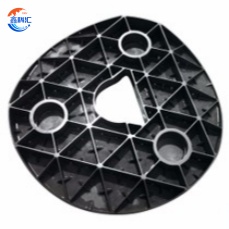

Silicon Carbide Prism / Daim iav Rau Infrared Optics Aerospace-Qib

Daim duab qhia ntxaws

Txheej txheem cej luam

Cov iav silicon carbide (SiC) tiaj tus iav yog cov khoom siv kho qhov muag zoo tshaj plaws tsim los ntawm SiC ceramics siab heev. Featuring tshwj xeeb nruj-rau-hnyav piv, superior infrared kev ua tau zoo, thiab zoo ib puag ncig durability, nws yog ib qho kev xaiv zoo tshaj plaws rau kev thov kho qhov muag. Piv nrog rau cov ntaub ntawv ib txwm muaj xws li fused silica, germanium, thiab zinc selenide, SiC tsom iav tsis tsuas yog ua tau zoo nyob rau hauv nruab nrab mus rau qhov deb-infrared spectrum tab sis kuj xa lub teeb yuag, siab mechanical zog, thiab kev ruaj ntseg mus sij hawm ntev hauv kev ua haujlwm hnyav.

Daim iav no tau siv dav hauv aerospace payloads, laser systems, infrared imaging, thiab high-precision metrology.

Cov yam ntxwv tseem ceeb

-

Lub teeb yuag structural optimization: Advanced tsim nrog honeycomb thiab topology lug txo qhov hnyav yam tsis muaj kev txi lub zog.

Lub teeb yuag structural optimization: Advanced tsim nrog honeycomb thiab topology lug txo qhov hnyav yam tsis muaj kev txi lub zog. -

Ultra-lub teeb yuag: Ntau qhov sib zog dua li cov qauv iav substrates, qhov tseem ceeb rau aerospace thiab mobile platforms.

-

Siab tawv: Txhim kho qhov tseeb ntawm daim duab txawm tias muaj qhov loj-aperture thiab nyias-daim iav configurations.

-

Tsawg thermal expansion: Guarantes optical kev ua tau zoo nyob rau hauv ceev ceev los yog huab kub variations.

-

Scratch & hnav tsis kam: Hardness ze rau pob zeb diamond, resistant rau ib puag ncig puas.

-

High-precision nto finishing: Flatness ≤ 1 μm, nto zoo tsim nyog rau kev thov cov duab thiab cov ntawv siv laser.

Kev Ua Haujlwm Zoo

-

High modulus & dimensional stability: Elastic modulus mus txog 420-450 GPa, ua kom ruaj khov kev ua haujlwm nyob rau hauv hnyav loads thiab vibrations.

-

Tsawg thermal distortion: Tsis tshua muaj coefficient ntawm thermal expansion (CTE), ua kom pom kev ruaj ntseg nyob rau hauv qhov sib txawv thermal ib puag ncig.

-

Thermal shock & corrosion kuj: Ruaj khov tiv thaiv acid / alkali ib puag ncig thiab tiv taus kub kub hloov pauv sai.

-

ntom, pore-dawb microstructure: Tej qhov ceev txog li 3.14 g / cm³ tsis muaj qhov seem porosity tom qab machining, muab kev xav zoo heev thiab kev ncaj ncees.

Daim ntawv thov

-

Infrared optics: Mid- thiab far-infrared imaging systems, thermal lub koob yees duab, thiab soj ntsuam optics.

-

Laser & optoelectronics: High-power laser iav, beam steering, thiab reflective optical sib dhos.

-

Aerospace thiab astronomy: Tsom iav tsom iav qhov chaw, satellite payloads, thiab airborne optical instruments.

-

Kev ruaj ntseg & kev ruaj ntseg: IR kev taw qhia tshuab, tsom iav tsom iav, thiab kev pom kev hmo ntuj.

-

Precision metrology: Interferometry, kev sim flatness, thiab siv optics rau calibration.

FAQ

Q1: Puas yog SiC daim iav muaj kev cuam tshuam nyob rau hauv qhov pom wavelengths?

A1: Lub substrate nws tus kheej yog opaque, tab sis nrog qhov tsim nyog coatings (hlau los yog dielectric), SiC ca iav tuaj yeem ua haujlwm zoo hauv kev pom, infrared, thiab txawm laser wavelengths.

Q2: Dab tsi zoo dua SiC muaj tshaj iav lossis hlau iav?

A2: SiC yog qhov sib zog, tawv, thiab thermally ruaj khov dua li iav lossis hlau substrates. Nws tseem nyob deb dua nyob rau hauv hnyav lossis qhov chaw ib puag ncig.

Q3: SiC daim iav tiaj tus puas tuaj yeem siv rau hauv cov ntawv thov laser siab?

A3: Yog. Nrog zoo thermal conductivity thiab mechanical stability, SiC substrates yog qhov zoo tagnrho rau high-power lossis high-zog laser tsom iav thaum ua ke nrog cov txheej txheem tsim nyog.

Q4: Dab tsi ntawm flatness tuaj yeem ua tiav?

A4: Tom qab ultra-precision polishing, flatness tuaj yeem ncav cuag ≤ 1 μm, nrog rau kev sib luag thiab kev ntxhib los mos ntawm qhov chaw tswj kom tau raws li cov kev qhia tshwj xeeb.

Txog Peb

XKH tshwj xeeb hauv kev tsim cov thev naus laus zis, tsim khoom, thiab muag cov iav tshwj xeeb kho qhov muag thiab cov ntaub ntawv siv lead ua tshiab. Peb cov khoom siv kho qhov muag khoom siv hluav taws xob, khoom siv hluav taws xob, thiab tub rog. Peb muab Sapphire optical Cheebtsam, xov tooj ntawm tes lens npog, Ceramics, LT, Silicon Carbide SIC, Quartz, thiab semiconductor siv lead ua wafers. Nrog cov kws tshaj lij thiab cov cuab yeej siv niaj hnub, peb ua tau zoo hauv kev ua cov khoom lag luam uas tsis yog tus qauv, aiming los ua ib qho khoom siv optoelectronic high-tech enterprise.