SiC Ceramic tais End Effector Wafer tuav Custom-Made Components

SiC Ceramic & Alumina Ceramic Custom Cheebtsam luv

Silicon Carbide (SiC) Ceramic Custom Cheebtsam

Silicon Carbide (SiC) ceramic kev cai Cheebtsam yog high-kev ua tau zoo muaj cov ntaub ntawv ceramic renowned rau lawvtsis tshua muaj siab hardness, zoo heev thermal stability, exceptional corrosion kuj, thiab siab thermal conductivity. Silicon Carbide (SiC) ceramic kev cai Cheebtsam pab kom muaj kev ruaj ntseg hauv cov qauvKev kub siab ib puag ncig thaum tiv thaiv kev yaig los ntawm cov kua qaub, alkalis, thiab cov hlau molten. SiC ceramics yog tsim los ntawm cov txheej txheem xws liTsis muaj zog sintering, tshuaj tiv thaiv sintering, los yog kub xovxwm sinteringthiab tuaj yeem hloov kho rau hauv cov duab tsis yooj yim, suav nrog cov tshuab foob lub nplhaib, lub tes tsho ncej, lub taub hau, lub tshuab ua kom sov, lub nkoj wafer, thiab cov hnab looj tes tiv thaiv.

Alumina Ceramic Custom Cheebtsam

Alumina (Al₂O₃) ceramic kev cai Cheebtsam hais txogsiab rwb thaiv tsev, zoo mechanical zog, thiab hnav tsis kam. Muab faib los ntawm qib purity (piv txwv li, 95%, 99%), Alumina (Al₂O₃) ceramic kev cai Cheebtsam nrog precision machining tso cai rau lawv ua crafted rau hauv insulators, bearings, txiav cov cuab yeej, thiab kev kho mob cog. Alumina ceramics feem ntau yog tsim los ntawmqhuav nias, txhaj tshuaj molding, lossis isostatic nias txheej txheem, nrog rau qhov chaw polishable rau daim iav tiav.

XKH tshwj xeeb hauv R & D thiab kev tsim khoom ntawmsilicon carbide (SiC) thiab alumina (Al₂O₃) ceramics. SiC cov khoom siv ceramic tsom mus rau qhov kub thiab txias, hnav, thiab corrosive ib puag ncig, npog cov ntawv siv semiconductor (xws li, wafer nkoj, cantilever paddles, furnace tubes) nrog rau cov thermal field Cheebtsam thiab high-end seals rau lub zog tshiab. Alumina ceramic khoom hais txog kev rwb thaiv tsev, sealing, thiab biomedical zog, xws li hluav taws xob substrates, mechanical seal rings, thiab kev kho mob cog. Siv technologies xws liisostatic nias, pressureless sintering, thiab precision machining, peb muab cov kev daws teeb meem zoo tshaj plaws rau kev lag luam xws li semiconductors, photovoltaics, aerospace, kev kho mob, thiab kev ua tshuaj lom neeg, ua kom cov khoom ua tau raws li qhov yuav tsum tau ua kom nruj rau qhov tseeb, kev ua neej ntev, thiab kev ntseeg siab hauv huab cua.

SiC Ceramic Functional Chucks & CMP Sib Tsoo Discs Taw Qhia

SiC Ceramic Nqus Chucks

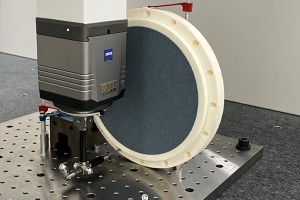

Silicon Carbide (SiC) Ceramic Nqus Chucks yog cov cuab yeej adsorption siab uas tsim los ntawm cov khoom siv zoo silicon carbide (SiC) ceramic. Lawv tau tsim tshwj xeeb rau cov ntawv thov uas xav tau kev huv huv thiab ruaj khov, xws li semiconductor, photovoltaic, thiab precision manufacturing industries. Lawv cov txiaj ntsig tseem ceeb suav nrog: daim iav-theem polished nto (flatness tswj nyob rau hauv 0.3-0.5 μm), ultra-siab nruj thiab tsis tshua muaj coefficient ntawm thermal expansion (xyuas nano-theem duab thiab txoj hauj lwm stability), ib tug heev heev lub teeb yuag qauv (qhov tseem ceeb heev), tseem ceeb heev thiab tsis muaj zog (mob siab heev) mus txog 9.5, deb tshaj lub neej ntawm cov hlau chucks). Cov khoom no ua rau kev ua haujlwm ruaj khov hauv ib puag ncig nrog kev hloov pauv siab thiab qis qis, muaj zog corrosion, thiab kev ceev ceev, kev txhim kho cov txiaj ntsig thiab kev tsim khoom zoo rau cov khoom siv precision xws li wafers thiab cov khoom siv kho qhov muag.

Silicon Carbide (SiC) Nqus Nqus Chuck rau Metrology thiab Kev Tshuaj Xyuas

Tsim los rau cov txheej txheem tshuaj xyuas qhov tsis xws luag, cov cuab yeej ua haujlwm siab adsorption no yog tsim los ntawm silicon carbide (SiC) cov khoom siv ceramic . Nws cov qauv pob zeb tshwj xeeb muab lub zog nqus nqus adsorption quab yuam thaum txo qhov chaw sib cuag nrog lub wafer, yog li tiv thaiv kev puas tsuaj los yog kis mus rau qhov chaw wafer thiab ua kom muaj kev ruaj ntseg thiab raug thaum kuaj xyuas. Lub chuck muaj qhov tshwj xeeb flatness (0.3-0.5 μm) thiab daim iav-polished nto, ua ke nrog ultra-lub teeb yuag thiab siab tawv kom ruaj ntseg thaum lub sij hawm kev kub ceev. Nws tsis tshua muaj coefficient ntawm thermal expansion guarantees seem stability nyob rau hauv kub hloov pauv, thaum zoo hnav tsis kam ncua kev pab cuam lub neej. Cov khoom txhawb kev hloov kho hauv 6, 8, thiab 12-nti specifications ua kom tau raws li qhov xav tau ntawm kev tshuaj xyuas ntawm ntau qhov sib txawv wafer.

