12 nti SiC Substrate N Hom Loj Loj Siab Ua Haujlwm RF Daim Ntawv Thov

Technical parameters

| 12 nti Silicon Carbide (SiC) Substrate Specification | |||||

| Qib | ZeroMPD Production Qib (Z Qib) | Txuj ntau lawm Qib (P Qib) | Dummy Qib (D Qib) | ||

| Txoj kab uas hla | 300mm ~ 1305mm | ||||

| Thickness | 4 H-N | 750μm ± 15μm | 750μm ± 25μm | ||

| 4 H-SI | 750μm ± 15μm | 750μm ± 25μm | |||

| Wafer Orientation | Tawm axis: 4.0 ° mus rau <1120> ± 0.5 ° rau 4H-N, On axis: <0001> ± 0.5 ° rau 4H-SI | ||||

| Micropipe ntom ntom | 4 H-N | ≤0.4cm-2 | ≤4cm-2 | ≤25cm-2 | |

| 4 H-SI | ≤5cm-2 | ≤10cm-2 | ≤25cm-2 | ||

| Kev tiv thaiv | 4 H-N | 0.015 ~ 0.024 Ω·cm | 0.015 ~ 0.028 Ω·cm | ||

| 4 H-SI | ≥1E10 Ω·cm | ≥1E5 Ω·cm | |||

| Thawj Txoj Kev Ncaj Ncees | {10-10} ± 5.0° | ||||

| Qhov Loj Loj Loj | 4 H-N | N/A | |||

| 4 H-SI | Ntsig | ||||

| Ntug Exclusion | 3 hli | ||||

| LTV/TTV/How/Warp | ≤5μm / ≤15μm / ≤35μm / ≤55μm | ≤ 5μm / ≤15μm / ≤35 □ μm / ≤55 □ μm | |||

| Roughness | Polish Ra≤1nm | ||||

| CMP Ra≤0.2nm | Ra≤0.5nm | ||||

| Ntug Cracks Los ntawm High Intensity Light Hex Phaj Los Ntawm Lub Teeb Siab Siab Polytype Areas Los ntawm High Intensity Light Visual Carbon suav nrog Silicon Surface Scratches Los ntawm High Intensity Light | Tsis muaj Thaj tsam ≤ 0.05% Tsis muaj Thaj tsam ≤ 0.05% Tsis muaj | Qhov ntev ≤ 20 hli, ib qhov ntev ≤ 2 hli Qhov loj me ≤0.1% Thaj tsam ≤ 3% Qhov loj me ≤ 3% Qhov ntev ≤1 × wafer txoj kab uas hla | |||

| Ntug Chips Los ntawm High Intensity Light | Tsis muaj kev tso cai ≥0.2mm dav thiab qhov tob | 7 tso cai, ≤1mm txhua | |||

| (TSD) Threading ntsia hlau dislocation | ≤500cm-2 | N/A | |||

| (BPD) Base dav hlau dislocation | ≤1000cm-2 | N/A | |||

| Silicon Surface Contamination Los ntawm High Intensity Light | Tsis muaj | ||||

