High-purity silicon carbide (SiC) ceramics tau tshwm sim los ua cov ntaub ntawv zoo tshaj plaws rau cov khoom tseem ceeb hauv semiconductor, aerospace, thiab chemical industries vim lawv qhov tshwj xeeb thermal conductivity, tshuaj stability, thiab mechanical zog. Nrog rau kev xav tau ntau ntxiv rau cov khoom siv ua haujlwm siab, tsis muaj kuab lom cov khoom siv ceramic, kev txhim kho cov cuab yeej siv tau zoo thiab ua kom muaj peev xwm ua tau zoo rau cov khoom siv purity SiC ceramics tau dhau los ua kev tshawb fawb thoob ntiaj teb. Daim ntawv no tau tshuaj xyuas cov txheej txheem tseem ceeb tam sim no rau kev ua haujlwm siab purity SiC ceramics, suav nrog recrystallization sintering, pressureless sintering (PS), kub nias (HP), spark plasma sintering (SPS), thiab additive manufacturing (AM), nrog rau qhov tseem ceeb ntawm kev sib tham txog cov txheej txheem sintering, cov ntsiab lus tseem ceeb, cov khoom siv, thiab cov txheej txheem uas twb muaj lawm.

Kev thov ntawm SiC ceramics hauv kev ua tub rog thiab engineering

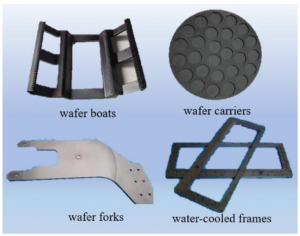

Tam sim no, high-purity SiC ceramic Cheebtsam yog dav siv nyob rau hauv silicon wafer manufacturing khoom, koom nyob rau hauv cov txheej txheem tseem ceeb xws li oxidation, lithography, etching, thiab ion implantation. Nrog rau kev nce qib ntawm wafer technology, nce wafer qhov ntau thiab tsawg tau dhau los ua qhov tseem ceeb. Tam sim no lub ntsiab wafer loj yog 300 hli, ua tiav qhov sib npaug ntawm tus nqi thiab muaj peev xwm ntau lawm. Txawm li cas los xij, tau tsav los ntawm Moore Txoj Cai, cov khoom loj ntawm 450 mm wafers twb nyob rau hauv cov txheej txheem. Cov wafers loj dua feem ntau yuav tsum muaj lub zog ntau dua los tiv thaiv kev sib tsoo thiab deformation, ntxiv rau qhov kev xav tau loj hlob ntxiv rau qhov loj-loj, muaj zog, siab-purity SiC ceramic Cheebtsam. Nyob rau hauv xyoo tas los no, kev tsim khoom siv ntxiv (3D luam ntawv), raws li kev siv thev naus laus zis sai uas yuav tsum tsis muaj pwm, tau pom muaj peev xwm loj heev hauv kev tsim cov txheej txheem SiC ceramics vim nws cov txheej txheem los ntawm txheej txheej thiab kev tsim qauv tsim tau yooj yim, ua rau muaj kev nyiam ntau.

Daim ntawv no yuav txheeb xyuas tsib tus neeg sawv cev npaj txoj hauv kev rau siab purity SiC ceramics-recrystallization sintering, pressureless sintering, kub pressing, spark plasma sintering, thiab additive manufacturing-tsom rau lawv sintering mechanisms, txheej txheem optimization tswv yim, cov yam ntxwv ntawm cov khoom siv, thiab muaj daim ntawv thov kev cia siab.

