Hauv cov txheej txheem kev loj hlob ntawm kev lag luam semiconductor, cov khoom siv crystallized ib leegcov silicon wafersua lub luag haujlwm tseem ceeb. Lawv ua haujlwm ua cov khoom siv tseem ceeb rau kev tsim ntau yam khoom siv microelectronic. Txij li cov voj voog sib xyaw ua ke nyuaj thiab meej mus rau cov microprocessors ceev ceev thiab cov sensors ntau yam, cov siv lead ua ci ntsa iabcov silicon wafersyog qhov tseem ceeb. Qhov sib txawv ntawm lawv cov kev ua tau zoo thiab cov lus qhia tshwj xeeb cuam tshuam ncaj qha rau qhov zoo thiab kev ua tau zoo ntawm cov khoom kawg. Hauv qab no yog cov lus qhia tshwj xeeb thiab cov kev teeb tsa ntawm cov khoom siv ci ntsa iab ib leeg silicon wafers:

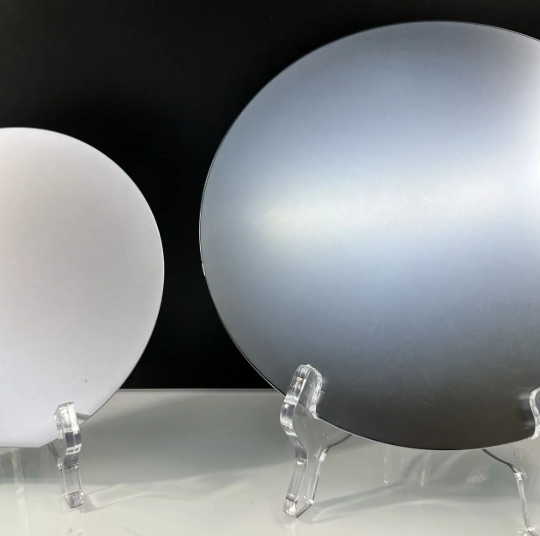

Txoj kab uas hla: Qhov loj ntawm cov semiconductor ib leeg siv lead ua silicon wafers yog ntsuas los ntawm lawv txoj kab uas hla, thiab lawv muaj ntau yam kev qhia tshwj xeeb. Txoj kab uas hla feem ntau suav nrog 2 nti (50.8mm), 3 nti (76.2mm), 4 nti (100mm), 5 nti (125mm), 6 nti (150mm), 8 nti (200mm), 12 nti (300mm), thiab 18 nti (450mm). Txoj kab uas hla sib txawv yog haum rau ntau yam kev xav tau ntau lawm thiab cov txheej txheem xav tau. Piv txwv li, cov wafers me dua feem ntau siv rau cov khoom siv microelectronic tshwj xeeb, me me, thaum cov wafers loj dua qhia txog kev ua haujlwm zoo dua thiab cov nqi zoo dua hauv kev tsim khoom loj. Cov kev xav tau ntawm qhov chaw yog cais ua ib sab polished (SSP) thiab ob sab polished (DSP). Ib sab polished wafers yog siv rau cov khoom siv uas xav tau qhov tiaj tiaj siab ntawm ib sab, xws li qee cov sensors. Ob sab polished wafers feem ntau siv rau cov integrated circuits thiab lwm yam khoom uas xav tau qhov precision siab ntawm ob qho chaw. Qhov Yuav Tsum Tau Ua (Tiav): Ib sab polished SSP / Ob sab polished DSP.

