Kev ntxuav ntub dej (Wet Clean) yog ib qho ntawm cov kauj ruam tseem ceeb hauv cov txheej txheem tsim khoom semiconductor, txhawm rau tshem tawm ntau yam kab mob los ntawm qhov chaw ntawm lub wafer kom ntseeg tau tias cov txheej txheem tom ntej tuaj yeem ua tiav ntawm qhov chaw huv.

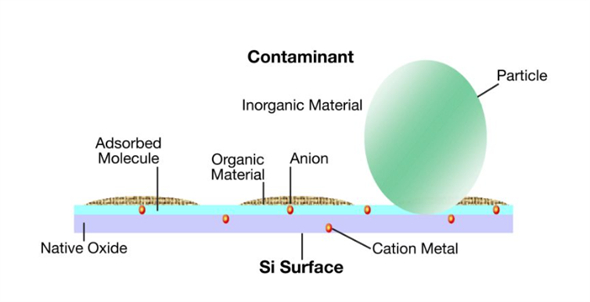

Raws li qhov loj ntawm cov khoom siv semiconductor txuas ntxiv zuj zus thiab qhov yuav tsum tau ua kom raug nce ntxiv, cov kev xav tau ntawm cov txheej txheem tu wafer tau dhau los ua nruj. Txawm tias cov khoom me me, cov khoom siv organic, hlau ions, lossis oxide residues ntawm lub wafer nto tuaj yeem cuam tshuam cov cuab yeej kev ua tau zoo, yog li cuam tshuam rau cov txiaj ntsig thiab kev ntseeg siab ntawm cov khoom siv semiconductor.

Cov Ntsiab Cai ntawm Wafer Cleaning

Lub hauv paus ntawm wafer tu yog nyob rau hauv zoo tshem tawm ntau yam kab mob ntawm lub wafer nto los ntawm lub cev, tshuaj, thiab lwm yam txoj kev los xyuas kom meej tias lub wafer muaj ib tug huv si nto haum rau kev ua tom ntej.

Hom Kev Tiv Thaiv

Cov kev cuam tshuam tseem ceeb ntawm cov yam ntxwv ntawm cov cuab yeej

| Kab mob paug | Txawv tsis xws luag

Ion implantation defects

Insulating zaj duab xis breakdown defects

| |

| Metallic Contamination | Alkali hlau | MOS transistor tsis ruaj khov

Lub rooj vag oxide zaj duab xis tawg / degradation

|

| Hnyav Hlau | Nce PN junction thim rov qab to tam sim no

Lub rooj vag oxide zaj duab xis tawg tsis xws luag

Minority carrier lifetime degradation

Oxide excitation txheej defect tiam

| |

| Chemical Contamination | Organic Khoom | Lub rooj vag oxide zaj duab xis tawg tsis xws luag

CVD zaj duab xis variations (lub sij hawm incubation)

Thermal oxide zaj duab xis thickness variations (accelerated oxidation)

Haze tshwm sim (wafer, lens, daim iav, daim npog qhov ncauj, reticle)

|

| Inorganic Dopants (B, P) | MOS transistor Vth hloov

Si substrate thiab siab kuj poly-silicon ntawv kuj variations

| |

| Inorganic Bases (amines, ammonia) & Acids (SOx) | Degradation ntawm kev daws teeb meem ntawm chemically amplified resists

Qhov tshwm sim ntawm particle contamination thiab haze vim ntsev tsim

| |

| Haiv neeg thiab tshuaj Oxide zaj duab xis vim muaj dej noo, huab cua | Nce kev tiv thaiv

Lub rooj vag oxide zaj duab xis tawg / degradation

| |

Tshwj xeeb, cov hom phiaj ntawm cov txheej txheem wafer tu muaj xws li:

Kev tshem tawm Particle: Siv lub cev los yog cov tshuaj siv los tshem tawm cov khoom me me uas txuas rau ntawm qhov chaw wafer. Cov khoom me me yog qhov nyuaj dua los tshem tawm vim muaj zog electrostatic zog ntawm lawv thiab wafer nto, yuav tsum tau kho tshwj xeeb.

Kev tshem tawm cov khoom siv organic: Cov khoom tsis huv xws li roj thiab cov khoom siv hluav taws xob tuaj yeem ua raws li qhov chaw wafer. Cov kab mob no feem ntau raug tshem tawm siv cov tshuaj oxidizing muaj zog lossis cov kuab tshuaj.

