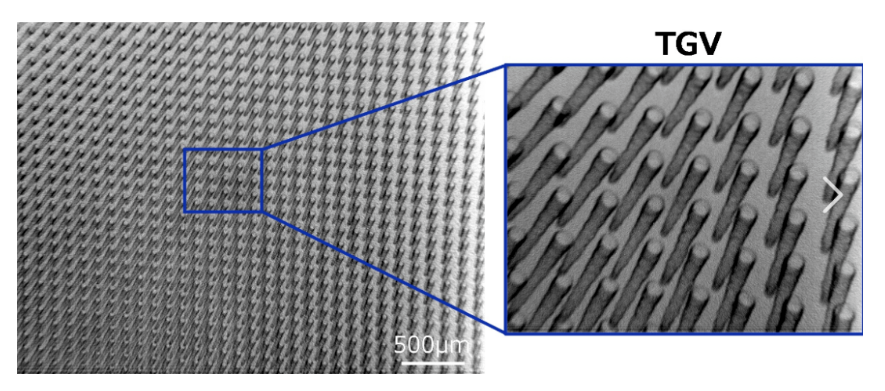

TGV yog dab tsi?

TGV, (Tau-iav via), ib lub tshuab ntawm kev tsim los ntawm-qhov ntawm lub iav substrate, Hauv cov ntsiab lus yooj yim, TGV yog lub tsev siab siab uas xuas nrig ntaus, sau thiab txuas mus rau hauv lub khob los tsim kev sib koom ua ke ntawm cov iav hauv pem teb. Cov thev naus laus zis no suav tias yog lub thev naus laus zis tseem ceeb rau tiam tom ntej ntawm 3D ntim.

Dab tsi yog cov yam ntxwv ntawm TGV?

1. Structure: TGV yog vertically penetrating conductive los ntawm lub qhov ua rau ntawm ib tug iav substrate. Los ntawm kev tso ib txheej hlau conductive rau ntawm phab ntsa pore, lub sab sauv thiab qis txheej ntawm cov hluav taws xob teeb liab sib cuam tshuam.

2. Cov txheej txheem tsim khoom: TGV manufacturing muaj xws li substrate pretreatment, qhov ua, hlau txheej deposition, qhov filling thiab flattening kauj ruam. Kev tsim cov txheej txheem yog tshuaj etching, laser drilling, electroplating thiab lwm yam.

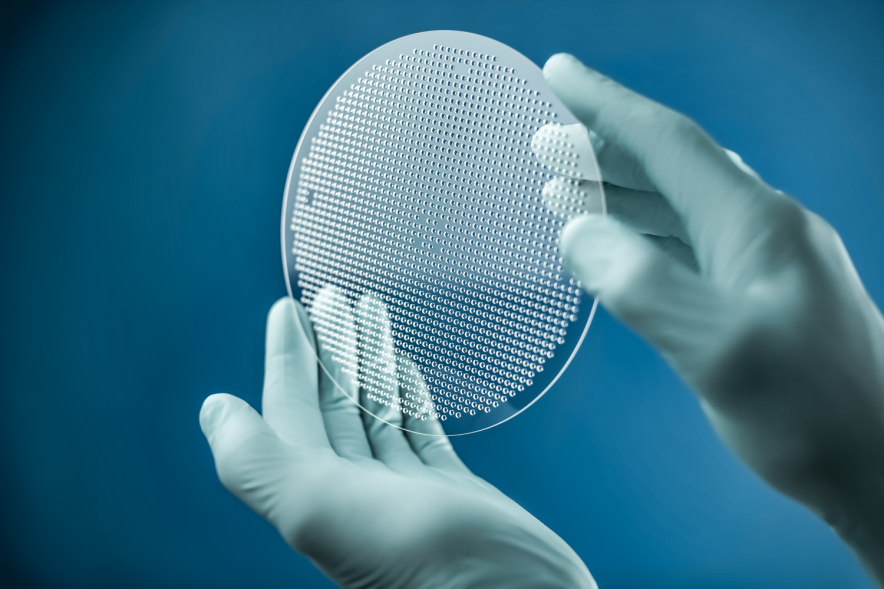

3. Daim ntawv thov zoo: Piv nrog cov tsoos hlau los ntawm lub qhov, TGV muaj qhov zoo ntawm qhov me me, kev sib txuas ntau dua, kev ua haujlwm zoo dua tshav kub thiab lwm yam. Dav siv nyob rau hauv microelectronics, optoelectronics, MEMS thiab lwm yam kev lag luam ntawm high-density interconnection.