Flip Chip Bonding Chuck

Flip chip bonding chuck yog ib qho tseem ceeb hauv cov txheej txheem chip flip-chip bonding txheej txheem, tshwj xeeb tshaj yog tsim los rau precisely adsorbing wafers los xyuas kom meej stability thaum lub sij hawm high-ceev, high-precision bonding ua hauj lwm. Nws nta ib daim iav-polished nto (flatness / parallelism ≤1 μm) thiab precision gas channel grooves kom ua tau raws li lub tshuab nqus tsev adsorption quab yuam, tiv thaiv wafer hloov chaw lossis kev puas tsuaj. Nws lub siab tawv thiab tsis tshua muaj coefficient ntawm thermal expansion (ze rau cov khoom siv silicon) ua kom muaj kev ruaj ntseg nyob rau hauv qhov kub thiab txias, thaum cov khoom siv high-density (piv txwv li, silicon carbide los yog ceramics tshwj xeeb) zoo tiv thaiv roj permeation, tswj lub tshuab nqus tsev mus ntev. Cov yam ntxwv no koom ua ke txhawb micron-level bonding raug thiab txhim khu kev ntim ntim cov khoom tawm.

SiC Bonding Chuck

Lub silicon carbide (SiC) bonding chuck yog ib tug tseem ceeb fixture nyob rau hauv daim ntawv cog lus cov txheej txheem, tshwj xeeb yog tsim los rau precisely adsorbing thiab ruaj wafers, kom ntseeg tau ultra-ruaj khov kev kawm nyob rau hauv high-temperature thiab high-pressure bonding tej yam kev mob. Tsim los ntawm high-density silicon carbide ceramic (porosity <0.1%), nws ua tiav cov khoom siv hluav taws xob sib txawv (kev sib txawv <5%) los ntawm nanometer-theem iav polishing (sov roughness Ra <0.1 μm) thiab precision gas fer channel grooves 5 μm (qhov chaw ntawm qhov chaw: 5 m) kev puas tsuaj. Nws cov coefficient ultra-low ntawm thermal expansion (4.5 × 10⁻⁶ / ℃) zoo sib xws ntawm silicon wafers, txo cov thermal stress-induced warpage. Ua ke nrog qhov siab tawv (elastic modulus> 400 GPa) thiab ≤1 μm flatness / parallelism , nws lav qhov kev sib raug zoo ntawm kev sib raug zoo. Dav siv nyob rau hauv semiconductor ntim, 3D stacking, thiab Chiplet integration, nws txhawb high-end manufacturing daim ntaub ntawv uas yuav tsum tau nanoscale precision thiab thermal stability.

CMP Sib Tsoo Disc

CMP kev sib tsoo disc yog cov khoom siv tseem ceeb ntawm cov khoom siv tshuaj lom neeg polishing (CMP), tshwj xeeb tsim los tuav ruaj khov thiab ruaj khov wafers thaum lub sij hawm ceev polishing, ua rau nanometer-theem ntiaj teb kev npaj. Tsim los ntawm cov khoom muaj zog, siab ceev (piv txwv li, silicon carbide ceramics los yog cov alloys tshwj xeeb), nws ua kom lub tshuab nqus tsev nqus adsorption los ntawm precision-engineered gas channel grooves . Nws daim iav-polished nto (flatness / parallelism ≤3 μm) lav tsis muaj kev ntxhov siab rau kev sib cuag nrog wafers, thaum lub ultra-low coefficient ntawm thermal expansion (sib haum rau silicon) thiab sab hauv cua txias channel zoo suppress thermal deformation. Tau tshaj 12-nti (750 mm txoj kab uas hla) wafers, lub disc leverages diffusion bonding tshuab los xyuas kom meej seamless kev koom ua ke thiab mus ntev kev cia siab ntawm multilayer lug nyob rau hauv siab kub thiab pressures, ho txhim kho CMP txheej txheem uniformity thiab yield.

Customized ntau yam SiC Ceramics Parts Taw qhia

Silicon Carbide (SiC) Daim iav Square

Silicon Carbide (SiC) Square Mirror yog cov khoom siv kho qhov muag zoo tshaj plaws tsim los ntawm qib siab silicon carbide ceramic, tshwj xeeb tsim rau cov khoom siv hluav taws xob high-end semiconductor xws li lithography tshuab. Nws ua tiav qhov hnyav ultra-lub teeb thiab siab tawv (elastic modulus> 400 GPa) los ntawm lub teeb pom kev zoo tsim qauv (piv txwv li, backside honeycomb hollowing), thaum nws tsis tshua muaj thermal expansion coefficient (≈4.5 × 10⁻⁻⁻⁻⁻⁶) qhov kub thiab txias. Daim iav nto, tom qab precision polishing, attains ≤1 μm flatness / parallelness , thiab nws qhov tshwj xeeb hnav tsis kam (Mohs hardness 9.5) ncua kev pab cuam lub neej. Nws yog dav siv nyob rau hauv lithography tshuab workstations, laser reflectors, thiab chaw telescopes qhov twg ultra-high precision thiab stability yog ib qho tseem ceeb.

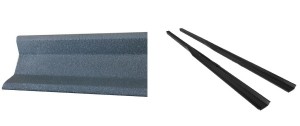

Silicon Carbide (SiC) Cua Floatation Guides

![]() Silicon Carbide (SiC) Air Floatation Guides siv cov cuab yeej tsis sib cuag aerostatic, qhov twg cov pa roj compressed tsim cov yeeb yaj kiab cua hauv micron (feem ntau 3-20μm) kom ua tiav kev sib txhuam tsis muaj kev vibration thiab tsis muaj kev vibration. Lawv muab cov lus tsa suab nanometric raug (rov ua dua qhov tseeb txog ± 75nm) thiab sub-micron geometric precision (txoj kev ncaj ± 0.1-0.5μm, flatness ≤1μm), qhib los ntawm kaw-loop tawm tswv yim tswj nrog precision grating scales lossis laser interferometer. Cov tub ntxhais silicon carbide ceramic khoom (kev xaiv muaj xws li Coresic® SP / Marvel Sic series) muab ultra-siab nruj (elastic modulus> 400 GPa), ultra-low thermal expansion coefficient (4.0–4.5 × 10⁻⁶/K, txuam silicon) <0.1%). Nws lub teeb yuag tsim (qhov ntom 3.1g / cm³, thib ob tsuas yog txhuas) txo qis zog inertia, thaum tshwj xeeb hnav tsis kam (Mohs hardness 9.5) thiab thermal stability ua kom muaj kev ntseeg tau ntev nyob rau hauv high-speed (1m / s) thiab high-acceleration (4G). Cov lus qhia no tau siv dav hauv semiconductor lithography, wafer tshuaj xyuas, thiab ultra-precision machining.

