12 nti SIC substrate silicon carbide prime qib txoj kab uas hla 300mm loj loj 4H-N Haum rau siab zog ntaus ntawv kub dissipation

Cov yam ntxwv ntawm cov khoom

1. High thermal conductivity: thermal conductivity ntawm silicon carbide yog ntau tshaj 3 npaug ntawm silicon, uas yog haum rau high-power ntaus ntawv tshav kub dissipation.

2. High breakdown field strength: Lub zog tawg yog 10 npaug ntawm silicon, haum rau kev siv siab.

3.Wide bandgap: Lub bandgap yog 3.26eV (4H-SiC), haum rau kev kub siab thiab kev siv ntau zaus.

4. High hardness: Mohs hardness yog 9.2, thib ob tsuas yog pob zeb diamond, zoo heev hnav tsis kam thiab txhua yam muaj zog.

5. Chemical stability: muaj zog corrosion kuj, ruaj khov kev ua tau zoo nyob rau hauv high kub thiab hnyav ib puag ncig.

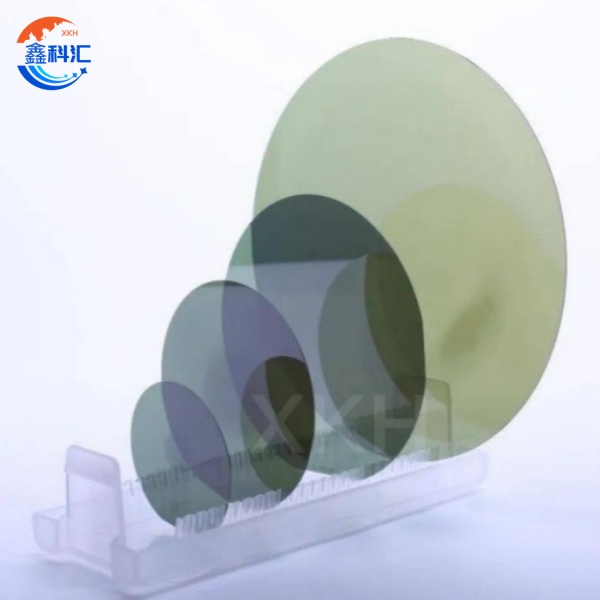

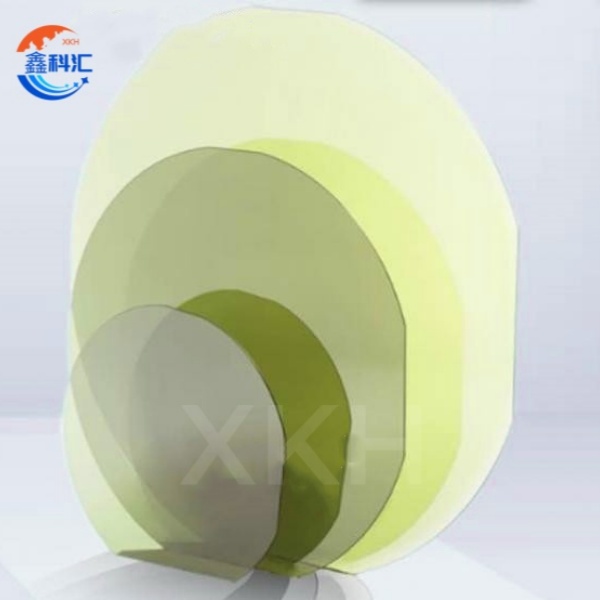

6. Loj loj: 12 nti (300mm) substrate, txhim kho kev tsim khoom, txo nqi tsev.

7.Low defect density: siab zoo ib leeg siv lead ua kev loj hlob technology los xyuas kom meej qhov tsis xws luag thiab siab sib xws.

Cov khoom tseem ceeb daim ntawv thov kev taw qhia

1. Lub zog hluav taws xob:

Mosfets: Siv nyob rau hauv lub tsheb fais fab, industrial motor drives thiab fais fab converters.

Diodes: xws li Schottky diodes (SBD), siv rau kev kho kom zoo thiab hloov cov khoom siv hluav taws xob.

2. Cov khoom siv rf:

Rf fais fab amplifier: siv nyob rau hauv 5G kev sib txuas lus hauv paus chaw nres tsheb thiab satellite kev sib txuas lus.