High-purity silicon carbide raw khoom yuav tsum

I. Recrystallization Sintering

Recrystallized silicon carbide (RSiC) yog cov khoom siv siab ntshiab SiC npaj tsis muaj sintering pab ntawm qhov kub ntawm 2100-2500 ° C. Txij li thaum Fredriksson thawj zaug pom qhov tshwm sim recrystallization nyob rau hauv lub xyoo pua puv 19, RSiC tau txais kev saib xyuas tseem ceeb vim nws cov kab lis kev cai huv si thiab tsis muaj iav theem thiab impurities. Thaum qhov kub thiab txias, SiC nthuav tawm cov pa siab siab, thiab nws cov txheej txheem sintering feem ntau cuam tshuam nrog cov txheej txheem evaporation-condensation: cov nplej zoo evaporate thiab rov qab tso rau ntawm qhov chaw ntawm cov nplej loj, txhawb nqa caj dab loj hlob thiab kev sib txuas ncaj qha ntawm cov nplej, yog li txhim kho cov khoom siv zog.

Xyoo 1990, Kriegesmann tau npaj RSiC nrog cov txheeb ze ntom ntom ntawm 79.1% siv cov nplaum nplaum ntawm 2200 ° C, nrog rau ntu ntu uas qhia txog microstructure muaj li ntawm cov nplej ntxhib thiab qhov pores. Tom qab ntawd, Yi et al. siv gel casting los npaj lub cev ntsuab thiab sintered lawv ntawm 2450 ° C, tau RSiC ceramics nrog ib tug loj ceev ntawm 2.53 g / cm³ thiab ib tug flexural zog ntawm 55.4 MPa.

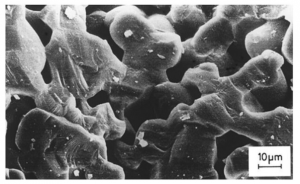

SEM tawg nto ntawm RSiC

Piv rau SiC ntom ntom, RSiC muaj qhov ntom ntom qis (kwv yees li 2.5 g / cm³) thiab li 20% qhib porosity, txwv nws cov kev ua tau zoo hauv cov ntawv thov muaj zog. Yog li ntawd, kev txhim kho qhov ceev thiab cov khoom siv kho tshuab ntawm RSiC tau dhau los ua qhov kev tshawb fawb tseem ceeb. Sung et al. npaj infiltrating molten silicon rau hauv carbon / β-SiC sib xyaw compacts thiab recrystallizing ntawm 2200 ° C, ua tiav lub network qauv tsim los ntawm α-SiC coarse nplej. Qhov tshwm sim RSiC tau ua tiav qhov ceev ntawm 2.7 g / cm³ thiab lub zog flexural ntawm 134 MPa, tswj xyuas cov neeg kho tshuab zoo ntawm qhov kub thiab txias.

Txhawm rau txhim kho qhov ceev ntxiv, Guo et al. Ua haujlwm polymer infiltration thiab pyrolysis (PIP) thev naus laus zis rau ntau yam kev kho mob ntawm RSiC. Siv PCS / xylene cov kev daws teeb meem thiab SiC / PCS / xylene slurries li infiltrants, tom qab 3-6 PIP cycles, qhov ceev ntawm RSiC tau zoo dua (txog 2.90 g / cm³), nrog rau nws lub zog flexural. Tsis tas li ntawd, lawv tau npaj ib lub tswv yim cyclic combining PIP thiab recrystallization: pyrolysis ntawm 1400 ° C ua raws li recrystallization ntawm 2400 ° C, zoo clearing particle blockages thiab txo porosity. Cov khoom siv RSiC kawg tau ua tiav qhov ceev ntawm 2.99 g / cm³ thiab lub zog flexural ntawm 162.3 MPa, ua kom pom kev ua tau zoo.

SEM dluab ntawm microstructure evolution ntawm polished RSiC tom qab polymer impregnation thiab pyrolysis (PIP)-recrystallization cycles: Pib RSiC (A), tom qab thawj PIP-recrystallization voj voog (B), thiab tom qab peb lub voj voog (C)

II. Pressureless Sintering

Pressureless-sintered silicon carbide (SiC) ceramics feem ntau yog npaj siv high-purity, ultrafine SiC hmoov raws li raw khoom, nrog me me ntawm sintering pab ntxiv, thiab sintered nyob rau hauv ib tug inert cua los yog nqus tsev vacuum ntawm 1800-2150 ° C. Txoj kev no yog tsim los tsim cov khoom loj thiab cov txheej txheem ceramic. Txawm li cas los xij, txij li SiC feem ntau yog sib koom ua ke, nws tus kheej diffusion coefficient tsawg heev, ua rau kev sib zog nyuaj yam tsis muaj kev pabcuam sintering.

