Kev Txheeb Xyuas Txog Cov Txheej Txheem Kev Loj Hlob Monocrystalline Silicon

1. Keeb Kwm ntawm Kev Txhim Kho Monocrystalline Silicon

Kev nce qib ntawm thev naus laus zis thiab kev thov kom muaj cov khoom siv ntse ua haujlwm tau zoo tau ua rau lub hauv paus tseem ceeb ntawm kev lag luam integrated circuit (IC) hauv kev txhim kho hauv tebchaws. Raws li lub hauv paus ntawm kev lag luam IC, semiconductor monocrystalline silicon ua lub luag haujlwm tseem ceeb hauv kev tsav tsheb tsim kho tshiab thiab kev loj hlob ntawm kev lag luam.

Raws li cov ntaub ntawv los ntawm International Semiconductor Industry Association, kev lag luam thoob ntiaj teb semiconductor wafer tau txog tus nqi muag khoom ntawm $ 12.6 billion, nrog rau kev xa khoom loj hlob mus rau 14.2 billion square inches. Ntxiv mus, qhov kev thov rau silicon wafers txuas ntxiv nce siab tas li.

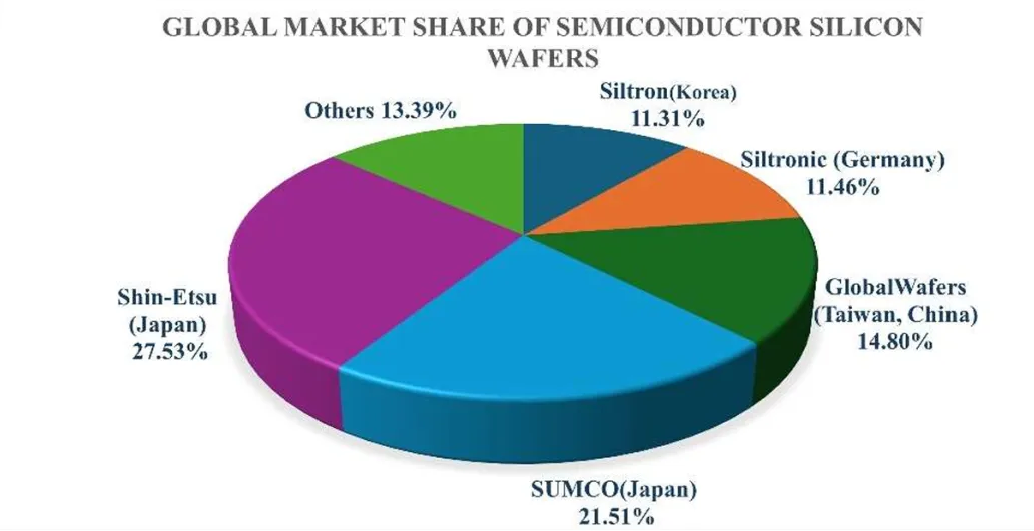

Txawm li cas los xij, kev lag luam thoob ntiaj teb silicon wafer muaj ntau heev, nrog rau tsib tus neeg muab khoom saum toj kawg nkaus tswj hwm ntau dua 85% ntawm cov feem ntawm kev ua lag luam, raws li qhia hauv qab no:

-

Shin-Etsu Chemical (Nyiv Pooj)

-

SUMCO (Nyiv Pooj)

-

Cov Wafer Thoob Ntiaj Teb

-

Siltronic (Lub Tebchaws Yelemees)

-

SK Siltron (Kaum Teb Kauslim Teb)

Qhov kev lag luam oligopoly no ua rau Tuam Tshoj vam khom ntau rau cov monocrystalline silicon wafers uas xa tuaj, uas tau dhau los ua ib qho ntawm cov teeb meem tseem ceeb uas txwv tsis pub txoj kev loj hlob ntawm lub teb chaws kev lag luam integrated circuit.

Txhawm rau kov yeej cov teeb meem tam sim no hauv kev tsim khoom siv semiconductor silicon monocrystal, kev nqis peev rau kev tshawb fawb thiab kev txhim kho thiab txhawb nqa lub peev xwm tsim khoom hauv tsev yog qhov kev xaiv tsis zam.