Hom/Dopant: (1) N-hom Semiconductor: Thaum qee cov impurity atoms raug nkag mus rau hauv lub intrinsic semiconductor, lawv hloov nws cov conductivity. Piv txwv li, thaum pentavalent cov ntsiab lus xws li nitrogen (N), phosphorus (P), arsenic (As), lossis antimony (Sb) raug ntxiv, lawv cov valence electrons tsim covalent bonds nrog cov valence electrons ntawm cov silicon atoms nyob ib puag ncig, tawm hauv ib qho electron ntxiv tsis khi los ntawm covalent bond. Qhov no ua rau muaj electron concentration ntau dua li qhov concentration ntawm qhov, tsim ib qho N-hom semiconductor, tseem hu ua electron-type semiconductor. N-hom semiconductors yog qhov tseem ceeb hauv kev tsim cov khoom siv uas xav tau electrons ua cov neeg nqa khoom tseem ceeb, xws li qee yam khoom siv fais fab. (2) P-hom Semiconductor: Thaum trivalent impurity elements xws li boron (B), gallium (Ga), lossis indium (In) raug nkag mus rau hauv silicon semiconductor, cov valence electrons ntawm cov impurity atoms tsim covalent bonds nrog cov silicon atoms nyob ib puag ncig, tab sis lawv tsis muaj tsawg kawg ib qho valence electron thiab tsis tuaj yeem tsim covalent bond tiav. Qhov no ua rau muaj qhov concentration ntau dua li qhov concentration ntawm electron, tsim cov P-type semiconductor, tseem hu ua qhov-type semiconductor. P-type semiconductors ua lub luag haujlwm tseem ceeb hauv kev tsim cov khoom siv uas qhov ua haujlwm ua cov khoom thauj loj, xws li diodes thiab qee cov transistors.

Kev Tiv Thaiv: Kev tiv thaiv yog qhov tseem ceeb ntawm lub cev uas ntsuas qhov kev ua hluav taws xob ntawm cov khoom siv ci ntsa iab silicon wafers. Nws tus nqi qhia txog cov khoom siv ua haujlwm. Qhov qis dua qhov resistivity, qhov zoo dua qhov conductivity ntawm silicon wafer; conversely, qhov siab dua qhov resistivity, qhov tsis zoo qhov conductivity. Qhov resistivity ntawm silicon wafers yog txiav txim siab los ntawm lawv cov khoom siv khoom, thiab qhov kub thiab txias kuj muaj qhov cuam tshuam loj heev. Feem ntau, qhov resistivity ntawm silicon wafers nce nrog rau qhov kub thiab txias. Hauv kev siv ua haujlwm, cov khoom siv microelectronic sib txawv muaj cov kev xav tau resistivity sib txawv rau silicon wafers. Piv txwv li, wafers siv hauv kev tsim khoom siv hluav taws xob sib xyaw xav tau kev tswj hwm qhov resistivity kom ntseeg tau tias cov khoom siv ruaj khov thiab txhim khu kev qha.

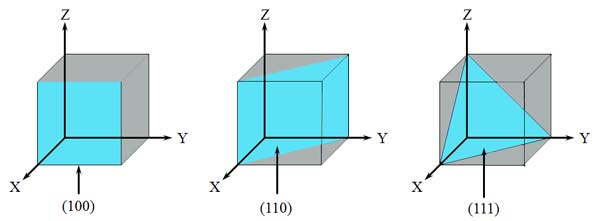

Kev Taw Qhia: Qhov kev taw qhia siv lead ua ntawm lub wafer sawv cev rau qhov kev taw qhia crystallographic ntawm lub silicon lattice, feem ntau teev los ntawm Miller cov ntsuas xws li (100), (110), (111), thiab lwm yam. Cov kev taw qhia siv lead ua sib txawv muaj cov khoom sib txawv, xws li qhov ceev ntawm kab, uas sib txawv raws li kev taw qhia. Qhov sib txawv no tuaj yeem cuam tshuam rau kev ua haujlwm ntawm wafer hauv cov kauj ruam ua tom ntej thiab kev ua haujlwm kawg ntawm cov khoom siv microelectronic. Hauv cov txheej txheem tsim khoom, kev xaiv lub silicon wafer nrog kev taw qhia tsim nyog rau cov kev xav tau sib txawv ntawm cov khoom siv tuaj yeem ua kom zoo dua kev ua haujlwm ntawm cov khoom siv, txhim kho kev ua haujlwm ntau lawm, thiab txhim kho cov khoom zoo.

