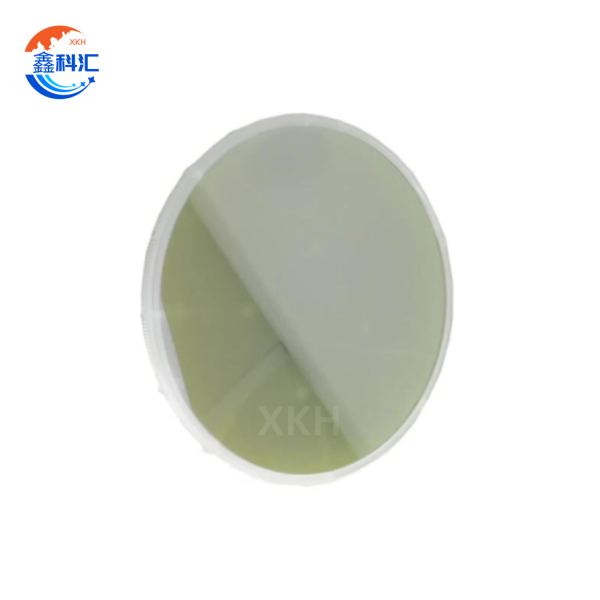

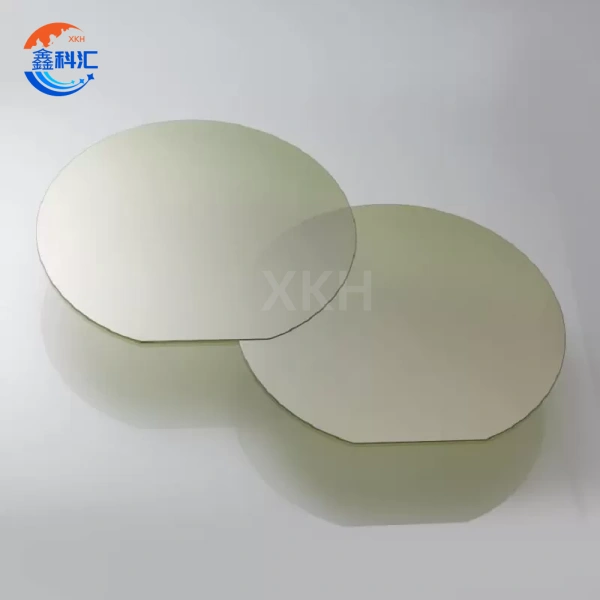

Custom N Hom SiC Seed Substrate Dia153/155mm Rau Fais Fab Electronics

Qhia

Silicon Carbide (SiC) noob substrates ua cov khoom siv hauv paus rau tiam thib peb semiconductors, txawv los ntawm lawv cov thermal conductivity tshwj xeeb, superior tawg hluav taws xob lub zog, thiab siab electron txav mus los. Cov khoom no ua rau lawv tsis muaj peev xwm siv hluav taws xob hluav taws xob, RF khoom siv, tsheb hluav taws xob (EVs), thiab kev siv hluav taws xob tauj dua tshiab. XKH tshwj xeeb hauv R & D thiab tsim cov khoom zoo SiC cov noob substrates, siv cov txheej txheem kev loj hlob zoo xws li Lub Cev Vapor Transport (PVT) thiab High-Temperature Chemical Vapor Deposition (HTCVD) kom ntseeg tau tias kev lag luam ua cov crystalline zoo.

XKH muab 4-nti, 6-nti, thiab 8-nti SiC noob substrates nrog customizable N-type / P-type doping, ua tiav qib resistivity ntawm 0.01-0.1 Ω·cm thiab dislocation densities hauv qab 500 cm⁻², ua rau lawv zoo tagnrho rau kev tsim MOSFETs, Schottky. Peb cov txheej txheem vertically integrated ntau lawm npog siv lead ua kev loj hlob, wafer slicing, polishing, thiab soj ntsuam, nrog ib lub hlis ntau lawm ntau tshaj 5,000 wafers kom tau raws li ntau haiv neeg xav tau kev tshawb fawb cov koom haum, semiconductor manufacturers, thiab tauj dua tshiab zog tuam txhab uas muag.