Silicon Carbide (SiC) Air Floatation Guides siv cov cuab yeej tsis sib cuag aerostatic, qhov twg cov pa roj compressed tsim cov yeeb yaj kiab cua hauv micron (feem ntau 3-20μm) kom ua tiav kev sib txhuam tsis muaj kev vibration thiab tsis muaj kev vibration. Lawv muab cov lus tsa suab nanometric raug (rov ua dua qhov tseeb txog ± 75nm) thiab sub-micron geometric precision (txoj kev ncaj ± 0.1-0.5μm, flatness ≤1μm), qhib los ntawm kaw-loop tawm tswv yim tswj nrog precision grating scales lossis laser interferometer. Cov tub ntxhais silicon carbide ceramic khoom (kev xaiv muaj xws li Coresic® SP / Marvel Sic series) muab ultra-siab nruj (elastic modulus> 400 GPa), ultra-low thermal expansion coefficient (4.0–4.5 × 10⁻⁶/K, txuam silicon) <0.1%). Nws lub teeb yuag tsim (qhov ntom 3.1g / cm³, thib ob tsuas yog txhuas) txo qis zog inertia, thaum tshwj xeeb hnav tsis kam (Mohs hardness 9.5) thiab thermal stability ua kom muaj kev ntseeg tau ntev nyob rau hauv high-speed (1m / s) thiab high-acceleration (4G). Cov lus qhia no tau siv dav hauv semiconductor lithography, wafer tshuaj xyuas, thiab ultra-precision machining.

Silicon Carbide (SiC) Hla Beams

Silicon Carbide (SiC) Cross-Beams yog cov khoom siv tseem ceeb tsim los rau cov khoom siv semiconductor thiab high-end industrial applications, feem ntau ua haujlwm los nqa cov theem wafer thiab coj lawv raws cov kev qhia tshwj xeeb rau kev kub ceev, ultra-precision motion . Siv cov kev ua tau zoo silicon carbide ceramic (cov kev xaiv suav nrog Coresic® SP lossis Marvel Sic series) thiab cov qauv tsim qauv, lawv ua tiav ultra-lub teeb yuag nrog siab tawv (elastic modulus> 400 GPa), nrog rau cov coefficient ultra-low coefficient ntawm thermal expansion ⁻ ⁻ 5 × 1 (⁉) siab ceev (porosity <0.1%), ua kom muaj kev ruaj ntseg nanometric (flatness / parallelism ≤1μm) nyob rau hauv thermal thiab mechanical stresses. Lawv cov khoom sib xyaw ua ke txhawb kev ua haujlwm siab thiab nrawm nrawm (piv txwv li, 1m / s, 4G), ua rau lawv zoo tagnrho rau cov tshuab lithography, wafer tshuaj xyuas tshuab, thiab precision manufacturing, ho txhim kho cov lus tsa suab thiab dynamic teb efficiency.

Silicon Carbide (SiC) Motion Cheebtsam

Silicon Carbide (SiC) Motion Cheebtsam yog qhov tseem ceeb tsim los rau high-precision semiconductor motion systems , siv cov ntaub ntawv SiC high-density (piv txwv li, Coresic® SP lossis Marvel Sic series, porosity <0.1%) thiab lub teeb yuag structural tsim kom ua tiav ultra-pas 4 (0. Nrog rau qhov tsis tshua muaj coefficient ntawm thermal expansion (≈4.5 × 10⁻⁶ / ℃), lawv ua kom nanometric stability (flatness / parallelism ≤1μm) nyob rau hauv thermal fluctuations. Cov khoom sib xyaw no txhawb kev ua haujlwm siab thiab nrawm nrawm (piv txwv li, 1m / s, 4G), ua rau lawv zoo tagnrho rau cov tshuab lithography, wafer tshuaj xyuas tshuab, thiab precision manufacturing, ho txhim khu cov lus tseeb thiab dynamic teb efficiency.

Silicon Carbide (SiC) Optical Path Phaj

Silicon Carbide (SiC) Optical Path Plate yog lub hauv paus tseem ceeb uas tsim los rau ob txoj hauv kev kho qhov muag hauv cov khoom siv tshuaj xyuas wafer. Tsim los ntawm kev ua tau zoo ntawm silicon carbide ceramic , nws ua tiav ultra-lub teeb ( ntom ≈3.1 g / cm³) thiab siab tawv (elastic modulus> 400 GPa) los ntawm kev tsim qauv tsim, thaum muaj qhov ua kom muaj zog ntawm qis qis. (≈4.5 × 10⁻⁶ / ℃) thiab siab ceev (porosity <0.1%), ua kom muaj kev ruaj ntseg nanometric (flatness / parallelism ≤0.02mm) nyob rau hauv thermal thiab mechanical fluctuations. Nrog nws qhov loj tshaj qhov loj (900 × 900mm) thiab qhov tshwj xeeb kev ua tau zoo, nws muab lub hauv paus ruaj khov rau lub sijhawm ntev rau cov tshuab kho qhov muag, txhim kho kev soj ntsuam qhov tseeb thiab kev ntseeg tau. Nws yog dav siv nyob rau hauv semiconductor metrology, optical alignment, thiab high-precision imaging systems.