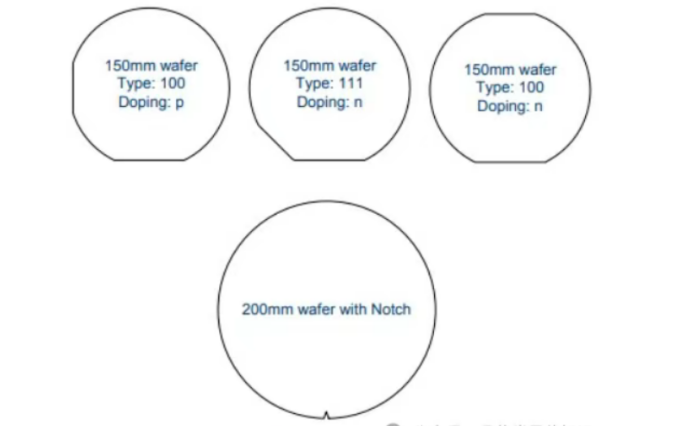

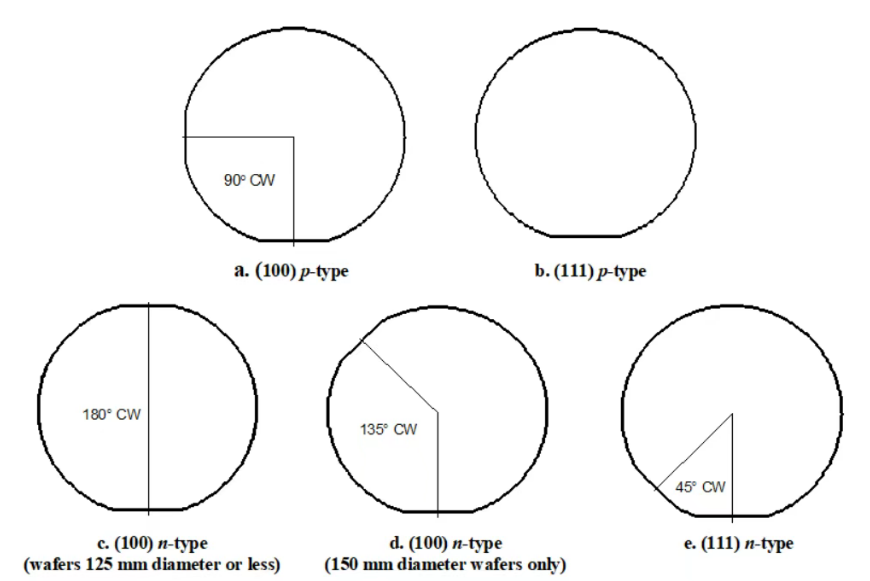

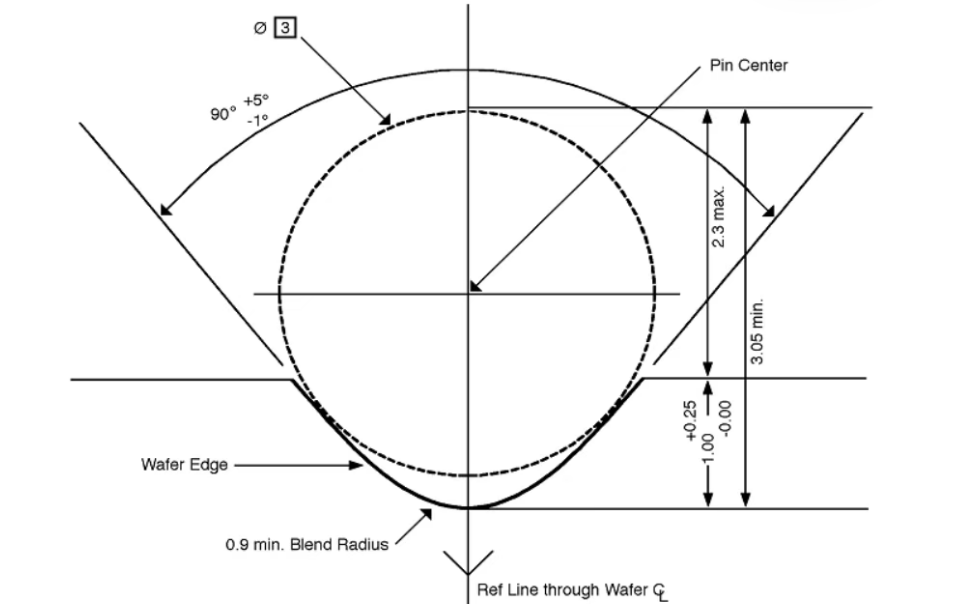

Tiaj/Notch: Ntug tiaj (Tiaj) lossis V-notch (Notch) ntawm qhov ncig ntawm lub silicon wafer ua lub luag haujlwm tseem ceeb hauv kev sib phim ntawm cov siv lead ua ke thiab yog qhov tseem ceeb hauv kev tsim khoom thiab kev ua cov wafer. Cov wafers ntawm ntau txoj kab uas hla sib xws rau cov qauv sib txawv rau qhov ntev ntawm Tiaj lossis Notch. Cov npoo sib phim raug faib ua thawj tiaj thiab thib ob tiaj. Lub tiaj thawj feem ntau yog siv los txiav txim siab qhov yooj yim ntawm cov siv lead ua ke thiab kev ua cov ntaub ntawv ntawm wafer, thaum lub tiaj thib ob pab txhawb kev sib phim thiab kev ua tiav, kom ntseeg tau tias kev ua haujlwm raug thiab kev sib xws ntawm wafer thoob plaws hauv kab ntau lawm.

Thickness: Qhov tuab ntawm lub wafer feem ntau yog teev nyob rau hauv micrometers (μm), nrog rau cov tuab sib xws ntawm 100μm thiab 1000μm. Wafers ntawm cov tuab sib txawv yog tsim rau ntau hom microelectronic khoom siv. Thinner wafers (piv txwv li, 100μm - 300μm) feem ntau yog siv rau kev tsim cov chip uas xav tau kev tswj hwm tuab nruj, txo qhov loj thiab qhov hnyav ntawm lub chip thiab ua kom qhov sib xyaw ua ke ntau dua. Thicker wafers (piv txwv li, 500μm - 1000μm) yog siv dav hauv cov khoom siv uas xav tau lub zog siab dua, xws li cov khoom siv hluav taws xob semiconductor, kom ntseeg tau tias muaj kev ruaj khov thaum lub sijhawm ua haujlwm.