Hlau ion tshem tawm: Hlau ion residues ntawm lub wafer nto tuaj yeem degrade hluav taws xob kev ua tau zoo thiab txawm cuam tshuam cov kauj ruam tom ntej. Yog li ntawd, cov kev daws teeb meem tshwj xeeb yog siv los tshem tawm cov ions.

Kev tshem tawm Oxide: Qee cov txheej txheem xav kom lub ntsej muag wafer kom tsis txhob muaj oxide txheej, xws li silicon oxide. Hauv cov xwm txheej zoo li no, cov txheej txheem oxide ntuj yuav tsum tau muab tshem tawm thaum lub sijhawm ntxuav.

Qhov kev sib tw ntawm wafer tu tshuab yog nyob rau hauv kev tshem tawm cov kab mob zoo yam tsis muaj kev cuam tshuam rau lub wafer nto, xws li tiv thaiv nto roughening, corrosion, los yog lwm yam kev puas tsuaj rau lub cev.

2. Wafer Cleaning txheej txheem ntws

Cov txheej txheem tu wafer feem ntau muaj ntau cov kauj ruam los xyuas kom meej qhov kev tshem tawm tag nrho thiab ua tiav qhov huv huv.

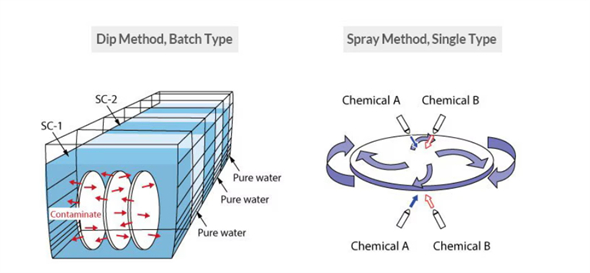

Daim duab: Sib piv ntawm Batch-Type thiab Ib Leeg-Wafer Tu

Cov txheej txheem wafer tu ib txwm suav nrog cov kauj ruam tseem ceeb hauv qab no:

1. Kev ntxuav ua ntej (Pre-Clean)

Lub hom phiaj ntawm kev ntxuav ua ntej yog tshem tawm cov kab mob xoob thiab cov khoom loj los ntawm qhov chaw wafer, uas feem ntau ua tiav los ntawm dej deionized (DI Dej) yaug thiab ntxuav ultrasonic. Deionized dej tuaj yeem pib tshem tawm cov khoom thiab yaj impurities los ntawm qhov chaw wafer, thaum ntxuav ultrasonic siv cov teebmeem cavitation los ua txhaum cov ntawv cog lus ntawm cov khoom thiab cov wafer nto, ua rau lawv yooj yim rau dislodge.

2. Tshuaj ntxuav

Kev tu tshuaj lom neeg yog ib qho ntawm cov kauj ruam tseem ceeb hauv cov txheej txheem tu wafer, siv cov tshuaj daws teeb meem kom tshem tawm cov khoom siv organic, hlau ions, thiab oxides los ntawm wafer nto.

Organic Cov Khoom Siv Tshem Tawm: Feem ntau, acetone los yog ammonia / peroxide sib tov (SC-1) yog siv los yaj thiab oxidize cov kab mob organic. Tus nqi piv rau SC-1 tov yog NH₄OH

₂O₂

₂O = 1: 1: 5, nrog kev ua haujlwm kub ntawm ib ncig ntawm 20 ° C.

Hlau ion tshem tawm: Nitric acid los yog hydrochloric acid / peroxide sib tov (SC-2) yog siv los tshem tawm cov hlau ions los ntawm wafer nto. Tus piv piv rau SC-2 tov yog HCl

₂O₂

₂O = 1:1:6, nrog rau qhov kub thiab txias ntawm kwv yees li 80 ° C.

Kev tshem tawm Oxide: Hauv qee cov txheej txheem, kev tshem tawm cov txheej txheem oxide ib txwm los ntawm wafer nto yuav tsum tau siv, uas siv cov tshuaj hydrofluoric acid (HF). Tus piv piv rau HF tov yog HF

₂O = 1:50, thiab nws tuaj yeem siv rau ntawm chav tsev kub.