Raws li cov txheej txheem sintering, pressureless sintering tuaj yeem muab faib ua ob pawg: pressureless kua-theem sintering (PLS-SiC) thiab pressureless solid-state sintering (PSS-SiC).

1.1 PLS-SiC (Liquid-Phase Sintering)

PLS-SiC feem ntau yog sintered hauv qab 2000 ° C los ntawm kev ntxiv kwv yees li 10 wt.% ntawm eutectic sintering aids (xws li Al₂O₃, CaO, MgO, TiO₂, thiab tsis tshua muaj-lub ntiaj teb oxides RE₂O₃) los tsim ib qho kev hloov pauv ntawm cov kua dej thiab cov khoom siv rov qab. Cov txheej txheem no tsim nyog rau qib kev lag luam-qib SiC ceramics, tab sis tsis muaj cov ntaub ntawv qhia txog kev ua kom huv si SiC ua tiav los ntawm cov kua-theem sintering.

1.2 PSS-SiC (Solid-State Sintering)

PSS-SiC suav nrog kev ua kom muaj zog ntawm lub xeev ntawm qhov kub siab tshaj 2000 ° C nrog kwv yees li 1 wt.% ntawm cov khoom ntxiv. Cov txheej txheem no tsuas yog nyob ntawm atomic diffusion thiab grain rearrangement uas tau tsav los ntawm qhov kub thiab txias kom txo tau lub zog saum npoo thiab ua tiav qhov ntom ntom. BC (boron-carbon) system yog ib qho kev sib xyaw ua ke, uas tuaj yeem txo qis ciam teb zog thiab tshem tawm SiO₂ ntawm SiC nto. Txawm li cas los xij, cov tshuaj BC ib txwm siv feem ntau qhia cov khoom tsis huv, txo SiC purity.

Los ntawm kev tswj cov ntsiab lus ntxiv (B 0.4 wt.%, C 1.8 wt.%) thiab sintering ntawm 2150 ° C rau 0.5 teev, high-purity SiC ceramics nrog purity ntawm 99.6 wt.% thiab tus txheeb ze ntom ntawm 98.4%. Lub microstructure pom columnar nplej (qee qhov ntev tshaj 450 µm), nrog me pores ntawm cov ciam teb nplej thiab graphite hais hauv cov nplej. Cov ceramics nthuav tawm lub zog flexural ntawm 443 ± 27 MPa, elastic modulus ntawm 420 ± 1 GPa, thiab thermal expansion coefficient ntawm 3.84 × 10⁻⁶ K⁻¹ nyob rau hauv thaj tsam ntawm chav tsev kub txog 600 ° C, ua kom pom kev zoo tag nrho.

Microstructure ntawm PSS-SiC: (A) SEM duab tom qab polishing thiab NaOH etching; (BD) BSD cov duab tom qab polishing thiab etching

III. Kub nias Sintering

Kub nias (HP) sintering yog cov txheej txheem densification uas ib txhij siv cov cua sov thiab uniaxial siab rau cov ntaub ntawv hmoov nyob rau hauv high-temperature thiab high-pressure tej yam kev mob. Kev kub siab tseem ceeb inhibits pore tsim thiab txwv kev loj hlob ntawm cov nplej, thaum kub siab txhawb cov nplej fusion thiab tsim cov qauv ntom ntom, thaum kawg ua cov khoom siv high-density, high-purity SiC ceramics. Vim qhov kev taw qhia ntawm kev nias, cov txheej txheem no nyiam ua rau cov nplej anisotropy, cuam tshuam rau txhua yam thiab hnav cov khoom.