4. Txoj kev loj hlob zoo: Nrog rau kev txhim kho cov khoom siv hluav taws xob ntawm cov khoom siv me me thiab kev sib koom ua ke siab, TGV thev naus laus zis tau txais ntau thiab ntau dua thiab siv tau. Nyob rau hauv lub neej yav tom ntej, nws cov txheej txheem tsim khoom yuav ua kom zoo dua qub, thiab nws qhov loj thiab kev ua tau zoo yuav txuas ntxiv txhim kho.

Dab tsi yog TGV txheej txheem:

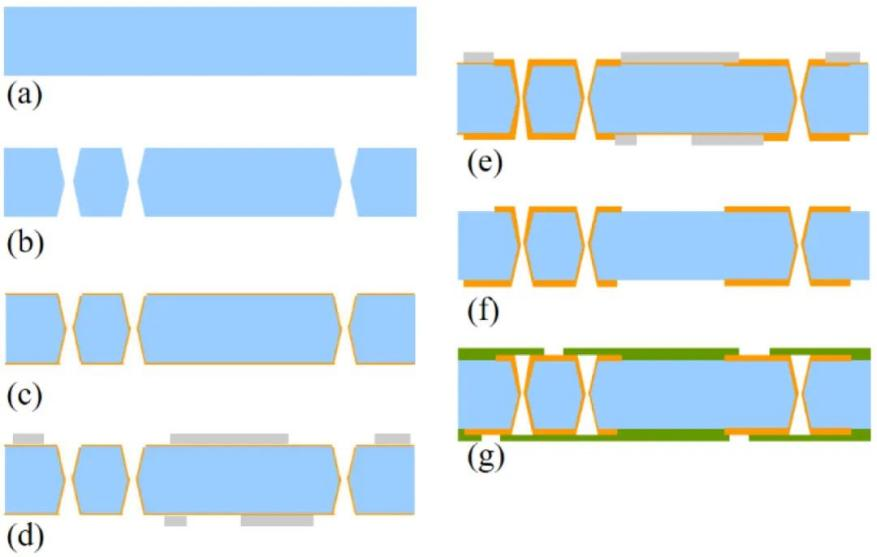

1. Kev npaj iav substrate (a): Npaj ib lub khob substrate thaum pib los xyuas kom meej tias nws qhov chaw yog du thiab huv.

2. Iav drilling (b): Ib lub laser yog siv los ua ib qho kev nkag mus rau hauv cov iav substrate. Cov duab ntawm lub qhov yog feem ntau conical, thiab tom qab kev kho mob laser ntawm ib sab, nws tau tig thiab ua tiav ntawm lwm sab.

3. Qhov phab ntsa metallization (c): Metallization yog nqa tawm ntawm lub qhov phab ntsa, feem ntau yog los ntawm PVD, CVD thiab lwm yam txheej txheem los tsim cov txheej txheem hlau txheej ntawm lub qhov phab ntsa, xws li Ti / Cu, Cr / Cu, thiab lwm yam.

4. Lithography (d): Qhov saum npoo ntawm iav substrate yog coated nrog photoresist thiab photopatterned. Tshem tawm cov khoom uas tsis xav tau plating, kom tsuas yog cov khoom uas xav tau plating raug.

5. Lub qhov filling (e): Electroplating tooj liab los sau cov iav los ntawm qhov los ua ib txoj hauv kev ua tiav. Nws yog feem ntau yuav tsum tau hais tias lub qhov yog tag nrho tsis muaj qhov. Nco ntsoov tias Cu nyob rau hauv daim duab tsis muaj neeg nyob.

6. Flat nto ntawm lub substrate (f): Qee cov txheej txheem TGV yuav ua kom lub ntsej muag ntawm lub khob ntim dej kom ntseeg tau tias qhov chaw ntawm lub substrate yog du, uas yog qhov zoo rau cov txheej txheem tom ntej.

7.Cov txheej txheem tiv thaiv thiab lub davhlau ya nyob twg txuas (g): Ib txheej tiv thaiv (xws li polyimide) yog tsim rau saum npoo ntawm iav substrate.

Hauv luv luv, txhua kauj ruam ntawm TGV txheej txheem yog qhov tseem ceeb thiab yuav tsum muaj kev tswj hwm thiab kev ua kom zoo. Peb tam sim no muab TGV iav los ntawm lub qhov tshuab yog tias xav tau. Thov koj xav tiv tauj peb!

(Cov ntaub ntawv saum toj no yog los ntawm Internet, censoring)

Post lub sij hawm: Jun-25-2024