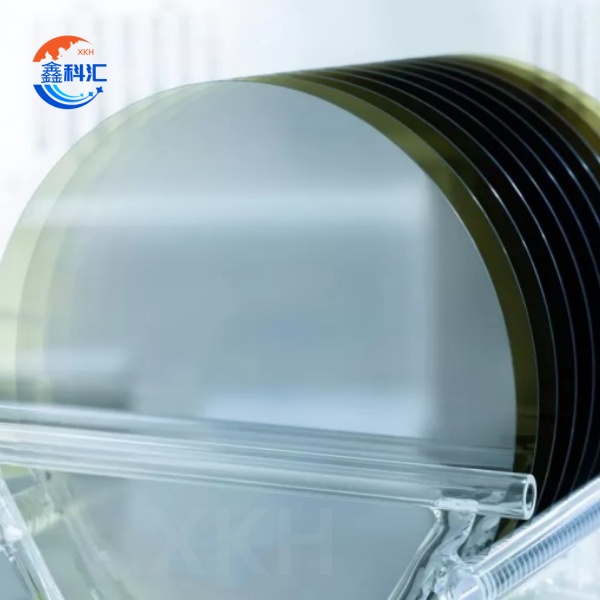

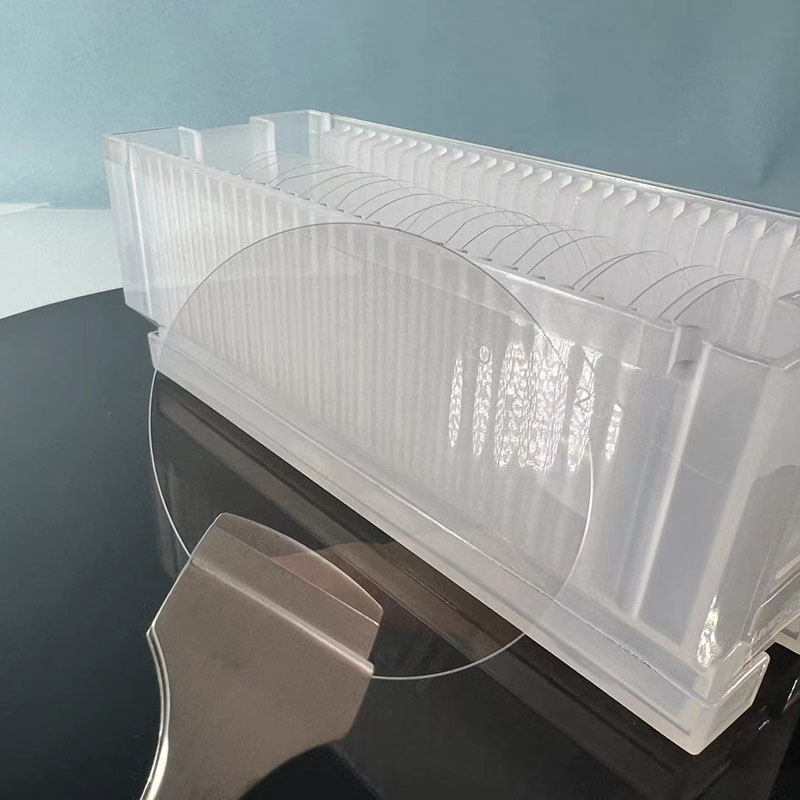

| Ntim | Multi-wafer Cassette lossis Ib Lub Thawv Wafer | ||||

| Nco tseg: | |||||

| 1 Cov kev txwv tsis raug siv rau tag nrho wafer nto tshwj tsis yog rau thaj tsam ntawm ntug kev cais tawm. 2 Cov khawb yuav tsum tau kuaj xyuas ntawm Si ntsej muag nkaus xwb. 3 Cov ntaub ntawv dislocation tsuas yog los ntawm KOH etched wafers. | |||||