Ntshiab SiC ceramics nyuaj rau densify yam tsis muaj additives, yuav tsum tau ultrahigh-siab sintering. Nadeau et al. ua tiav kev npaj siab ntom ntom SiC yam tsis muaj tshuaj ntxiv ntawm 2500 ° C thiab 5000 MPa; Sun et al. tau txais β-SiC cov ntaub ntawv ntau nrog Vickers hardness txog li 41.5 GPa ntawm 25 GPa thiab 1400 ° C. Siv 4 GPa siab, SiC ceramics nrog cov txheeb ze ntom ntom ntawm kwv yees li 98% thiab 99%, hardness ntawm 35 GPa, thiab elastic modulus ntawm 450 GPa tau npaj ntawm 1500 ° C thiab 1900 ° C, feem. Sintering micron-loj SiC hmoov ntawm 5 GPa thiab 1500 ° C yielded ceramics nrog ib tug hardness ntawm 31.3 GPa thiab ib tug txheeb ze ntom ntawm 98.4%.

Txawm hais tias cov txiaj ntsig no qhia tau hais tias lub siab siab ultrahigh tuaj yeem ua tiav cov khoom siv tsis muaj qhov ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntim tshuab tuaj yeem ua tiav cov khoom siv tsis muaj densification. Yog li ntawd, nyob rau hauv kev npaj tswv yim, kab ntxiv los yog hmoov granulation feem ntau yog siv los txhim kho sintering tsav tsheb.

Los ntawm kev ntxiv 4 wt.% phenolic resin ua ib qho additive thiab sintering ntawm 2350 ° C thiab 50 MPa, SiC ceramics nrog densification tus nqi ntawm 92% thiab purity ntawm 99.998% tau txais. Siv cov khoom siv qis qis (boric acid thiab D-fructose) thiab sintering ntawm 2050 ° C thiab 40 MPa, high-purity SiC nrog cov txheeb ze ntom> 99.5% thiab cov ntsiab lus B ntawm tsuas yog 556 ppm tau npaj. SEM cov duab qhia tau hais tias, piv rau cov qauv tsis muaj zog-sintered, cov qauv kub-nias muaj cov nplej me, tsawg qhov pores, thiab ntau dua. Lub zog flexural yog 453.7 ± 44.9 MPa, thiab elastic modulus mus txog 444.3 ± 1.1 GPa.

Los ntawm kev ncua lub sij hawm tuav ntawm 1900 ° C, grain loj nce los ntawm 1.5 μm mus rau 1.8 μm, thiab thermal conductivity zoo dua los ntawm 155 mus rau 167 W·m⁻¹·K⁻¹, thaum tseem txhim kho cov ntshav plasma corrosion.

Nyob rau hauv tej yam kev mob ntawm 1850 ° C thiab 30 MPa, kub nias thiab ceev kub nias ntawm granulated thiab annealed SiC hmoov yielded tag nrho ntom β-SiC ceramics tsis muaj additives, nrog ib tug ceev ntawm 3.2 g / cm³ thiab ib tug sintering kub 150-200 ° C qis dua ib txwm ua. Cov ceramics nthuav tawm qhov hardness ntawm 2729 GPa, tawg toughness ntawm 5.25-5.30 MPa·m^1/2, thiab zoo heev creep resistance (ceep tus nqi ntawm 9.9 × 10⁻¹⁰ s⁻¹ thiab 3.8 × 10⁻⁹ 1/0 ° C 1/4¹ 100 MPa).