3. Qhov kawg huv

Tom qab cov tshuaj ntxuav tu, wafers feem ntau dhau los ua qhov kawg tu cov kauj ruam kom ntseeg tau tias tsis muaj tshuaj lom neeg nyob hauv qhov chaw. Kev tu zaum kawg feem ntau yog siv cov dej deionized rau kev ntxuav kom huv. Tsis tas li ntawd, kev ntxuav dej ozone (O₃ / H₂O) yog siv los tshem tawm cov kab mob uas tseem tshuav ntawm qhov chaw wafer.

4. Qhuav

Cov wafers huv si yuav tsum tau qhuav sai sai kom tsis txhob muaj dej los yog rov txuas cov kab mob. Cov txheej txheem ziab kom qhuav muaj xws li spin drying thiab nitrogen purging. Cov qub tshem tawm cov dej noo los ntawm qhov chaw wafer los ntawm kev sib tw ntawm kev kub ceev, thaum lub tom kawg ua kom tiav ziab los ntawm tshuab ziab cov pa nitrogen thoob plaws wafer nto.

Cov kab mob

Tus txheej txheem ntxuav lub npe

Chemical Mixture Description

Tshuaj

| Cov khoom | Piranha (SPM) | Sulfuric acid / hydrogen peroxide / DI dej | H2SO4 / H2O2 / H2O 3-4: 1; 90 ° C |

| SC-1 (APM) | Ammonium hydroxide / hydrogen peroxide / DI dej | NH4OH/H2O2/H2O 1:4:20; 80 ° C | |

| Hlau (tsis yog tooj liab) | SC-2 (HPM) | Hydrochloric acid / hydrogen peroxide / DI dej | HCl/H2O2/H2O1:1:6; 85 ° C |

| Piranha (SPM) | Sulfuric acid / hydrogen peroxide / DI dej | H2O4/H2O2/H2O3-4:1; 90 ° C | |

| DHF | Dilute hydrofluoric acid / DI dej (yuav tsis tshem cov tooj liab) | HF/H2O1:50 | |

| Organics | Piranha (SPM) | Sulfuric acid / hydrogen peroxide / DI dej | H2SO4 / H2O2 / H2O 3-4: 1; 90 ° C |

| SC-1 (APM) | Ammonium hydroxide / hydrogen peroxide / DI dej | NH4OH/H2O2/H2O 1:4:20; 80 ° C | |

| DIO 3 | Ozone hauv dej de-ionized | O3 / H2O Optimized Mixtures | |

| Native Oxide | DHF | Dilute hydrofluoric acid / DI dej | HF/H2O 1:100 |

| BHF | Buffered hydrofluoric acid | NH4F/HF/H2O |

3. Hom Wafer Cleaning Method

1. Txoj kev ntxuav RCA

RCA tu txoj kev yog ib qho ntawm cov classic wafer tu cov txheej txheem hauv kev lag luam semiconductor, tsim los ntawm RCA Corporation tshaj 40 xyoo dhau los. Txoj kev no feem ntau yog siv los tshem tawm cov kab mob organic thiab hlau ion impurities thiab tuaj yeem ua tiav hauv ob kauj ruam: SC-1 (Standard Clean 1) thiab SC-2 (Standard Clean 2).

SC-1 Tu: Cov kauj ruam no yog siv los tshem tawm cov kab mob thiab cov kab mob. Cov tshuaj yog sib tov ntawm ammonia, hydrogen peroxide, thiab dej, uas tsim ib tug nyias silicon oxide txheej ntawm lub wafer nto.

SC-2 Kev Tu: Cov kauj ruam no feem ntau yog siv los tshem tawm cov kab mob hlau ion, siv cov sib xyaw ntawm hydrochloric acid, hydrogen peroxide, thiab dej. Nws tawm ib txheej nyias nyias ntawm wafer nto kom tiv thaiv kom tsis txhob muaj kab mob.