2. Kev Txheeb Xyuas Txog Cov Khoom Siv Monocrystalline Silicon

Monocrystalline silicon yog lub hauv paus ntawm kev lag luam integrated circuit. Txog niaj hnub no, ntau tshaj 90% ntawm IC chips thiab cov khoom siv hluav taws xob yog ua los ntawm monocrystalline silicon ua cov khoom siv tseem ceeb. Qhov kev thov dav dav rau monocrystalline silicon thiab nws cov ntawv thov kev lag luam sib txawv tuaj yeem yog vim ntau yam:

-

Kev Nyab Xeeb thiab Ib puag ncig zoo: Silicon muaj ntau nyob rau hauv lub ntiaj teb lub plhaub, tsis muaj tshuaj lom, thiab zoo rau ib puag ncig.

-

Kev rwb thaiv hluav taws xob: Silicon ntuj tsim muaj cov khoom rwb thaiv hluav taws xob, thiab thaum kho cua sov, nws tsim ib txheej tiv thaiv ntawm silicon dioxide, uas tiv thaiv kev poob ntawm cov nqi hluav taws xob.

-

Kev Siv Tshuab Loj HlobKeeb kwm ntev ntawm kev txhim kho thev naus laus zis hauv cov txheej txheem loj hlob silicon tau ua rau nws ntse dua li lwm cov ntaub ntawv semiconductor.

Cov yam no ua ke ua rau monocrystalline silicon nyob rau pem hauv ntej ntawm kev lag luam, ua rau nws tsis tuaj yeem hloov pauv los ntawm lwm cov ntaub ntawv.

Hais txog cov qauv siv lead ua, monocrystalline silicon yog cov khoom siv ua los ntawm cov silicon atoms uas teeb tsa ua ib lub lattice, tsim cov qauv txuas ntxiv mus. Nws yog lub hauv paus ntawm kev lag luam tsim cov chips.

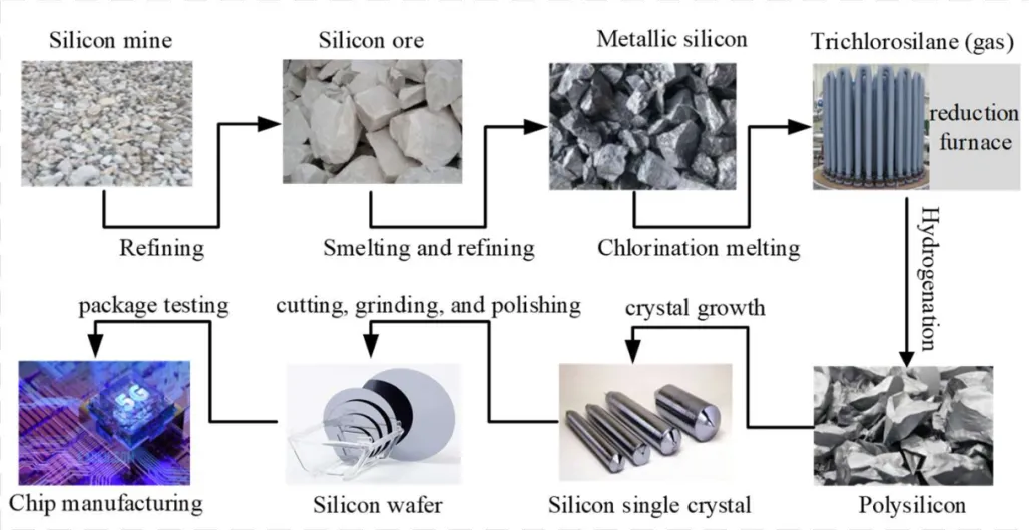

Daim duab hauv qab no qhia txog cov txheej txheem tiav ntawm kev npaj monocrystalline silicon:

Txheej Txheem Txheej Txheem:

Monocrystalline silicon yog tau los ntawm silicon ore los ntawm ntau cov kauj ruam refining. Ua ntej, polycrystalline silicon tau txais, uas tom qab ntawd loj hlob mus rau hauv ib lub monocrystalline silicon ingot hauv lub cub tawg crystal. Tom qab ntawd, nws raug txiav, polished, thiab ua tiav rau hauv silicon wafers uas tsim nyog rau kev tsim chips.

Feem ntau, cov silicon wafers raug muab faib ua ob pawg:photovoltaic-qibthiabqib semiconductorOb hom no sib txawv feem ntau hauv lawv cov qauv, kev huv, thiab qhov zoo ntawm qhov chaw.

-

Cov wafers semiconductormuaj qhov huv si siab heev txog li 99.999999999%, thiab yuav tsum yog monocrystalline.

