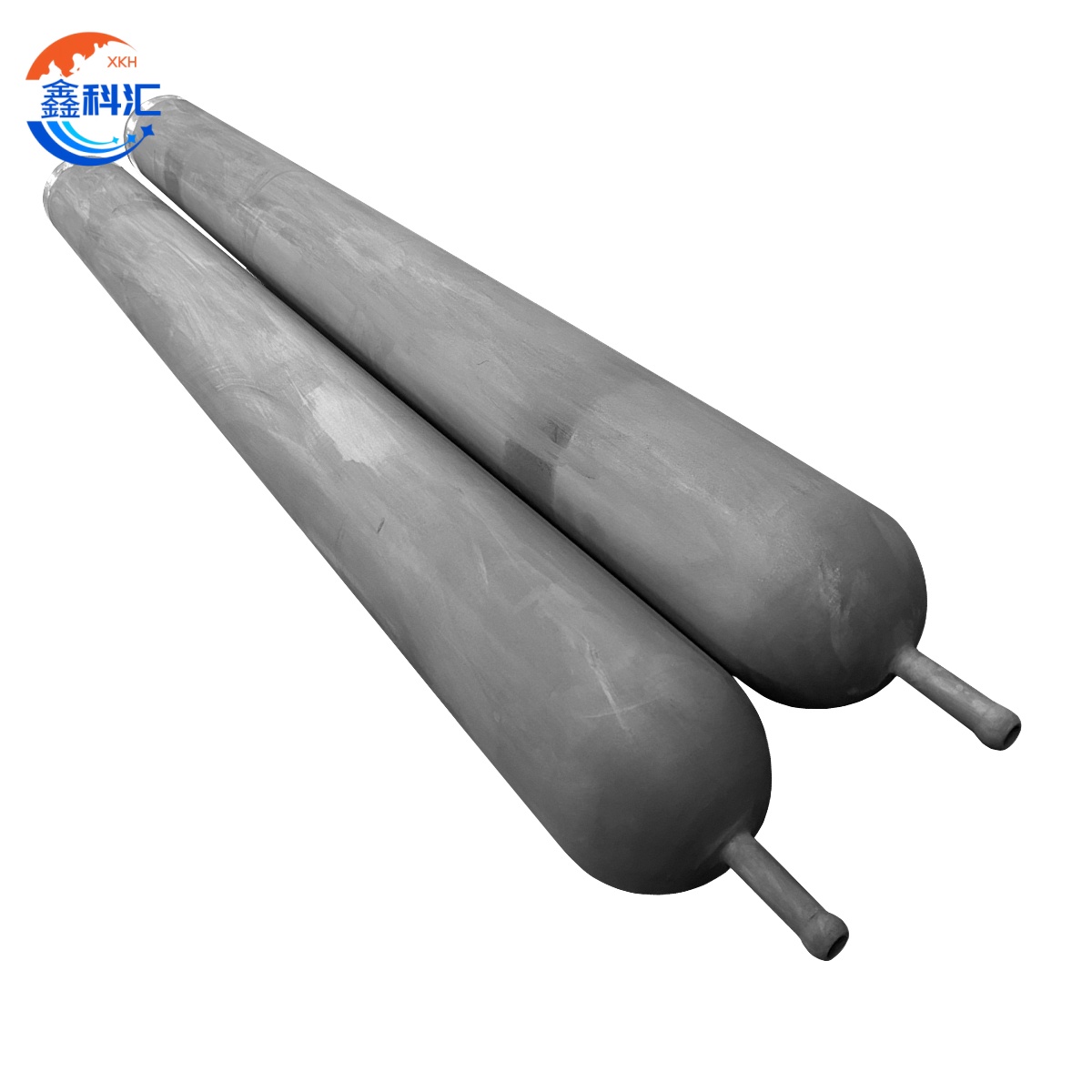

Silicon Carbide (SiC) Kab rov tav Rauv Tube

Daim duab qhia ntxaws

Product Positioning & Value Proposition

Silicon Carbide (SiC) Kab rov tav Rauv Tube ua haujlwm tseem ceeb hauv chamber thiab siab ciam teb rau high-temperature gas-phase reactions and heat treatments used in semiconductor fabrication, photovoltaic manufacturing, and advanced material processing.

Engineered nrog ib tug ib-thooj, additive-tsim SiC qauv ua ke nrog ib tug ntom CVD-SiC tiv thaiv txheej, lub raj no muab tshwj xeeb thermal conductivity, tsawg kis kab mob, muaj zog txhua yam kev ncaj ncees, thiab zoo heev tshuaj tiv thaiv.