Qhov Roughness ntawm Qhov Chaw: Qhov roughness ntawm qhov chaw yog ib qho ntawm cov yam tseem ceeb rau kev ntsuam xyuas qhov zoo ntawm wafer, vim nws cuam tshuam ncaj qha rau qhov kev sib txuas ntawm wafer thiab cov ntaub ntawv zaj duab xis nyias uas tau tso tom qab, nrog rau kev ua haujlwm hluav taws xob ntawm lub cuab yeej. Nws feem ntau yog qhia ua qhov roughness ntawm lub hauv paus nruab nrab (RMS) (hauv nm). Qhov roughness ntawm qhov chaw qis dua txhais tau tias qhov chaw wafer du dua, uas pab txo cov xwm txheej zoo li kev tawg ntawm hluav taws xob thiab txhim kho kev ua haujlwm ntawm lub cuab yeej thiab kev ntseeg siab. Hauv cov txheej txheem tsim khoom semiconductor siab heev, cov kev xav tau ntawm qhov chaw roughness tau dhau los ua qhov nruj dua, tshwj xeeb tshaj yog rau kev tsim khoom siv hluav taws xob siab, qhov twg qhov roughness ntawm qhov chaw yuav tsum tau tswj hwm rau ob peb nanometers lossis qis dua.

Kev Hloov Pauv Tag Nrho Thickness (TTV): Kev hloov pauv tag nrho cov tuab yog hais txog qhov sib txawv ntawm qhov siab tshaj plaws thiab qhov tsawg kawg nkaus tuab ntsuas ntawm ntau qhov chaw ntawm qhov chaw wafer, feem ntau qhia hauv μm. TTV siab yuav ua rau muaj kev hloov pauv hauv cov txheej txheem xws li photolithography thiab etching, cuam tshuam rau kev ua haujlwm ntawm cov khoom siv thiab cov txiaj ntsig. Yog li ntawd, kev tswj TTV thaum lub sijhawm tsim khoom wafer yog ib kauj ruam tseem ceeb hauv kev ua kom cov khoom zoo. Rau kev tsim khoom siv microelectronic siab, TTV feem ntau yuav tsum nyob hauv ob peb micrometers.