-

Cov wafers photovoltaic-qibtsis huv dua, nrog rau qib kev huv ntawm 99.99% txog 99.9999%, thiab tsis muaj cov kev cai nruj rau qhov zoo ntawm cov siv lead ua.

Tsis tas li ntawd xwb, cov wafers semiconductor-grade xav tau qhov du thiab huv dua li cov wafers photovoltaic-grade. Cov qauv siab dua rau cov wafers semiconductor ua rau ob qho tib si nyuaj ntawm lawv txoj kev npaj thiab lawv cov txiaj ntsig tom qab hauv kev siv.

Daim ntawv qhia hauv qab no qhia txog kev hloov pauv ntawm cov lus qhia txog semiconductor wafer, uas tau nce ntxiv los ntawm 4-nti (100mm) thiab 6-nti (150mm) wafers thaum ntxov mus rau 8-nti (200mm) thiab 12-nti (300mm) wafers tam sim no.

Hauv kev npaj silicon monocrystal tiag tiag, qhov loj ntawm wafer sib txawv raws li hom kev siv thiab cov nqi. Piv txwv li, cov chips nco feem ntau siv 12-nti wafers, thaum cov khoom siv fais fab feem ntau siv 8-nti wafers.

Hauv kev xaus, qhov kev hloov pauv ntawm qhov loj ntawm wafer yog qhov tshwm sim ntawm ob qho tib si Moore's Law thiab cov yam ntxwv kev lag luam. Qhov loj ntawm wafer loj dua ua rau muaj kev loj hlob ntawm thaj chaw silicon siv tau ntau dua nyob rau hauv tib qho kev ua haujlwm, txo cov nqi tsim khoom thaum txo cov khib nyiab los ntawm cov npoo wafer.

Ua ib yam khoom tseem ceeb hauv kev txhim kho thev naus laus zis niaj hnub no, semiconductor silicon wafers, los ntawm cov txheej txheem meej xws li photolithography thiab ion implantation, ua rau muaj ntau yam khoom siv hluav taws xob, suav nrog cov rectifiers muaj zog siab, transistors, bipolar junction transistors, thiab switching devices. Cov khoom siv no ua lub luag haujlwm tseem ceeb hauv cov teb xws li kev txawj ntse dag, 5G kev sib txuas lus, tsheb hluav taws xob, Internet ntawm Yam, thiab aerospace, tsim lub hauv paus ntawm kev txhim kho kev lag luam hauv tebchaws thiab kev tsim kho tshiab thev naus laus zis.

3. Kev Siv Tshuab Loj Hlob Monocrystalline Silicon

LubTxoj Kev Czochralski (CZ)yog ib qho txheej txheem zoo rau kev rub cov khoom siv monocrystalline zoo los ntawm cov yaj. Jan Czochralski tau hais tawm hauv xyoo 1917, txoj kev no kuj tseem hu uaSiv Crystal Rubtxoj kev.

Tam sim no, txoj kev CZ siv dav hauv kev npaj ntau yam khoom siv semiconductor. Raws li cov ntaub ntawv tsis tiav, kwv yees li 98% ntawm cov khoom siv hluav taws xob yog ua los ntawm monocrystalline silicon, nrog rau 85% ntawm cov khoom no tsim los ntawm kev siv txoj kev CZ.

Txoj kev CZ tau txais kev nyiam vim nws cov khoom siv crystal zoo heev, qhov loj me uas tswj tau, kev loj hlob sai, thiab kev ua haujlwm tau zoo. Cov yam ntxwv no ua rau CZ monocrystalline silicon yog cov khoom siv zoo tshaj plaws rau kev ua kom tau raws li qhov xav tau zoo thiab loj hauv kev lag luam hluav taws xob.

Lub hauv paus ntsiab lus ntawm kev loj hlob ntawm CZ monocrystalline silicon yog raws li nram no:

Cov txheej txheem CZ xav tau qhov kub siab, lub tshuab nqus tsev, thiab ib puag ncig kaw. Cov khoom siv tseem ceeb rau cov txheej txheem no yogsiv lead ua kom loj hlob cub tawg, uas ua rau cov mob no yooj yim dua.

Daim duab hauv qab no qhia txog cov qauv ntawm lub cub tawg loj hlob siv lead ua.

