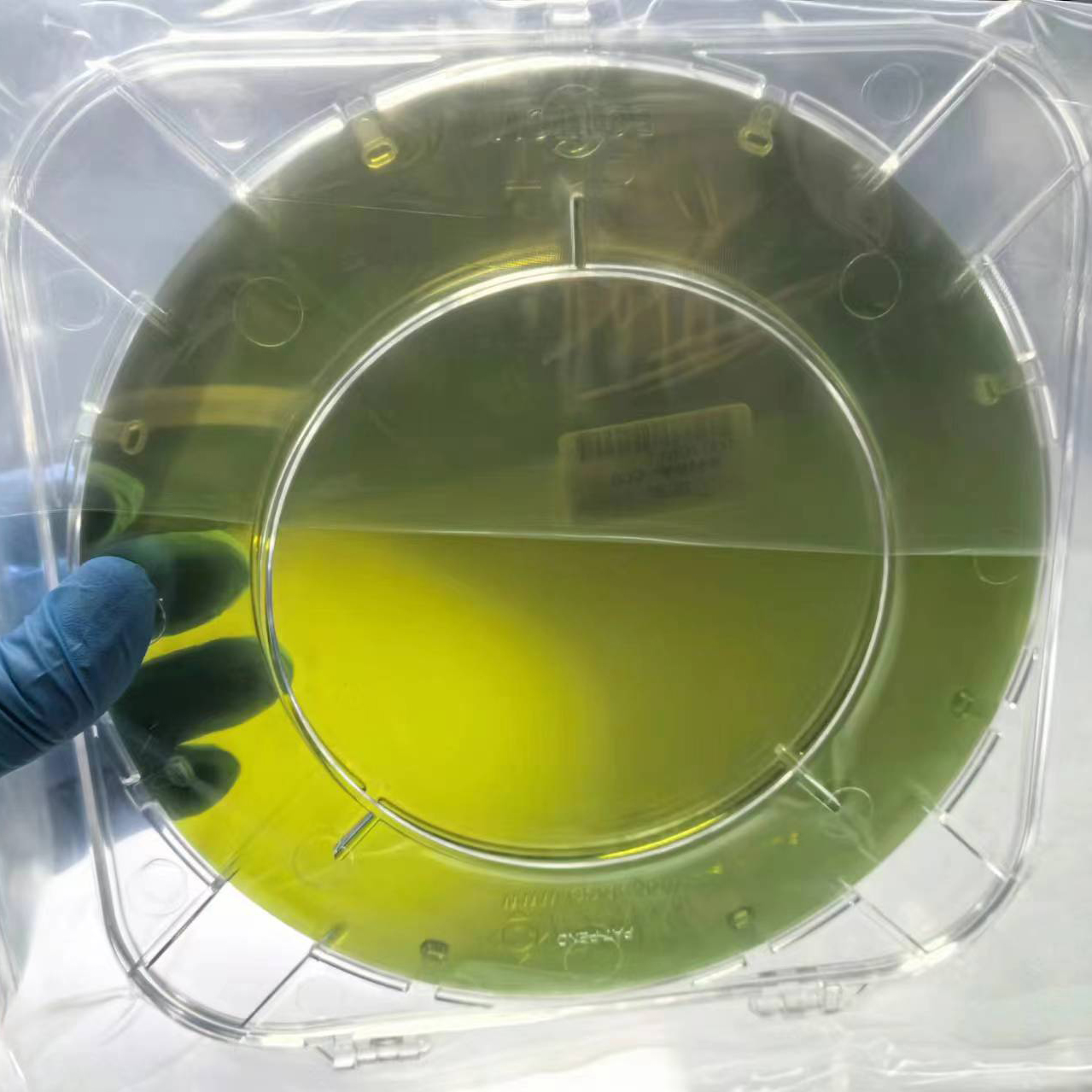

8 nti 200mm 4H-N SiC Wafer Conductive dummy tshawb fawb qib

Vim nws lub cev thiab cov khoom siv hluav taws xob tshwj xeeb, 200mm SiC wafer semiconductor khoom siv los tsim cov khoom siv hluav taws xob ua haujlwm siab, kub kub, hluav taws xob tiv thaiv, thiab cov khoom siv hluav taws xob ntau zaus. 8inch SiC substrate tus nqi qis zuj zus raws li cov thev naus laus zis dhau los thiab qhov kev thov loj tuaj. Kev txhim kho thev naus laus zis tsis ntev los no ua rau kev tsim khoom lag luam ntawm 200mm SiC wafers. Cov txiaj ntsig tseem ceeb ntawm SiC wafer semiconductor cov ntaub ntawv sib piv nrog Si thiab GaAs wafers: Lub zog hluav taws xob ntawm 4H-SiC thaum lub caij avalanche tawg yog ntau tshaj qhov kev txiav txim siab ntau dua li qhov sib thooj rau Si thiab GaAs. Qhov no ua rau muaj qhov txo qis hauv lub xeev kev tiv thaiv Ron. Tsawg nyob rau hauv lub xeev resistivity, ua ke nrog siab tam sim no ceev thiab thermal conductivity, tso cai rau siv cov me me tuag rau cov khoom siv fais fab. Lub siab thermal conductivity ntawm SiC txo cov thermal tsis kam ntawm cov nti. Cov khoom siv hluav taws xob ntawm cov khoom siv raws li SiC wafers ruaj khov nyob rau lub sijhawm thiab qhov kub thiab txias, uas ua kom muaj kev ntseeg siab ntawm cov khoom. Silicon carbide tsis tshua muaj zog tiv thaiv hluav taws xob, uas tsis degrade cov khoom hluav taws xob ntawm cov nti. Lub siab txwv kev ua haujlwm kub ntawm cov siv lead ua (ntau tshaj 6000C) tso cai rau koj los tsim cov khoom siv txhim khu kev qha rau kev ua haujlwm hnyav thiab kev siv tshwj xeeb. Tam sim no, peb tuaj yeem muab cov khoom me me 200mmSiC wafers tsis tu ncua thiab tsis tu ncua thiab muaj qee yam khoom hauv lub tsev rau khoom.