(A) SEM duab ntawm polished nto; (B) SEM duab ntawm cov pob txha tawg; (C, D) BSD daim duab ntawm polished nto

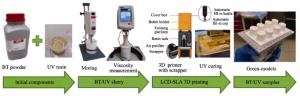

Nyob rau hauv 3D luam ntawv tshawb fawb rau piezoelectric ceramics, ceramic slurry, raws li lub hauv paus tseem ceeb muaj feem cuam tshuam rau kev tsim thiab kev ua tau zoo, tau dhau los ua qhov tseem ceeb hauv kev lag luam thiab thoob ntiaj teb. Cov kev tshawb fawb tam sim no feem ntau qhia tau hais tias tsis muaj xws li hmoov particle loj, slurry viscosity, thiab cov ntsiab lus tseem ceeb cuam tshuam rau kev tsim cov khoom zoo thiab piezoelectric zog ntawm cov khoom kawg.

Kev tshawb fawb tau pom tias ceramic slurries npaj siv micron-, submicron-, thiab nano-loj barium titanate hmoov muaj qhov sib txawv tseem ceeb hauv stereolithography (xws li LCD-SLA) cov txheej txheem. Raws li qhov loj me me zuj zus, slurry viscosity nce ntxiv, nrog nano-sized hmoov ua slurries nrog viscosities ncav cuag billions mPa·s. Slurries nrog micron-loj hmoov yog nquag delamination thiab tev tawm thaum luam ntawv, thaum submicron thiab nano-sized hmoov ua kom pom kev ruaj khov dua. Tom qab kub-kub sintering, cov txiaj ntsig ntawm cov qauv ceramic tau ua tiav qhov ntom ntawm 5.44 g / cm³, piezoelectric coefficient (d₃₃) ntawm kwv yees li 200 pC / N, thiab qhov poob qis, ua rau pom zoo heev electromechanical teb.

Tsis tas li ntawd, nyob rau hauv cov txheej txheem micro-stereolithography, kho cov ntsiab lus ntawm PZT-hom slurries (piv txwv li, 75 wt.%) yielded sintered lub cev nrog ib tug ceev ntawm 7.35 g / cm³, ua tiav ib tug piezoelectric tas li ntawm 600 pC / N nyob rau hauv poling hluav taws xob teb. Kev tshawb fawb ntawm micro-scale deformation them nyiaj tau zoo txhim kho qhov tseeb, txhim kho geometric precision txog li 80%.

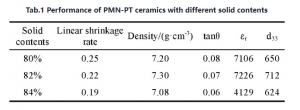

Lwm txoj kev tshawb fawb ntawm PMN-PT piezoelectric ceramics qhia tias cov ntsiab lus tseem ceeb cuam tshuam rau cov qauv ceramic thiab cov khoom hluav taws xob. Ntawm 80 wt.% cov ntsiab lus khoom, byproducts yooj yim tshwm sim hauv ceramics; Raws li cov ntsiab lus khoom tau nce mus rau 82 wt.% thiab siab dua, cov khoom lag luam maj mam ploj mus, thiab cov qauv ceramic ua purer, nrog kev ua tau zoo dua. Ntawm 82 wt.%, cov ceramics nthuav tawm cov khoom siv hluav taws xob zoo: piezoelectric tas li ntawm 730 pC / N, txheeb ze permittivity ntawm 7226, thiab dielectric poob tsuas yog 0.07.

Hauv cov ntsiab lus, qhov loj me, cov ntsiab lus, thiab cov khoom siv rheological ntawm cov slurries ceramic tsis tsuas yog cuam tshuam rau kev ruaj ntseg thiab qhov tseeb ntawm cov txheej txheem luam ntawv tab sis kuj ncaj qha txiav txim siab qhov ceev thiab piezoelectric teb ntawm sintered lub cev, ua rau lawv qhov tseem ceeb tsis zoo rau kev ua tau zoo 3D-luam piezoelectric ceramics.