Hauv cov txheej txheem CZ, cov silicon ntshiab raug muab tso rau hauv lub crucible, yaj, thiab cov noob siv lead ua rau hauv cov silicon uas yaj. Los ntawm kev tswj cov yam ntxwv xws li kub, rub nrawm, thiab qhov ceev ntawm crucible, cov atoms lossis molecules ntawm qhov sib txuas ntawm cov noob siv lead ua thiab cov silicon uas yaj tas li rov tsim kho dua tshiab, khov kho thaum lub kaw lus txias thiab thaum kawg tsim ib qho siv lead ua.

Cov txheej txheem loj hlob siv lead ua no tsim cov khoom zoo, loj-txoj kab uas hla monocrystalline silicon nrog cov kev taw qhia siv lead ua tshwj xeeb.

Cov txheej txheem kev loj hlob muaj ntau kauj ruam tseem ceeb, suav nrog:

-

Kev rhuav tshem thiab kev thauj khoomTshem tawm cov siv lead ua thiab ntxuav lub cub tawg thiab cov khoom kom huv si ntawm cov khoom tsis huv xws li quartz, graphite, lossis lwm yam khoom tsis huv.

-

Nqus Tsev thiab Yaj: Lub kaw lus raug tshem tawm mus rau hauv lub tshuab nqus tsev, ua raws li kev qhia txog roj argon thiab cua sov ntawm cov silicon charge.

-

Siv Crystal Rub: Cov noob siv lead ua rau hauv cov silicon uas yaj, thiab qhov kub ntawm qhov interface raug tswj kom zoo kom ntseeg tau tias cov crystallization zoo.

-

Kev Tswj Xyuas Lub Xub Pwg thiab Txoj Kab Uas hlaThaum lub siv lead ua loj hlob tuaj, nws txoj kab uas hla raug saib xyuas thiab kho kom zoo kom ntseeg tau tias nws loj hlob zoo ib yam.

-

Qhov Kawg ntawm Kev Loj Hlob thiab Kev Kaw Lub Qhov Cub: Thaum twg tau qhov loj me ntawm cov siv lead ua uas xav tau lawm, lub cub tawg yuav raug kaw, thiab cov siv lead ua yuav raug tshem tawm.

Cov kauj ruam ntxaws ntxaws hauv cov txheej txheem no ua kom ntseeg tau tias muaj kev tsim cov monocrystals zoo, tsis muaj qhov tsis zoo uas tsim nyog rau kev tsim khoom semiconductor.

4. Cov teeb meem hauv Monocrystalline Silicon Production

Ib qho ntawm cov teeb meem tseem ceeb hauv kev tsim cov monocrystals semiconductor loj yog nyob rau hauv kev kov yeej cov teeb meem kev lag luam thaum lub sijhawm loj hlob, tshwj xeeb tshaj yog hauv kev kwv yees thiab tswj cov teeb meem siv lead ua:

-

Kev Zoo Monocrystal Tsis Sib Xws thiab Qis YieldThaum cov silicon monocrystals loj zuj zus, qhov nyuaj ntawm qhov chaw loj hlob nce ntxiv, ua rau nws nyuaj rau tswj cov yam xws li thermal, flow, thiab magnetic fields. Qhov no ua rau txoj haujlwm ntawm kev ua tiav qhov zoo sib xws thiab cov qoob loo siab dua.

-

Cov Txheej Txheem Tswj Xyuas Tsis Ruaj KhoovCov txheej txheem loj hlob ntawm semiconductor silicon monocrystals yog qhov nyuaj heev, nrog ntau lub cev sib cuam tshuam, ua rau kev tswj hwm qhov tseeb tsis ruaj khov thiab ua rau cov khoom lag luam qis. Cov tswv yim tswj hwm tam sim no feem ntau tsom mus rau qhov loj me ntawm cov siv lead ua, thaum qhov zoo tseem raug kho raws li kev paub dhau los ntawm tes, ua rau nws nyuaj rau ua kom tau raws li qhov yuav tsum tau ua rau micro thiab nano fabrication hauv IC chips.

Yuav kom daws tau cov teeb meem no, kev tsim cov txheej txheem saib xyuas thiab kwv yees qhov zoo ntawm cov siv lead ua hauv online yog qhov xav tau sai, nrog rau kev txhim kho hauv cov txheej txheem tswj hwm kom ntseeg tau tias muaj kev tsim khoom ruaj khov thiab zoo ntawm cov monocrystals loj rau kev siv hauv cov voj voog sib xyaw.

Lub sijhawm tshaj tawm: Lub Kaum Hli-29-2025