SiC wafer's abstract

Silicon carbide (SiC) waferstau dhau los ua lub substrate ntawm kev xaiv rau high-power, high-frequency, thiab high-temperature electronics nyob rau hauv automotive, renewable zog, thiab aerospace sectors. Peb cov ntaub ntawv npog npog tseem ceeb polytypes thiab doping schemes-nitrogen-doped 4H (4H-N), high-purity semi-insulating (HPSI), nitrogen-doped 3C (3C-N), thiab p-hom 4H / 6H (4H / 6H-P) - muaj nyob rau hauv peb qib zoo: PRIME (tag nrho cov khoom siv polished), txheej txheem kev sim), thiab RESEARCH (kev cai epi txheej thiab doping profiles rau R&D). Wafer diameters span 2 ", 4", 6 ", 8", thiab 12" kom haum rau ob qho tib si legacy cuab yeej thiab siab heev fabs. Peb kuj muab monocrystalline boules thiab precisely oriented noob siv lead ua los pab txhawb kev loj hlob hauv tsev siv lead ua.

Peb 4H-N wafers muaj cov cab kuj ceev los ntawm 1 × 10¹⁶ mus rau 1 × 10¹⁹ cm⁻³ thiab resistivities ntawm 0.01-10 Ω·cm, xa cov khoom siv hluav taws xob zoo heev thiab kev tawg ua haujlwm siab tshaj 2 MV / cm-zoo tagnrho rau Schottky diodes, JFETs, thiab MOSFETs. HPSI substrates tshaj 1 × 10¹² Ω·cm resistivity nrog micropipe ntom hauv qab 0.1 cm⁻², kom ntseeg tau tias tsawg heev rau cov khoom siv RF thiab microwave. Cubic 3C-N, muaj nyob rau hauv 2 "thiab 4" hom, ua rau heteroepitaxy ntawm silicon thiab txhawb nqa cov ntawv thov tshiab photonic thiab MEMS. P-hom 4H / 6H-P wafers, doped nrog txhuas mus rau 1 × 10¹⁶–5 × 10¹⁸ cm⁻³, pab txhawb cov cuab yeej sib txuas ntxiv.

SiC wafer, PRIME wafers undergo tshuaj-mechanical polishing rau <0.2 nm RMS nto roughness, tag nrho thickness variation nyob rau hauv 3 µm, thiab hneev <10 µm. DUMMY substrates nrawm sib dhos thiab ntim cov ntawv xeem, thaum RESEARCH wafers feature epi-txheej thicknesses ntawm 2-30 µm thiab bespoke doping. Tag nrho cov khoom muaj ntawv pov thawj los ntawm X-ray diffraction (pob zeb nkhaus <30 arcsec) thiab Raman spectroscopy, nrog rau kev ntsuam xyuas hluav taws xob-Hall ntsuas, C-V profileing, thiab micropipe scanning- kom ntseeg tau tias JEDEC thiab SEMI ua raws.

Boules mus txog 150 mm txoj kab uas hla yog zus los ntawm PVT thiab CVD nrog dislocation densities hauv qab no 1 × 10³ cm⁻² thiab tsawg micropipe suav. Cov noob muaju raug txiav tsis pub dhau 0.1 ° ntawm c-axis los lav qhov kev loj hlob tuaj yeem loj hlob thiab siab slicing yields.

Los ntawm kev sib txuas ntau yam polytypes, doping variants, qib zoo, SiC wafer qhov ntau thiab tsawg, thiab hauv tsev boule thiab noob-crystal ntau lawm, peb SiC substrate platform streamlines muab chains thiab accelerates cov cuab yeej tsim kho rau hluav taws xob tsheb, ntse daim phiaj, thiab hnyav-ib puag ncig daim ntaub ntawv.

