Soda-Lime Glass Substrates - Precision Polished thiab nqi-zoo rau kev lag luam peb

Daim duab qhia ntxaws

Txheej txheem cej luam ntawm Quartz iav

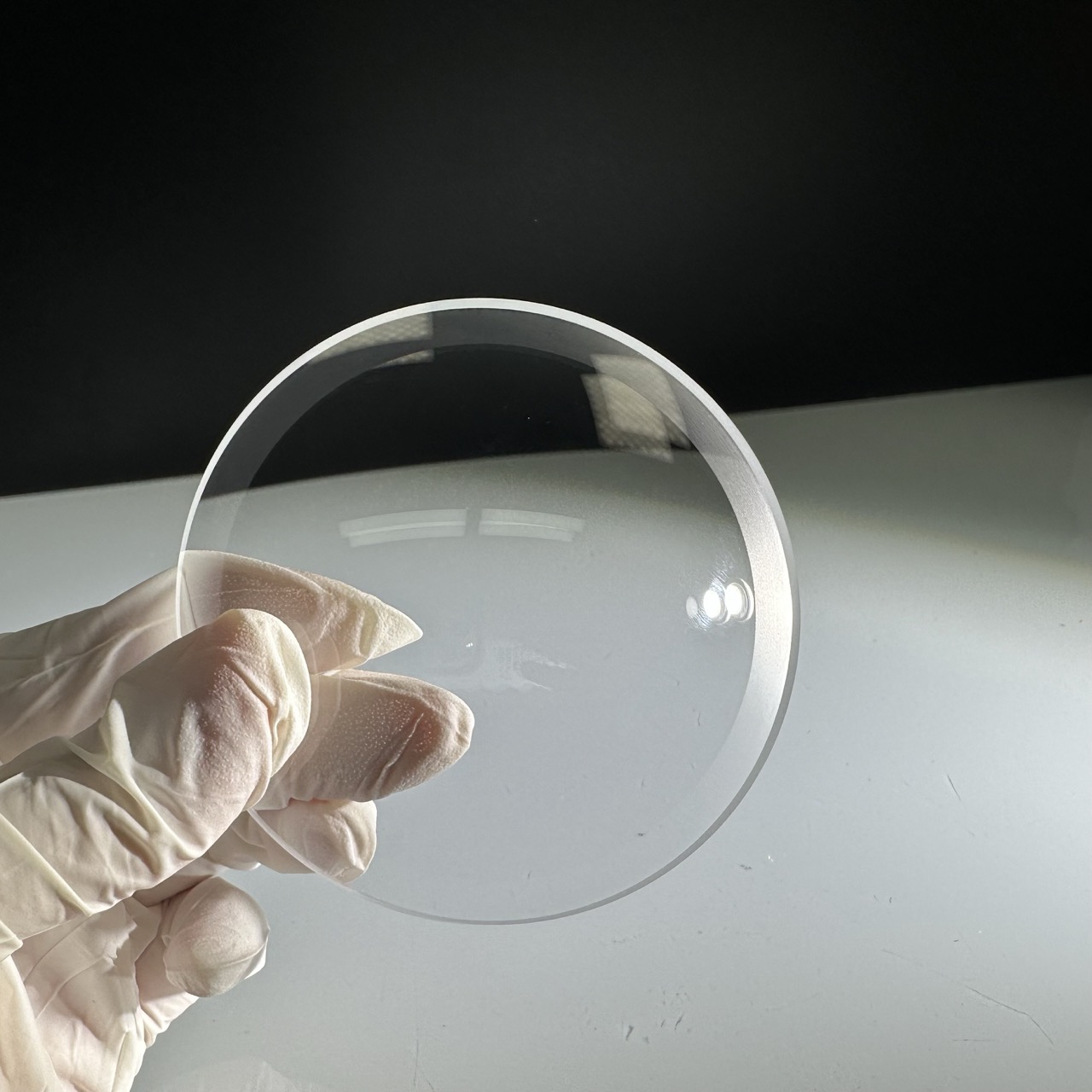

Soda-lime substratesyog cov iav iav wafers ua los ntawm qib high-qib soda-lime silicate iav - cov khoom siv ntau yam thiab cov nqi siv tau dav siv hauv kev lag luam kho qhov muag, hluav taws xob, thiab txheej txheej. Paub txog nws txoj kev sib kis tau zoo heev, qhov chaw tiaj tus zoo, thiab kev ruaj ntseg, cov iav soda-lime iav muab lub hauv paus txhim khu kev qha rau ntau yam nyias-zaj duab xis deposition, photolithography, thiab cov ntawv thov kev sim.

Nws qhov kev ua tau zoo ntawm lub cev thiab kho qhov muag ua rau nws muaj kev xaiv zoo rau R & D thiab ntim ntau lawm ib puag ncig.

Ntsiab nta & Cov txiaj ntsig

-

High Optical Clarity:Exceptional kis tau tus mob nyob rau hauv lub pom spectrum (400-800 nm), haum rau optical soj ntsuam thiab imaging.

-

Smooth Polished nto:Ob tog tuaj yeem ua tau zoo polished kom ua tiav qhov roughness tsawg (<2 nm), kom ntseeg tau zoo heev adhesion rau coatings.