Cov txheej txheem tseem ceeb ntawm LCD-SLA 3D luam ntawv ntawm BT / UV qauv

Cov khoom ntawm PMN-PT ceramics nrog cov khoom sib txawv

IV. Spark Plasma Sintering

Spark plasma sintering (SPS) yog ib qho kev siv tshuab sintering siab heev uas siv cov tshuab hluav taws xob tam sim no thiab cov tshuab ua haujlwm siab ib txhij siv rau cov hmoov kom ua tiav ceev ceev. Hauv cov txheej txheem no, tam sim no ncaj qha heats pwm thiab hmoov, tsim Joule tshav kub thiab ntshav, ua kom muaj txiaj ntsig zoo hauv lub sijhawm luv luv (feem ntau hauv 10 feeb). Cov cua kub nrawm txhawb kev sib kis ntawm qhov chaw, thaum lub txim hluav taws xob pab tshem tawm cov roj adsorbed thiab oxide txheej los ntawm cov hmoov av, txhim kho kev ua haujlwm sintering. Cov nyhuv electromigration induced los ntawm electromagnetic teb kuj txhim khu atomic diffusion.

Piv nrog rau cov xovxwm kub ib txwm siv, SPS ntiav cov cua sov ncaj qha, ua kom muaj qhov ntom ntom ntawm qhov kub thiab txias thaum muaj txiaj ntsig zoo inhibiting kev loj hlob ntawm cov nplej kom tau txais cov khoom zoo thiab cov microstructures. Piv txwv li:

- Tsis muaj cov tshuaj ntxiv, siv cov hmoov av SiC ua raw khoom, sintering ntawm 2100 ° C thiab 70 MPa rau 30 feeb yielded cov qauv nrog 98% txheeb ze ntom ntom.

- Sintering ntawm 1700 ° C thiab 40 MPa rau 10 feeb ua cubic SiC nrog 98% ntom thiab grain loj ntawm tsuas yog 30-50 nm.

- Siv 80 µm granular SiC hmoov thiab sintering ntawm 1860 ° C thiab 50 MPa rau 5 feeb ua rau muaj kev ua tau zoo SiC ceramics nrog 98.5% txheeb ze ntom ntom, Vickers microhardness ntawm 28.5 GPa, flexural zog ntawm 395 MPa, thiab tawg toughness.

Microstructural tsom xam pom tau hais tias raws li sintering kub nce los ntawm 1600 ° C mus rau 1860 ° C, cov khoom porosity poob ho, mus txog tag nrho ceev ntawm kub.

Lub microstructure ntawm SiC ceramics sintered ntawm qhov kub thiab txias: (A) 1600 ° C, (B) 1700 ° C, (C) 1790 ° C thiab (D) 1860 ° C

V. Additive Manufacturing

Additive manufacturing (AM) tsis ntev los no tau pom tias muaj peev xwm loj heev hauv kev tsim cov khoom siv ceramics vim nws cov txheej txheem tsim los ntawm txheej txheej. Rau SiC ceramics, ntau yam AM thev naus laus zis tau tsim, suav nrog binder jetting (BJ), 3DP, xaiv laser sintering (SLS), direct number case sau (DIW), thiab stereolithography (SL, DLP). Txawm li cas los xij, 3DP thiab DIW muaj qhov qis dua, thaum SLS nyiam ua rau muaj kev ntxhov siab thiab tawg. Hauv qhov sib piv, BJ thiab SL muaj qhov zoo dua hauv kev tsim cov khoom siv purity, high-precision complex ceramics.

- Binder Jetting (BJ)

BJ thev naus laus zis suav nrog txheej txheej los ntawm txheej txau ntawm binder rau daim ntawv cog lus hmoov, ua raws li kev debinding thiab sintering kom tau txais cov khoom ceramic kawg. Ua ke BJ nrog tshuaj vapor infiltration (CVI), siab-purity, tag nrho crystalline SiC ceramics tau ua tiav tiav. Cov txheej txheem suav nrog:

① Tsim SiC ceramic ntsuab lub cev siv BJ.

② Densifying ntawm CVI ntawm 1000 ° C thiab 200 Torr.