SiC wafer's abstract

Silicon carbide (SiC) waferstau dhau los ua SiC substrate ntawm kev xaiv rau high-power, high-frequency, thiab high-temperature electronics thoob plaws automotive, renewable zog, thiab aerospace sectors. Peb cov ntaub ntawv npog npog cov polytypes tseem ceeb thiab doping schemes-nitrogen-doped 4H (4H-N), high-purity semi-insulating (HPSI), nitrogen-doped 3C (3C-N), thiab p-hom 4H / 6H (4H / 6H-P) - muaj nyob rau hauv peb qib zoo: SiC waferPRIME (tag nrho polished, ntaus-qib substrates), DUMMY (lapped los yog unpolished rau txheej txheem sim), thiab RESEARCH (kev cai epi khaubncaws sab nraud povtseg thiab doping profiles rau R&D). SiC Wafer diameters span 2 ", 4", 6 ", 8", thiab 12" kom haum rau ob qho tib si legacy cuab yeej thiab siab heev fabs. Peb kuj muab monocrystalline boules thiab precisely oriented noob siv lead ua los pab txhawb kev loj hlob hauv tsev siv lead ua.

Peb 4H-N SiC wafers muaj cov cab kuj ceev los ntawm 1 × 10¹⁶ mus rau 1 × 10¹⁹ cm⁻³ thiab resistivities ntawm 0.01-10 Ω·cm, xa cov khoom siv hluav taws xob zoo heev thiab kev tawg ua haujlwm siab tshaj 2 MV / cm-zoo tagnrho rau Schottky diodes, thiab JFETs. HPSI substrates tshaj 1 × 10¹² Ω·cm resistivity nrog micropipe ntom hauv qab 0.1 cm⁻², kom ntseeg tau tias tsawg heev rau cov khoom siv RF thiab microwave. Cubic 3C-N, muaj nyob rau hauv 2 "thiab 4" hom, ua rau heteroepitaxy ntawm silicon thiab txhawb nqa cov ntawv thov tshiab photonic thiab MEMS. SiC wafer P-hom 4H / 6H-P wafers, doped nrog txhuas rau 1 × 10¹⁶–5 × 10¹⁸ cm⁻³, pab txhawb cov cuab yeej sib txuas ntxiv.

SiC wafer PRIME wafers undergo tshuaj-mechanical polishing rau <0.2 nm RMS nto roughness, tag nrho thickness variation nyob rau hauv 3 µm, thiab hneev <10 µm. DUMMY substrates nrawm sib dhos thiab ntim cov ntawv xeem, thaum RESEARCH wafers feature epi-txheej thicknesses ntawm 2-30 µm thiab bespoke doping. Tag nrho cov khoom muaj ntawv pov thawj los ntawm X-ray diffraction (pob zeb nkhaus <30 arcsec) thiab Raman spectroscopy, nrog rau kev ntsuam xyuas hluav taws xob-Hall ntsuas, C-V profileing, thiab micropipe scanning- kom ntseeg tau tias JEDEC thiab SEMI ua raws.

Boules mus txog 150 mm txoj kab uas hla yog zus los ntawm PVT thiab CVD nrog dislocation densities hauv qab no 1 × 10³ cm⁻² thiab tsawg micropipe suav. Cov noob muaju raug txiav tsis pub dhau 0.1 ° ntawm c-axis los lav qhov kev loj hlob tuaj yeem loj hlob thiab siab slicing yields.

Los ntawm kev sib txuas ntau yam polytypes, doping variants, qib zoo, SiC wafer qhov ntau thiab tsawg, thiab hauv tsev boule thiab noob-crystal ntau lawm, peb SiC substrate platform streamlines muab chains thiab accelerates cov cuab yeej tsim kho rau hluav taws xob tsheb, ntse daim phiaj, thiab hnyav-ib puag ncig daim ntaub ntawv.