-

Dimensional Stability:Ua kom zoo ib yam flatness thiab parallelism, sib xws nrog precision alignment thiab metrology setups.

-

Cov khoom siv raug nqi:Muab cov nqi qis dua rau borosilicate lossis fused silica substrates rau cov ntawv thov kub.

-

Machineability:Yooj yim txiav, drilled, los yog zoo li tus rau kev cai kho qhov muag thiab hluav taws xob tsim.

-

Tshuaj Compatibility:Tau tshaj photoresists, adhesives, thiab feem ntau nyias-film deposition cov ntaub ntawv (ITO, SiO₂, Al, Au).

Nrog nws kev sib xyaw ua ke ntawm clarity, lub zog, thiab kev pheej yig,dej qab zib-lime iavtseem yog ib qho ntawm feem ntau siv cov ntaub ntawv substrate nyob rau hauv lub chaw soj nstuam, kho qhov muag rhiav, thiab nyias-film txheej.

Manufacturing & Nto Zoo

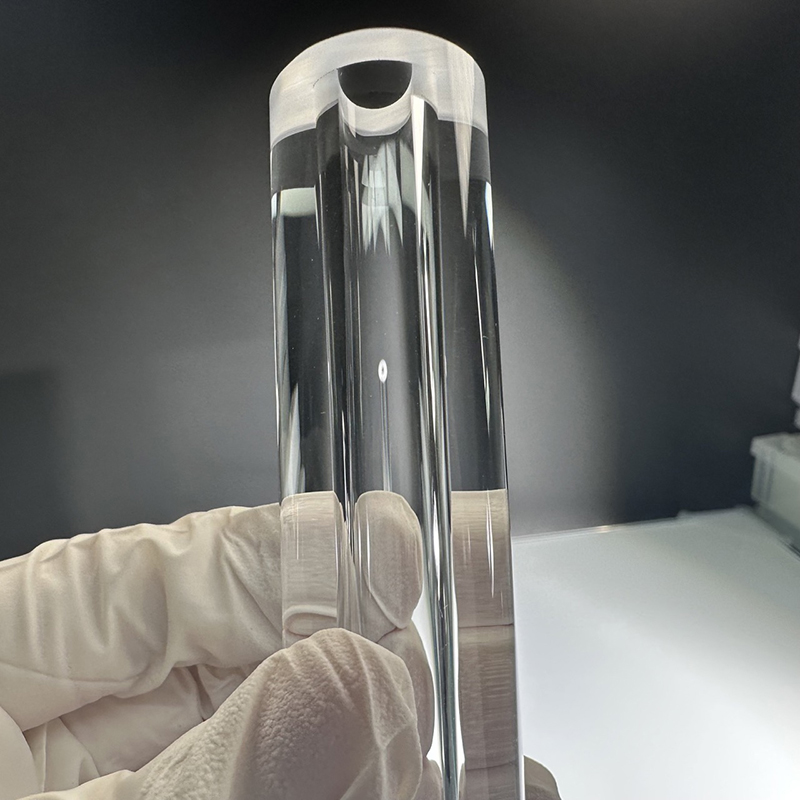

Txhuadej qab zib-lime substrateyog fabricated siv high-zoo ntab iav uas undergoes precision slicing, lapping, thiab ob-sided polishing kom ua tau ib tug optically tiaj tus.

Cov txheej txheem tsim khoom ib txwm muaj xws li:

-

Float txheej txheem:Ua ultra-pav ca, niaj hnub iav los ntawm molten tin ntab tshuab.

-

Txiav & Shaping:Laser los yog pob zeb diamond txiav rau hauv round lossis rectangular substrate hom.

-

Zoo Polishing:Ua tau zoo flatness thiab optical-qib smoothness ntawm ib los yog ob sab.

-

Ntxuav & Ntim:Ultrasonic tu hauv dej deionized, tshuaj xyuas tsis muaj particle, thiab ntim huv.

Cov txheej txheem no ua kom muaj kev sib luag zoo tshaj plaws thiab qhov chaw tiav tsim nyog rau kev kho qhov muag lossis microfabrication ua haujlwm.

Daim ntawv thov

Soda-lime substratesyog siv nyob rau hauv ntau yam scientific, optical, thiab semiconductor daim ntaub ntawv, xws li:

-

Optical Windows & Daim iav:Base phaj rau optical coatings thiab lim fabrication.

-

Thin-Film Deposition:Qhov zoo tshaj plaws cab kuj substrates rau ITO, SiO₂, TiO₂, thiab metallic films.

-

Zaub Technology:Siv nyob rau hauv backplane iav, tso saib tiv thaiv, thiab calibration qauv.

-

Kev Tshawb Fawb Semiconductor:Tus nqi qis los yog kuaj wafers hauv cov txheej txheem photolithography.

-

Laser & Sensor Platforms:Pob tshab txhawb cov khoom siv kho qhov muag thiab kev sojntsuam kuaj.

-

Kev Kawm & Kev Siv Tshuaj:Feem ntau siv nyob rau hauv cov chaw sim rau txheej, etching, thiab kev sib txuas ua ke.

