1. Taw qhia

Txawm hais tias ntau xyoo ntawm kev tshawb fawb, heteroepitaxial 3C-SiC loj hlob ntawm silicon substrates tseem tsis tau ua tiav cov khoom siv lead ua zoo txaus rau kev siv hluav taws xob siv hluav taws xob. Kev loj hlob feem ntau ua rau Si (100) lossis Si (111) substrates, txhua qhov kev sib tw sib txawv: cov tshuaj tiv thaiv theem rau (100) thiab tawg rau (111). Thaum [111] -oriented film Cov ntaub ntawv uas twb muaj lawm qhia tau hais tias kev loj hlob zoo tej yam kev mob tej zaum yuav yog kev taw qhia tshwj xeeb, cuam tshuam kev tshawb nrhiav. Qhov tseem ceeb, kev siv ntau dua-Miller-index Si substrates (piv txwv li, (311), (510)) rau 3C-SiC heteroepitaxy yeej tsis tau tshaj tawm, tawm hauv qhov chaw tseem ceeb rau kev tshawb fawb txog kev taw qhia-raws li kev loj hlob mechanisms.

2. Kev sim

3C-SiC txheej tau muab tso rau ntawm atmospheric-pressure chemical vapor deposition (CVD) siv SiH4/C3H8/H2 precursor gases. Cov substrates yog 1 cm² Si wafers nrog ntau yam orientations: (100), (111), (110), (211), (311), (331), (510), (553), (995). Tag nrho cov substrates tau nyob ntawm-axis tshwj tsis yog rau (100), qhov twg 2 ° tawm-txiav wafers tau kuaj ntxiv. Kev tu ua ntej kev loj hlob koom nrog ultrasonic degreasing hauv methanol. Txoj kev loj hlob muaj xws li haiv neeg oxide tshem tawm los ntawm H2 annealing ntawm 1000 ° C, ua raws li tus txheej txheem ob-kauj ruam: carburization rau 10 feeb ntawm 1165 ° C nrog 12 sccm C3H8, ces epitaxy rau 60 feeb ntawm 1350 ° C (C / Si ratio = 4cm .2cm . Txhua qhov kev loj hlob muaj xws li plaub mus rau tsib qhov sib txawv Si orientations, nrog tsawg kawg yog ib (100) siv wafer.

3. Cov txiaj ntsig thiab kev sib tham

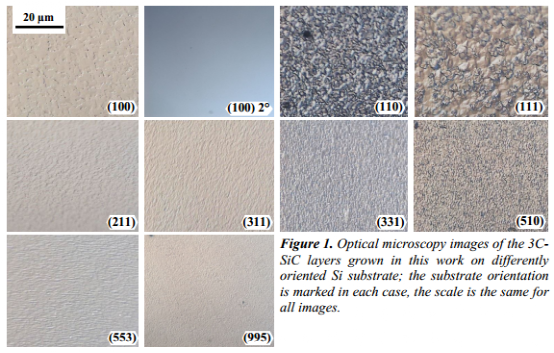

Lub morphology ntawm 3C-SiC cov khaubncaws sab nraud povtseg zus nyob rau ntau yam Si substrates (Fig. 1) pom txawv nto nta thiab roughness. Pom tau, cov qauv loj hlob ntawm Si (100), (211), (311), (553), thiab (995) tshwm iav zoo li, thaum lwm tus muaj xws li mis nyuj ((331), (510)) mus rau dull ((110), (111)). Qhov chaw smoothest (qhia qhov zoo tshaj plaws microstructure) tau txais ntawm (100) 2 ° tawm thiab (995) substrates. Remarkably, tag nrho cov khaubncaws sab nraud povtseg tseem tawg-dawb tom qab txias, nrog rau cov feem ntau muaj kev ntxhov siab-prone 3C-SiC (111). Cov qauv txwv loj tuaj yeem tiv thaiv kev tawg, txawm hais tias qee cov qauv nthuav tawm hneev nti (30-60 μm deflection ntawm nruab nrab mus rau ntug) pom tau nyob rau hauv optical microscopy ntawm 1000 × magnification vim muaj thermal stress. Cov khaubncaws sab nraud povtseg loj hlob ntawm Si (111), (211), thiab (553) substrates tso tawm cov duab concave uas qhia tias muaj zog tensile, xav tau kev sim thiab kev ua haujlwm ntxiv los cuam tshuam nrog crystallographic orientation.