Graphite + Tantalum Carbide Coated Guide Ntiv nplhaib

Lub Graphite + Tantalum Carbide Coated Guide Nplhaib yog ib qho tseem ceeb ntawm cov khoom tsim tshwj xeeb rau silicon carbide (SiC) ib qho khoom siv siv lead ua loj hlob. Nws lub luag haujlwm tseem ceeb yog ua kom ncaj qha cov roj kub kub, kom ntseeg tau tias muaj kev sib haum xeeb thiab kev ruaj ntseg ntawm qhov kub thiab txias thiab ntws hauv cov tshuaj tiv thaiv chamber. Ua los ntawm high-purity graphite substrate (purity> 99.99%) coated nrog CVD-deposited tantalum carbide (TaC) txheej (txheej impurity cov ntsiab lus <5 ppm), nws exhibits exceptional thermal conductivity (≈120 W / m. (nrog rau 2200 ° C), zoo tiv thaiv silicon vapor corrosion thiab suppressing impurity diffusion. Cov txheej txheej siab sib txawv (kev sib txawv <3%, thaj chaw tag nrho) ua kom cov kev taw qhia roj zoo ib yam thiab muaj kev ntseeg siab rau kev pabcuam ntev, ua kom muaj txiaj ntsig zoo thiab cov txiaj ntsig ntawm SiC ib qho kev loj hlob.

Silicon Carbide (SiC) Rauv Tube Abstract

Silicon Carbide (SiC) Vertical Furnace Tube

Silicon Carbide (SiC) Vertical Furnace Tube yog cov khoom siv tseem ceeb tsim los rau cov khoom siv hluav taws xob kub kub, feem ntau ua haujlwm tiv thaiv sab nraud kom ntseeg tau tias thermal faib nyob rau hauv lub cub tawg nyob rau hauv huab cua huab cua, nrog rau kev ua hauj lwm kub ntawm ib ncig ntawm 1200 ° C. Tsim los ntawm 3D printing integrated forming thev naus laus zis, nws muaj cov khoom siv impurity cov ntsiab lus <300 ppm, thiab tuaj yeem xaiv tau nruab nrog CVD silicon carbide txheej (txheej impurities <5 ppm). Ua ke nrog cov thermal conductivity (≈20 W / m·K) thiab tshwj xeeb thermal shock stability (tiv thaiv thermal gradients> 800 ° C), nws yog dav siv nyob rau hauv high-temperature txheej txheem xws li semiconductor tshav kub kho, photovoltaic cov ntaub ntawv sintering, thiab precision ceramic ntau lawm, ho txhim khu lub sij hawm ntev thermal reliability.

Silicon Carbide (SiC) Kab rov tav Rauv Tube

Silicon Carbide (SiC) Horizontal Furnace Tube yog cov khoom tseem ceeb tsim los rau cov txheej txheem kub kub, ua haujlwm ua cov raj ua haujlwm hauv cov huab cua uas muaj cov pa oxygen (reactive gas), nitrogen (cov roj tiv thaiv), thiab taug qab hydrogen chloride , nrog rau kev ua haujlwm kub li 12.5 ° C. Tsim los ntawm 3D printing integrated forming thev naus laus zis, nws muaj cov khoom siv impurity cov ntsiab lus <300 ppm, thiab tuaj yeem xaiv tau nruab nrog CVD silicon carbide txheej (txheej impurities <5 ppm). Ua ke nrog cov thermal conductivity (≈20 W / m·K) thiab tshwj xeeb thermal shock stability (tiv thaiv thermal gradients> 800 ° C), nws yog qhov zoo tagnrho rau kev thov cov khoom siv semiconductor xws li oxidation, diffusion, thiab nyias-zaj duab xis deposition, ua kom cov txheej txheem thermal stability thiab lub sij hawm ntev.

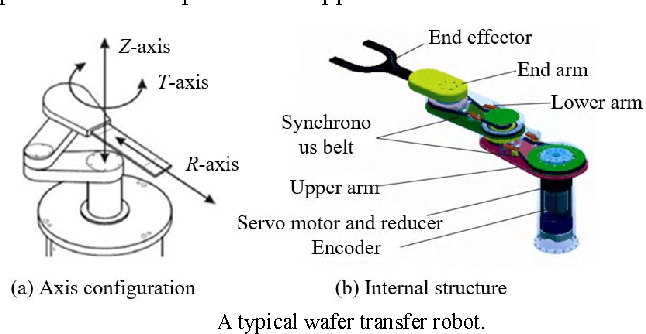

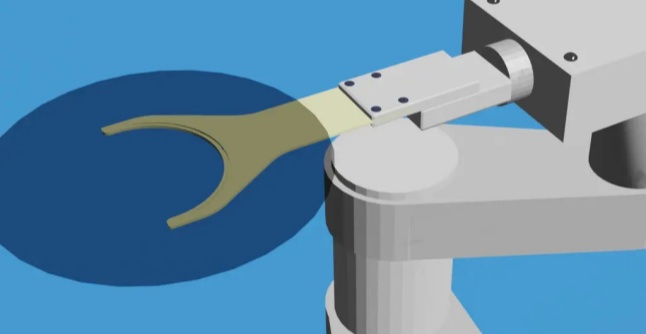

SiC Ceramic Fork Arms Taw Qhia

Semiconductor Manufacturing

Hauv kev tsim khoom semiconductor wafer, SiC ceramic diav rawg caj npab feem ntau yog siv rau kev hloov thiab tso wafers, feem ntau pom nyob rau hauv:

- Cov Khoom Siv Ua Haujlwm wafer: Xws li wafer cassettes thiab cov txheej txheem nkoj, uas ua haujlwm ruaj khov nyob rau hauv qhov kub thiab txias thiab corrosive txheej txheem ib puag ncig.

- Lithography Machine: Siv nyob rau hauv precision Cheebtsam xws li theem, kev taw qhia, thiab robotic caj npab, qhov twg lawv siab rigidity thiab tsawg thermal deformation xyuas kom meej nanometer-theem suab lus.

- Etching thiab Diffusion Txheej Txheem: Ua haujlwm ua ICP etching tais thiab cov khoom siv rau cov txheej txheem semiconductor diffusion, lawv cov purity siab thiab corrosion tsis kam tiv thaiv kev sib kis hauv cov txheej txheem.

Industrial Automation thiab Robotics

SiC ceramic diav rawg caj npab yog cov khoom tseem ceeb hauv kev ua haujlwm siab ntawm cov neeg hlau thiab cov cuab yeej siv tshuab:

- Robotic End Effectors: Siv rau kev tuav, sib dhos, thiab kev ua haujlwm raug. Lawv lub teeb yuag (qhov ntom ~ 3.21 g / cm³) txhim kho cov neeg hlau ceev thiab ua haujlwm tau zoo, thaum lawv cov tawv tawv siab (Vickers hardness ~ 2500) ua kom muaj qhov tshwj xeeb hnav tsis kam.

