Tam sim no, peb lub tuam txhab tuaj yeem muab cov khoom me me ntawm 8inchN hom SiC wafers, yog tias koj muaj cov qauv xav tau, thov hu rau kuv. Peb muaj qee cov qauv wafers npaj xa tuaj.

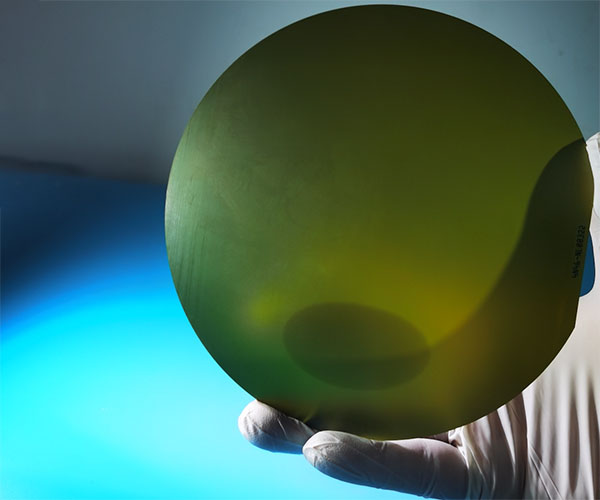

Hauv kev lag luam ntawm cov khoom siv semiconductor, lub tuam txhab tau ua tiav kev tshawb fawb thiab kev loj hlob ntawm cov loj loj SiC crystals. Los ntawm kev siv nws tus kheej cov noob muaju tom qab ntau lub voj voog ntawm txoj kab uas hla, lub tuam txhab tau ua tiav 8-nti N-hom SiC crystals, uas daws teeb meem nyuaj xws li qhov kub tsis sib xws, siv lead ua tawg thiab roj theem raw khoom faib rau hauv cov txheej txheem kev loj hlob ntawm 8-nti SIC crystals, thiab ua kom muaj kev loj hlob ntawm qhov loj loj SIC muaju thiab cov txheej txheem kev tswj hwm thiab tswj tau. Txhim kho lub tuam txhab kev sib tw tseem ceeb hauv SiC ib leeg siv lead ua substrate kev lag luam. Nyob rau tib lub sijhawm, lub tuam txhab nquag txhawb nqa cov khoom siv thev naus laus zis thiab cov txheej txheem ntawm qhov loj me silicon carbide substrate npaj kev sim kab, ntxiv dag zog rau kev sib pauv kev lag luam thiab kev koom tes hauv kev lag luam hauv cov dej ntws thiab cov dej ntws, thiab koom tes nrog cov neeg siv khoom kom rov ua cov khoom lag luam tas li, thiab sib koom ua ke txhawb kev ua haujlwm ntawm kev siv cov khoom siv silicon carbide.

| 8 nti N-hom SiC DSP Specs | |||||

| Tus lej | Yam khoom | Chav tsev | Ntau lawm | Kev tshawb fawb | Dummy |

| 1. Parameters | |||||

| 1.1 | polytype | -- | 4H | 4H | 4H |

| 1.2 | nto orientation | ° | <11-20>4 ± 0.5 | <11-20>4 ± 0.5 | <11-20>4 ± 0.5 |

| 2. Kev ntsuas hluav taws xob | |||||

| 2.1 | dopant | -- | n-hom Nitrogen | n-hom Nitrogen | n-hom Nitrogen |

| 2.2 | tiv taus | ohm · cm | 0.015 ~ 0.025 hli | 0.01-0.03 Nws | NA |

| 3. Mechanical parameter | |||||

| 3.1 | txoj kab uas hla | mm | 200 ± 0.2 | 200 ± 0.2 | 200 ± 0.2 |

| 3.2 | tuab | ib m | 500 ± 25 | 500 ± 25 | 500 ± 25 |

| 3.3 | Notch orientation | ° | [1-100] ± 5 | [1-100] ± 5 | [1-100] ± 5 |

| 3.4 | Notch Qhov tob | mm | 1 ~ 1.5 hli | 1 ~ 1.5 hli | 1 ~ 1.5 hli |

| 3.5 | LTV | ib m | ≤5 (10mm * 10mm) | ≤5 (10mm * 10mm) | ≤10 (10mm * 10mm) |

| 3.6 | TTV | ib m | ≤10 | ≤10 | ≤ 15 |

| 3.7 | Hneev | ib m | - 25-25 | -45-45 | -65-65 |

| 3.8 | Warp | ib m | ≤ 30 | ≤ 50 | ≤70 |

| 3.9 | AFM | nm | Ra≤0.2 | Ra≤0.2 | Ra≤0.2 |

| 4. Cov qauv | |||||

| 4.1 | micropipe ceev | ua/cm2 | ≤ 2 | ≤10 | ≤ 50 |

| 4.2 | cov ntsiab lus hlau | atom/cm2 | ≤1E11 | ≤1E11 | NA |

| 4.3 | TSD | ua/cm2 | ≤500 | ≤1000 | NA |

| 4.4 | BPD | ua/cm2 | ≤2000 | ≤5000 | NA |

| 4.5 | TED | ua/cm2 | ≤7000 | ≤10000 | NA |

| 5. Zoo zoo | |||||

| 5.1 | pem hauv ntej | -- | Si | Si | Si |

| 5.2 | nto tiav | -- | Lub ntsej muag CMP | Lub ntsej muag CMP | Lub ntsej muag CMP |

| 5.3 | particle | ua/wafer | ≤100 (qhov loj me ≥0.3μm) | NA | NA |

| 5.4 | khawb | ua/wafer | ≤5, Tag Nrho Ntev ≤200mm | NA | NA |

| 5.5 | Ntug chips/indents/cracks/stains/contamination | -- | Tsis muaj | Tsis muaj | NA |

| 5.6 | Polytype cheeb tsam | -- | Tsis muaj | Thaj tsam ≤10% | Thaj tsam ≤30% |

| 5.7 | pem hauv ntej cim | -- | Tsis muaj | Tsis muaj | Tsis muaj |

| 6. Rov qab zoo | |||||

| 6.1 | rov qab ua tiav | -- | C-ntsej muag MP | C-ntsej muag MP | C-ntsej muag MP |

| 6.2 | khawb | mm | NA | NA | NA |

| 6.3 | Back defects ntug chips/indents | -- | Tsis muaj | Tsis muaj | NA |

| 6.4 | Rov qab roughness | nm | Ra≤5 | Ra≤5 | Ra≤5 |

| 6.5 | Back marking | -- | Ntsig | Ntsig | Ntsig |

| 7. Ntug | |||||

| 7.1 | ntug | -- | Chamfer | Chamfer | Chamfer |

| 8. Pob | |||||

| 8.1 | ntim | -- | Epi-npaj nrog lub tshuab nqus tsev ntim | Epi-npaj nrog lub tshuab nqus tsev ntim | Epi-npaj nrog lub tshuab nqus tsev ntim |

| 8.2 | ntim | -- | Multi-wafer ntim cassette | Multi-wafer ntim cassette | Multi-wafer ntim cassette |

Lub sij hawm xa tuaj: Plaub Hlis-18-2023