6inch 4H-N hom SiC wafer cov ntaub ntawv

| 6inch SiC wafers cov ntaub ntawv | ||||

| Parameter | Sub Parameter | Z Qib | P Qib | D Qib |

| Txoj kab uas hla | 149.5–150.0 hli | 149.5–150.0 hli | 149.5–150.0 hli | |

| Thickness | 4 H-N | 350 µm ± 15 µm | 350 µm ± 25 µm | 350 µm ± 25 µm |

| Thickness | 4 H-SI | 500 µm ± 15 µm | 500 µm ± 25 µm | 500 µm ± 25 µm |

| Wafer Orientation | Tawm axis: 4.0 ° mus rau <11-20> ± 0.5 ° (4H-N); Ntawm axis: <0001> ± 0.5 ° (4H-SI) | Tawm axis: 4.0 ° mus rau <11-20> ± 0.5 ° (4H-N); Ntawm axis: <0001> ± 0.5 ° (4H-SI) | Tawm axis: 4.0 ° mus rau <11-20> ± 0.5 ° (4H-N); Ntawm axis: <0001> ± 0.5 ° (4H-SI) | |

| Micropipe ntom ntom | 4 H-N | ≤ 0.2 cm⁻² | ≤ 2 cm⁻² | ≤ 15 cm⁻² |

| Micropipe ntom ntom | 4 H-SI | ≤ 1 cm⁻² | ≤ 5 cm⁻² | ≤ 15 cm⁻² |

| Kev tiv thaiv | 4 H-N | 0.015-0.024 Ω · cm | 0.015-0.028 Ω · cm | 0.015-0.028 Ω · cm |

| Kev tiv thaiv | 4 H-SI | ≥ 1 × 10¹⁰ Ω·cm | ≥ 1 × 10⁵ Ω·cm | |

| Thawj Txoj Kev Ncaj Ncees | [10-10] ± 5.0° | [10-10] ± 5.0° | [10-10] ± 5.0° | |

| Qhov Loj Loj Loj | 4 H-N | 47.5 hli ± 2.0 hli | ||

| Qhov Loj Loj Loj | 4 H-SI | Ntsig | ||

| Ntug Exclusion | 3 hli | |||

| Warp/LTV/TTV/Bow | ≤2.5 µm / ≤6 µm / ≤25 µm / ≤35 µm | ≤5 µm / ≤15 µm / ≤40 µm / ≤60 µm | ||

| Roughness | Polish | Ra ≤ 1 nm | ||

| Roughness | CMP | Ra ≤ 0.2 nm | Ra ≤ 0.5nm | |

| Ntug Cracks | Tsis muaj | Qhov ntev ≤ 20 mm, ib leeg ≤ 2 mm | ||

| Hex daim hlau | Qhov ntau thiab tsawg ≤ 0.05% | Cov cheeb tsam ≤ 0.1% | Qhov ntau thiab tsawg ≤ 1% | |

| Polytype Areas | Tsis muaj | Qhov ntau thiab tsawg ≤ 3% | Qhov ntau thiab tsawg ≤ 3% | |

| Carbon suav nrog | Qhov ntau thiab tsawg ≤ 0.05% | Qhov ntau thiab tsawg ≤ 3% | ||

| Nto Scratches | Tsis muaj | Qhov ntev ≤ 1 × wafer txoj kab uas hla | ||

| Ntug Chips | Tsis muaj kev tso cai ≥ 0.2 mm dav & qhov tob | Txog li 7 nti, ≤ 1 hli txhua | ||

| TSD (Threading Screw Dislocation) | ≤ 500 cm⁻² | N/A | ||

| BPD (Base Plane Dislocation) | ≤ 1000 cm⁻² | N/A | ||

| Nto Cov Kab Mob | Tsis muaj | |||

| Ntim | Multi-wafer cassette los yog ib lub thawv wafer | Multi-wafer cassette los yog ib lub thawv wafer | Multi-wafer cassette los yog ib lub thawv wafer | |