Tsis tas li ntawd, peb muab cov kev cai daws teeb meem, suav nrog:

Crystal orientation customization (4H-SiC, 6H-SiC)

Tshwj xeeb doping (Aluminium, Nitrogen, Boron, thiab lwm yam)

Ultra-smooth polishing (Ra <0.5nm)

XKH txhawb nqa cov qauv ua qauv, kev sib tham, thiab kev ua qauv me me kom xa cov kev daws teeb meem zoo rau SiC substrate.

Technical parameters

| Silicon carbide noob wafer | |

| Polytype | 4H |

| Deg orientation yuam kev | 4 ° rau <11-20> ± 0.5º |

| Kev tiv thaiv | kev cai |

| Txoj kab uas hla | 205 ± 0.5 hli |

| Thickness | 600 ± 50μm |

| Roughness | CMP, Ra≤0.2nm |

| Micropipe ntom ntom | ≤ 1 ea/cm2 |

| Kos | ≤5, Tag Nrho Length≤2 * Txoj kab uas hla |

| Ntug chips / indents | Tsis muaj |

| Pem hauv ntej laser npav | Tsis muaj |

| Kos | ≤2, Tag Nrho Length≤ Diameter |

| Ntug chips / indents | Tsis muaj |

| Polytype cheeb tsam | Tsis muaj |

| Rov qab laser npav | 1mm (los ntawm sab saum toj ntug) |

| Ntug | Chamfer |

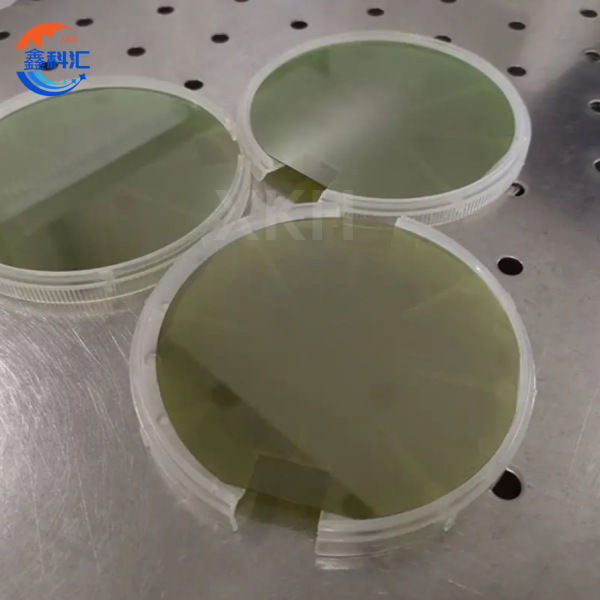

| Ntim | Multi-wafer cassette |

SiC Seed Substrates - Cov yam ntxwv tseem ceeb

1. Exceptional Physical Properties

· Cov thermal conductivity (~ 490 W / m·K), ua tau zoo tshaj silicon (Si) thiab gallium arsenide (GaAs), ua rau nws zoo tagnrho rau cov khoom siv hluav taws xob siab txias.

· Kev tawg lub zog (~ 3 MV / cm), ua haujlwm ruaj khov nyob rau hauv high-voltage tej yam kev mob, tseem ceeb heev rau EV inverters thiab industrial fais fab modules.

· Wide bandgap (3.2 eV), txo cov dej ntws tawm ntawm qhov kub thiab txias thiab txhim kho kev ntseeg tau ntawm cov cuab yeej.

2. Superior Crystalline Zoo

· PVT + HTCVD hybrid kev loj hlob thev naus laus zis txo qis micropipe qhov tsis xws luag, tswj kom tsis muaj qhov sib txawv hauv qab 500 cm⁻².

· Wafer hneev / warp < 10 μm thiab nto roughness Ra < 0.5 nm, ua kom muaj kev sib raug zoo nrog cov txheej txheem lithography siab thiab cov txheej txheem txheej txheej txheej txheej txheej.

3. Ntau hom kev xaiv Doping

· N-hom (Nitrogen-doped): Tsawg resistivity (0.01-0.02 Ω·cm), optimized rau high-frequency RF li.

· P-hom (Aluminium-doped): Zoo tagnrho rau lub zog MOSFETs thiab IGBTs, txhim kho cov cab kuj.

· Semi-insulating SiC (Vanadium-doped): Resistivity> 10⁵ Ω·cm, haum rau 5G RF pem hauv ntej-kawg modules.

4. Kev ruaj ntseg ib puag ncig

· Kub-kub kuj (> 1600 ° C) thiab hluav taws xob hardness, haum rau aerospace, khoom siv nuclear, thiab lwm qhov chaw huab cua.

