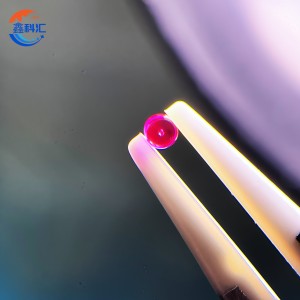

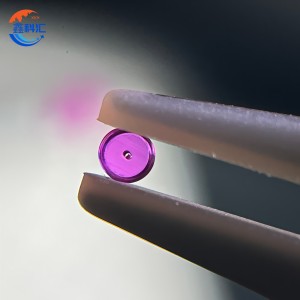

Los ntawm-Hole Ruby Bearing

Daim duab qhia ntxaws

Product Overview

Los ntawm lub qhov ruby bearings yog precision-engineered Cheebtsam ua los ntawm hluavtaws ib leeg-crystal ruby (Al₂O₃ doped nrog Cr₂O₃). Cov kabmob no yog tsim los nrog lub hauv nruab nrab ntawm lub qhov uas tso cai rau cov shafts, pins, lossis optical fibers kom dhau los ntawm kev sib tw thaum txo kev sib txhuam thiab hnav. Raws li ruby lub hardness (Mohs 9), zoo heev tshuaj stability, thiab zoo heev nto tag, cov bearings yog dav siv nyob rau hauv precision instruments, metering devices, fiber optic assemblies, thiab micro-mechanical systems uas stability thiab ntev lifespan tseem ceeb heev.

Khoom siv thiab cov qauv

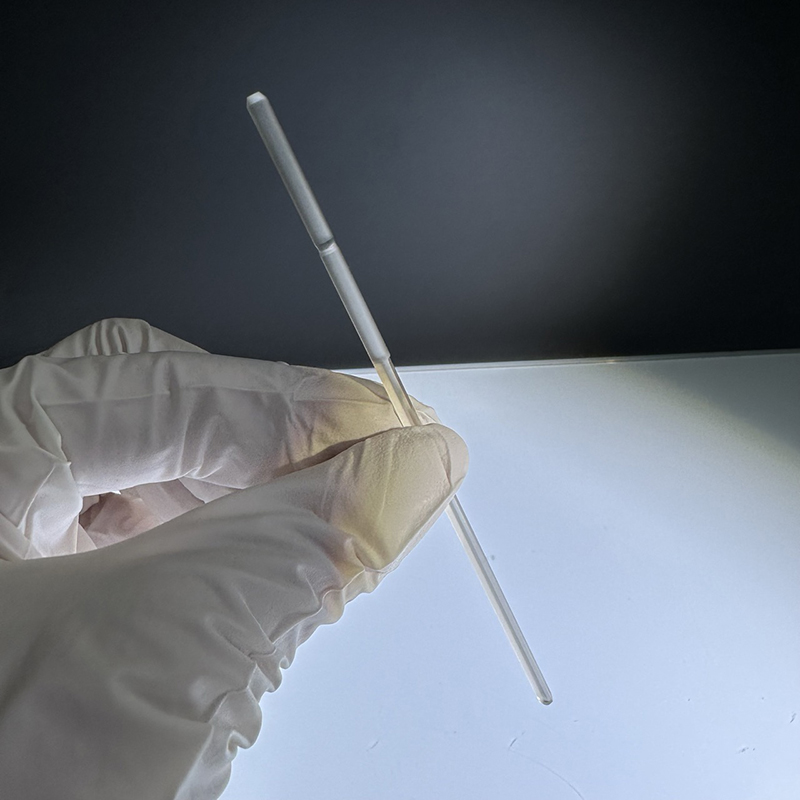

Lub cev bearing yog ua los ntawm hluavtaws corundum siv lead ua, loj hlob nyob rau hauv kev tswj xyuas kom zoo ib yam hardness thiab purity. Chromium doping muab cov khoom nws tus yam ntxwv xim liab thiab ntxiv optical clarity thiab corrosion kuj. Lub qhov los ntawm lub qhov yog precisely machined thiab polished kom ua tiav micron-theem seem qhov tseeb thiab smoothness, kom ntseeg tau zoo heev coaxiality thiab tsis tshua muaj kev sib txhuam nyob rau hauv teb los yog oscillating zog.

Yam Parameters

| Parameter | Tus nqi |

|---|---|

| Khoom siv | Synthetic Ruby (Al₂O₃ + trace Cr₂O₃) |

| Hardness | 9 ntawm Mohs scale |

| Qhov ntom | 3.98 g / cm³ |

| Ua haujlwm kub | -60 ° C rau 500 ° C |

| Lub taub hau | 0.05-5.0mm (kev cai muaj) |

| Sab nraud | 0.5-10 hli |

| Roundness kam rau ua | ≤ 0.0025 hli |

| Nto tiav | Ra ≤ 0.02 μm |

Technical nta

Hardness thiab ruaj khov heev - Lub ruby siv lead ua tawm tsam deformation, puas, thiab tshuaj tua kab mob txawm nyob rau hauv qhov chaw ua haujlwm hnyav.