Daim duab 1 qhia txog XRD thiab AFM (scanning ntawm 20 × 20 μ m2) cov txiaj ntsig ntawm 3C-SC cov khaubncaws sab nraud povtseg ntawm Si substrates nrog cov kev taw qhia sib txawv.

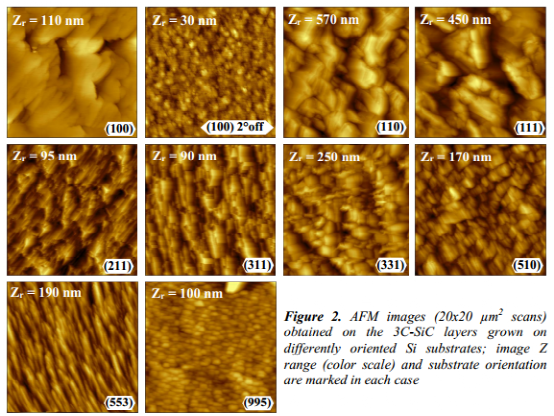

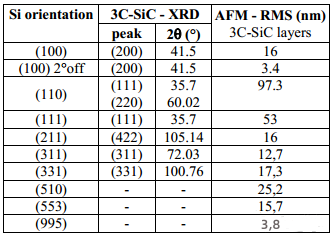

Atomic force microscopy (AFM) cov duab (Fig. 2) corroborated optical kev soj ntsuam. Hauv paus-mean-square (RMS) qhov tseem ceeb tau lees paub qhov smoothest nto ntawm (100) 2 ° tawm thiab (995) substrates, featuring grain-zoo li cov qauv nrog 400-800 nm lateral dimensions. Cov txheej (110)-loj hlob yog qhov roughest, thaum elongated thiab / lossis cov yam ntxwv sib luag nrog qee lub sijhawm ntse ciam teb tshwm sim hauv lwm qhov kev taw qhia ((331), (510)). X-ray diffraction (XRD) θ-2θ scans (cov ntsiab lus hauv Table 1) tau nthuav tawm ua tiav heteroepitaxy rau qis-Miller-index substrates, tshwj tsis yog rau Si(110) uas pom tias sib xyaw 3C-SiC (111) thiab (110) peaks qhia polycrystallinity. Qhov kev taw qhia kev sib xyaw no tau tshaj tawm yav dhau los rau Si (110), tab sis qee qhov kev tshawb fawb tau pom tshwj xeeb (111)-oriented 3C-SiC, qhia txog kev txhim kho kev loj hlob yog qhov tseem ceeb. Rau Miller indices ≥5 ((510), (553), (995)), tsis muaj XRD peaks tau kuaj pom nyob rau hauv tus qauv θ-2θ configuration vim cov high-index dav hlau no tsis-diffracting nyob rau hauv no geometry. Qhov tsis muaj qhov ntsuas qis 3C-SiC peaks (piv txwv li, (111), (200)) qhia txog kev loj hlob ib leeg-crystalline, xav tau cov qauv tilting kom pom qhov sib txawv ntawm cov dav hlau qis.

Daim duab 2 qhia txog kev suav ntawm lub dav hlau lub kaum sab xis hauv CFC siv lead ua qauv.

