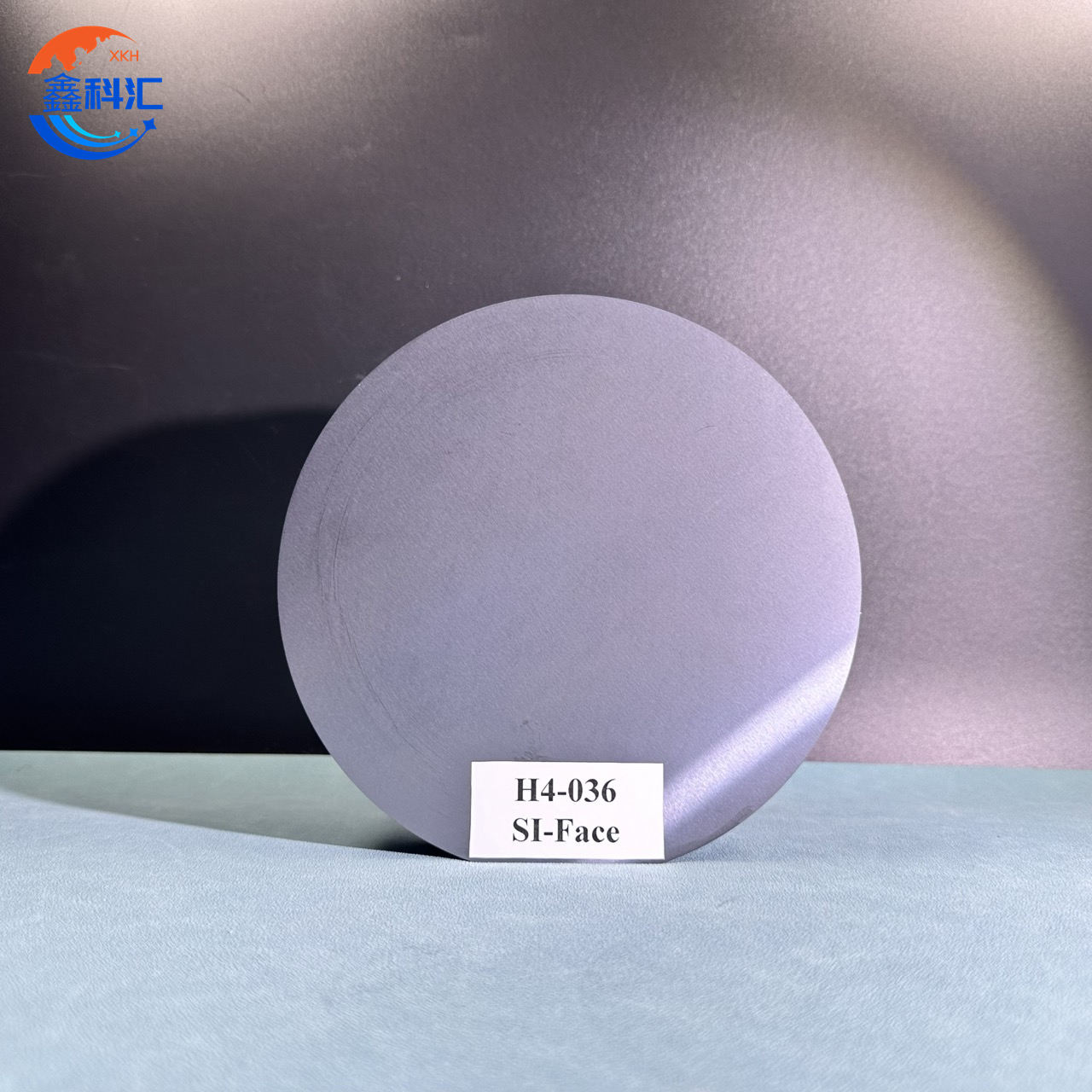

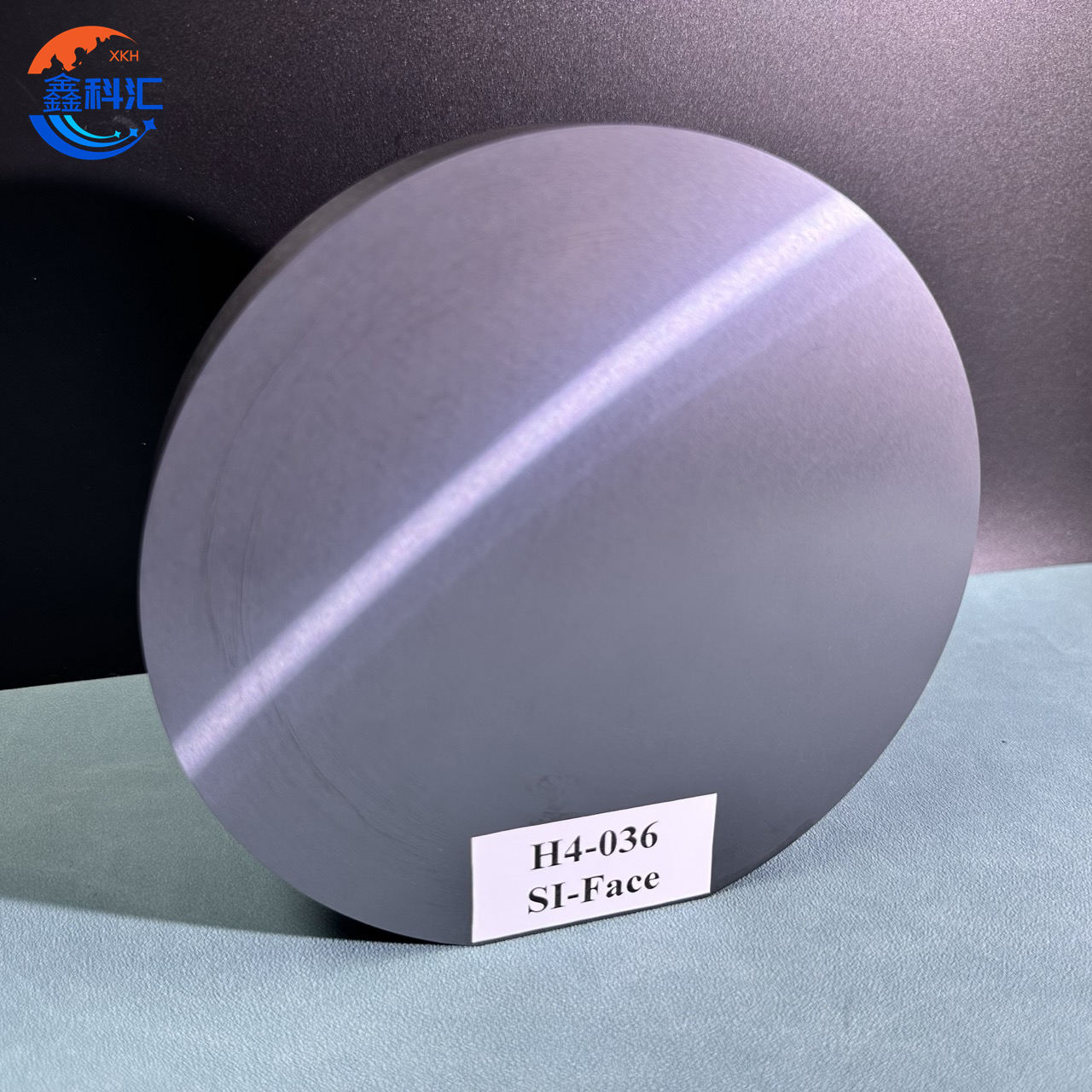

6 hauv Silicon Carbide 4H-SiC Semi-Insulating Ingot, Dummy Qib

Cov khoom

1. Lub cev thiab lub cev muaj zog

● Khoom siv: Silicon Carbide (SiC)