Hneev: Hneev yog hais txog qhov sib txawv ntawm qhov chaw ntawm lub wafer thiab lub dav hlau tiaj tiaj, feem ntau ntsuas hauv μm. Cov wafers uas muaj kev khoov ntau dhau yuav tawg lossis muaj kev ntxhov siab tsis sib xws thaum lub sijhawm ua tiav tom qab, cuam tshuam rau kev ua haujlwm zoo thiab cov khoom zoo. Tshwj xeeb tshaj yog nyob rau hauv cov txheej txheem uas xav tau qhov tiaj tiaj siab, xws li photolithography, kev khoov yuav tsum tau tswj hwm hauv qhov ntau yam tshwj xeeb kom ntseeg tau tias qhov tseeb thiab kev sib xws ntawm cov qauv photolithographic.

Kev Ntshaw: Kev Ntshaw qhia txog qhov sib txawv ntawm qhov chaw ntawm lub wafer thiab lub duab kheej kheej zoo tagnrho, kuj ntsuas hauv μm. Zoo ib yam li lub hneev, kev ntxhaw yog ib qho cim qhia tseem ceeb ntawm kev tiaj tus ntawm lub wafer. Kev ntxhaw ntau dhau tsis yog tsuas yog cuam tshuam rau qhov tseeb ntawm qhov chaw ntawm lub wafer hauv cov khoom siv ua haujlwm xwb tab sis kuj tseem tuaj yeem ua rau muaj teeb meem thaum lub sijhawm ntim khoom, xws li kev sib txuas tsis zoo ntawm lub chip thiab cov khoom ntim, uas ua rau cuam tshuam rau kev ntseeg tau ntawm lub cuab yeej. Hauv kev tsim khoom semiconductor siab kawg, cov kev xav tau ntawm kev ntxhaw tau dhau los ua qhov nruj dua kom tau raws li qhov xav tau ntawm kev tsim khoom chip thiab cov txheej txheem ntim khoom siab heev.

Cov Qauv Ntug: Cov qauv ntug ntawm lub wafer yog qhov tseem ceeb rau nws cov txheej txheem tom qab thiab kev tuav. Nws feem ntau yog teev los ntawm Edge Exclusion Zone (EEZ), uas txhais qhov deb ntawm ntug wafer uas tsis pub ua tiav. Cov qauv ntug tsim kom zoo thiab kev tswj hwm EEZ kom raug pab tiv thaiv cov qhov tsis zoo ntawm ntug, kev ntxhov siab, thiab lwm yam teeb meem thaum lub sijhawm ua tiav, txhim kho qhov zoo ntawm wafer thiab cov txiaj ntsig. Hauv qee cov txheej txheem tsim khoom siab heev, qhov tseeb ntawm cov qauv ntug yuav tsum nyob rau theem sub-micron.

Kev suav cov khoom me me: Tus lej thiab qhov loj ntawm cov khoom me me ntawm qhov chaw wafer cuam tshuam rau kev ua haujlwm ntawm cov khoom siv microelectronic. Cov khoom me me ntau dhau lossis loj tuaj yeem ua rau cov khoom siv tsis ua haujlwm, xws li luv luv lossis xau, txo cov khoom tsim tawm. Yog li ntawd, kev suav cov khoom me me feem ntau yog ntsuas los ntawm kev suav cov khoom me me ib cheeb tsam, xws li tus lej ntawm cov khoom me me loj dua 0.3μm. Kev tswj hwm nruj ntawm kev suav cov khoom me me thaum lub sijhawm tsim khoom wafer yog qhov tseem ceeb rau kev ua kom cov khoom zoo. Cov thev naus laus zis ntxuav siab heev thiab ib puag ncig huv si yog siv los txo cov khoom me me ntawm qhov chaw wafer.

![]()

![]()

![]()

![]()

![]()

Kev tsim khoom cuam tshuam

Ib Leeg Crystal Silicon Wafer Si Substrate Hom N/P Xaiv tau Silicon Carbide Wafer

FZ CZ Si wafer hauv Tshuag 12 nti Silicon wafer Prime lossis Test

Lub sijhawm tshaj tawm: Plaub Hlis-18-2025