Specification

| Tus lej | Yam khoom | Chav tsev | Ntau lawm | Kev tshawb fawb | Dummy |

| 1. Parameters | |||||

| 1.1 | polytype | -- | 4H | 4H | 4H |

| 1.2 | nto orientation | ° | <11-20>4 ± 0.5 | <11-20>4 ± 0.5 | <11-20>4 ± 0.5 |

| 2. Kev ntsuas hluav taws xob | |||||

| 2.1 | dopant | -- | n-hom Nitrogen | n-hom Nitrogen | n-hom Nitrogen |

| 2.2 | tiv taus | ohm · cm | 0.015 ~ 0.025 hli | 0.01-0.03 Nws | NA |

| 3. Mechanical parameter | |||||

| 3.1 | txoj kab uas hla | mm | 200 ± 0.2 | 200 ± 0.2 | 200 ± 0.2 |

| 3.2 | tuab | ib m | 500 ± 25 | 500 ± 25 | 500 ± 25 |

| 3.3 | Notch orientation | ° | [1-100] ± 5 | [1-100] ± 5 | [1-100] ± 5 |

| 3.4 | Notch Qhov tob | mm | 1 ~ 1.5 hli | 1 ~ 1.5 hli | 1 ~ 1.5 hli |

| 3.5 | LTV | ib m | ≤5 (10mm * 10mm) | ≤5 (10mm * 10mm) | ≤10 (10mm * 10mm) |

| 3.6 | TTV | ib m | ≤10 | ≤10 | ≤ 15 |

| 3.7 | Hneev | ib m | - 25-25 | -45-45 | -65-65 |

| 3.8 | Warp | ib m | ≤ 30 | ≤ 50 | ≤70 |

| 3.9 | AFM | nm | Ra≤0.2 | Ra≤0.2 | Ra≤0.2 |

| 4. Cov qauv | |||||

| 4.1 | micropipe ceev | ua/cm2 | ≤ 2 | ≤10 | ≤ 50 |

| 4.2 | cov ntsiab lus hlau | atom/cm2 | ≤1E11 | ≤1E11 | NA |

| 4.3 | TSD | ua/cm2 | ≤500 | ≤1000 | NA |

| 4.4 | BPD | ua/cm2 | ≤2000 | ≤5000 | NA |

| 4.5 | TED | ua/cm2 | ≤7000 | ≤10000 | NA |

| 5. Zoo zoo | |||||

| 5.1 | pem hauv ntej | -- | Si | Si | Si |

| 5.2 | nto tiav | -- | Lub ntsej muag CMP | Lub ntsej muag CMP | Lub ntsej muag CMP |

| 5.3 | particle | ua/wafer | ≤100 (qhov loj me ≥0.3μm) | NA | NA |

| 5.4 | khawb | ua/wafer | ≤5, Tag Nrho Ntev ≤200mm | NA | NA |

| 5.5 | Ntug chips/indents/cracks/stains/contamination | -- | Tsis muaj | Tsis muaj | NA |

| 5.6 | Polytype cheeb tsam | -- | Tsis muaj | Thaj tsam ≤10% | Thaj tsam ≤30% |

| 5.7 | pem hauv ntej cim | -- | Tsis muaj | Tsis muaj | Tsis muaj |

| 6. Rov qab zoo | |||||

| 6.1 | rov qab ua tiav | -- | C-ntsej muag MP | C-ntsej muag MP | C-ntsej muag MP |

| 6.2 | khawb | mm | NA | NA | NA |

| 6.3 | Back defects ntug chips/indents | -- | Tsis muaj | Tsis muaj | NA |

| 6.4 | Rov qab roughness | nm | Ra≤5 | Ra≤5 | Ra≤5 |

| 6.5 | Back marking | -- | Ntsig | Ntsig | Ntsig |

| 7. Ntug | |||||

| 7.1 | ntug | -- | Chamfer | Chamfer | Chamfer |

| 8. Pob | |||||

| 8.1 | ntim | -- | Epi-npaj nrog lub tshuab nqus tsev ntim | Epi-npaj nrog lub tshuab nqus tsev ntim | Epi-npaj nrog lub tshuab nqus tsev ntim |

| 8.2 | ntim | -- | Multi-wafer ntim cassette | Multi-wafer ntim cassette | Multi-wafer ntim cassette |