●Polytype: 4H-SiC, hexagonal siv lead ua qauv

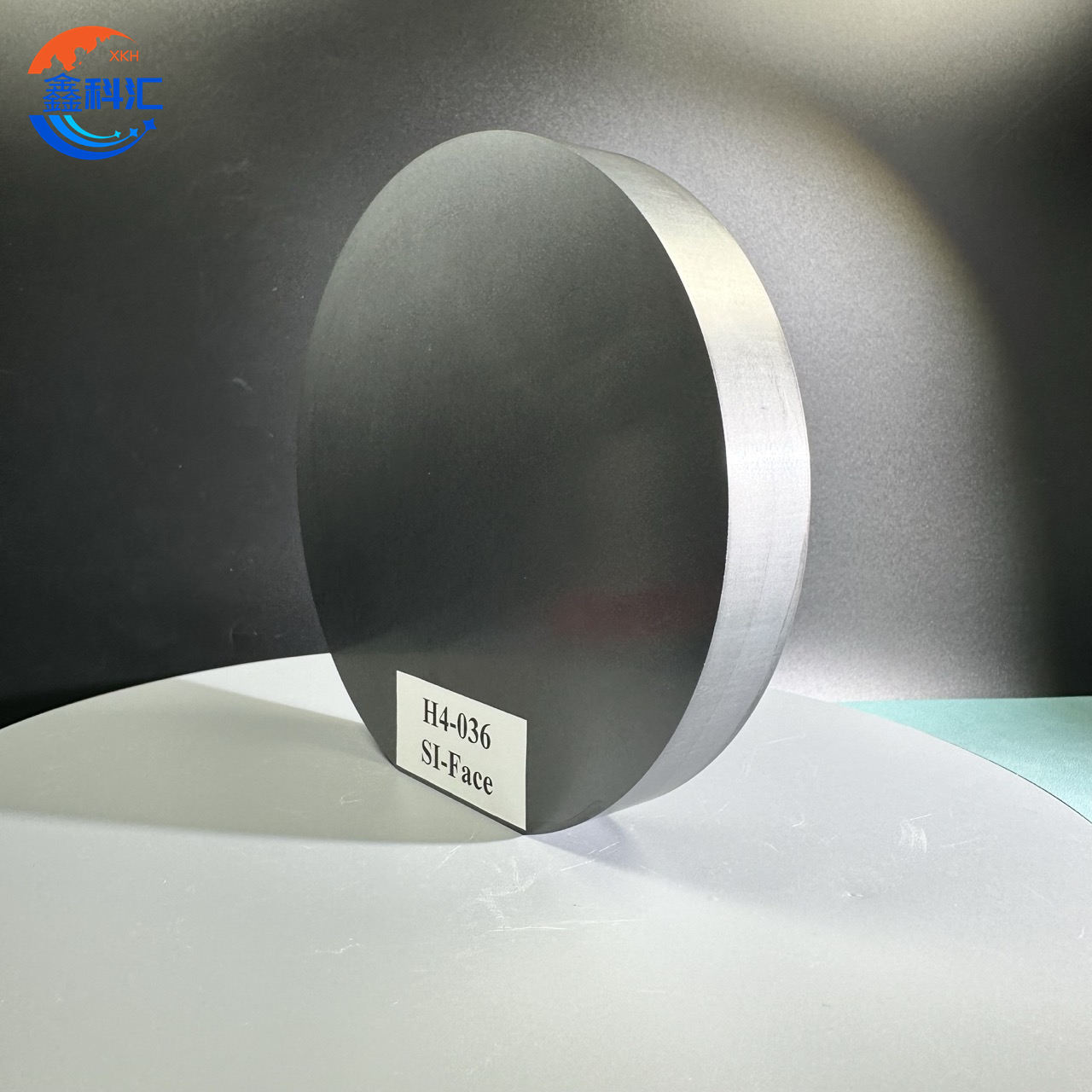

● Dia: 6 nti (150 mm)

