rau txawv daim ntawv thov yuav tsum tau |

Core Application Areas

| Kev thov Sector | Tej yam siv | Kev Ua Haujlwm Zoo |

|---|---|---|

| Fais fab Electronics | EV inverters, chaw nres tsheb them, cov khoom siv fais fab | High breakdown voltage, txo switching poob |

| RF thiab 5G | Base chaw nres tsheb fais fab amplifiers, millimeter-yoj Cheebtsam | Tsawg parasitics, txhawb GHz-ntau cov haujlwm |

| MEMS Sensors | Harsh-environment pressure sensors, navigation-qib MEMS | High thermal stability, tiv taus hluav taws xob |

| Aerospace & Kws muaj txuj ci | Satellite kev sib txuas lus, avionics fais fab modules | Kev ntseeg siab nyob rau hauv huab cua kub thiab hluav taws xob raug |

| Ntse Grid | HVDC converters, solid-state circuit breakers | High rwb thaiv tsev minimizes fais fab tuag |

| Optoelectronics | UV LEDs, laser substrates | High crystalline zoo txhawb nqa lub teeb pom kev zoo |

Fabrication ntawm 4H-SiCOI

Kev tsim khoom ntawm 4H-SiCOI wafers tiav los ntawmwafer bonding thiab thinning txheej txheem, ua kom zoo zoo insulating interfaces thiab tsis muaj teeb meem tsis muaj SiC cov khaubncaws sab nraud povtseg.

-

a: Schematic ntawm 4H-SiCOI khoom platform fabrication.

-

b: Duab ntawm 4-nti 4H-SiCOI wafer siv kev sib txuas thiab thinning; cim qhov chaw tsis raug.