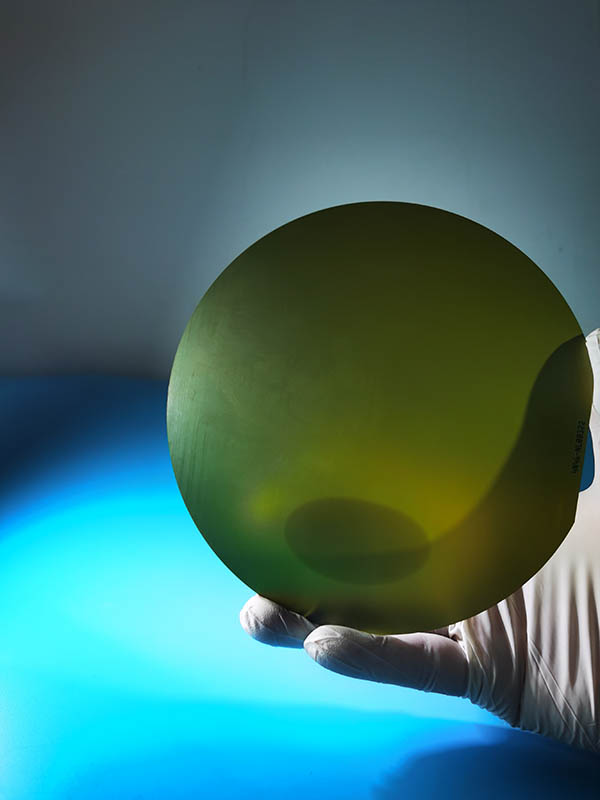

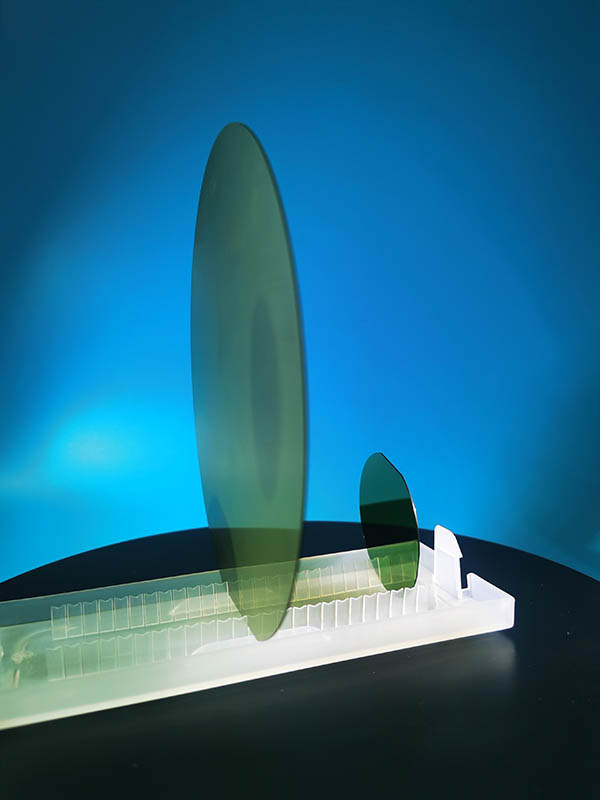

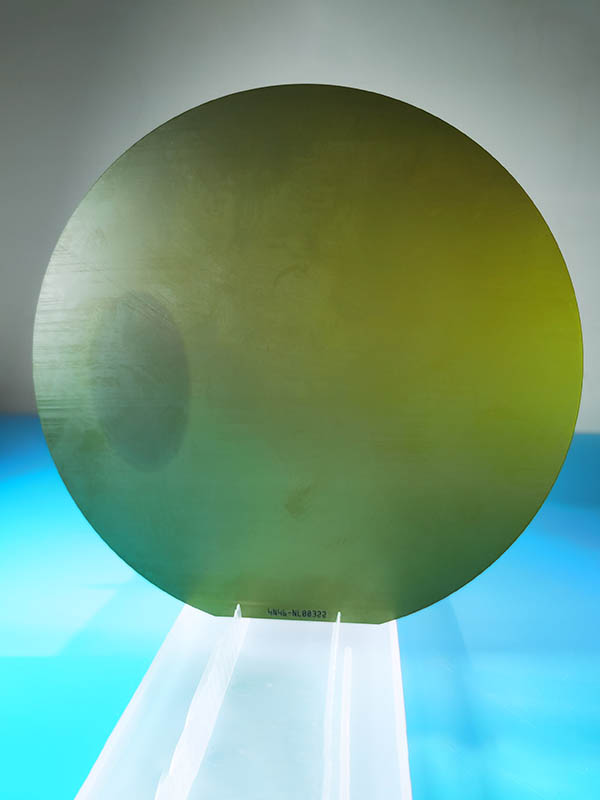

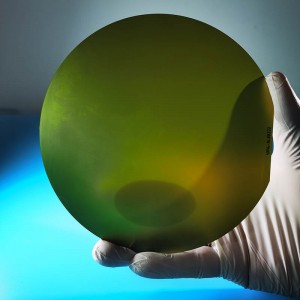

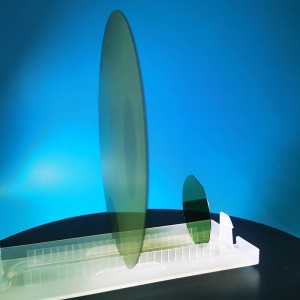

Daim duab qhia ntxaws