● Thickness: Configurable (5-15 hli raug rau qib dummy)

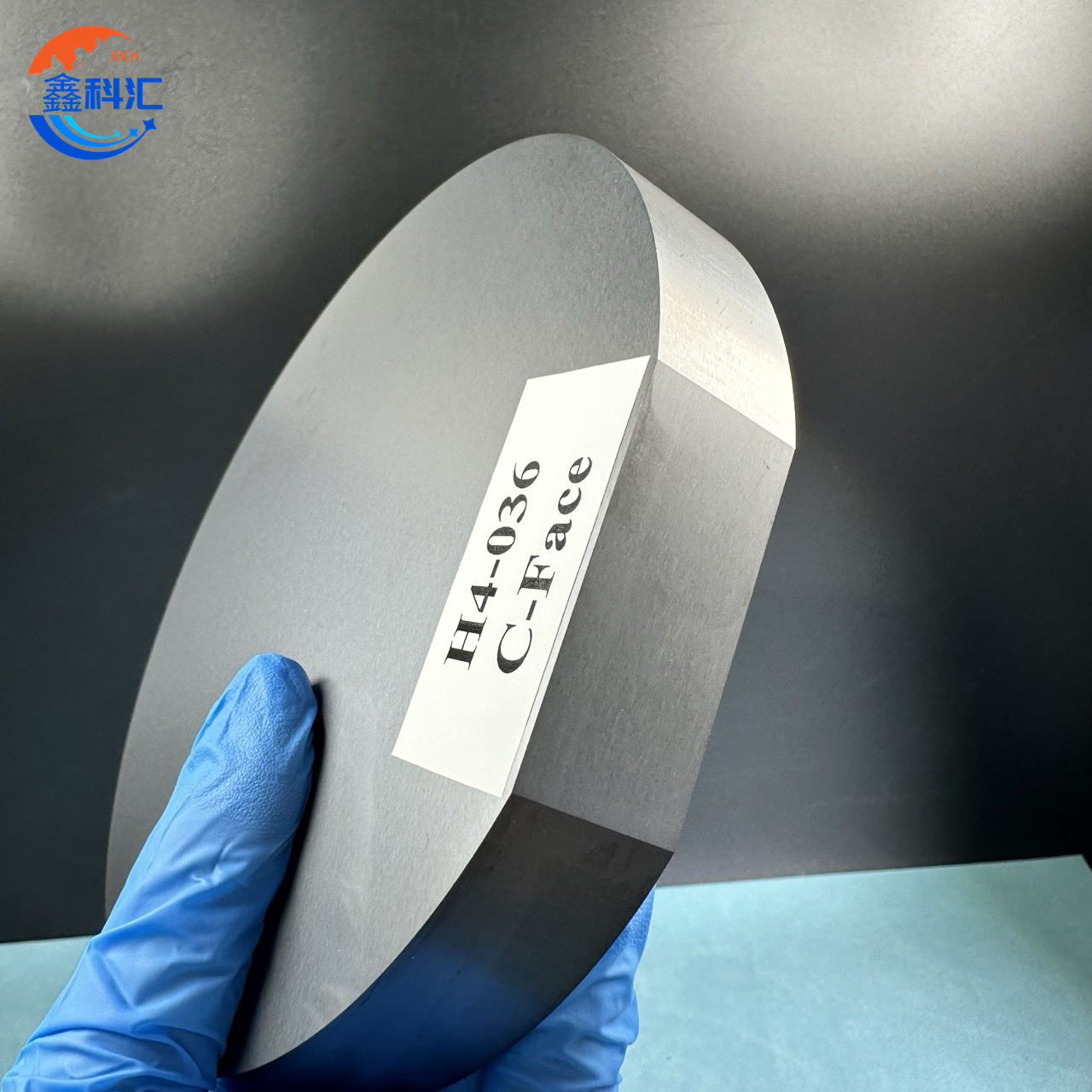

●Crystal Orientation:

oPrimary: [0001] (C-plane)

oSecondary xaiv: Off-axis 4° rau optimized epitaxial loj hlob

●Primary Flat Orientation: (10-10) ± 5°

●Secondary Flat Orientation: 90 ° counterclockwise los ntawm thawj lub tiaj tus ± 5 °

2. Cov khoom siv hluav taws xob

●Resistivity:

oSemi-insulating (> 106 ^ 66 Ω·cm), zoo tagnrho rau kev txo cov kab mob parasitic capacitance.

