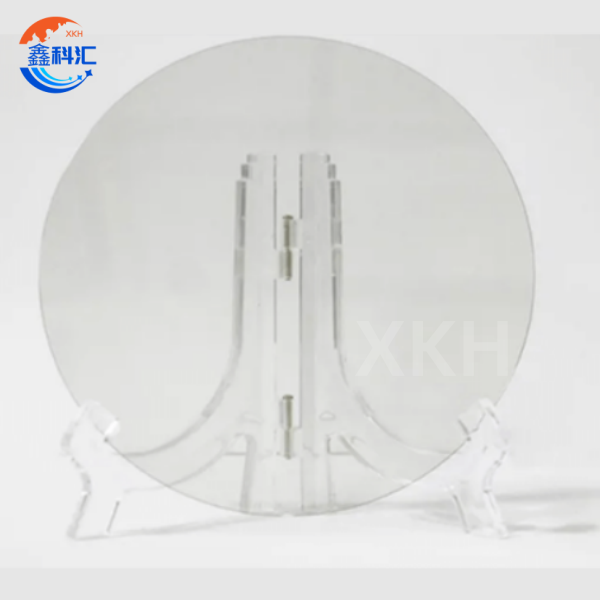

6 Nti 4H SEMI Hom SiC composite substrate Thickness 500μm TTV≤5μm MOS qib

Technical parameters

| Cov khoom | Specification | Cov khoom | Specification |

| Txoj kab uas hla | 150 ± 0.2 hli | Pem hauv ntej (Si-face) roughness | Ra≤0.2nm (5μm × 5μm) |

| Polytype | 4H | Ntug Chip, Scratch, Crack (kev tshuaj xyuas pom) | Tsis muaj |

| Kev tiv thaiv | ≥1E8 Ω·cm | TTV | ≤ 5 hli |

| Hloov txheej Thickness | ≥0.4 hli | Warp | ≤ 35 hli |

| Tsis muaj (2mm> D> 0.5mm) | ≤5 ea / Wafer | Thickness | 500 ± 25 hli |

Cov yam ntxwv tseem ceeb

1. Exceptional High-Frequency Performance

Lub 6-nti semi-insulating SiC composite substrate ntiav cov txheej txheem dielectric txheej tsim, kom ntseeg tau tias dielectric qhov sib txawv ntawm <2% hauv Ka-band (26.5-40 GHz) thiab txhim kho theem sib xws los ntawm 40%. 15% nce hauv kev ua tau zoo thiab 20% qis zog siv hauv T / R modules siv cov substrate no.

2. Kev Tswj Thermal Breakthrough

Ib qho tshwj xeeb "thermal choj" cov qauv sib xyaw ua rau sab nraud thermal conductivity ntawm 400 W / m·K. Hauv 28 GHz 5G hauv paus chaw nres tsheb PA modules, qhov sib txuas kub tsuas yog nce los ntawm 28 ° C tom qab 24 teev ntawm kev ua haujlwm tas mus li - 50 ° C qis dua li cov kev daws teeb meem.

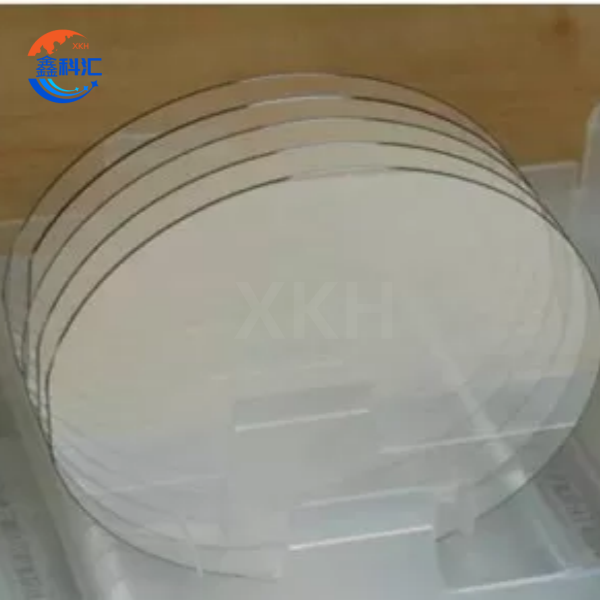

3. Superior Wafer Zoo

Los ntawm txoj kev ua kom zoo rau lub cev Vapor Transport (PVT), peb ua tiav qhov ntom ntom ntom <500 / cm² thiab Tag Nrho Thickness Variation (TTV) <3 μm.

