Silicon carbide (SiC) tsis yog tsuas yog cov cuab yeej tseem ceeb rau kev tiv thaiv hauv tebchaws tab sis kuj tseem yog cov khoom siv tseem ceeb rau kev lag luam tsheb thoob ntiaj teb thiab lub zog. Raws li thawj kauj ruam tseem ceeb hauv SiC ib leeg-crystal ua, wafer slicing ncaj qha txiav txim siab qhov zoo ntawm cov thinning tom qab thiab polishing. Cov txheej txheem slicing ib txwm siv feem ntau qhia cov kab nrib pleb thiab subsurface, nce wafer breakage tus nqi thiab cov nqi tsim khoom. Yog li ntawd, kev tswj qhov tawg tawg yog qhov tseem ceeb rau kev nce qib SiC cov cuab yeej tsim khoom.

Tam sim no, SiC ingot slicing ntsib ob qhov teeb meem loj:

- Cov khoom poob siab nyob rau hauv cov tsoos multi-wire sawing :SiC qhov nyuaj thiab brittleness ua rau nws yooj yim rau warping thiab tawg thaum txiav, sib tsoo, thiab polishing. Raws li Infineon cov ntaub ntawv, ib txwm reciprocating pob zeb diamond-resin-bonded multi-wire sawing ua tiav tsuas yog 50% cov khoom siv hauv kev txiav, nrog rau tag nrho ib leeg-wafer poob mus txog ~ 250 μm tom qab polishing, tawm hauv cov khoom siv tsawg tsawg.

- Tsawg efficiency thiab ntev ntau lawm voj voog:Kev txheeb xyuas thoob ntiaj teb ntau lawm qhia tau tias ua tau 10,000 wafers siv 24-teev nruam ntau-xaim sawing yuav siv sij hawm ~ 273 hnub. Txoj kev no yuav tsum muaj cov cuab yeej siv dav thiab cov khoom siv tau zoo thaum tsim kom muaj qhov siab roughness thiab muaj kuab paug (plua plav, dej khib nyiab).

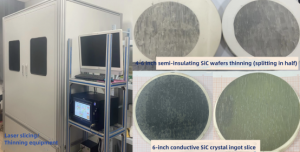

Txhawm rau daws cov teeb meem no, Xib Fwb Xiu Xiangqian pab pawg ntawm Nanjing University tau tsim cov cuab yeej siv laser slicing siab rau SiC, siv tshuab laser ultrafast kom txo qis qhov tsis xws luag thiab txhawb kev tsim khoom. Rau 20-mm SiC ingot, cov cuab yeej no ua rau ob npaug ntawm wafer tawm los piv rau cov tsoos hlau sawing. Tsis tas li ntawd, lub laser-sliced wafers pom zoo geometric uniformity, ua kom tuab txo mus rau 200 μm ib wafer thiab ntxiv cov zis ntau ntxiv.

Cov txiaj ntsig tseem ceeb:

- Ua tiav R&D ntawm cov khoom siv loj-loj qauv, siv tau rau kev txiav 4-6-nti semi-insulating SiC wafers thiab 6-nti conductive SiC ingots.

- 8-nti ingot slicing yog nyob rau hauv kev tshuaj xyuas.

- Lub sij hawm txiav luv luv, ntau cov zis txhua xyoo, thiab> 50% tawm los txhim kho.

XKH's SiC substrate of type 4H-N

Kev Lag Luam Muaj Peev Xwm:

Cov cuab yeej no tau npaj los ua cov kev daws teeb meem tseem ceeb rau 8-nti SiC ingot slicing, tam sim no yeej los ntawm Nyij Pooj ntshuam nrog cov nqi siab thiab kev txwv kev xa tawm. Kev thov hauv tsev rau cov khoom siv laser slicing / thinning ntau tshaj 1,000 units, tseem tsis muaj kev paub tab ntawm Suav teb. Nanjing University cov thev naus laus zis tuav cov nqi lag luam loj thiab muaj peev xwm nyiaj txiag.

Multi-Material Compatibility:

Tshaj li SiC, cov cuab yeej txhawb nqa laser ua ntawm gallium nitride (GaN), aluminium oxide (Al₂O₃), thiab pob zeb diamond, nthuav dav nws cov ntawv thov kev lag luam.

Los ntawm kev hloov pauv SiC wafer ua, qhov kev tsim kho tshiab no hais txog qhov tseem ceeb hauv kev tsim cov khoom siv hluav taws xob semiconductor thaum ua raws li cov qauv thoob ntiaj teb rau kev ua tau zoo, cov khoom siv hluav taws xob zoo.

Kev xaus

Raws li tus thawj coj hauv kev lag luam hauv silicon carbide (SiC) substrate manufacturing, XKHnpe tshwj xeeb hauv kev muab 2-12-nti puv-loj SiC substrates (xws li 4H-N / SEMI-type, 4H / 6H / 3C-type) tailored rau high-growth sectors PVN (cov khoom siv hluav taws xob xws li cov khoom siv hluav taws xob, hluav taws xob PVN) thiab cov khoom siv hluav taws xob tshiab. 5G kev sib txuas lus. Leveraging loj-dimension wafer low-loss slicing technology thiab high-precision processing thev naus laus zis, peb tau ua tiav cov khoom loj ntawm 8-nti substrates thiab breakthroughs hauv 12-nti conductive SiC siv lead ua kev loj hlob thev naus laus zis, txo qis nqi ntawm ib chav tsev nti. Tsiv mus tom ntej, peb yuav txuas ntxiv ua kom zoo dua ingot-theem laser slicing thiab cov txheej txheem tswj kev ntxhov siab ntse kom nce 12-nti substrate tawm los rau cov qib kev sib tw thoob ntiaj teb, txhawb nqa kev lag luam hauv SiC kom tawg thoob ntiaj teb monopolies thiab ua kom cov ntawv thov siv tau hauv high-end domains xws li automotive-qib cov khoom siv hluav taws xob.

XKH's SiC substrate of type 4H-N

Post lub sij hawm: Aug-15-2025