12inch Tag Nrho Tsis Siv Neeg Precision Dicing Pom Cov Khoom Siv Wafer Dedicated Cutting System rau Si / SiC & HBM (Al)

Technical parameters

| Parameter | Specification |

| Ua Haujlwm Loj | Φ8 ", Φ12" |

| Spindle | Dual-axis 1.2 / 1.8 / 2.4 / 3.0, Max 60000 rpm |

| Hniav Loj | 2 "~ 3" |

| Y1 / Y2 axis

| Ib kauj ruam nce ntxiv: 0.0001 hli |

| Positioning precision: <0.002 hli | |

| Txiav ntau yam: 310mm | |

| X axis | Pub ceev ntau yam: 0.1-600 mm / s |

| Z1 / Z2 Axis

| Ib kauj ruam nce ntxiv: 0.0001 hli |

| Positioning raug: ≤ 0.001 mm | |

| θ Axis | Qhov tseeb qhov tseeb: ± 15 " |

| Chaw nres tsheb ntxuav

| Kev sib hloov ceev: 100-3000 rpm |

| Txoj kev ntxuav: Nws pib yaug & tig-qhuav | |

| Kev khiav hauj lwm voltage | 3-theem 380V 50Hz |

| Qhov Loj (W × D × H) | 1550 × 1255 × 1880 hli |

| Qhov hnyav | 2100 kg ib |

Txoj Cai Ua Haujlwm

Cov cuab yeej ua tiav high-precision txiav los ntawm cov thev naus laus zis hauv qab no:

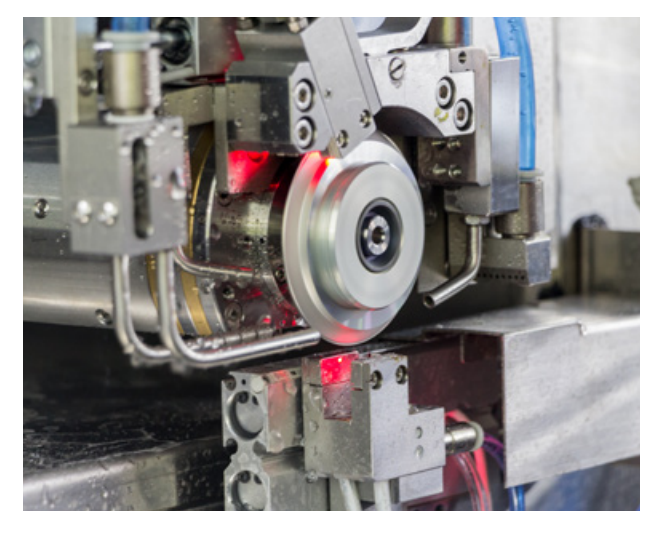

1.High-Rigidity Spindle System: Kev sib hloov ceev mus txog 60,000 RPM, nruab nrog pob zeb diamond hniav lossis laser txiav taub hau kom hloov mus rau cov khoom sib txawv.

2.Multi-Axis Motion Control: X / Y / Z-axis positioning raug ntawm ± 1μm, ua ke nrog high-precision grating scales kom paub meej qhov sib txawv-dawb txiav txoj kev.

3.Intelligent Visual Alignment: High-resolution CCD (5 megapixels) txiav txim siab txiav txoj kev thiab them nyiaj rau cov khoom warping lossis misalignment.

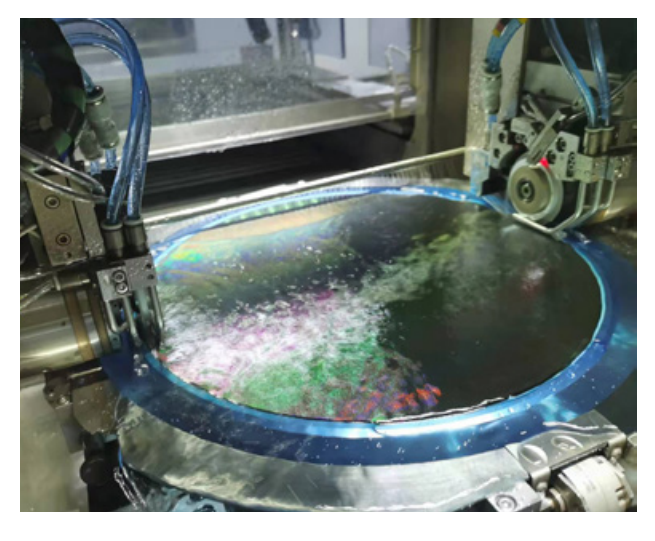

4.Cooling & Plua plav tshem tawm: Kev sib xyaw ua ke ntawm cov dej ntshiab huv thiab lub tshuab nqus tsev nqus plua plav tshem tawm kom txo qis thermal cuam tshuam thiab cov kab mob sib kis.

Txiav hom

1.Blade Dicing: Haum rau cov khoom siv semiconductor ib txwm muaj xws li Si thiab GaAs, nrog kerf dav ntawm 50-100μm.