2. Piranha Cleaning Method (Piranha Ech Clean)

Txoj kev tu Piranha yog cov txheej txheem zoo heev rau kev tshem tawm cov khoom siv organic, siv kev sib xyaw ntawm sulfuric acid thiab hydrogen peroxide, feem ntau hauv qhov sib piv ntawm 3: 1 lossis 4: 1. Vim lub zog oxidative tsis tshua muaj zog ntawm cov tshuaj no, nws tuaj yeem tshem tawm ntau cov organic teeb meem thiab tawv tawv. Txoj kev no yuav tsum muaj kev tswj xyuas nruj heev, tshwj xeeb tshaj yog nyob rau hauv qhov kub thiab txias, kom tsis txhob ua rau lub wafer puas.

Ultrasonic tu siv cov nyhuv cavitation uas tsim los ntawm cov suab nrov zaus hauv cov kua kom tshem tawm cov kab mob ntawm lub wafer nto. Piv nrog rau kev tu ultrasonic tsoos, kev tu megasonic ua haujlwm ntawm qhov zaus ntau dua, ua kom muaj txiaj ntsig zoo dua tshem tawm cov khoom me me me me yam tsis muaj kev puas tsuaj rau lub wafer nto.

4. Ozone ntxuav

Ozone tu tshuab siv cov khoom muaj zog oxidizing ntawm ozone kom decompose thiab tshem tawm cov kab mob organic los ntawm qhov chaw wafer, thaum kawg hloov lawv mus rau cov pa roj carbon dioxide thiab dej tsis zoo. Txoj kev no tsis tas yuav siv cov tshuaj reagents kim heev thiab ua rau muaj kev ua qias tuaj ib puag ncig, ua rau nws yog ib qho kev siv technology tshiab hauv kev tu wafer.

4. Cov khoom siv tu txheej txheem Wafer

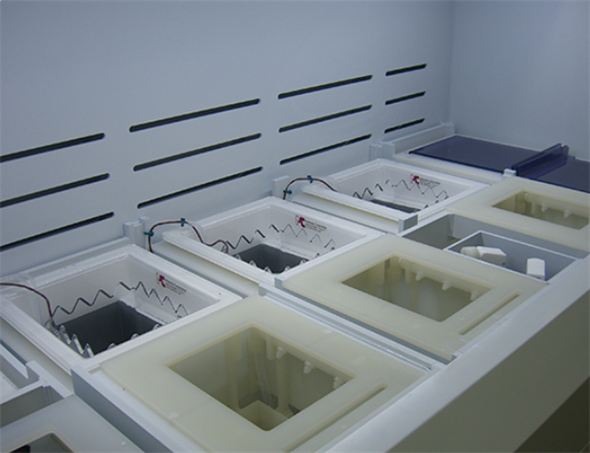

Txhawm rau kom ua tau zoo thiab kev nyab xeeb ntawm cov txheej txheem tu wafer, ntau yam khoom siv tu siab heev yog siv hauv kev tsim khoom semiconductor. Cov hom tseem ceeb muaj xws li:

