Nrog rau kev txhim kho txuas ntxiv ntawm cov thev naus laus zis thev naus laus zis, hauv kev lag luam semiconductor thiab txawm tias kev lag luam photovoltaic, cov kev xav tau rau qhov zoo ntawm daim ntawv wafer substrate lossis epitaxial ntawv tseem nruj heev. Yog li, dab tsi yog qhov kev xav tau zoo rau wafers? nojsapphire wafers ua piv txwv, cov ntsuas dab tsi tuaj yeem siv los ntsuas qhov zoo ntawm wafers?

Dab tsi yog qhov ntsuas ntsuas wafers?

Peb qhov ntsuas

Rau sapphire wafers, nws cov ntsuas ntsuas yog tag nrho thickness sib txawv (TTV), khoov (Bow) thiab Warp (Warp). Peb qhov kev ntsuas no ua ke qhia txog qhov flatness thiab thickness uniformity ntawm silicon wafer, thiab tuaj yeem ntsuas qhov degree ntawm ripple ntawm wafer. Lub corrugation tuaj yeem ua ke nrog lub tiaj tiaj los ntsuas qhov zoo ntawm wafer nto.

TTV, BOW, Warp yog dab tsi?

TTV (Tag nrho Thickness Variation)

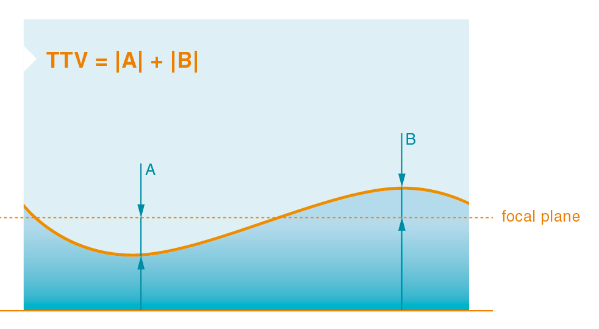

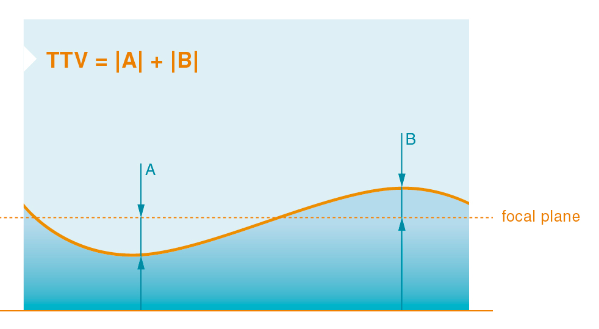

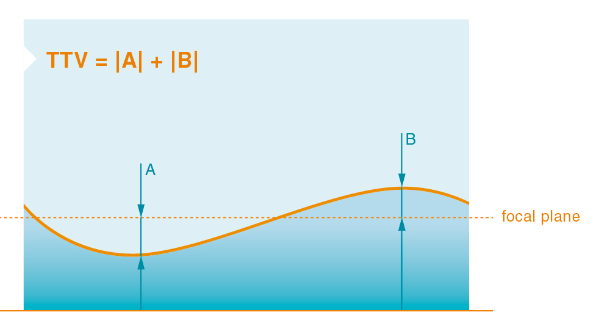

TTV yog qhov txawv ntawm qhov siab tshaj plaws thiab qhov tsawg kawg nkaus thickness ntawm wafer. Qhov no parameter yog ib qho tseem ceeb index siv los ntsuas wafer thickness uniformity. Nyob rau hauv ib tug txheej txheem semiconductor, lub thickness ntawm lub wafer yuav tsum yog heev sib xws nyob rau hauv tag nrho cov nto. Kev ntsuas feem ntau yog ua nyob rau tsib qhov chaw ntawm lub wafer thiab qhov sib txawv yog xam. Thaum kawg, tus nqi no yog lub hauv paus tseem ceeb rau kev txiav txim siab qhov zoo ntawm wafer.