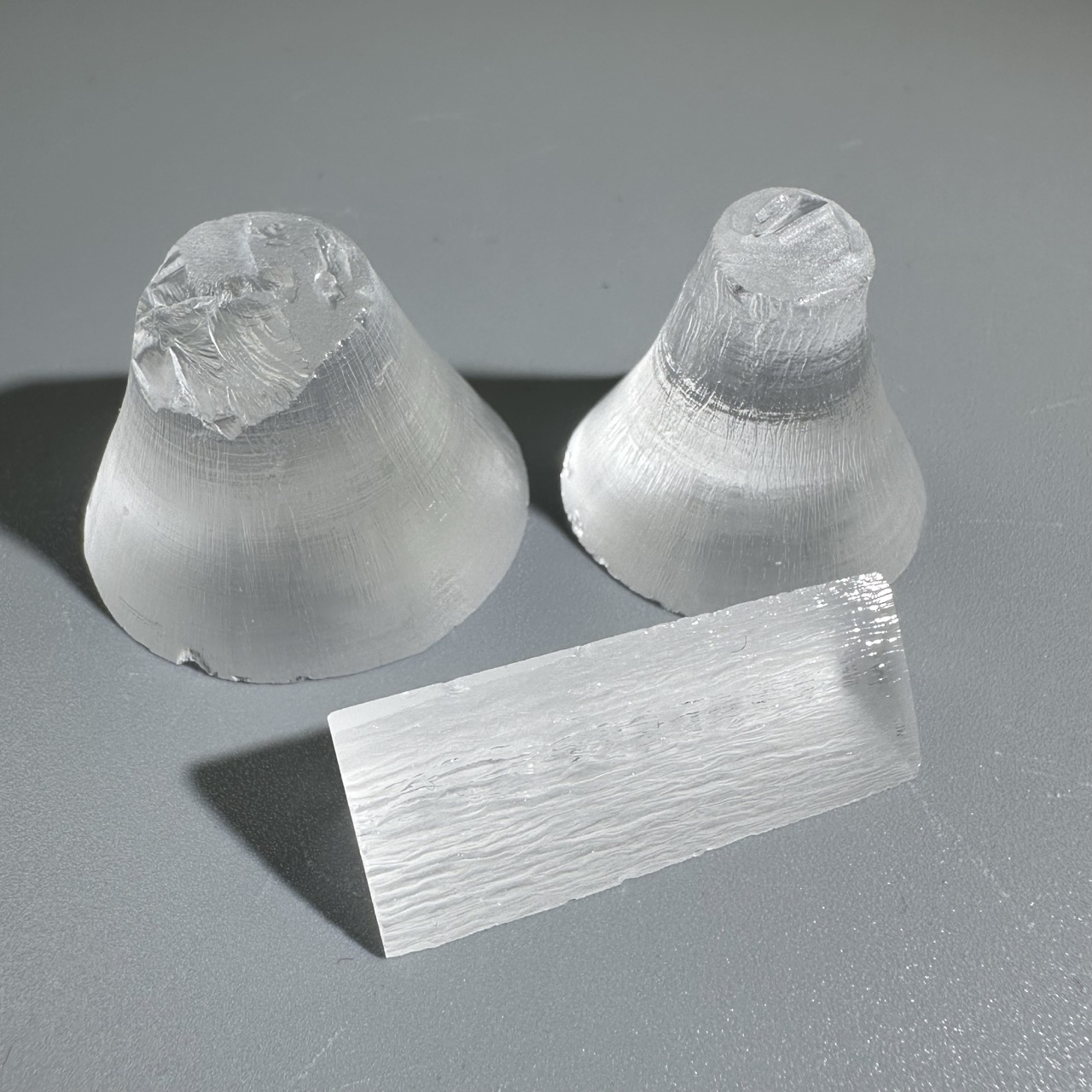

2.Stealth Laser Dicing: Siv rau ultra-thin wafers (<100μm) lossis cov ntaub ntawv tsis yooj yim (xws li LT/LN), ua kom muaj kev sib cais tsis muaj kev ntxhov siab.