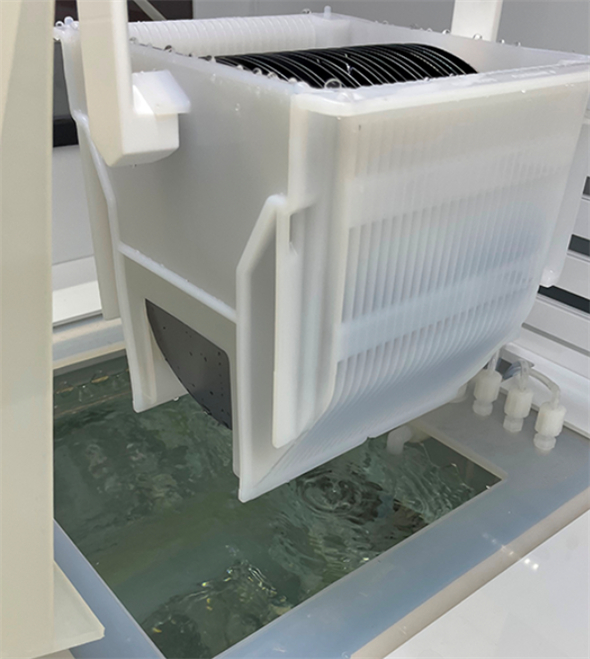

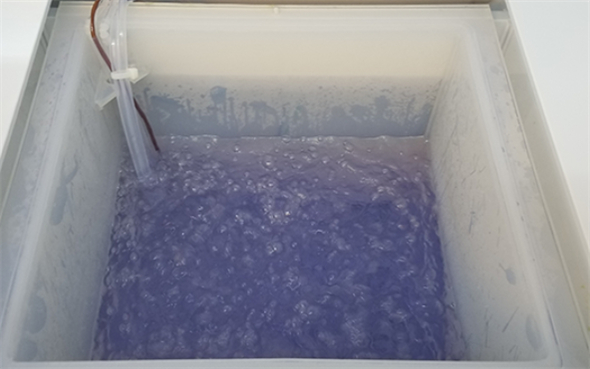

1. Cov khoom siv ntxhua khaub ncaws ntub dej

Cov cuab yeej tu ntub dej muaj xws li ntau lub tso tsheb hlau luam, cov twj tso kua mis ultrasonic tu, thiab tshuab ziab khaub ncaws. Cov cuab yeej no ua ke cov khoom siv dag zog thiab cov tshuaj chemical reagents kom tshem tawm cov kab mob ntawm qhov chaw wafer. Immersion tso tsheb hlau luam feem ntau yog nruab nrog lub tshuab ntsuas kub kom ntseeg tau tias kev ruaj ntseg thiab kev ua tau zoo ntawm cov tshuaj daws teeb meem.

2. Cov cuab yeej ntxuav kom qhuav

Cov cuab yeej siv ziab qhuav feem ntau suav nrog cov tshuaj ntxuav ntshav plasma, uas siv cov khoom siv hluav taws xob siab hauv cov ntshav los tiv thaiv thiab tshem tawm cov khoom seem ntawm lub wafer nto. Kev ntxuav plasma yog tshwj xeeb tshaj yog haum rau cov txheej txheem uas yuav tsum tau ua kom muaj kev ncaj ncees ntawm qhov chaw yam tsis muaj tshuaj lom neeg.

3. Tsis siv neeg tu tshuab

Nrog rau kev nthuav dav ntawm cov khoom siv semiconductor tas mus li, kev siv lub tshuab tu tshuab tsis siv neeg tau dhau los ua qhov kev xaiv zoo tshaj plaws rau kev tu wafer loj. Cov tshuab no feem ntau suav nrog cov tshuab hloov pauv hloov pauv, ntau lub tank tu tshuab, thiab kev tswj xyuas qhov tseeb kom ntseeg tau tias cov txiaj ntsig tu zoo ib yam rau txhua lub wafer.

5. Yav tom ntej Trends

Raws li cov khoom siv semiconductor txuas ntxiv zuj zus, wafer tu tshuab tau hloov mus rau cov kev daws teeb meem zoo dua thiab zoo ib puag ncig. Yav tom ntej tu technologies yuav tsom rau:

Sub-nanometer Particle Tshem Tawm: Cov thev naus laus zis tu tam sim no tuaj yeem ua cov khoom siv nanometer-scale, tab sis nrog kev txo qis hauv cov cuab yeej ntxiv, tshem cov sub-nanometer hais yuav dhau los ua qhov kev sib tw tshiab.

Green thiab Eco-friendly Cleaning: Txo kev siv cov tshuaj phem ib puag ncig thiab txhim kho ntau txoj kev ntxuav hauv eco, xws li kev tu ozone thiab kev tu megasonic, yuav dhau los ua qhov tseem ceeb.

Qib siab ntawm Automation thiab Kev Txawj Ntse: Cov tshuab ntse yuav ua kom muaj kev saib xyuas thiab hloov kho ntawm ntau yam tsis zoo thaum lub sij hawm ntxuav, ntxiv kev txhim kho kev tu thiab kev tsim khoom.

Wafer tu tshuab, raws li cov kauj ruam tseem ceeb hauv kev tsim khoom semiconductor, plays lub luag haujlwm tseem ceeb hauv kev ua kom huv wafer nto rau cov txheej txheem tom ntej. Kev sib xyaw ua ke ntawm ntau txoj hauv kev tu kom zoo tshem tawm cov kab mob, muab lub substrate huv si rau cov kauj ruam tom ntej. Raws li kev siv thev naus laus zis, cov txheej txheem tu yuav txuas ntxiv ua kom zoo kom tau raws li qhov xav tau kom siab dua qhov tseeb thiab qis dua tus nqi hauv kev tsim khoom semiconductor.

Post lub sij hawm: Oct-08-2024