4inch 4H-N hom SiC wafer cov ntaub ntawv

| 4inch SiC wafer cov ntaub ntawv | |||

| Parameter | Zero MPD Production | Standard Qhuav Qib (P Qib) | Qib Dummy (D qib) |

| Txoj kab uas hla | 99.5mm-100.0 hli | ||

| Thickness (4H-N) | 350 µm ± 15 µm | 350 µm ± 25 µm | |

| Thickness (4H-Si) | 500 µm ± 15 µm | 500 µm ± 25 µm | |

| Wafer Orientation | Tawm axis: 4.0 ° mus rau <1120> ± 0.5 ° rau 4H-N; Ntawm axis: <0001> ± 0.5 ° rau 4H-Si | ||

| Micropipe ntom ntom (4H-N) | ≤0.2cm⁻² | ≤ 2 cm⁻² | ≤15 cm⁻² |

| Micropipe ntom ntom (4H-Si) | ≤1cm⁻² | ≤ 5 cm⁻² | ≤15 cm⁻² |

| Kev tiv thaiv (4H-N) | 0.015-0.024 Ω · cm | 0.015-0.028 Ω · cm | |

| Kev tiv thaiv (4H-Si) | ≥1E10 Ω·cm | ≥1E5 Ω·cm | |

| Thawj Txoj Kev Ncaj Ncees | [10-10] ± 5.0° | ||

| Qhov Loj Loj Loj | 32.5 hli ± 2.0 hli | ||

| Secondary Flat Length | 18.0 hli ± 2.0 hli | ||

| Secondary Flat Orientation | Silicon ntsej muag: 90 ° CW los ntawm prime ca ± 5.0 ° | ||

| Ntug Exclusion | 3 hli | ||

| LTV/TTV/Bow Warp | ≤ 2.5 µm / ≤ 5 µm / ≤ 15 µm / ≤ 30 µm | ≤ 10 µm / ≤ 15 µm / ≤ 25 µm / ≤ 40 µm | |

| Roughness | Polish Ra ≤1 nm; CMP Ra ≤0.2nm | Ra ≤0.5nm | |

| Ntug Cracks Los ntawm High Intensity Light | Tsis muaj | Tsis muaj | Qhov ntev ≤10 hli; ib qhov ntev ≤2 hli |

| Hex Phaj Los Ntawm Lub Teeb Siab Siab | Thaj tsam ≤ 0.05% | Thaj tsam ≤ 0.05% | Qhov loj me ≤0.1% |

| Polytype Areas Los Ntawm Lub Teeb Siab Siab | Tsis muaj | Qhov loj me ≤ 3% | |

| Visual Carbon suav nrog | Thaj tsam ≤ 0.05% | Qhov loj me ≤ 3% | |

| Silicon Surface Scratches Los ntawm High Intensity Light | Tsis muaj | Qhov ntev ntev ≤1 wafer txoj kab uas hla | |

| Ntug Chips Los ntawm High Intensity Light | Tsis muaj kev tso cai ≥0.2 hli dav thiab qhov tob | 5 tso cai, ≤1mm txhua | |

| Silicon Surface Contamination Los ntawm High Intensity Light | Tsis muaj | ||

| Threading ntsia hlau dislocation | ≤ 500 cm⁻² | N/A | |

| Ntim | Multi-wafer cassette los yog ib lub thawv wafer | Multi-wafer cassette los yog ib lub thawv wafer | Multi-wafer cassette los yog ib lub thawv wafer |

4inch HPSI hom SiC wafer cov ntaub ntawv

| 4inch HPSI hom SiC wafer cov ntaub ntawv | |||

| Parameter | Zero MPD Qhuav Qib (Z Qib) | Standard Qhuav Qib (P Qib) | Qib Dummy (D qib) |

| Txoj kab uas hla | 99.5-100.0 hli | ||

| Thickness (4H-Si) | 500 µm ± 20 µm | 500 µm ± 25 µm | |

| Wafer Orientation | Tawm axis: 4.0 ° mus rau <11-20> ± 0.5 ° rau 4H-N; Ntawm axis: <0001> ± 0.5 ° rau 4H-Si | ||

| Micropipe ntom ntom (4H-Si) | ≤1cm⁻² | ≤ 5 cm⁻² | ≤15 cm⁻² |

| Kev tiv thaiv (4H-Si) | ≥1E9 Ω·cm | ≥1E5 Ω·cm | |

| Thawj Txoj Kev Ncaj Ncees | (10-10) ± 5.0° | ||

| Qhov Loj Loj Loj | 32.5 hli ± 2.0 hli | ||

| Secondary Flat Length | 18.0 hli ± 2.0 hli | ||

| Secondary Flat Orientation | Silicon ntsej muag: 90 ° CW los ntawm prime ca ± 5.0 ° | ||