Cov yam ntxwv tseem ceeb

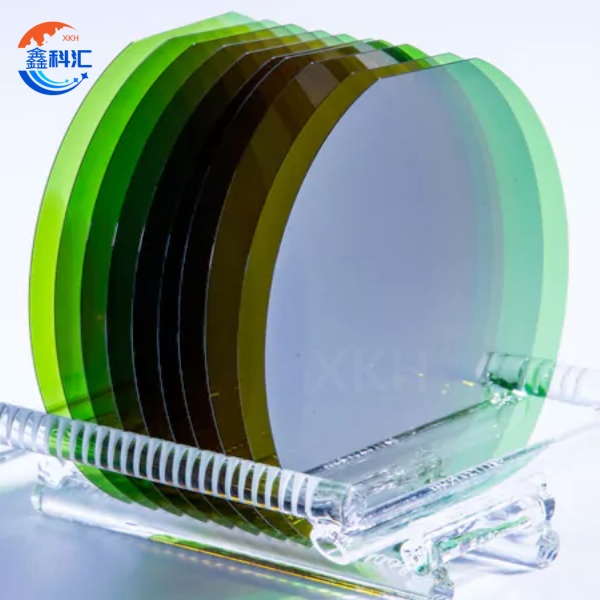

1. Qhov Zoo Tshaj Loj Loj: 12-nti SiC substrate (12-nti silicon carbide substrate) muaj thaj tsam loj dua ib qho wafer, ua kom muaj ntau cov chips los tsim ib lub wafer, yog li txo cov nqi tsim khoom thiab nce yield.

2. Cov Khoom Siv Ua Haujlwm Zoo: Silicon carbide qhov kub thiab txias ua haujlwm siab ua rau 12-nti substrate zoo tagnrho rau high-voltage thiab high-frequency daim ntaub ntawv, xws li EV inverters thiab fast-charging systems.

3. Kev Ua Tau Zoo: Txawm tias muaj kev nyuaj siab thiab kev ua haujlwm nyuaj ntawm SiC, 12-nti SiC substrate ua tiav qhov tsis xws luag hauv qab ntawm cov txheej txheem txiav thiab polishing, txhim kho cov khoom tawm los.

4. Superior Thermal Management: Nrog rau cov thermal conductivity zoo dua li cov khoom siv silicon, 12-nti substrate ua haujlwm tau zoo thaum tshav kub kub dissipation hauv cov cuab yeej siv hluav taws xob siab, ua kom cov cuab yeej siv tau ntev.

Cov ntawv thov tseem ceeb

1. Lub Tsheb Hluav Taws Xob: Lub 12-nti SiC substrate (12-nti silicon carbide substrate) yog lub hauv paus tseem ceeb ntawm cov tshuab hluav taws xob txuas ntxiv mus, ua kom muaj txiaj ntsig zoo inverters uas txhim kho ntau yam thiab txo lub sijhawm them nyiaj.

2. 5G Base Stations: Loj-loj SiC substrates txhawb nqa cov khoom siv RF zaus, ua tau raws li qhov xav tau ntawm 5G hauv paus chaw nres tsheb rau lub zog siab thiab poob qis.

3.Industrial Power Supplies: Nyob rau hauv hnub ci inverters thiab cov phiajcim ntse, 12-nti substrate tuaj yeem tiv taus qhov hluav taws xob ntau dua thaum txo qis zog.

4.Consumer Electronics: Yav tom ntej ceev chargers thiab cov ntaub ntawv chaw fais fab khoom siv yuav siv 12-nti SiC substrates kom ua tau raws li qhov loj me thiab ua haujlwm zoo dua.

XKH's Services

Peb tshwj xeeb hauv kev pabcuam ua haujlwm rau 12-nti SiC substrates (12-nti silicon carbide substrates), suav nrog:

1. Dicing & Polishing: Tsawg-kev puas tsuaj, high-flatness substrate ua raws li cov neeg siv khoom xav tau, kom ntseeg tau tias cov cuab yeej ruaj khov.

2. Kev Txhawb Kev Loj Hlob Epitaxial: Cov kev pabcuam zoo epitaxial wafer kom ceev cov chips raug tsim.

3. Small-Batch Prototyping: Txhawb R & D validation rau kev tshawb fawb cov koom haum thiab kev lag luam, shortening txoj kev loj hlob mus.

4. Kev Pabcuam Kev Pabcuam: Cov kev daws teeb meem kawg-rau-kawg los ntawm kev xaiv cov khoom siv rau kev ua kom zoo dua qub, pab cov neeg siv khoom kov yeej SiC cov kev cov nyom.

Txawm hais tias yog rau kev tsim khoom loj lossis kev tsim tshwj xeeb, peb cov kev pabcuam 12-nti SiC substrate ua raws li koj qhov kev xav tau, txhawb kev ua haujlwm thev naus laus zis.