● Doping Hom:

o Unintentionally doped, ua rau muaj hluav taws xob tiv taus thiab ruaj khov nyob rau hauv ntau yam kev ua haujlwm.

3. Thermal Properties

●Thermal Conductivity: 3.5-4.9 W / cm·K, ua kom muaj cua sov zoo hauv cov tshuab hluav taws xob siab.

●Thermal Expansion Coefficient: 4.2 × 10−64.2 \times 10^{-6}4.2 × 10−6 / K, kom ntseeg tau qhov ruaj khov ntawm qhov ntev thaum ua haujlwm kub.

4. Optical Properties

●Bandgap: Dav bandgap ntawm 3.26 eV, tso cai rau kev ua haujlwm nyob rau hauv high voltages thiab kub.

●Transparency: High transparency rau UV thiab pom wavelengths, pab tau rau kev kuaj optoelectronic.

5. Mechanical Properties

● Hardness: Mohs scale 9, thib ob tsuas yog pob zeb diamond, ua kom muaj zog thaum ua haujlwm.

● Tsis Txaus Siab:

oControlled rau me me macro defects, kom ntseeg tau zoo txaus rau dummy-qib daim ntaub ntawv.

● Flatness: Uniformity nrog deviations

| Parameter | Paub meej | Chav tsev |

| Qib | Dummy Qib | |

| Txoj kab uas hla | 150.0 ± 0.5 | mm |

| Wafer Orientation | On-axis: <0001> ± 0.5° | degree |

| Hluav taws xob Resistivity | > 1E5 | Ω·cm |

| Thawj Txoj Kev Ncaj Ncees | {10-10} ± 5.0° | degree |

| Qhov Loj Loj Loj | Ntsig | |

| Cracks (High-Intensity Light Inspection) | <3 mm nyob rau hauv radial | mm |

| Hex Phaj (High-Intensity Light Inspection) | Qhov ntau thiab tsawg ≤ 5% | % |

| Polytype Areas (High-Intensity Light Inspection) | Qhov ntau thiab tsawg ≤ 10% | % |

| Micropipe ntom ntom | <50 | cm-2^-2-2 |

| Ntug Chiping | 3 tso cai, txhua ≤ 3 hli | mm |

| Nco tseg | Slicing wafer thickness <1 hli,> 70% (tsis suav ob kawg) ua tau raws li cov kev cai saum toj no |

Daim ntawv thov

1. Prototyping thiab tshawb fawb

Lub dummy-qib 6-nti 4H-SiC ingot yog ib qho khoom siv zoo tshaj plaws rau kev tsim qauv thiab kev tshawb fawb, tso cai rau cov tuam ntxhab thiab cov chaw soj nstuam rau:

●Test process parameters in Chemical Vapor Deposition (CVD) or Physical Vapor Deposition (PVD).

● Tsim thiab kho cov txheej txheem etching, polishing, thiab wafer slicing cov txheej txheem.

● Tshawb nrhiav cov cuab yeej tshiab tsim ua ntej hloov mus rau cov khoom siv qib siab.

2. Ntaus Calibration thiab kuaj

Cov khoom siv hluav taws xob semi-insulating ua rau qhov ingot no tsis muaj nqis rau:

● Kev ntsuas thiab ntsuas cov khoom hluav taws xob ntawm cov khoom siv hluav taws xob siab thiab cov khoom siv siab.

● Simulating kev ua haujlwm rau MOSFETs, IGBTs, lossis diodes hauv qhov chaw sim.

