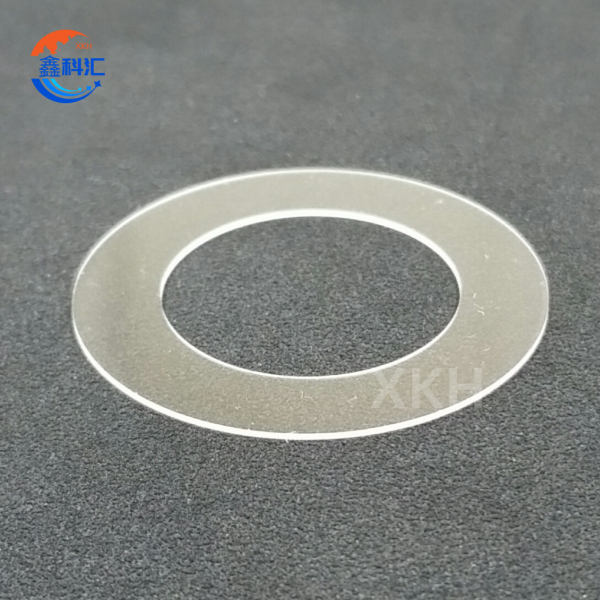

Customized Shaped Sapphire Optical Windows Sapphire Cheebtsam nrog Precision Polishing

Technical parameters

| Sapphire qhov rais | |

| Dimension | 8-400 hli |

| Dimensional kam rau ua | 0/-0.05 hli |

| Nto zoo (kos & khawb) | 40/20 |

| Qhov tseeb | λ/10per @ 633nm |

| Clear Aperture | >85%, ~ 90% |

| Parallelism kam rau ua | ± 2 '' - ± 3 '' |

| Bevel | 0.1-0.3 hli |

| Txheej | AR / AF / raws li tus neeg thov |

Cov yam ntxwv tseem ceeb

1.Material Superiority

· Txhim kho Thermal Properties: Exhibits thermal conductivity ntawm 35 W / m·K (ntawm 100 ° C), nrog ib tug tsawg thermal expansion coefficient (5.3 × 10⁻⁶ / K) uas tiv thaiv optical distortion nyob rau hauv kub ceev cycling. Cov khoom siv tswj kev ncaj ncees txawm tias thaum lub sij hawm thermal shock hloov ntawm 1000 ° C mus rau chav sov hauv vib nas this.

· Chemical Stability: Qhia xoom degradation thaum raug cov concentrated acids (HF tsis suav nrog) thiab alkalis (pH 1-14) rau lub sij hawm ntev, ua rau nws zoo tagnrho rau cov khoom siv tshuaj.

· Kho qhov muag kho qhov muag: Los ntawm kev loj hlob ntawm C-axis siv lead ua, ua tiav> 85% kev sib kis hauv qhov pom spectrum (400-700nm) nrog tawg poob qis dua 0.1% / cm.

· Kev xaiv hyper-hemispherical polishing txo qhov kev xav ntawm qhov chaw mus rau <0.2% ib qhov chaw ntawm 1064nm.

2.Precision Engineering Muaj peev xwm

· Nanoscale Surface Control: Siv magnetorheological finishing (MRF), ua tiav nto roughness <0.3nm Ra, tseem ceeb rau high-power laser daim ntaub ntawv qhov twg LIDT tshaj 10J / cm² ntawm 1064nm, 10ns pulses.

· Complex Geometry Fabrication: Incorporates 5-axis ultrasonic machining rau tsim microfluidic raws (50μm dav kam rau ua) thiab diffractive optical ntsiab (DOE) nrog <100nm feature daws teeb meem.

· Metrology Integration: Sib txuas cov dawb-light interferometry thiab atomic force microscopy (AFM) rau 3D deg characterization, ua kom cov ntaub ntawv raug <100nm PV hla 200mm substrates.

Cov ntawv thov tseem ceeb

1. Kev Tiv Thaiv Kev Txhim Kho

· Hypersonic Tsheb Domes: Engineered los tiv thaiv Mach 5+ aerothermal loads thaum tswj MWIR kis tau tus mob rau cov neeg nrhiav taub hau. Tshwj xeeb nanocomposite ntug seals tiv thaiv delamination nyob rau hauv 15G vibration loads.

· Quantum Sensing Platforms: Ultra-low birefringence (<5nm/cm) versions pab kom precision magnetometry hauv submarine detection systems.

2.Industrial Process Innovation

· Semiconductor Extreme UV Lithography: Qib AA polished qhov rais nrog <0.01nm nto roughness txo EUV (13.5nm) tawg poob hauv cov txheej txheem stepper.

· Nuclear Reactor Monitoring: Neutron-pob tshab variants (Al₂O₃ isotopically purified) muab kev saib xyuas lub sijhawm pom hauv Gen IV reactor cores.

3.Kev sib koom ua ke thev naus laus zis

· Space-Based Optical Comms: Radiation-hardened versions (tom qab 1Mrad gamma raug) tuav> 80% kis rau LEO satellite laser crosslinks.

· Biophotonics Interfaces: Bio-inert nto kho mob pab implantable Raman spectroscopy windows rau kev soj ntsuam cov piam thaj tas li.

4.Advanced Energy Systems

· Fusion Reactor Diagnostics: Multi-layer conductive coatings (ITO-AlN) muab ob qho tib si plasma saib thiab EMI shielding hauv tokamak installations.

· Hydrogen Infrastructure: Cryogenic-qib versions (kuaj rau 20K) tiv thaiv hydrogen embrittlement nyob rau hauv kua H₂ cia saib.

XKH Services & Supply Capabilities

1. Kev Pabcuam Chaw Tsim Khoom

· Drawing-raws li Customization: Txhawb cov qauv tsis tsim qauv (1 hli txog 300 hli qhov ntev), 20-hnub xa khoom sai, thiab thawj zaug prototyping hauv 4 lub lis piam.

· Txheej Txheej: Anti-reflection (AR), anti-fouling (AF), thiab wavelength-specific coatings (UV/IR) kom txo qhov kev xav poob.

· Precision Polishing & Kev Ntsuas: Atomic-theem polishing ua tiav ≤0.5nm nto roughness, nrog interferometry kom ntseeg tau λ / 10 flatness ua raws.

2.Supply Chain & Technical Support

· Vertical Integration: Tag nrho cov txheej txheem tswj los ntawm kev loj hlob siv lead ua (Czochralski txoj kev) rau kev txiav, polishing, thiab txheej, lav cov khoom purity (void-/txheej-dawb) thiab batch sib xws.

· Kev Sib Koom Tes Kev Lag Luam: Muaj ntawv pov thawj los ntawm cov neeg ua haujlwm hauv aerospace; koom tes nrog CAS los tsim superlattice heterostructures rau kev hloov pauv hauv tsev.

3.Product Portfolio & Logistics

· Cov khoom lag luam txheem: 6-nti rau 12-nti wafer hom; unit pricing los ntawm 43to82 (loj / txheej-nyob ntawm seb), nrog rau tib hnub shipping.

· Kev sab laj rau kev tsim cov ntawv thov tshwj xeeb (xws li, cov qhov rais stepped rau lub tshuab nqus tsev vacuum, thermal shock-resistant lug).