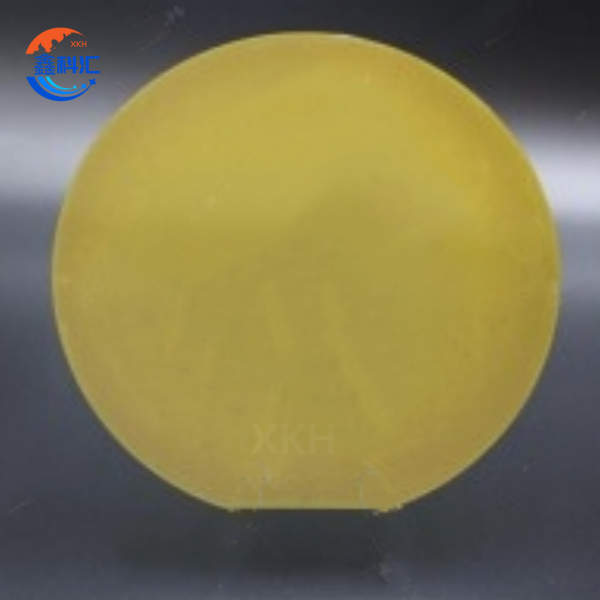

6 nti Conductive ib leeg siv lead ua SiC ntawm polycrystalline SiC composite substrate Txoj kab uas hla 150mm P hom N hom

Technical parameters

| Loj: | 6 nti |

| Txoj kab uas hla: | 150 hli |

| Thickness: | 400-500 m |

| Monocrystalline SiC Zaj duab xis Parameters | |

| Polytype: | 4H-SiC los yog 6H-SiC |

| Doping Concentration: | 1 × 10¹⁴ - 1 × 10¹⁸ cm⁻³ |

| Thickness: | 5-20 hli |

| Daim ntawv Resistance: | 10-1000 Ω / sq |

| Electron Mobility: | 800-1200 cm² / Vs |

| Qhov Mobility: | 100-300 cm² / Vs |

| Polycrystalline SiC Buffer Layer Parameters | |

| Thickness: | 50-300 hli |

| Thermal conductivity: | 150-300 W/m·K |

| Monocrystalline SiC Substrate Parameters | |

| Polytype: | 4H-SiC los yog 6H-SiC |

| Doping Concentration: | 1 × 10¹⁴ - 1 × 10¹⁸ cm⁻³ |

| Thickness: | 300-500 hli |

| Loj Loj: | > 1 mm |

| Nto Roughness: | <0.3 hli RMS |

| Mechanical & Electrical Properties | |

| Hardness: | 9-10 hmo |

| Compressive zog: | 3-4 GPa |

| Tensile zog: | 0.3-0.5 GPa |

| Breakdown Field Strength: | > 2 MV/cm |

| Total Dose Tolerance: | > 10 Mas |

| Ib qho xwm txheej cuam tshuam kuj: | > 100 MeV · cm²/mg |

| Thermal conductivity: | 150-380 W/m·K |

| Kev khiav hauj lwm qhov kub thiab txias: | -55 rau 600 ° C |

Cov yam ntxwv tseem ceeb

Lub 6-nti conductive monocrystalline SiC ntawm polycrystalline SiC composite substrate muaj qhov sib npaug ntawm cov khoom siv thiab kev ua tau zoo, ua rau nws tsim nyog rau kev xav tau kev lag luam ib puag ncig:

1.Cost-Effectiveness: Lub hauv paus polycrystalline SiC txo cov nqi piv rau tag nrho-monocrystalline SiC, thaum lub monocrystalline SiC active txheej ua kom cov cuab yeej-qib kev ua tau zoo, zoo tagnrho rau cov nqi-sensitive daim ntaub ntawv.

2.Exceptional Electrical Properties: Cov txheej txheem monocrystalline SiC nthuav tawm cov neeg nqa khoom siab (> 500 cm² / V·s) thiab qhov tsis xws luag, txhawb kev ua haujlwm siab thiab lub zog siab.

3.High-Temperature Stability: SiC's inherent high-temperature resistance (> 600 ° C) ua kom cov substrate sib xyaw tseem ruaj khov nyob rau hauv huab cua txias, ua rau nws haum rau cov tsheb fais fab thiab kev siv lub cev muaj zog.