● Ua tus nqi hloov pauv rau cov khoom siv purity siab thaum lub sij hawm tsim kho thaum ntxov.

3. Fais fab Electronics

Lub siab thermal conductivity thiab dav bandgap yam ntxwv ntawm 4H-SiC ua kom muaj kev ua haujlwm zoo hauv hluav taws xob hluav taws xob, suav nrog:

● Cov khoom siv hluav taws xob siab.

● Lub tsheb hluav taws xob (EV) inverter.

●Renewable zog systems, xws li hnub ci inverters thiab cua turbines.

4. Kev siv xov tooj cua zaus (RF).

4H-SiC qhov tsis tshua muaj hluav taws xob poob thiab kev txav hluav taws xob siab ua rau nws tsim nyog rau:

●RF amplifiers thiab transistors hauv kev sib txuas lus infrastructure.

●High-frequency radar systems rau aerospace thiab tiv thaiv daim ntawv thov.

●Wireless network Cheebtsam rau 5G thev naus laus zis.

5. Radiation-Resistant Devices

Vim nws qhov kev tiv thaiv tsis zoo rau hluav taws xob vim qhov tsis xws luag, semi-insulating 4H-SiC yog qhov zoo tagnrho rau:

● Cov cuab yeej tshawb nrhiav chaw, suav nrog cov khoom siv hluav taws xob satellite thiab cov tshuab hluav taws xob.

● Radiation-hardened electronics rau nuclear xyuas thiab tswj.

● Cov ntawv thov kev tiv thaiv yuav tsum muaj kev ruaj khov nyob rau hauv qhov chaw tsis zoo.

6. Optoelectronics

Optical transparency thiab dav bandgap ntawm 4H-SiC pab kom nws siv nyob rau hauv:

● UV photodetectors thiab high-power LEDs.

●Testing optical coatings thiab deg kho.

●Prototyping optical Cheebtsam rau advanced sensors.

Qhov zoo ntawm Dummy-Qib Khoom

Nqi Efficiency:

Qib dummy yog qhov pheej yig dua rau kev tshawb fawb lossis cov khoom siv qib siab, ua rau nws zoo tagnrho rau kev sim niaj hnub thiab kev ua kom zoo dua qub.

Customizability:

Configurable qhov ntev thiab siv lead ua orientations kom muaj kev sib raug zoo nrog ntau yam kev siv.

Scalability:

Lub 6-inch inch ua raws li cov qauv kev lag luam, tso cai seamless scaling rau cov txheej txheem ntau lawm.

Robustness:

High mechanical zog thiab thermal stability ua rau lub ingot ruaj thiab txhim khu kev qha nyob rau hauv ntau yam kev sim.

Versatility:

Haum rau ntau yam kev lag luam, los ntawm lub zog rau kev sib txuas lus thiab optoelectronics.

Xaus

Lub 6-nti Silicon Carbide (4H-SiC) semi-insulating ingot, qib dummy, muaj kev txhim khu kev qha thiab ntau yam platform rau kev tshawb fawb, prototyping, thiab kev sim hauv cov khoom siv thev naus laus zis. Nws tshwj xeeb thermal, hluav taws xob, thiab cov khoom siv kho tshuab, ua ke nrog kev pheej yig thiab kev hloov kho, ua rau nws yog ib qho khoom siv tseem ceeb rau kev kawm thiab kev lag luam. Los ntawm hluav taws xob hluav taws xob mus rau RF systems thiab cov khoom siv hluav taws xob ua kom muaj zog, qhov ingot no txhawb kev tsim kho tshiab ntawm txhua theem ntawm txoj kev loj hlob.

Xav paub ntau ntxiv specifications los yog thov ib tug quote, thov hu rau peb ncaj qha. Peb pab neeg ua haujlwm tau npaj los pab nrog cov kev daws teeb meem kom ua tau raws li koj xav tau.

Daim duab qhia ntxaws