③ Qhov kawg SiC ceramic muaj qhov ceev ntawm 2.95 g / cm³, thermal conductivity ntawm 37 W / m·K, thiab flexural zog ntawm 297 MPa.

Schematic daim duab ntawm nplaum dav hlau (BJ) luam ntawv. (A) Computer-aided design (CAD) qauv, (B) schematic daim duab ntawm BJ txoj cai, (C) luam ntawv ntawm SiC los ntawm BJ, (D) densification ntawm SiC los ntawm tshuaj vapor infiltration (CVI)

- Stereolithography (SL)

SL yog UV-kho-raws li ceramic forming technology nrog high precision thiab complex qauv fabrication peev xwm. Txoj kev no siv cov photosensitive ceramic slurries nrog cov khoom siv siab thiab cov viscosity tsawg los ua 3D ceramic ntsuab lub cev los ntawm photopolymerization, ua raws li kev debinding thiab kub-kub sintering kom tau txais cov khoom kawg.

Siv 35 vol.% SiC slurry, high-zoo 3D ntsuab lub cev tau npaj nyob rau hauv 405 nm UV irradiation thiab ntxiv densified ntawm polymer burnout ntawm 800 ° C thiab PIP kev kho mob. Cov txiaj ntsig tau pom tias cov qauv npaj nrog 35 vol.% slurry ua tiav qhov txheeb ze ntawm 84.8%, ua tau zoo tshaj 30% thiab 40% tswj pawg.

Los ntawm kev qhia txog lipophilic SiO₂ thiab phenolic epoxy resin (PEA) los hloov cov slurry, photopolymerization kev ua tau zoo tau zoo dua qub. Tom qab sintering ntawm 1600 ° C rau 4 h, nyob ze-ua tiav kev hloov pauv mus rau SiC tau ua tiav, nrog cov ntsiab lus oxygen kawg ntawm tsuas yog 0.12%, ua rau ib-kauj ruam fabrication ntawm high-purity, complex-structured SiC ceramics tsis pre-oxidation los yog pre-infiltration kauj ruam.

Piv txwv ntawm cov qauv luam ntawv thiab nws cov txheej txheem sintering. Cov tsos ntawm cov qauv tom qab ziab ntawm (A) 25 ° C, pyrolysis ntawm (B) 1000 ° C, thiab sintering ntawm (C) 1600 ° C.

Los ntawm kev tsim photosensitive Si₃N₄ ceramics slurries rau stereolithography 3D luam ntawv thiab ua hauj lwm debinding-presintering thiab high-temperature aging txheej txheem, Si₃N₄ ceramics nrog 93.3% theoretical ntom, tensile zog ntawm 279.8 MPa, thiab flexural.3. Cov kev tshawb fawb pom tias nyob rau hauv cov xwm txheej ntawm 45 vol.% cov ntsiab lus khoom thiab 10 s lub sij hawm raug, ib txheej ntsuab lub cev nrog IT77-theem curing precision yuav tau. Cov txheej txheem qis qis qis nrog qhov cua sov ntawm 0.1 ° C / min tau pab tsim lub cev ntsuab tsis tawg.

Sintering yog ib kauj ruam tseem ceeb cuam tshuam rau kev ua tau zoo kawg hauv stereolithography. Kev tshawb fawb qhia tau hais tias ntxiv cov khoom siv sintering tuaj yeem txhim kho ceramic ntom ntom thiab cov khoom siv kho tshuab. Siv CeO₂ ua ib qho kev pabcuam sintering thiab hluav taws xob-pab sintering thev naus laus zis los npaj cov khoom siv hluav taws xob siab Si₃N₄ ceramics, CeO₂ tau pom los cais ntawm cov ciam teb nplej, txhawb nqa cov ciam teb zawv zawg thiab qhov ntom ntom. Cov txiaj ntsig ceramics tau nthuav tawm Vickers hardness ntawm HV10/10 (1347.9 ± 2.4) thiab tawg toughness ntawm (6.57 ± 0.07) MPa·m¹/². Nrog MgO-Y₂O₃ ua cov khoom siv ntxiv, ceramic microstructure homogeneity tau txhim kho, txhim kho kev ua tau zoo. Ntawm tag nrho cov doping theem ntawm 8 wt.%, flexural zog thiab thermal conductivity mus txog 915.54 MPa thiab 59.58 W·m⁻¹·K⁻¹, feem.