-

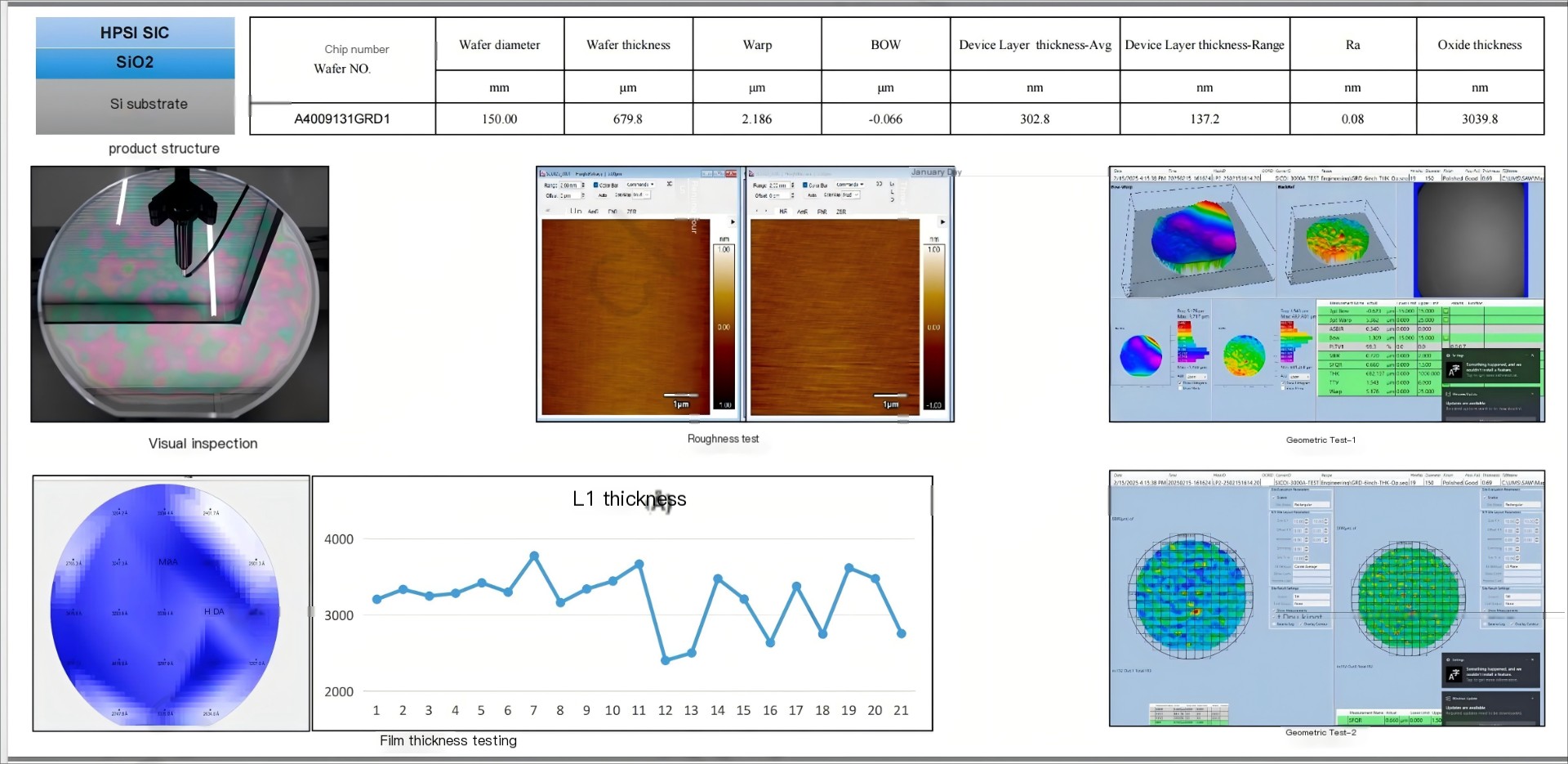

c: Thickness uniformity characterization ntawm 4H-SiCOI substrate.

-

d: Optical duab ntawm 4H-SiCOI tuag.

-

e: Txheej txheem ntws rau fabricating SiC microdisk resonator.

-

f: SEM ntawm kev ua tiav microdisk resonator.

-

g: Enlarged SEM qhia resonator sidewall; AFM inset depicts nanoscale nto smoothness.

-

h: Hla-sectional SEM illustrating parabolic-zoo li tus saum npoo.

FAQ ntawm SICOI Wafers

Q1: Qhov txiaj ntsig zoo li cas SICOI wafers muaj tshaj li SiC wafers?

A1: Tsis zoo li cov qauv SiC substrates, SICOI wafers suav nrog cov txheej txheej insulating uas txo cov kab mob cab thiab cov dej ntws tawm, ua rau muaj kev ua tau zoo dua, cov lus teb zoo dua, thiab kev ua haujlwm zoo dua thermal.

Q2: Qhov ntau thiab tsawg wafer feem ntau muaj?

A2: SICOI wafers feem ntau tsim nyob rau hauv 4-nti, 6-nti, thiab 8-nti hom, nrog customized SiC thiab insulating txheej thickness muaj nyob ntawm cov khoom yuav tsum tau.

Q3: Cov kev lag luam twg tau txais txiaj ntsig zoo tshaj plaws los ntawm SICOI wafers?

A3: Cov kev lag luam tseem ceeb suav nrog hluav taws xob hluav taws xob rau lub tsheb hluav taws xob, RF electronics rau 5G tes hauj lwm, MEMS rau aerospace sensors, thiab optoelectronics xws li UV LEDs.

Q4: Cov txheej txheem insulating zoo li cas txhim kho cov cuab yeej ua haujlwm?

A4: Cov zaj duab xis insulating (SiO₂ lossis Si₃N₄) tiv thaiv cov xau tam sim no thiab txo cov hluav taws xob sib tham, ua kom muaj hluav taws xob ntau dua, hloov tau zoo dua, thiab txo cov cua sov.

Q5: Puas yog SICOI wafers haum rau cov ntawv thov kub?

A5: Yog lawm, nrog cov thermal conductivity thiab tsis kam tshaj 500 ° C, SICOI wafers yog tsim los ua kom muaj kev ntseeg siab nyob rau hauv huab cua kub thiab nyob rau hauv ib puag ncig hnyav.

Q6: SICOI wafers puas tuaj yeem hloov kho?

A6: Yog lawm. Cov neeg tsim khoom muab cov qauv tsim tshwj xeeb rau cov thicknesses, doping qib, thiab substrate ua ke kom tau raws li kev tshawb fawb sib txawv thiab kev xav tau ntawm kev lag luam.