Nws cov qauv tsim ua kom muaj qhov sib txawv ntawm qhov kub thiab txias, kev pabcuam txuas ntxiv, thiab kev ua haujlwm ruaj khov mus ntev.

Core Zoo

-

Boosts system kub sib xws, huv si, thiab tag nrho cov cuab yeej siv tau zoo (OEE).

-

Txo cov sij hawm poob rau kev tu thiab ncua sij hawm hloov pauv, txo tus nqi tag nrho ntawm cov tswv cuab (TCO).

-

Muab lub neej ntev chamber uas muaj peev xwm tuav tau qhov kub thiab txias oxidative thiab chlorine-nplua nuj chemistry nrog tsawg tsawg.

Siv tau Atmospheres & Txheej Txheem Qhov rai

-

Reactive gases: oxygen (O₂) thiab lwm yam oxidizing tov

-

Carrier/protective gases: nitrogen (N₂) thiab ultra-ntshiab inert gases

-

Tau hom: taug qab cov chlorine-cov kabmob gases (concentration thiab dwell time daim ntawv qhia-tswj)

Cov txheej txheem: qhuav / ntub oxidation, annealing, diffusion, LPCVD / CVD deposition, nto ua kom muaj zog, photovoltaic passivation, ua hauj lwm nyias-zaj duab xis loj hlob, carbonization, nitridation, thiab lwm yam.

Cov xwm txheej ua haujlwm

-

Kub: chav tsev kub txog 1250 ° C (tso 10-15% kev nyab xeeb npoo nyob ntawm lub rhaub tsim thiab ΔT)

-

Siab: los ntawm qhov tsis tshua muaj siab / LPCVD lub tshuab nqus tsev mus rau ze-cua huab cua zoo siab (qhov kawg spec rau kev yuav khoom)

Materials & Structure Logic

Monolithic SiC Lub Cev (Additive Manufactured)

-

High-density β-SiC los yog multiphase SiC, ua ib qho kev tivthaiv-tsis muaj cov pob qij txha lossis cov seams uas tuaj yeem xau lossis tsim cov ntsiab lus kev ntxhov siab.

-

High thermal conductivity enables ceev thermal teb thiab zoo heev axial / radial kub uniformity.

-

Tsawg, ruaj khov coefficient ntawm thermal expansion (CTE) ua kom muaj qhov ruaj khov thiab txhim khu kev ruaj ntseg ntawm qhov kub siab.

CVD SiC Functional Txheej

CVD SiC Functional Txheej

-

Nyob rau hauv-situ deposited, ultra-ntshiab (nto / txheej impurities <5 ppm) los suppress particle tiam thiab hlau ion tso.

-

Superb tshuaj inertness tiv thaiv oxidizing thiab chlorine-cov kabmob gases, tiv thaiv phab ntsa nres lossis rov ua dua.

-

Zone-specific thickness xaiv kom sib npaug corrosion kuj thiab thermal responsiveness.

Cov txiaj ntsig sib xyaw: SiC lub cev muaj zog muab cov qauv tsim muaj zog thiab kev ua kom sov, thaum CVD txheej lav kev huv thiab kev tiv thaiv corrosion rau qhov siab tshaj plaws kev ntseeg tau thiab dhau los.

Cov Hom Phiaj Tseem Ceeb

-

Kev siv tsis tu ncua kub:≤ 1250 ° C

-

Tej substrate impurities:<300 ppm

-

CVD-SiC nto impurities:<5 ppm

-

Dimensional kam rau ua: OD ± 0.3-0.5 hli; coaxiality ≤ 0.3mm / m (ntau dua muaj)

-

Inner-wall roughness: Ra ≤ 0.8-1.6 µm (polished los yog ze-daim iav tiav xaiv tau)

-

Helium leak rate: ≤ 1 × 10⁻⁹ Pa·m³ / s

-

Thermal-shock endurance: ciaj sia rov kub / txias cycling yam tsis muaj cracking los yog spallation

-

Kev sib dhos chav huv: ISO Class 5-6 nrog cov ntawv pov thawj particle / hlau-ion residue qib

Configurations & Options

-

Geometry: OD 50-400 mm (loj dua los ntawm kev ntsuam xyuas) nrog ntev ib qho kev tsim kho; phab ntsa thickness optimized rau txhua yam muaj zog, hnyav, thiab kub flux.