- Automated Production Lines: Nyob rau hauv cov xwm txheej uas yuav tsum tau muaj kev ua haujlwm siab, kev ua haujlwm siab (piv txwv li, e-commerce warehouses, Hoobkas cia), SiC diav rawg caj npab lav kev ua haujlwm ruaj khov mus ntev.

Aerospace thiab Tshiab Zog

Nyob rau hauv ib puag ncig huab, SiC ceramic diav rawg caj npab leverage lawv qhov kub thiab txias tsis kam, corrosion kuj, thiab thermal shock resistance:

- Aerospace: Siv nyob rau hauv cov khoom tseem ceeb ntawm lub dav hlau thiab drones, qhov twg lawv lub teeb yuag thiab lub zog muaj zog pab txo qhov hnyav thiab txhim kho kev ua haujlwm.

- Lub Zog Tshiab: Siv rau hauv cov khoom siv ntau lawm rau kev lag luam photovoltaic (xws li, diffusion furnaces) thiab raws li cov khoom siv hauv cov khoom siv lithium-ion roj teeb.

High-Temperature Industrial Processing

SiC ceramic diav rawg caj npab tuaj yeem tiv taus qhov kub siab tshaj 1600 ° C, ua rau lawv haum rau:

- Metallurgy, Ceramics, thiab iav Industries: Siv nyob rau hauv high-temperature manipulators, setter daim hlau, thiab laub daim hlau.

- Nuclear Zog: Vim lawv cov hluav taws xob tiv thaiv, lawv tsim nyog rau qee yam hauv cov reactors nuclear.

Khoom siv kho mob

Hauv kev kho mob, SiC ceramic diav rawg caj npab feem ntau yog siv rau:

- Kev Kho Mob Robots thiab Surgical Instruments: Muaj nuj nqis rau lawv cov biocompatibility, corrosion resistance, thiab stability nyob rau hauv sterilization ib puag ncig.

SiC Txheej Txheej txheem cej luam

| Yam khoom | Chav tsev | Tus nqi |

| Qauv |

| FCC β theem |

| Kev taw qhia | Feem ntau (%) | 111 nyiam |

| Qhov ntom ntom | g/cm³ | 3.21 |

| Hardness | Vickers hardness | 2500 |

| Thaum tshav kub kub muaj peev xwm | J·kg-1 · K-1 | 640 |

| Thermal expansion 100-600 ° C (212-1112 ° F) | 10-6K-1 | 4.5 |

| Young's Modulus | Gpa (4pt khoov, 1300 ℃) | 430 |

| Loj Loj | ib m | 2 ~ 10 |

| Sublimation kub | ℃ | 2700 ib |

| Felexural zog | MPa (RT 4-point) | 415 |

| Thermal conductivity | (W / mK) | 300 |

Silicon Carbide Ceramic Structure Parts Overview

SiC Seal Parts Overview

SiC cov ntsaws ruaj ruaj yog qhov kev xaiv zoo tshaj plaws rau qhov chaw hnyav (xws li kub kub, siab siab, corrosive media, thiab high-ceev hnav) vim lawv qhov tshwj xeeb hardness, hnav tsis kam, kub-resistant (nrog kub txog 1600 ° C los yog txawm 2000 ° C), thiab corrosion kuj. Lawv cov thermal conductivity ua kom yooj yim rau cov cua sov dissipation, thaum lawv tsis tshua muaj kev sib txhuam coefficient thiab nws tus kheej-lubricating zog ntxiv kom sealing kev ntseeg siab thiab ntev kev pab cuam lub neej nyob rau hauv huab kev ua hauj lwm tej yam kev mob. Cov yam ntxwv no ua rau SiC cov ntsaws ruaj ruaj tau siv dav hauv kev lag luam xws li petrochemicals, mining, semiconductor manufacturing, dej khib nyiab, thiab lub zog, txo cov nqi tu, txo qis qis, thiab txhim kho cov cuab yeej ua haujlwm zoo thiab kev nyab xeeb.

SiC Ceramic Phaj Luv luv

Silicon Carbide (SiC) ceramic phaj muaj npe nrov rau lawv qhov tshwj xeeb hardness (Mohs hardness txog 9.5, thib ob tsuas yog pob zeb diamond), zoo thermal conductivity (ntau tshaj feem ntau ceramics rau kev tswj kom sov), thiab cov tshuaj zoo kawg nkaus inertness thiab thermal shock resistance ( withstanding flucliss, acids thiab kub ceev). Cov khoom no ua kom muaj kev ruaj ntseg thiab txhim khu kev qha hauv qhov chaw huab cua (xws li, kub kub, puas, thiab corrosion), thaum txuas ntxiv kev pab cuam lub neej thiab txo cov kev tu ncua.

SiC ceramic phaj yog dav siv hauv kev ua haujlwm siab:

•Abrasives thiab sib tsoo cov cuab yeej: Leveraging ultra-siab hardness rau manufacturing sib tsoo log thiab polishing cov cuab yeej, pab tau precision thiab durability nyob rau hauv abrasive ib puag ncig.

•Refractory Materials : Ua hauj lwm ua rau cov khoom siv hluav taws xob thiab cov khoom siv hluav taws xob, tswj kev ruaj ntseg siab dua 1600 ° C los txhim kho thermal efficiency thiab txo cov nqi kho.

•Semiconductor Kev Lag Luam: Ua raws li cov substrates rau cov khoom siv hluav taws xob muaj zog (xws li, lub zog diodes thiab RF amplifiers), txhawb kev ua haujlwm siab thiab kub kub los txhawb kev ntseeg siab thiab kev siv hluav taws xob.

• Casting thiab Smelting : Hloov cov khoom siv ib txwm siv hauv kev ua hlau kom ntseeg tau tias muaj kev hloov hluav taws xob zoo thiab cov tshuaj tiv thaiv corrosion, txhim kho metallurgical zoo thiab nqi-zoo.