| Ntug Exclusion | 3 hli | ||

| LTV/TTV/Bow Warp | ≤ 3 µm / ≤ 5 µm / ≤ 15 µm / ≤ 30 µm | ≤ 10 µm / ≤ 15 µm / ≤ 25 µm / ≤ 40 µm | |

| Roughness (C ntsej muag) | Polish | Ra ≤1nm | |

| Roughness (Si ntsej muag) | CMP | Ra ≤0.2nm | Ra ≤0.5nm |

| Ntug Cracks Los ntawm High Intensity Light | Tsis muaj | Qhov ntev ≤10 hli; ib qhov ntev ≤2 hli | |

| Hex Phaj Los Ntawm Lub Teeb Siab Siab | Thaj tsam ≤ 0.05% | Thaj tsam ≤ 0.05% | Qhov loj me ≤0.1% |

| Polytype Areas Los Ntawm Lub Teeb Siab Siab | Tsis muaj | Qhov loj me ≤ 3% | |

| Visual Carbon suav nrog | Thaj tsam ≤ 0.05% | Qhov loj me ≤ 3% | |

| Silicon Surface Scratches Los ntawm High Intensity Light | Tsis muaj | Qhov ntev ntev ≤1 wafer txoj kab uas hla | |

| Ntug Chips Los ntawm High Intensity Light | Tsis muaj kev tso cai ≥0.2 hli dav thiab qhov tob | 5 tso cai, ≤1mm txhua | |

| Silicon Surface Contamination Los ntawm High Intensity Light | Tsis muaj | Tsis muaj | |

| Threading Screw Dislocation | ≤ 500 cm⁻² | N/A | |

| Ntim | Multi-wafer cassette los yog ib lub thawv wafer | ||

SiC wafer daim ntawv thov

-

SiC Wafer Fais Fab Modules rau EV Inverters

SiC wafer-based MOSFETs thiab diodes ua los ntawm cov khoom zoo SiC wafer substrates xa ultra-tsawg hloov pauv. Los ntawm kev siv SiC wafer thev naus laus zis, cov khoom siv hluav taws xob no ua haujlwm ntawm qhov siab dua thiab qhov kub thiab txias, ua kom muaj txiaj ntsig zoo dua traction inverters. Kev koom ua ke SiC wafer tuag rau hauv cov theem hluav taws xob txo cov kev xav tau cua txias thiab hneev taw, ua kom pom tag nrho lub peev xwm ntawm SiC wafer innovation. -

High-Frequency RF & 5G Devices ntawm SiC Wafer

RF amplifiers thiab keyboards fabricated ntawm semi-insulating SiC wafer platforms muaj superior thermal conductivity thiab tawg voltage. SiC wafer substrate txo qis dielectric poob ntawm GHz zaus, thaum SiC wafer cov khoom siv lub zog tso cai rau kev ua haujlwm ruaj khov nyob rau hauv high-power, high-temperature condition-ua SiC wafer lub substrate ntawm kev xaiv rau tom ntej-gen 5G base stations thiab radar systems. -

Optoelectronic & LED Substrates los ntawm SiC Wafer

Xiav thiab UV LEDs loj hlob ntawm SiC wafer substrates tau txais txiaj ntsig los ntawm kev sib xyaw ua ke zoo heev thiab cov cua sov dissipation. Siv cov polished C-lub ntsej muag SiC wafer ua kom cov khaubncaws sab nraud povtseg epitaxial, thaum lub hardness ntawm SiC wafer ua kom zoo wafer thinning thiab txhim khu kev qha khoom ntim. Qhov no ua rau SiC wafer mus rau lub platform rau lub zog siab, kev siv lub neej ntev LED.