Hneev

Hneev nyob rau hauv semiconductor manufacturing hais txog qhov khoov ntawm ib tug wafer, freeing qhov kev ncua deb ntawm lub midpoint ntawm ib tug unclamped wafer thiab lub dav hlau siv. Lo lus tej zaum yog los ntawm kev piav qhia ntawm cov duab ntawm ib yam khoom thaum nws khoov, zoo li cov duab nkhaus ntawm hneev. Tus nqi Bow yog txhais los ntawm kev ntsuas qhov sib txawv ntawm qhov nruab nrab thiab ntug ntawm silicon wafer. Tus nqi no feem ntau qhia hauv micrometers (µm).

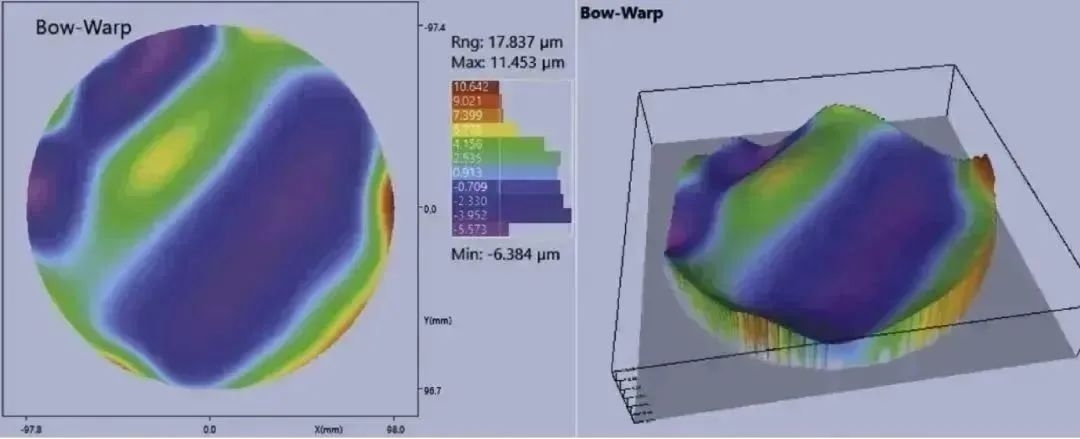

Warp

Warp yog lub ntiaj teb cov cuab yeej ntawm wafers uas ntsuas qhov sib txawv ntawm qhov siab tshaj plaws thiab qhov tsawg kawg nkaus ntawm qhov nruab nrab ntawm ib qho kev ywj pheej wafer thiab lub dav hlau siv. Sawv cev qhov deb ntawm qhov chaw ntawm silicon wafer mus rau lub dav hlau.

Qhov txawv ntawm TTV, Bow, Warp yog dab tsi?

TTV tsom rua kev hloov ntawm tuab thiab tsis cuam tshuam nrog kev khoov lossis distortion ntawm wafer.

Hneev tsom rau ntawm qhov khoov tag nrho, feem ntau xav txog qhov khoov ntawm qhov chaw nruab nrab thiab ntug.

Warp yog qhov dav dua, suav nrog khoov thiab sib tw ntawm tag nrho wafer nto.

Txawm hais tias peb qhov kev ntsuas no muaj feem xyuam nrog cov duab thiab cov duab geometric ntawm silicon wafer, lawv tau ntsuas thiab piav qhia txawv, thiab lawv qhov cuam tshuam rau cov txheej txheem semiconductor thiab kev ua wafer kuj txawv.

Qhov me me ntawm peb qhov ntsuas, qhov zoo dua, thiab qhov loj dua qhov ntsuas, qhov loj dua qhov tsis zoo ntawm cov txheej txheem semiconductor. Yog li ntawd, raws li ib tug kws xyaum semiconductor, peb yuav tsum paub qhov tseem ceeb ntawm wafer profile tsis rau tag nrho cov txheej txheem, ua semiconductor txheej txheem, yuav tsum xyuam xim rau cov ntsiab lus.

(censoring)

Post lub sij hawm: Jun-24-2024