SiC Wafer Boat Abstract

XKH SiC tej nkoj nquam xa khoom zoo tshaj thermal stability, tshuaj inertness, precision engineering, thiab economic efficiency, muab ib tug high-kev ua tau zoo carrier tov rau semiconductor manufacturing. Lawv txhim kho wafer tuav kev ruaj ntseg, huv si, thiab ntau lawm efficiency, ua rau lawv indispensable Cheebtsam nyob rau hauv advanced wafer fabrication.

SiC ceramic nkoj daim ntawv thov:

SiC ceramic nkoj yog dav siv nyob rau hauv pem hauv ntej-kawg semiconductor txheej txheem, xws li:

• Cov txheej txheem tso tawm: Xws li LPCVD (Tsawg-Pressure Chemical Vapor Deposition) thiab PECVD (Plasma-Enhanced Chemical Vapor Deposition).

•High-Tub Kho Mob : Xws li thermal oxidation, annealing, diffusion, thiab ion implantation.

• Cov txheej txheem ntub dej thiab ntxuav: wafer tu thiab tshuaj tuav cov theem.

Tau tshaj ob qho tib si atmospheric thiab nqus txheej txheem ib puag ncig,

lawv yog qhov zoo tagnrho rau fabs nrhiav kom txo tau qhov kev pheej hmoo ntawm kev sib kis thiab txhim kho kev tsim khoom.

Parameters ntawm SiC Wafer Nkoj:

| Technical Properties | ||||

| Index | Chav tsev | Tus nqi | ||

| Khoom npe | Cov tshuaj tiv thaiv Sintered Silicon Carbide | Siab tsis muaj Sintered Silicon Carbide | Recrystallized Silicon Carbide | |

| Kev sib xyaw | RBSiC | SIB | R-SiC | |

| Kev ceev ceev | g/cm3 | 3 | 3.15 ± 0.03 | 2.60-2.70 Nws |

| Flexural zog | MPa (kpsi) | 338 (49) hnub | 380 (55) hnub | 80-90 (20 ° C) 90-100 (1400 ° C) |

| Compressive zog | MPa (kpsi) | 1120 (158) hnub | 3970 (560) hnub | > 600 |

| Hardness | Knoop | 2700 ib | 2800 | / |

| Txhaum Tenacity | MPa m1/2 | 4.5 | 4 | / |

| Thermal conductivity | W/mk | 95 | 120 | 23 |

| Coefficient ntawm Thermal Expansion | 10-6.1/°C | 5 | 4 | 4.7 |

| Tshwj xeeb kub | Joule/g 0k | 0.8 ua | 0.67 ib | / |

| Max kub hauv huab cua | ℃ | 1200 | 1500 | 1600 |

| Elastic Modulus | Gpa | 360 | 410 | 240 |

SiC Ceramics Ntau yam kev cai Cheebtsam zaub

SiC Ceramic Membrane

SiC ceramic membrane yog ib qho kev pom zoo tshaj plaws uas tau tsim los ntawm cov ntshiab silicon carbide, uas muaj cov txheej txheem peb-txheej txheej (txheej txheej, hloov txheej, thiab sib cais membrane) engineered los ntawm high-temperature sintering txheej txheem. Qhov kev tsim no ua kom lub zog tshwj xeeb ntawm lub zog, qhov pore loj faib, thiab ua haujlwm zoo heev. Nws ua tau zoo nyob rau hauv ntau hom kev lag luam siv los ntawm kev sib cais, tsom, thiab ua kom cov kua dej huv. Cov khoom siv tseem ceeb suav nrog kev kho dej thiab dej khib nyiab (tshem tawm cov khib nyiab pov tseg, cov kab mob, thiab cov kuab paug organic), kev ua zaub mov thiab dej haus (ua kom pom tseeb thiab ua kom cov kua txiv hmab txiv ntoo, cov khoom noj siv mis, thiab cov kua fermented), kev lag luam tshuaj thiab biotechnology (purifying biofluids thiab intermediates), kev ua tshuaj lom neeg (filtering corrosive fluids thiab roj thiab cov khoom siv roj thiab cov khoom siv hluav taws xob).

SiC Pipes

SiC (silicon carbide) cov raj yog cov khoom siv ua haujlwm siab ua haujlwm tsim los rau cov tshuab hluav taws xob semiconductor, tsim los ntawm cov khoom siv siab-purity nplua-grained silicon carbide los ntawm cov txheej txheem sintering siab heev. Lawv nthuav tawm qhov tshwj xeeb thermal conductivity, qhov kub thiab txias stability (sab dhau 1600 ° C), thiab tshuaj tiv thaiv corrosion . Lawv tsis tshua muaj thermal expansion coefficient thiab siab mechanical zog ua kom muaj kev ruaj ntseg nyob rau hauv huab cua thermal cycling, zoo txo thermal deformation thiab hnav. SiC raj yog tsim rau diffusion furnaces, oxidation furnaces, thiab LPCVD / PECVD systems, ua kom zoo ib yam kub faib thiab ruaj khov txheej txheem tej yam kev mob kom txo tau wafer tsis xws luag thiab txhim kho nyias-film deposition homogeneity. Ib qho ntxiv, cov qauv tsis sib xws, cov kuab tshuaj tsis txaus siab thiab cov pa roj carygen xws li oxygen, thiab ammonia, txuas ntxiv kev pabcuam lub neej thiab ua kom cov txheej txheem kev nyiam huv. SiC tubes tuaj yeem ua raws li qhov loj thiab phab ntsa tuab, nrog kev ua haujlwm zoo ua kom tiav cov npoo sab hauv thiab siab concentricity los txhawb laminar ntws thiab sib npaug thermal profiles. Deg polishing los yog txheej txheej xaiv ntxiv txo cov khoom tsim thiab txhim khu kev tiv thaiv corrosion, ua tau raws li cov kev cai nruj ntawm semiconductor manufacturing rau precision thiab kev ntseeg tau.