Hom Specifications

| Parameter | Specification |

|---|---|

| Khoom siv | Soda-Lime Silicate iav |

| Txoj kab uas hla | 2 ", 3", 4", 6", 8 "(customized muaj) |

| Thickness | 0.3-1.1mm txheem |

| Nto tiav | Ob sab polished los yog ib sab polished |

| Flatness | ≤ 15 µm |

| Nto Roughness (Ra) | <2 nm |

| Kev sib kis | ≥90% (pom ntau: 400-800 nm) |

| Qhov ntom | 2.5 g / cm³ |

| Coefficient ntawm Thermal Expansion | ~ 9 × 10⁻⁶ /K |

| Hardness | ~6 hmo |

| Refractive Index (nD) | ~ 1.52 |

FAQ

Q1: Dab tsi yog dej qab zib-lime substrates feem ntau siv rau?

A: Lawv yog siv los ua cov ntaub ntawv hauv cov txheej txheem txheej txheej, kev sim kho qhov muag, kuaj photolithography, thiab kho qhov muag qhov rais vim lawv qhov pom tseeb thiab tiaj tus.

Q2: Soda-lime substrates puas tuaj yeem tiv taus qhov kub thiab txias?

A: Lawv tuaj yeem ua haujlwm txog li 300 ° C. Rau kev kub siab dua, borosilicate lossis fused silica substrates raug pom zoo.

Q3: Puas yog cov substrates haum rau txheej deposition?

A: Yog lawm, lawv qhov chaw du thiab huv si zoo tagnrho rau lub cev vapor deposition (PVD), tshuaj vapor deposition (CVD), thiab sputtering txheej txheem.

Q4: Puas yog customization tau?

A: Yog lawm. Kev cai qhov ntau thiab tsawg, cov duab, thicknesses, thiab ntug tiav yog muaj raws li cov kev thov tshwj xeeb.

Q5: Lawv piv rau borosilicate substrates li cas?

A: Soda-lime iav yog kev lag luam ntau dua thiab yooj yim rau kev ua tab sis muaj qis dua thermal thiab tshuaj tiv thaiv piv rau borosilicate iav.

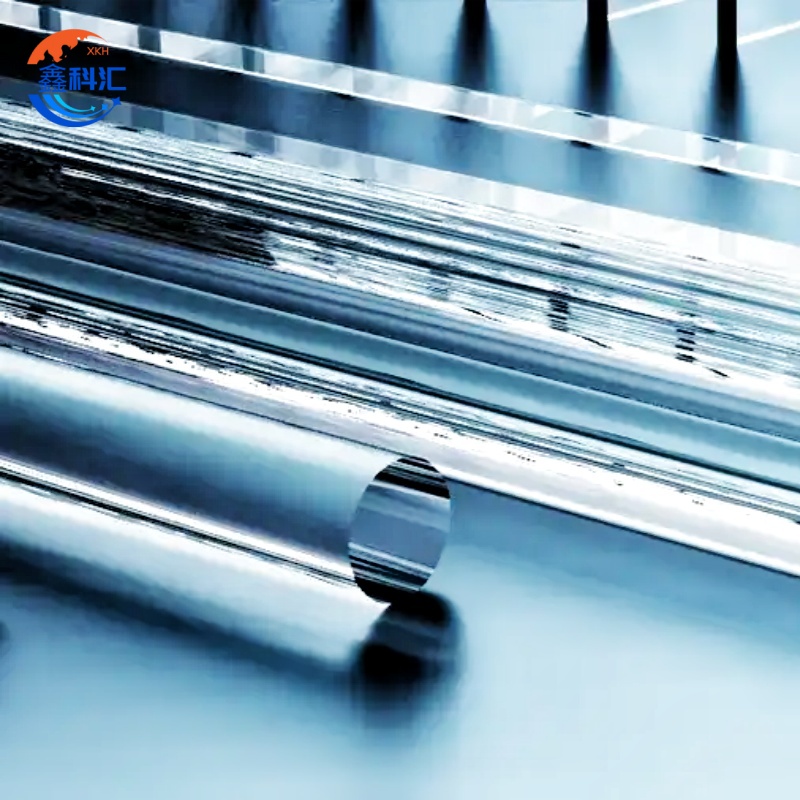

Txog Peb

XKH tshwj xeeb hauv kev tsim cov thev naus laus zis, tsim khoom, thiab muag cov iav tshwj xeeb kho qhov muag thiab cov ntaub ntawv siv lead ua tshiab. Peb cov khoom siv kho qhov muag khoom siv hluav taws xob, khoom siv hluav taws xob, thiab tub rog. Peb muab Sapphire optical Cheebtsam, xov tooj ntawm tes lens npog, Ceramics, LT, Silicon Carbide SIC, Quartz, thiab semiconductor siv lead ua wafers. Nrog cov kws tshaj lij thiab cov cuab yeej siv niaj hnub, peb ua tau zoo hauv kev ua cov khoom lag luam uas tsis yog tus qauv, aiming los ua ib qho khoom siv optoelectronic high-tech enterprise.