-

Kawg tsim: flanges, tswb-qhov ncauj, bayonet, nrhiav rings, O-ring grooves, thiab kev cai twj tso kua mis-tawm los yog siab ports.

-

Functional ports: thermocouple feedthroughs, pom-iav rooj zaum, bypass gas inlets-tag nrho cov engineered rau high-temperature, leak-tight lag luam.

-

Txheej txheej txheej: sab hauv phab ntsa (default), sab nrauv phab ntsa, los yog tag nrho cov kev pab cuam; targeted shielding los yog graded thickness rau high-impingement cheeb tsam.

-

Kev kho deg & kev huv: Ntau qib roughness, ultrasonic / DI tu, thiab kev cai ci / qhuav raws tu qauv.

-

Cov khoom siv: graphite/ceramic/hlau flanges, seals, nrhiav fixtures, tuav tes tsho, thiab cradles cia.

Kev sib piv

| Metric | SiC Tube | Quartz Tube | Alumina Tube | Graphite Tube |

|---|---|---|---|---|

| Thermal conductivity | Siab, uniform | Tsawg | Tsawg | Siab |

| High-temperature zog / creep | Zoo heev | Ncaj ncees | Zoo | Zoo (oxidation-rhiab heev) |

| Thermal shock | Zoo heev | Tsis muaj zog | Nruab nrab | Zoo heev |

| Kev huv huv / hlau ions | Zoo heev (qis) | Nruab nrab | Nruab nrab | pluag |

| Oxidation & Cl-chemistry | Zoo heev | Ncaj ncees | Zoo | Tsis zoo (oxidizes) |

| Tus nqi vs. kev pab lub neej | Nruab nrab / ntev lub neej | Tsawg / luv | Nruab nrab / nruab nrab | Nruab nrab / ib puag ncig-limited |

Cov lus nug nquag nug (FAQ)

Q1. Vim li cas thiaj xaiv 3D luam tawm monolithic SiC lub cev?

A. Nws tshem tawm cov seams thiab brazes uas tuaj yeem xau lossis mloog zoo rau kev ntxhov siab, thiab txhawb nqa cov geometry nyuaj nrog qhov tseeb qhov tseeb.

Q2. Puas yog SiC resistant rau chlorine-cov kabmob gases?

A. Yog. CVD-SiC yog inert heev nyob rau hauv qhov ntsuas kub thiab siab txwv. Rau cov cheeb tsam uas muaj kev cuam tshuam loj, cov txheej txheej hauv cheeb tsam tuab thiab muaj zog tshem tawm / tshem tawm cov tshuab raug pom zoo.

Q3. Yuav ua li cas kom zoo dua quartz tubes?

A. SiC muaj kev pab lub neej ntev dua, qhov kub thiab txias zoo dua qub, qis qis / hlau-ion paug, thiab txhim kho TCO-tshwj xeeb tshaj li ntawm ~ 900 ° C lossis hauv oxidizing / chlorinated atmospheres.

Q4. Lub raj puas tuaj yeem ua haujlwm nrawm nrawm?

A. Yog lawm, muab qhov siab tshaj plaws ΔT thiab ramp-rate cov lus qhia raug soj ntsuam. Pairing lub siab-κ SiC lub cev nrog nyias CVD txheej txhawb kev hloov pauv ceev ceev.

Q5. Thaum twg yuav tsum tau hloov?

A. Hloov lub raj yog tias koj pom flange lossis ntug tawg, txheej pits lossis spallation, nce tus nqi xau, qhov tseem ceeb ntawm qhov kub thiab txias-profile drift, lossis cov khoom tsim tsis zoo.

Txog Peb

XKH tshwj xeeb hauv kev tsim cov thev naus laus zis, tsim khoom, thiab muag cov iav tshwj xeeb kho qhov muag thiab cov ntaub ntawv siv lead ua tshiab. Peb cov khoom siv kho qhov muag khoom siv hluav taws xob, khoom siv hluav taws xob, thiab tub rog. Peb muab Sapphire optical Cheebtsam, xov tooj ntawm tes lens npog, Ceramics, LT, Silicon Carbide SIC, Quartz, thiab semiconductor siv lead ua wafers. Nrog cov kws tshaj lij thiab cov cuab yeej siv niaj hnub, peb ua tau zoo hauv kev ua cov khoom lag luam uas tsis yog tus qauv, aiming los ua ib qho khoom siv optoelectronic high-tech enterprise.