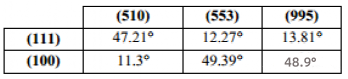

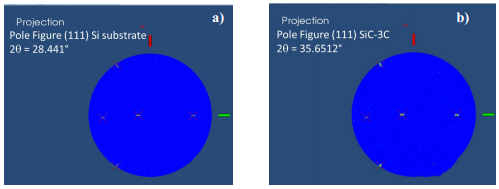

Qhov ntsuas crystallographic cov ces kaum ntawm high-index thiab low-index dav hlau (Table 2) pom loj misorientations (> 10 °), piav qhia lawv tsis nyob rau hauv tus qauv θ-2θ scans. Pole daim duab tsom xam yog li ntawd tau ua nyob rau hauv (995)-oriented qauv vim nws txawv txawv granular morphology (tej zaum los ntawm columnar loj hlob los yog twinning) thiab tsawg roughness. Daim duab (111) ncej (Fig. 3) los ntawm Si substrate thiab 3C-SiC txheej yog ze li zoo tib yam, paub meej tias kev loj hlob ntawm epitaxial tsis muaj ntxaib. Qhov chaw nruab nrab tau tshwm sim ntawm χ≈15 °, piv rau theoretical (111)-(995) lub kaum sab xis. Peb qhov sib npaug sib npaug tau tshwm sim ntawm qhov xav tau ntawm txoj haujlwm (χ = 56.2 ° / φ = 269.4 °, χ = 79 ° / φ = 146.7 ° thiab 33.6 °), txawm tias qhov chaw tsis muaj zog ntawm χ = 62 ° / φ = 93.3 ° yuav tsum tau tshawb xyuas ntxiv. Lub crystalline zoo, soj ntsuam ntawm qhov chaw dav hauv φ-scans, zoo nkaus li kev cog lus, txawm hais tias kev ntsuas kev ntsuas qhov nkhaus yuav tsum tau ua kom muaj nuj nqis. Cov duab ncej rau (510) thiab (553) cov qauv tseem yuav tsum tau ua kom tiav kom paub meej tias lawv qhov xwm txheej epitaxial.

Daim duab 3 qhia txog XRD ncov daim duab sau rau ntawm (995) cov qauv taw qhia, uas qhia txog (111) dav hlau ntawm Si substrate (a) thiab 3C-SiC txheej (b).

4. Cov lus xaus

Heteroepitaxial 3C-SiC kev loj hlob tau ua tiav ntawm Si orientations feem ntau tsuas yog (110), uas tau txais cov khoom siv polycrystalline. Si (100) 2 ° tawm thiab (995) substrates tau tsim cov txheej txheem smoothest (RMS <1 nm), thaum (111), (211), thiab (553) pom qhov tseem ceeb nyo hau (30-60 μm). High-index substrates yuav tsum tau tshaj XRD tus yam ntxwv (xws li, ncej cov duab) kom paub meej tias epitaxy vim tsis tuaj θ-2θ peaks. Kev ua haujlwm tsis tu ncua suav nrog kev ntsuas qhov nkhaus nkhaus, ntsuas kev ntxhov siab Raman, thiab nthuav dav ntxiv rau cov kev taw qhia siab ntxiv kom ua tiav qhov kev tshawb nrhiav no.

Raws li ib tug vertically integrated chaw tsim tshuaj paus, XKH muab kev customized ua kev pab cuam nrog ib tug tag nrho portfolio ntawm silicon carbide substrates, muab cov qauv thiab tshwj xeeb hom xws li 4H / 6H-N, 4H-Semi, 4H / 6H-P, thiab 3C-SiC, muaj nyob rau hauv diameters ntawm 2-nti mus rau 12-nti. Peb cov kws tshaj lij kawg-rau-kawg hauv kev loj hlob siv lead ua, precision machining, thiab kev ruaj ntseg zoo ua kom cov kev daws teeb meem zoo rau hluav taws xob hluav taws xob, RF, thiab cov ntawv thov tshiab.

Post lub sij hawm: Aug-08-2025