4.6-nti Standardized Wafer Loj: Piv rau cov tsoos 4-nti SiC substrates, 6-nti hom ntawv nce nti tawm los ntawm ntau dua 30%, txo cov nqi khoom siv ib zaug.

5.Conductive Design: Pre-doped N-hom lossis P-hom khaubncaws sab nraud povtseg txo ion implantation cov kauj ruam hauv kev tsim khoom, txhim kho kev tsim khoom thiab tawm los.

6.Superior Thermal Management: Lub polycrystalline SiC puag lub thermal conductivity (~120 W/m·K) mus txog ntawm monocrystalline SiC, zoo daws cov teeb meem kub dissipation nyob rau hauv high-power devices.

Cov yam ntxwv no tso rau 6-nti conductive monocrystalline SiC ntawm polycrystalline SiC composite substrate raws li kev sib tw rau kev lag luam xws li lub zog tauj dua tshiab, kev tsheb ciav hlau, thiab aerospace.

Cov ntawv thov tseem ceeb

Lub 6-nti conductive monocrystalline SiC ntawm polycrystalline SiC composite substrate tau ua tiav nyob rau hauv ntau qhov kev thov siab:

1.Electric Vehicle Powertrains: Siv nyob rau hauv high-voltage SiC MOSFETs thiab diodes los txhim kho inverter efficiency thiab ntev roj teeb ntau yam (xws li, Tesla, BYD qauv).

2.Industrial Tsav Tsav Tsheb: Ua kom muaj qhov kub thiab txias, hloov pauv-zaus fais fab modules, txo kev siv hluav taws xob hauv cov tshuab hnyav thiab cua turbines.

3.Photovoltaic Inverters: SiC li txhim kho lub hnub ci kev ua tau zoo (> 99%), thaum cov khoom sib xyaw ua ke ntxiv txo cov nqi hluav taws xob.

4.Rail Tsheb thauj mus los: Siv rau hauv traction converters rau high-speed rail thiab subway systems, muab high-voltage resistance (> 1700V) thiab compact form factor.

5.Aerospace: Zoo tagnrho rau satellite fais fab system thiab aircraft cav tswj circuits, muaj peev xwm tiv taus huab cua kub thiab hluav taws xob.

Hauv kev tsim cov tswv yim, 6-nti conductive monocrystalline SiC ntawm polycrystalline SiC composite substrate tau ua tiav nrog cov txheej txheem SiC cov txheej txheem (piv txwv li, lithography, etching), yuav tsum tsis muaj peev txheej ntxiv.

XKH Services

XKH muab kev txhawb nqa rau 6-nti conductive monocrystalline SiC ntawm polycrystalline SiC composite substrate, npog R & D rau ntau lawm:

1.Customization: Adjustable monocrystalline txheej thickness (5-100 μm), doping concentration (1e15–1e19 cm⁻³), thiab siv lead ua orientation (4H / 6H-SiC) kom tau raws li cov khoom siv sib txawv.