SiC wafer's Q&A

1. Q: SiC wafers ua li cas?

A:

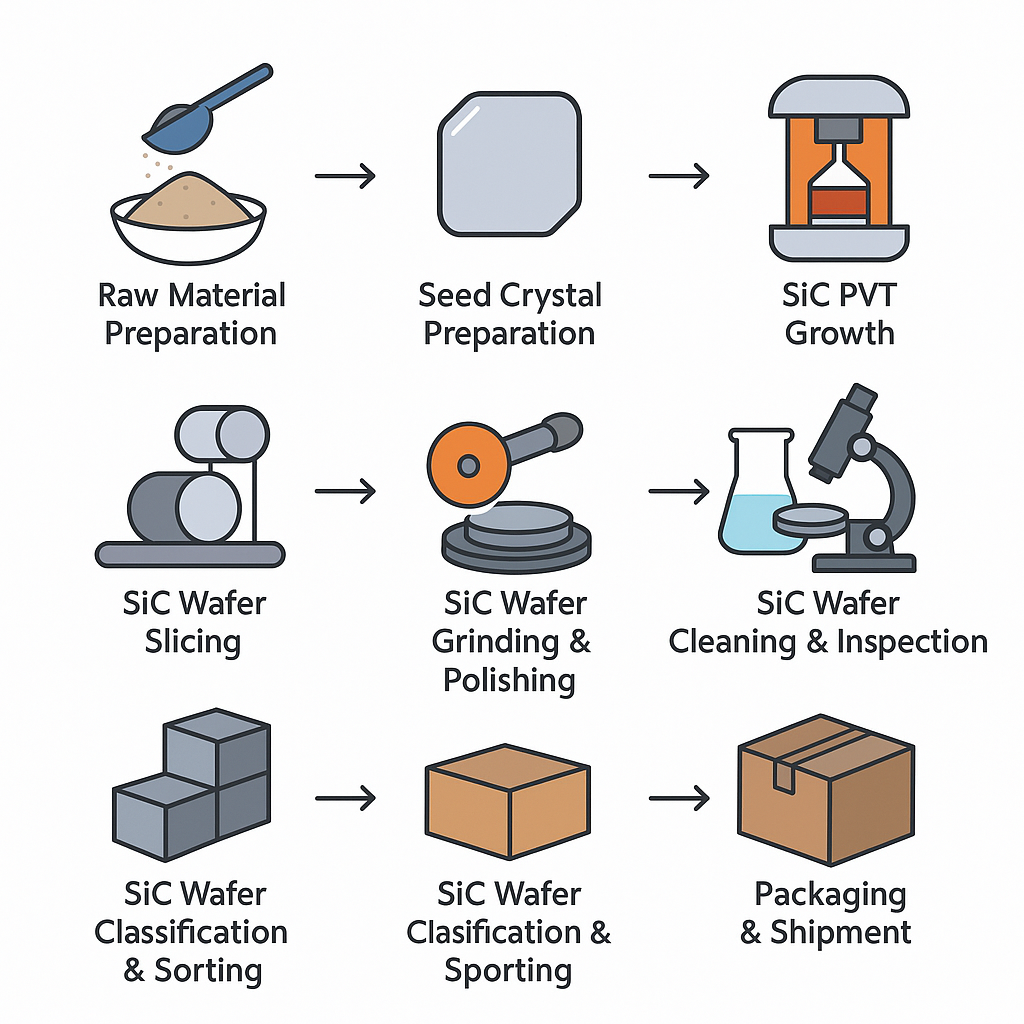

SiC wafers tsimCov kauj ruam ntxaws

-

SiC wafersKev npaj raw khoom

- Siv ≥5N-qib SiC hmoov (impurities ≤1 ppm).

- Sieve thiab ua ntej ci kom tshem tawm cov residual carbon los yog nitrogen tebchaw.

-

SiCNoob Crystal Npaj

-

Siv ib daim ntawm 4H-SiC ib leeg siv lead ua, hlais raws 〈0001〉 kev taw qhia rau ~ 10 × 10 mm².