Precision Through-Hole Design - Txhua qhov bore tiav nrog optical-qib polishing rau ultra-smooth suab thiab kev sib txhuam tsawg.

Corrosion thiab hnav tsis kam - Ruby bearings tswj kev ua haujlwm hauv cov dej noo, cov kuab tshuaj, thiab cov kua qaub yam tsis muaj degradation.

Zoo Geometric Accuracy - Tightly tswj kev tsim ua kom zoo meej coaxial sib dhos thiab roundness rau kev sib hloov.

Kev ntseeg ntev ntev - Ua haujlwm tau ntau xyoo yam tsis muaj lubrication lossis qhov dav dav, zoo tagnrho rau kev thov txuas ntxiv lossis rov ua dua.

Daim ntawv thov

Los ntawm lub qhov ruby bearings feem ntau siv hauv:

-

Cov cuab yeej ntsuas Precision:Micrometers, gauges, thiab metrology cov cuab yeej uas yuav tsum tau muaj qhov tseeb ntawm kev txav mus los.

-

Optical thiab Laser Systems:Ua raws li kev taw qhia thiab muab tso rau cov khoom siv kho qhov muag, cov lo ntsiab muag, thiab cov khoom siv laser alignment.

-

Watches thiab Miniature Motors:Muab cov ntsiab lus tsis pub hnav-dawb pivot rau me me rotating shafts thiab axles.

-

Cov cuab yeej kho mob:Siv rau hauv cov twj tso kua mis, cov tshuab kuaj mob, thiab cov tswj kev khiav dej num uas qhov kev ua haujlwm siab yog qhov tseem ceeb.

-

Aerospace thiab Navigation Equipment:Xyuas kom ruaj khov thiab raug nyob rau hauv compact thiab vibration-resistant mechanisms.

FAQ

Q1: Dab tsi ua rau lub qhov ruby bearings haum rau cov cuab yeej precision?

A: Lawv hardness, roundness, thiab ultra-smooth bore txo kev co thiab kev sib txhuam, uas yog ib qho tseem ceeb rau qhov tseeb thiab ruaj khov txav hauv precision ntsuas cov cuab yeej.

Q2: Lawv puas tuaj yeem siv rau hauv lub tshuab nqus tsev lossis chav huv?

A: Yog. Ruby bearings yog dawb ntawm cov ntaub ntawv tsis hloov pauv thiab ua haujlwm zoo kawg nkaus yam tsis muaj lubrication, ua rau lawv zoo tagnrho rau lub tshuab nqus tsev lossis semiconductor ib puag ncig.

Q3: Puas muaj kev txwv ntawm cov khoom siv los yog qhov chaw tiav?

A: Rau kev ua tau zoo, shafts ua los ntawm polished stainless hlau, tungsten carbide, los yog sapphire raug pom zoo kom txo qis kev sib txhuam thiab hnav.

Q4: Kuv puas tuaj yeem thov qhov tsis yog tus qauv bore loj lossis cov duab geometry?

A: Yog. Peb txhawb nqa tag nrho customized ruby bearings raws li kev kos duab, suav nrog asymmetric bores, countersinks, thiab flange tsim.

Q5: Yuav ua li cas ruby piv nrog sapphire rau kev siv cov kabmob?

A: Ob leeg sib koom cov qauv siv lead ua zoo sib xws thiab cov tawv tawv, tab sis ruby's chromium doping txhim kho kev pom thiab hnav kev taug qab, ua rau nws nyiam me ntsis rau kev soj ntsuam thiab tshuaj xyuas qhov muag.

Txog Peb

XKH tshwj xeeb hauv kev tsim cov thev naus laus zis, tsim khoom, thiab muag cov iav tshwj xeeb kho qhov muag thiab cov ntaub ntawv siv lead ua tshiab. Peb cov khoom siv kho qhov muag khoom siv hluav taws xob, khoom siv hluav taws xob, thiab tub rog. Peb muab Sapphire optical Cheebtsam, xov tooj ntawm tes lens npog, Ceramics, LT, Silicon Carbide SIC, Quartz, thiab semiconductor siv lead ua wafers. Nrog cov kws tshaj lij thiab cov cuab yeej siv niaj hnub, peb ua tau zoo hauv kev ua cov khoom lag luam uas tsis yog tus qauv, aiming los ua ib qho khoom siv optoelectronic high-tech enterprise.