Microwave li: Tsim nyog rau radar thiab wireless kev sib txuas lus systems.

3. Lub zog tshiab tsheb:

Electric tsav systems: lub cev muaj zog controllers thiab inverters rau hluav taws xob tsheb.

Charger pawg: Fais fab module rau cov khoom siv ceev ceev.

4. Muaj kev siv:

High voltage inverter: rau kev tswj lub cev muaj zog thiab tswj lub zog.

Daim phiaj ntse: Rau HVDC kis tau tus mob thiab lub zog hluav taws xob hloov hluav taws xob.

5. Aerospace:

Cov khoom siv hluav taws xob kub kub: haum rau qhov kub thiab txias ib puag ncig ntawm cov khoom siv aerospace.

6. Kev tshawb fawb teb:

Kev tshawb fawb dav dav bandgap semiconductor: rau kev txhim kho cov ntaub ntawv tshiab thiab cov khoom siv semiconductor.

Lub 12-nti silicon carbide substrate yog ib hom kev ua tau zoo ntawm cov khoom siv semiconductor substrate nrog cov khoom zoo xws li thermal conductivity, siab tawg teb lub zog thiab dav band sib txawv. Nws yog dav siv nyob rau hauv lub hwj chim electronics, xov tooj cua zaus li, tshiab zog tsheb, industrial tswj thiab aerospace, thiab yog ib tug tseem ceeb cov ntaub ntawv los txhawb txoj kev loj hlob ntawm cov tiam tom ntej ntawm npaum thiab high-power electronics.

Thaum silicon carbide substrates tam sim no muaj tsawg dua kev siv hluav taws xob hauv cov neeg siv khoom siv hluav taws xob xws li AR tsom iav, lawv lub peev xwm hauv kev tswj hwm lub zog thiab cov khoom siv hluav taws xob me me tuaj yeem txhawb nqa lub teeb yuag, kev ua haujlwm siab ntawm cov khoom siv AR / VR yav tom ntej. Tam sim no, txoj kev loj hlob tseem ceeb ntawm silicon carbide substrate yog concentrated nyob rau hauv kev lag luam teb xws li tshiab zog tsheb, kev sib txuas lus infrastructure thiab industrial automation, thiab txhawb kev lag luam semiconductor los txhim kho nyob rau hauv ib tug ntau npaum thiab txhim khu kev qha kev taw qhia.

XKH tau cog lus los muab cov khoom zoo 12 "SIC substrates nrog kev txhawb nqa thiab kev pabcuam, suav nrog:

1. Customized ntau lawm: Raws li cov neeg siv khoom xav tau los muab qhov sib txawv resistivity, siv lead ua orientation thiab deg kho substrate.

2. Txheej txheem optimization: Muab cov neeg siv khoom nrog kev txhawb nqa ntawm epitaxial kev loj hlob, kev tsim khoom thiab lwm yam txheej txheem los txhim kho cov khoom ua haujlwm.

3. Kev ntsuam xyuas thiab ntawv pov thawj: Muab cov kev kuaj xyuas nruj thiab cov ntawv pov thawj zoo los xyuas kom meej tias cov substrate ua tau raws li cov qauv kev lag luam.

4.R&d kev koom tes: Koom tes tsim cov khoom siv silicon carbide tshiab nrog cov neeg siv khoom los txhawb kev tsim kho thev naus laus zis.

Daim ntawv qhia

| 1 2 nti Silicon Carbide (SiC) Substrate Specification | |||||

| Qib | ZeroMPD Production Qib (Z Qib) | Txheem ntau lawm Qib (P Qib) | Dummy Qib (D Qib) | ||

| Txoj kab uas hla | 300 hli ~ 305mm | ||||

| Thickness | 4 H-N | 750μm ± 15μm | 750μm ± 25μm | ||

| 4 H-SI | 750μm ± 15μm | 750μm ± 25μm | |||

| Wafer Orientation | Tawm axis: 4.0 ° mus rau <1120> ± 0.5 ° rau 4H-N, On axis: <0001> ± 0.5 ° rau 4H-SI | ||||