4. Kev tsim khoom-phooj ywg ua haujlwm

Peb cov txheej txheem laser annealing tshwj xeeb tsim rau 6-nti semi-insulating SiC composite substrate txo qhov ntom ntom ntom ntom ntom ntom los ntawm ob qhov kev txiav txim siab ua ntej epitaxy.

Cov ntawv thov tseem ceeb

1. 5G Base Station Core Cheebtsam

Hauv Massive MIMO kav hlau txais xov arrays, GaN HEMT li ntawm 6-nti semi-insulating SiC composite substrates ua tiav 200W tso zis zog thiab> 65% efficiency. Kev ntsuam xyuas teb ntawm 3.5 GHz tau pom tias muaj 30% nce hauv qhov kev pab cuam lub vojvoog.

2. Kev sib txuas lus satellite

Low-Earth orbit (LEO) satellite transceivers siv lub substrate no nthuav tawm 8 dB siab dua EIRP hauv Q-band (40 GHz) thaum txo qhov hnyav los ntawm 40%. SpaceX Starlink terminals tau txais nws rau ntau lawm.

3. Tub rog Radar Systems

Phased-array radar T / R modules ntawm lub substrate no ua tiav 6-18 GHz bandwidth thiab lub suab nrov qis li 1.2 dB, txuas ntxiv kev tshawb pom ntau yam los ntawm 50 km hauv kev ceeb toom radar thaum ntxov.

4. Automotive millimeter-Wave Radar

79 GHz automotive radar chips siv lub substrate no txhim kho angular daws teeb meem rau 0.5 °, ua tau raws li L4 autonomous tsav tsheb.

Peb muab cov kev pabcuam kev pabcuam kev pabcuam rau 6-nti semi-insulating SiC composite substrates. Nyob rau hauv cov nqe lus ntawm customizing cov ntaub ntawv tsis, peb txhawb cov kev cai ntawm resistivity nyob rau hauv qhov ntau ntawm 10⁶-10¹⁰ Ω·cm. Tshwj xeeb tshaj yog rau kev siv tub rog, peb tuaj yeem muab qhov kev xaiv siab tshaj plaws ntawm> 10⁹ Ω·cm. Nws muaj peb lub thickness specifications ntawm 200μm, 350μm thiab 500μm ib txhij, nrog rau kev kam rau siab nruj tswj nyob rau hauv ± 10μm, ua tau raws li cov kev cai sib txawv los ntawm high-frequency li mus rau high-power daim ntaub ntawv.

Nyob rau hauv cov nqe lus ntawm cov txheej txheem kho deg, peb muab ob txoj kev daws teeb meem: Tshuaj Mechanical Polishing (CMP) tuaj yeem ua tiav atomic-level nto flatness nrog Ra <0.15nm, ua tau raws li qhov xav tau tshaj plaws ntawm kev loj hlob ntawm epitaxial; Lub epitaxial npaj deg kho tshuab rau kev xav tau sai sai tuaj yeem muab qhov chaw du nrog Sq <0.3nm thiab residual oxide thickness <1nm, ua kom yooj yim rau cov txheej txheem pretreatment ntawm tus neeg siv khoom kawg.

XKH muab cov kev daws teeb meem rau 6-nti semi-insulating SiC composite substrates

1. Khoom Parameter Customization

Peb muab cov kev tiv thaiv zoo nyob rau hauv thaj tsam ntawm 10⁶-10¹⁰ Ω·cm, nrog cov kev xaiv tshwj xeeb ultra-siab resistivity> 10⁹ Ω·cm muaj rau kev siv tub rog / aerospace.

2. Thickness Specifications

Peb cov txheej txheem thickness xaiv:

· 200μm (zoo rau cov khoom siv ntau zaus)

· 350μm (tus qauv specification)

· 500μm (tsim rau kev siv hluav taws xob siab)

· Txhua qhov sib txawv tswj cov tuab tuab ntawm ± 10μm.

3. Cov thev naus laus zis kho deg

Chemical Mechanical Polishing (CMP): Ua tiav atomic-theem nto flatness nrog Ra <0.15nm, ua tau raws li qhov xav tau kev loj hlob ntawm epitaxial nruj rau RF thiab cov khoom siv fais fab.

4. Epi-Ready Surface Processing

· Muab cov nplaim du nrog Sq<0.3nm roughness

· Tswj ib txwm oxide thickness rau <1nm

· Tshem tawm mus txog 3 cov kauj ruam ua ntej ntawm cov neeg siv khoom