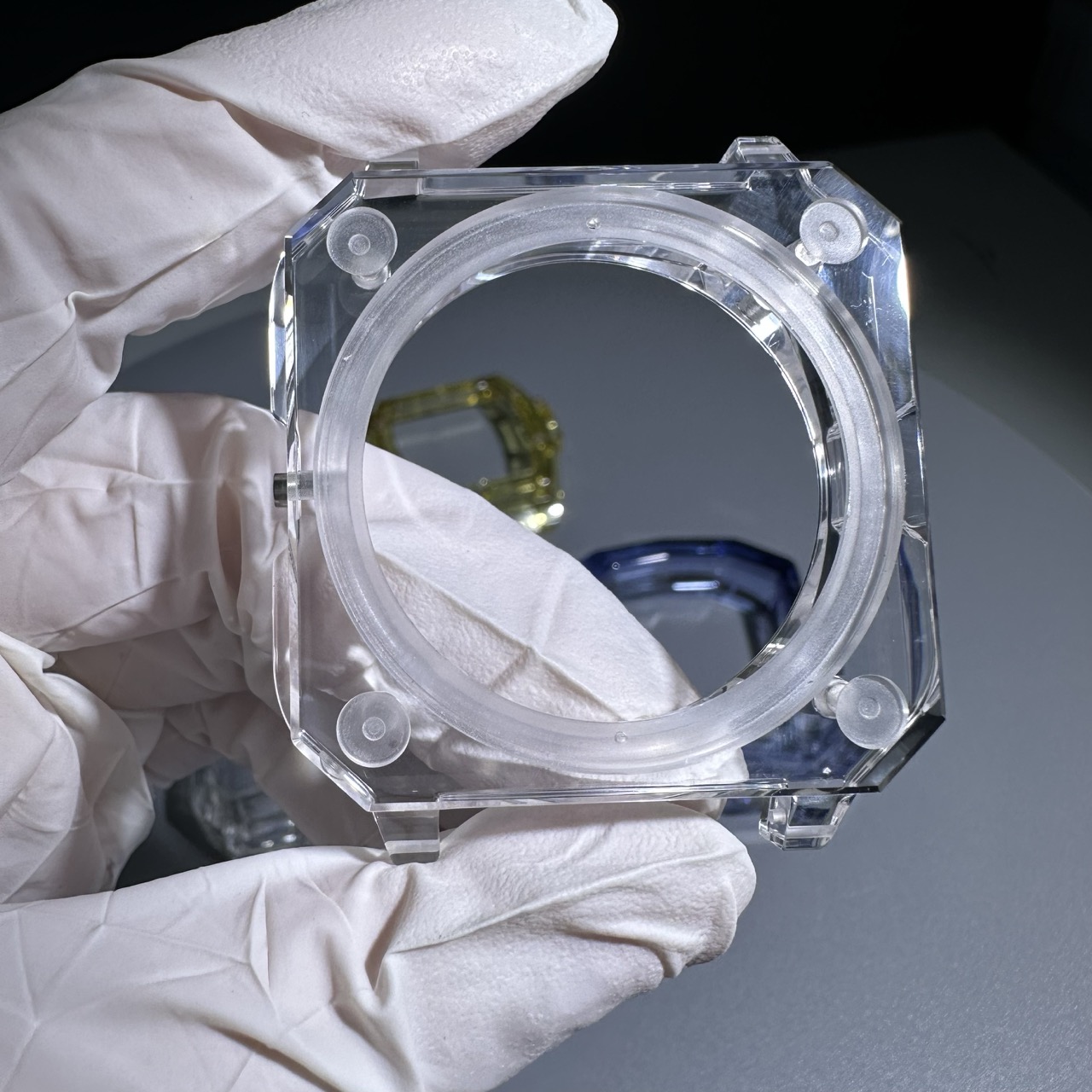

2.Wafer Processing: Tej khoom ntawm 6-nti substrates nrog backside thinning thiab metallization kev pab cuam rau plug-and-play kev koom ua ke.

3.Technical Validation: suav nrog XRD crystallinity tsom xam, Hall effect test, thiab thermal resistance ntsuas kom ceev cov khoom tsim nyog.

4.Rapid Prototyping: 2- mus rau 4-nti cov qauv (cov txheej txheem tib yam) rau cov koom haum tshawb fawb kom ceev txoj kev loj hlob.

5.Failure Analysis & Optimization: Cov khoom siv-theem kev daws teeb meem rau kev sib tw ua haujlwm (xws li epitaxial txheej tsis xws luag).

Peb lub luag haujlwm yog tsim kom muaj 6-nti conductive monocrystalline SiC ntawm polycrystalline SiC composite substrate raws li tus nqi-kev ua tau zoo tshaj plaws rau SiC fais fab hluav taws xob, muab kev txhawb nqa kawg-rau-kawg los ntawm kev ua qauv rau ntim ntau lawm.

Xaus

Lub 6-nti conductive monocrystalline SiC ntawm polycrystalline SiC composite substrate ua tiav qhov sib npaug ntawm kev ua tau zoo thiab tus nqi los ntawm nws cov qauv tshiab mono / polycrystalline hybrid. Raws li hluav taws xob tsheb loj hlob zuj zus thiab Kev Lag Luam 4.0 nce qib, lub substrate no muab cov khoom siv txhim khu kev qha rau cov khoom siv hluav taws xob txuas ntxiv mus. XKH zoo siab txais tos kev sib koom tes los tshawb nrhiav cov peev txheej ntawm SiC thev naus laus zis.