| Micropipe ntom ntom | 4 H-N | ≤0.4cm-2 | ≤ 4cm-2 | ≤25cm-2 | |

| 4 H-SI | ≤5cm-2 | ≤10cm-2 | ≤25cm-2 | ||

| Kev tiv thaiv | 4 H-N | 0.015 ~ 0.024 Ω·cm | 0.015 ~ 0.028 Ω·cm | ||

| 4 H-SI | ≥1E10 Ω·cm | ≥1E5 Ω·cm | |||

| Thawj Txoj Kev Ncaj Ncees | {10-10} ± 5.0° | ||||

| Qhov Loj Loj Loj | 4 H-N | N/A | |||

| 4 H-SI | Ntsig | ||||

| Ntug Exclusion | 3 hli | ||||

| LTV/TTV/How/Warp | ≤5μm / ≤15μm / ≤35μm / ≤55μm | ≤ 5μm / ≤15μm / ≤35 □ μm / ≤55 □ μm | |||

| Roughness | Polish Ra≤1nm | ||||

| CMP Ra≤0.2nm | Ra≤0.5nm | ||||

| Ntug Cracks Los ntawm High Intensity Light Hex Phaj Los Ntawm Lub Teeb Siab Siab Polytype Areas Los Ntawm Lub Teeb Siab Siab Visual Carbon suav nrog Silicon Surface Scratches Los ntawm High Intensity Light | Tsis muaj Thaj tsam ≤ 0.05% Tsis muaj Thaj tsam ≤ 0.05% Tsis muaj | Qhov ntev ≤ 20 hli, ib qhov ntev ≤ 2 hli Cov cheeb tsam sib sau ≤0.1% Thaj tsam ≤ 3% Qhov loj me ≤ 3% Qhov ntev ≤1 × wafer txoj kab uas hla | |||

| Ntug Chips Los ntawm High Intensity Light | Tsis muaj kev tso cai ≥0.2mm dav thiab qhov tob | 7 tso cai, ≤1mm txhua | |||

| (TSD) Threading ntsia hlau dislocation | ≤500cm-2 | N/A | |||

| (BPD) Base dav hlau dislocation | ≤1000cm-2 | N/A | |||

| Silicon Surface Contamination Los ntawm High Intensity Light | Tsis muaj | ||||

| Ntim | Multi-wafer Cassette lossis Ib Lub Thawv Wafer | ||||

| Nco tseg: | |||||

| 1 Cov kev txwv tsis raug siv rau tag nrho wafer nto tshwj tsis yog rau thaj tsam ntawm ntug kev cais tawm. 2 Cov khawb yuav tsum tau kuaj xyuas ntawm Si ntsej muag nkaus xwb. 3 Cov ntaub ntawv dislocation tsuas yog los ntawm KOH etched wafers. | |||||

XKH tseem yuav nqis peev rau hauv kev tshawb fawb thiab kev tsim kho los txhawb kev ua tiav ntawm 12-nti silicon carbide substrates hauv qhov loj, qhov tsis xws luag thiab siab sib xws, thaum XKH tshawb nrhiav nws cov ntawv thov hauv cov khoom siv hluav taws xob (xws li cov khoom siv hluav taws xob rau AR / VR) thiab quantum suav. Los ntawm kev txo cov nqi thiab nce peev xwm, XKH yuav coj kev vam meej rau kev lag luam semiconductor.

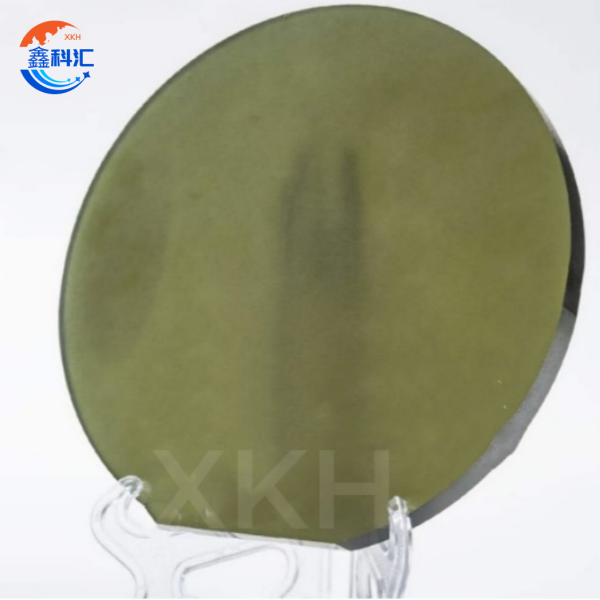

Daim duab qhia ntxaws