SiC Ceramic Cantilever Paddle

Lub monolithic tsim ntawm SiC cantilever hniav ua tau zoo txhim kho cov neeg kho tshuab robustness thiab thermal uniformity thaum tshem tawm cov pob qij txha thiab cov ntsiab lus tsis muaj zog hauv cov khoom sib xyaw. Lawv qhov chaw yog precision-polished rau ze-daim iav tiav, txo qhov feem ntau tiam thiab ua tau raws li cov qauv huv. Lub inertia tshuaj inertia ntawm SiC tiv thaiv outgassing, corrosion, thiab txheej txheem paug nyob rau hauv reactive ib puag ncig (xws li, oxygen, chav), ua kom ruaj khov thiab kev ntseeg siab nyob rau hauv diffusion / oxidation txheej txheem. Txawm hais tias kev caij tsheb kauj vab nrawm nrawm, SiC tswj kev ua haujlwm ncaj ncees, txuas ntxiv kev pab cuam lub neej thiab txo qis txij nkawm. Lub teeb yuag ntawm SiC ua rau cov lus teb thermal sai, ua kom cov cua sov / cua txias thiab txhim kho cov khoom lag luam thiab kev siv hluav taws xob. Cov hniav no muaj nyob rau hauv customizable qhov ntau thiab tsawg (sib haum nrog 100mm mus rau 300mm + wafers) thiab hloov mus rau ntau lub cub tawg tsim, xa cov kev ua tau zoo nyob rau hauv ob qho tib si pem hauv ntej-kawg thiab rov qab-kawg semiconductor txheej txheem.

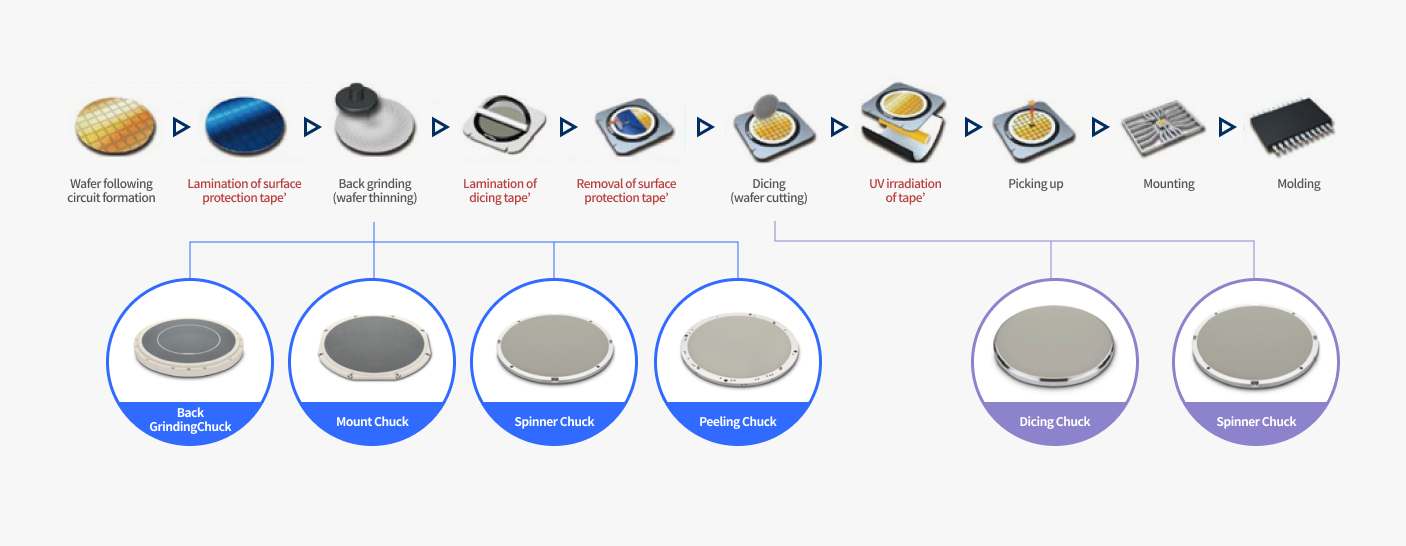

Alumina Nqus Chuck Taw Qhia

Al₂O₃ lub tshuab nqus tsev chucks yog cov cuab yeej tseem ceeb hauv kev tsim khoom semiconductor, muab kev txhawb nqa ruaj khov thiab meej thoob plaws ntau yam txheej txheem:•Thinning : Muab kev txhawb nqa zoo ib yam thaum lub sij hawm wafer thinning, kom ntseeg tau tias muaj kev txiav txim siab ntawm cov substrate los txhim kho cov nti kub dissipation thiab cov cuab yeej ua haujlwm.

•Dicing : Muab kev ruaj ntseg adsorption thaum lub sij hawm wafer dicing, txo qhov kev pheej hmoo ntawm kev puas tsuaj thiab xyuas kom huv si txiav rau ib tug neeg daim.

• Ntxuav : Nws tus du, tsis zoo adsorption nto ua kom muaj kev tshem tawm cov kab mob zoo yam tsis muaj kev puas tsuaj wafers thaum lub sij hawm ntxuav.

• Kev Thauj Mus Los: Muab kev txhawb nqa txhim khu kev qha thiab ruaj ntseg thaum tuav wafer thiab kev thauj mus los, txo kev pheej hmoo ntawm kev puas tsuaj thiab kev sib kis.

1.Uniform Micro-porous Ceramic Technology

•Utilizes nano-hmoov los tsim tusyees faib thiab interconnected pores, uas ua rau siab porosity thiab ib tug uniformly ntom qauv rau zoo ib yam thiab txhim khu kev qha wafer txhawb.

2.Exceptional Material Properties

-Fabricated los ntawm ultra-ntshiab 99.99% alumina (Al₂O₃), nws nthuav tawm:

•Thermal Properties : Kev kub siab ua haujlwm thiab thermal conductivity zoo heev, haum rau qhov kub-kub semiconductor ib puag ncig.

•Mechanical Properties : Siab zog thiab hardness kom durability, hnav tsis kam, thiab kev pab lub neej ntev.

•Qhov Zoo Ntxiv : Muaj hluav taws xob rwb thaiv tsev thiab corrosion kuj, yoog raws ntau hom kev tsim khoom.

3.Superior Flatness thiab Parallelism• Xyuas kom meej thiab ruaj khov wafer tuav nrog siab flatness thiab parallelism, txo qhov kev pheej hmoo ntawm kev puas tsuaj thiab ua kom muaj txiaj ntsig zoo ib yam. Nws zoo huab cua permeability thiab uniform adsorption quab yuam ntxiv txhim khu kev lag luam kev ntseeg siab.