VI. Xaus

Nyob rau hauv cov ntsiab lus, high-purity silicon carbide (SiC) ceramics, raws li ib tug zoo heev engineering ceramic khoom, tau pom dav daim ntawv thov prospects nyob rau hauv semiconductors, aerospace, thiab huab cua txias khoom. Daim ntawv no tau txheeb xyuas tsib txoj hauv kev npaj rau siab-purity SiC ceramics-recrystallization sintering, pressureless sintering, kub pressing, spark plasma sintering, thiab additive manufacturing-nrog cov ncauj lus kom ntxaws kev sib tham ntawm lawv densification mechanisms, qhov tseem ceeb parameter optimization, cov ntaub ntawv ua tau zoo, thiab hais txog qhov zoo thiab kev txwv.

Nws yog pov thawj tias cov txheej txheem sib txawv txhua tus muaj cov yam ntxwv tshwj xeeb ntawm kev ua tiav siab purity, siab ceev, cov qauv nyuaj, thiab muaj peev xwm ua tau. Additive manufacturing technology, tshwj xeeb tshaj yog, tau pom muaj zog muaj peev xwm nyob rau hauv fabricating complex-zoo li tus thiab customized Cheebtsam, nrog breakthroughs nyob rau hauv subfields xws li stereolithography thiab binder jetting, ua rau nws yog ib qho tseem ceeb txoj kev loj hlob kev taw qhia rau high-purity SiC ceramic npaj.

Kev tshawb fawb yav tom ntej ntawm kev ua siab dawb siab zoo SiC ceramic npaj yuav tsum tau ua kom tob dua, txhawb kev hloov pauv ntawm chav kuaj ntsuas mus rau qhov loj, cov ntaub ntawv siv hluav taws xob txhim khu kev qha zoo, yog li muab cov khoom siv tseem ceeb rau kev tsim khoom siv high-end thiab lwm cov ntaub ntawv thev naus laus zis.

XKH yog lub tuam txhab high-tech tshwj xeeb hauv kev tshawb fawb thiab tsim cov khoom siv hluav taws xob ua haujlwm siab. Nws tau mob siab rau muab cov kev daws teeb meem rau cov neeg siv khoom hauv daim ntawv ntawm high-purity silicon carbide (SiC) ceramics. Lub tuam txhab muaj cov txheej txheem kev npaj cov khoom siv qib siab thiab muaj peev xwm ua tiav. Nws txoj kev lag luam suav nrog kev tshawb fawb, kev tsim khoom, kev ua tiav, thiab kev kho saum npoo ntawm high-purity SiC ceramics, ua tau raws li cov kev cai nruj ntawm cov khoom siv hluav taws xob, lub zog tshiab, aerospace thiab lwm yam kev ua haujlwm siab rau cov khoom siv ceramic. Leveraging mature sintering txheej txheem thiab additive manufacturing technologies, peb muaj peev xwm muab cov neeg muas zaub ib tug ib-nres kev pab cuam los ntawm cov khoom formula optimization, complex qauv tsim kom meej ua, xyuas kom meej tias cov khoom muaj zoo heev mechanical zog, thermal stability thiab corrosion kuj.

Post lub sij hawm: Lub Xya hli ntuj-30-2025

-300x228.png)

1600°C、(B)1700°C、(C)1790°C-和(D)1860°C-300x223.png)

25°C-下干燥、(B)1000°C-下热解和(C)1600°C-下烧结后的外观-300x225.png)