SiC Seed Substrates - Cov ntawv thov tseem ceeb

1. Fais fab Electronics

· Hluav taws xob tsheb (EVs): Siv nyob rau hauv on-board chargers (OBC) thiab inverters los txhim kho efficiency thiab txo thermal tswj xav tau.

· Cov Hluav Taws Xob Hluav Taws Xob: Txhim kho photovoltaic inverters thiab cov phiajcim ntse, ua tiav> 99% kev hloov pauv hluav taws xob.

2. Cov khoom siv RF

· 5G Base Stations: Semi-insulating SiC substrates pab kom GaN-on-SiC RF fais fab amplifiers, txhawb nqa high-frequency, high-power signal kis tau tus mob.

Kev sib txuas lus satellite: Cov yam ntxwv qis qis ua rau nws haum rau cov khoom siv millimeter-yoj.

3. Kev Siv Hluav Taws Xob & Lub Zog Cia

· Hnub Ci Lub Zog: SiC MOSFETs txhawb DC-AC hloov dua siab tshiab thaum txo cov nqi hluav taws xob.

· Energy Storage Systems (ESS): Optimizes bidirectional converters thiab extends roj teeb lifespan.

4. Kev Tiv Thaiv & Aerospace

· Radar Systems: High-power SiC li siv nyob rau hauv AESA (Active Electronically Scanned Array) radars.

· Spacecraft Power Management: Radiation-resistant SiC substrates yog qhov tseem ceeb rau kev ua haujlwm tob tob.

5. Kev Tshawb Fawb & Kev Tshawb Fawb Txog Kev Tshawb Fawb

· Quantum xam: High-purity SiC enables spin qubit kev tshawb fawb.

· High-Temperature Sensors: Deployed nyob rau hauv kev tshawb nrhiav roj thiab nuclear reactor xyuas.

SiC Seed Substrates - XKH Services

1. Supply Chain Advantages

· Vertically integrated manufacturing: Tag nrho tswj los ntawm high-purity SiC hmoov rau tiav wafers, xyuas kom meej lub sij hawm txhuas ntawm 4-6 lub lis piam rau cov khoom txheem.

· Tus nqi sib tw: Kev lag luam ntawm cov nplai ua rau 15-20% tus nqi qis dua li cov neeg sib tw, nrog kev txhawb nqa rau Daim Ntawv Pom Zoo Ntev (LTAs).

2. Kev Pabcuam Customization

· Crystal orientation: 4H-SiC (tus qauv) lossis 6H-SiC (kev siv tshwj xeeb).

· Doping optimization: Tailored N-hom / P-hom / semi-insulating zog.

· Advanced polishing: CMP polishing thiab epi-npaj nto kho (Ra <0.3 nm).

3. Kev pab txhawb nqa

· Cov qauv kuaj dawb: suav nrog XRD, AFM, thiab Hall effect ntsuas cov ntaub ntawv.

· Cov cuab yeej simulation kev pab: Txhawb kev loj hlob ntawm epitaxial thiab cov cuab yeej tsim kom zoo.

4. Teb ceev ceev

· Tsawg-volume prototyping: Yam tsawg kawg nkaus ntawm 10 wafers, xa hauv 3 lub lis piam.

· Kev thauj mus los thoob ntiaj teb: Kev koom tes nrog DHL thiab FedEx rau qhov rooj rau qhov rooj.

5. Kev ruaj ntseg zoo

· Kev tshuaj xyuas tag nrho: Npog X-ray topography (XRT) thiab kev soj ntsuam qhov tsis xws luag.

· Cov ntawv pov thawj thoob ntiaj teb: Ua raws li IATF 16949 (automotive-qib) thiab AEC-Q101 cov qauv.

Xaus

XKH's SiC noob substrates ua tau zoo nyob rau hauv crystalline zoo, cov saw hlau ruaj khov, thiab kev hloov kho yooj yim, ua haujlwm rau hluav taws xob hluav taws xob, 5G kev sib txuas lus, lub zog tauj dua tshiab, thiab kev tiv thaiv thev naus laus zis. Peb txuas ntxiv mus ua ntej 8-nti SiC loj-tsim thev naus laus zis los tsav kev lag luam thib peb ntawm semiconductor rau pem hauv ntej.