Tej kev siv

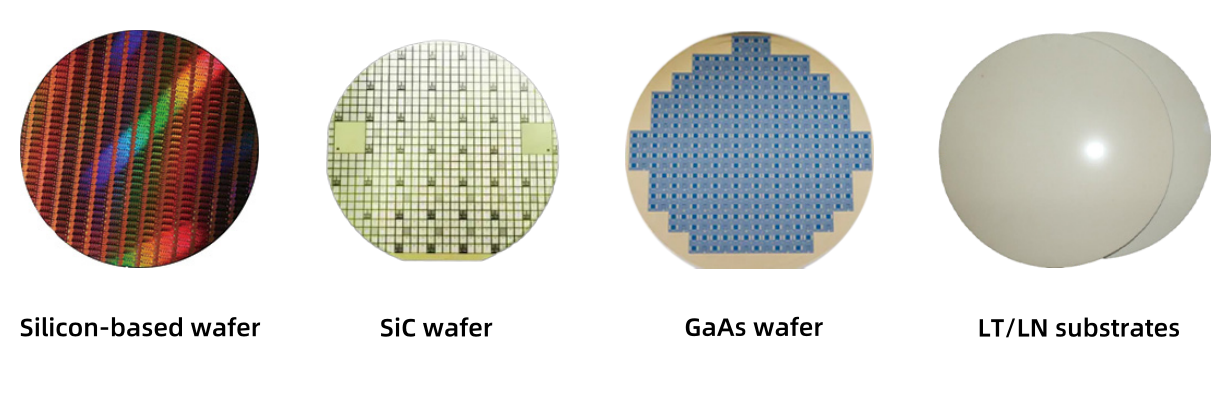

| Cov khoom siv sib xws | Daim ntawv thov teb | Kev yuav tsum tau ua |

| Silicon (Si) | ICs, MEMS sensors | High-precision txiav, chipping <10μm |

| Silicon Carbide (SiC) | Cov khoom siv fais fab (MOSFET / diodes) | Tsawg-kev puas tsuaj, thermal tswj optimization |

| Gallium Arsenide (GaAs) | Cov khoom siv RF, optoelectronic chips | Micro-crack tiv thaiv, tswj kev huv |

| LT/LN substrates | SAW filters, optical modulators | Txiav tsis muaj kev ntxhov siab, khaws cia piezoelectric zog |

| Ceramic substrates | Lub zog modules, LED ntim | High-hardness khoom ua, ntug flatness |

| QFN/DFN Frames | Advanced ntim | Multi-chip simultaneous txiav, efficiency optimization |

| WLCSP Wafers | Wafer-level ntim | Kev puas tsuaj-dawb dicing ntawm ultra-nyias wafers (50μm) |

Qhov zoo

1. High-speed cassette thav duab scanning nrog kev sib tsoo lub tswb ceeb toom, ceev hloov chaw, thiab muaj zog yuam kev-kho muaj peev xwm.

2. Optimized dual-spindle txiav hom, kev txhim kho efficiency kwv yees li 80% piv rau ib leeg-spindle systems.

3. Precision-imported pob screws, linear guides, thiab Y-axis grating scale kaw-voj tswj, kom ntseeg tau ntev stability ntawm high-precision machining.

4. Tag nrho automated loading / unloading, hloov chaw, sib dhos txiav, thiab kerf tshuaj xyuas, txo tus neeg teb xov tooj (OP) workload.

5.Gantry-style spindle mounting qauv, nrog qhov tsawg kawg nkaus dual-hluav taws qhov sib nrug ntawm 24 hli, ua kom dav dua adaptability rau dual-spindle txiav cov txheej txheem.

Nta

1.High-precision tsis tiv tauj qhov siab ntsuas.

2.Multi-wafer dual-blade txiav ntawm ib lub tais.

3. Tsis siv neeg calibration, kerf tshuaj xyuas, thiab cov hniav tawg kom paub cov tshuab.

4.Supports ntau yam txheej txheem nrog xaiv tsis siv neeg algorithms alignment.

5.Kev kho tus kheej ua haujlwm tsis raug thiab kev saib xyuas ntau txoj haujlwm ntawm lub sijhawm.

6.Thawj-txiav tshuaj ntsuam muaj peev xwm tom qab pib dicing.

7.Customizable Hoobkas automation modules thiab lwm yam kev xaiv ua haujlwm.

Cov khoom siv

Peb muab kev txhawb nqa los ntawm kev xaiv cov khoom siv mus rau kev saib xyuas mus sij hawm ntev:

(1) Customized Development

· Pom zoo cov hniav / laser txiav cov kev daws teeb meem raws li cov khoom siv (xws li SiC hardness, GaAs brittleness).

· Muab cov qauv kuaj dawb los kuaj xyuas qhov zoo (xws li chipping, kerf dav, nto roughness, thiab lwm yam).

(2) Kev cob qhia txuj ci

· Kev cob qhia yooj yim: Cov cuab yeej ua haujlwm, kev hloov pauv, kev saib xyuas niaj hnub.

· Cov Kev Kawm Qib Siab: Cov txheej txheem ua kom zoo rau cov ntaub ntawv nyuaj (piv txwv li, txiav tsis muaj kev ntxhov siab ntawm LT substrates).

(3) Kev them nyiaj yug tom qab muag

· 24/7 Teb: Kev kuaj mob nyob deb lossis kev pab ntawm qhov chaw.

· Spare Parts Supply: Stocked spindles, blades, and optical Cheebtsam rau kev hloov ceev.

· Kev Tiv Thaiv Kev Tiv Thaiv: Kev ntsuas tsis tu ncua kom tswj tau qhov tseeb thiab txuas ntxiv lub neej kev pabcuam.

Peb Qhov Zoo

✔ Kev Lag Luam Kev Lag Luam: Pab 300+ thoob ntiaj teb semiconductor thiab electronics manufacturers.

✔ Cutting-Edge Technology: Precision linear guides thiab servo systems kom muaj kev ruaj ntseg hauv kev lag luam.

✔ Ntiaj Teb Kev Pabcuam Network: Kev Pabcuam hauv Asia, Europe, thiab North America rau kev txhawb nqa hauv zos.

Rau kev sim lossis kev nug, tiv tauj peb!