-

Precision polish rau Ra ≤0.1 nm thiab kos cim siv lead ua orientation.

-

-

SiCPVT Kev Loj Hlob (lub cev vapor thauj)

-

Load graphite crucible: hauv qab nrog SiC hmoov, sab saum toj nrog cov noob siv lead ua.

-

Tshem tawm mus rau 10⁻³–10⁻⁵ Torr lossis rov qab nrog cov purity helium ntawm 1 atm.

-

Tshav kub qhov chaw rau 2100-2300 ℃, tswj cov noob thaj tsam 100-150 ℃ txias.

-

Tswj kev loj hlob ntawm 1-5 mm / h kom sib npaug zoo thiab dhau los.

-

-

SiCIngot Annealing

-

Anneal li-loj SiC ingot ntawm 1600-1800 ℃ rau 4-8 teev.

-

Lub hom phiaj: txo cov thermal stresses thiab txo dislocation ceev.

-

-

SiCWafer Slicing

-

Siv lub pob zeb diamond hlau hlais cov ingot rau hauv 0.5-1 hli tuab wafers.

-

Txo kev vibration thiab lateral quab yuam kom tsis txhob muaj microcracks.

-

-

SiCWaferSib tsoo & Polishing

-

Coarse sib tsootshem tawm kev puas tsuaj (roughness ~ 10-30 µm).

-

Kev sib tsoo zookom ua tiav flatness ≤5 µm.

-

Tshuaj-Mechanical Polishing (CMP)kom ncav cuag daim iav zoo li tiav (Ra ≤0.2 nm).

-

-

SiCWaferNtxuav & Tshuaj xyuas

-

Ultrasonic tuhauv Piranha tov (H₂SO₄:H₂O₂), DI dej, ces IPA.

-

XRD / Raman spectroscopykom paub meej polytype (4H, 6H, 3C).

-

Interferometryntsuas flatness (<5 µm) thiab warp (<20 µm).

-

Plaub-point sojntsuamtxhawm rau ntsuas kev tiv thaiv (xws li HPSI ≥10⁹ Ω·cm).

-

Kev tshuaj xyuas tsis raugnyob rau hauv polarized lub teeb microscope thiab khawb tester.

-

-

SiCWaferClassification & Sorting

-

Cais wafers los ntawm polytype thiab hluav taws xob hom:

-

4H-SiC N-hom (4H-N): cab kuj concentration 10¹⁶–10¹⁸ cm⁻³

-

4H-SiC High Purity Semi-Insulating (4H-HPSI): resistivity ≥10⁹ Ω·cm

-

6H-SiC N-hom (6H-N)

-

Lwm yam: 3C-SiC, P-hom, thiab lwm yam.

-

-

-

SiCWaferNtim & Xa khoom

2. Q: Dab tsi yog qhov zoo ntawm SiC wafers tshaj silicon wafers?

A: Piv rau silicon wafers, SiC wafers pab:

-

Kev ua haujlwm siab dua(> 1,200 V) nrog qis ntawm kev ua haujlwm.

-

Kev kub siab dua(> 300 ° C) thiab txhim kho thermal tswj.

-

Kev hloov pauv ceev duanrog kev hloov pauv qis dua, txo qhov system-qib txias thiab qhov loj me hauv lub zog hloov pauv.

4. Q: Cov teeb meem dab tsi cuam tshuam rau SiC wafer tawm los thiab kev ua haujlwm?

A: Cov teeb meem tseem ceeb hauv SiC wafers suav nrog micropipes, basal dav hlau dislocations (BPDs), thiab khawb nto. Micropipes tuaj yeem ua rau muaj kev puas tsuaj rau cov cuab yeej tsis ua haujlwm; BPDs nce qhov kev tiv thaiv thaum lub sijhawm; thiab khawb nto ua rau wafer tawg lossis tsis zoo epitaxial loj hlob. Kev soj ntsuam nruj thiab txo qhov tsis xws luag yog li ntawd qhov tseem ceeb los ua kom tiav SiC wafer tawm los.

Post lub sij hawm: Jun-30-2025