Al₂O₃ lub tshuab nqus tsev chuck integrates Advanced micro-porous technology, exceptional material properties, thiab siab precision los txhawb cov txheej txheem tseem ceeb ntawm semiconductor, kom ntseeg tau tias kev ua tau zoo, kev ntseeg tau, thiab kev tswj kev sib kis thoob plaws thinning, dicing, tu, thiab thauj theem.

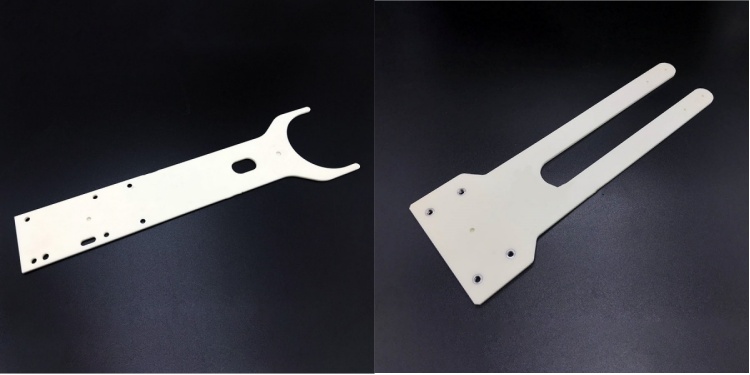

Alumina Robot Arm & Alumina Ceramic End Effector Luv luv

Alumina (Al₂O₃) ceramic robotic caj npab yog cov khoom tseem ceeb rau wafer tuav hauv semiconductor manufacturing. Lawv ncaj qha hu rau wafers thiab muaj lub luag haujlwm rau kev hloov pauv thiab qhov chaw nyob hauv qhov xav tau ib puag ncig xws li lub tshuab nqus tsev lossis qhov kub thiab txias. Lawv cov txiaj ntsig tseem ceeb nyob hauv kev ua kom muaj kev nyab xeeb ntawm wafer, tiv thaiv kev sib kis, thiab txhim kho cov cuab yeej ua haujlwm zoo thiab tawm los ntawm cov khoom tshwj xeeb.

| Feature Dimension | Cov lus piav qhia ntxaws |

| Mechanical Properties | High-purity alumina (xws li,> 99%) muab siab hardness (Mohs hardness txog li 9) thiab flexural zog (txog 250-500 MPa), xyuas kom hnav tsis kam thiab deformation zam, yog li ncua kev pab cuam lub neej.

|

| Hluav taws xob rwb thaiv tsev | Chav ntsuas kub txog li 10¹⁵ Ω·cm thiab rwb thaiv tsev lub zog ntawm 15 kV / mm tuaj yeem tiv thaiv electrostatic tawm (ESD), tiv thaiv rhiab wafers los ntawm hluav taws xob cuam tshuam thiab kev puas tsuaj.

|

| Thermal stability | Melting point siab li 2050 ° C tuaj yeem tiv taus cov txheej txheem kub (xws li RTA, CVD) hauv kev tsim khoom semiconductor. Tsawg thermal expansion coefficient txo qis warping thiab tswj qhov seem stability nyob rau hauv tshav kub.

|

| Tshuaj Inertness | Inert rau feem ntau acids, alkalis, txheej txheem gases, thiab ntxuav cov neeg ua hauj, tiv thaiv particle contamination los yog hlau ion tso tawm. Qhov no ua kom muaj qhov chaw tsim khoom huv heev thiab tsis txhob muaj kab mob wafer.

|

| Lwm qhov zoo | Mature processing technology muab cov nqi-zoo; Qhov chaw tuaj yeem ua tau zoo-polished kom tsis tshua muaj roughness, ntxiv txo qhov kev pheej hmoo ntawm kev tsim.

|

Alumina ceramic robotic caj npab feem ntau yog siv nyob rau hauv pem hauv ntej-kawg semiconductor manufacturing txheej txheem, suav nrog:

• Wafer tuav thiab Positioning : Muaj kev nyab xeeb thiab meej hloov thiab txoj hauj lwm wafers (piv txwv li, 100mm txog 300mm + qhov ntau thiab tsawg) nyob rau hauv lub tshuab nqus tsev los yog high-purity inert gas ib puag ncig, txo qhov kev puas tsuaj thiab paug txaus ntshai.

• Cov Txheej Txheem Kub Kub: Xws li ceev thermal annealing (RTA), tshuaj vapor deposition (CVD), thiab plasma etching , qhov uas lawv tswj kev ruaj khov nyob rau hauv qhov kub thiab txias, ua kom cov txheej txheem sib xws thiab tawm los.

•Automated Wafer Handling Systems : Kev koom ua ke rau hauv wafer tuav cov neeg hlau ua qhov kawg effectors automate wafer hloov ntawm cov cuab yeej, txhim kho kev tsim khoom.

Xaus

XKH tshwj xeeb hauv R&D thiab tsim cov khoom siv tshwj xeeb silicon carbide (SiC) thiab alumina (Al₂O₃) ceramic Cheebtsam, nrog rau cov caj npab robotic, cantilever paddles, nqus chucks, wafer tej nkoj nquam, furnace tubes, thiab lwm yam high-kev ua tau zoo qhov chaw, pab semiconductors, tshiab zog, atemperature. Peb ua raws li kev tsim khoom, kev tswj xyuas nruj, thiab kev tsim kho thev naus laus zis, siv cov txheej txheem sintering siab heev (xws li, tsis muaj zog sintering, cov tshuaj tiv thaiv sintering) thiab precision machining cov tswv yim (xws li CNC sib tsoo, polishing) kom paub meej tshwj xeeb kub-kub kuj, txhua yam muaj zog, tshuaj inertness, thiab qhov tseeb. Peb txhawb kev hloov kho raws li cov duab kos, muab cov kev daws teeb meem rau qhov ntev, cov duab, cov khoom tiav, thiab cov qib khoom kom tau raws li cov neeg siv khoom tshwj xeeb. Peb tau cog lus los muab cov khoom lag luam txhim khu kev qha thiab muaj txiaj ntsig zoo rau kev tsim khoom thoob ntiaj teb high-end, txhim kho cov cuab yeej ua haujlwm thiab kev ua haujlwm ntau lawm rau peb cov neeg siv khoom.