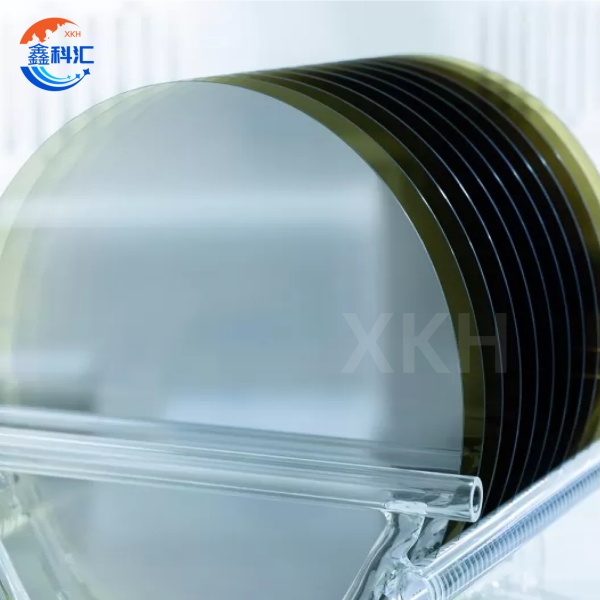

Customized SiC Noob Crystal Substrates Dia 205/203/208 4H-N Hom rau Optical Communications

Technical parameters

Silicon carbide noob wafer | |

Polytype | 4H |

Deg orientation yuam kev | 4 ° rau <11-20> ± 0.5º |

Kev tiv thaiv | kev cai |

Txoj kab uas hla | 205 ± 0.5 hli |

Thickness | 600 ± 50μm |

Roughness | CMP, Ra≤0.2nm |

Micropipe ntom ntom | ≤ 1 ea/cm2 |

Kos | ≤5, Tag Nrho Length≤2 * Txoj kab uas hla |

Ntug chips / indents | Tsis muaj |

Pem hauv ntej laser npav | Tsis muaj |

Kos | ≤2, Tag Nrho Length≤ Diameter |

Ntug chips / indents | Tsis muaj |

Polytype cheeb tsam | Tsis muaj |

Rov qab laser npav | 1mm (los ntawm sab saum toj ntug) |

Ntug | Chamfer |

Ntim | Multi-wafer cassette |

Cov yam ntxwv tseem ceeb

1. Crystal Structure thiab hluav taws xob ua haujlwm

· Crystallographic Stability: 100% 4H-SiC polytype dominance, xoom multicrystalline inclusions (piv txwv li, 6H/15R), nrog XRD rocking nkhaus puv-dav ntawm ib nrab-siab tshaj plaws (FWHM) ≤32.7 arcsec.

· High Carrier Mobility: Electron zog ntawm 5,400 cm² / V·s (4H-SiC) thiab qhov txav ntawm 380 cm² / V·s, ua kom muaj kev tsim khoom siv ntau zaus.

· Radiation Hardness: Withstands 1 MeV neutron irradiation nrog rau kev puas tsuaj rau qhov chaw pib ntawm 1 × 10¹⁵ n / cm², zoo tagnrho rau kev siv aerospace thiab nuclear.

2. Thermal thiab Mechanical Properties

· Exceptional Thermal Conductivity: 4.9 W / cm · K (4H-SiC), triple ntawm silicon, txhawb kev ua haujlwm siab tshaj 200 ° C.

· Tsawg Thermal Expansion Coefficient: CTE ntawm 4.0 × 10⁻⁶ / K (25–1000 ° C), ua kom muaj kev sib raug zoo nrog cov ntim khoom siv silicon thiab txo qis thermal stress.

3. Kev tswj tsis raug thiab ua tiav Precision

· Micropipe Density: <0.3 cm⁻² (8-nti wafers), dislocation ceev <1,000 cm⁻² (tsim los ntawm KOH etching).

· Nto Zoo: CMP-polished rau Ra <0.2 nm, ntsib EUV lithography-qib flatness yuav tsum.

Cov ntawv thov tseem ceeb

| Domain ua | Daim ntawv thov Scenarios | Technical Advantages |

| Kev sib txuas lus kho qhov muag | 100G / 400G lasers, silicon photonics hybrid modules | InP noob substrates pab ncaj qha bandgap (1.34 eV) thiab Si-raws li heteroepitaxy, txo cov optical coupling poob. |

| New Energy Tsheb | 800V high-voltage inverter, onboard chargers (OBC) | 4H-SiC substrates tiv taus> 1,200 V, txo qhov kev poob qis los ntawm 50% thiab lub cev ntim los ntawm 40%. |

| 5G Kev Sib Txuas Lus | millimeter-wave RF li (PA/LNA), lub hauv paus chaw nres tsheb fais fab amplifiers | Semi-insulating SiC substrates (resistivity> 10⁵ Ω·cm) pab kom muaj kev sib tw siab (60 GHz +) passive kev koom ua ke. |

| Cov Khoom Siv Hluav Taws Xob | High-temperature sensors, tam sim no transformers, nuclear reactor saib | InSb noob substrates (0.17 eV bandgap) xa magnetic rhiab heev txog 300% @ 10 T. |

Qhov Zoo Tshaj Plaws

SiC (silicon carbide) noob siv lead ua substrates xa cov kev ua tau zoo tsis sib xws nrog 4.9 W / cm · K thermal conductivity, 2-4 MV / cm tawg lub zog, thiab 3.2 eV dav bandgap, ua kom lub zog siab, siab zaus, thiab kev siv kub. Featuring xoom micropipe ntom ntom thiab <1,000 cm⁻² dislocation ceev, cov substrates ua kom muaj kev ntseeg siab nyob rau hauv huab cua. Lawv cov tshuaj inertness thiab CVD-tshaj qhov chaw (Ra <0.2 nm) txhawb kev loj hlob heteroepitaxial (piv txwv li, SiC-on-Si) rau optoelectronics thiab EV fais fab tshuab.

XKH Services:

1. Customized ntau lawm

· Cov hom ntawv yooj yim Wafer: 2-12-nti wafers nrog ncig, duab plaub, los yog kev cai-zoo li txiav (± 0.01 hli kam rau ua).

· Doping Control: Precise nitrogen (N) thiab txhuas (Al) doping ntawm CVD, ua tiav qhov kev tiv thaiv ntawm 10⁻³ txog 10⁶ Ω·cm.

2. Cov txheej txheem Advanced Technologyua

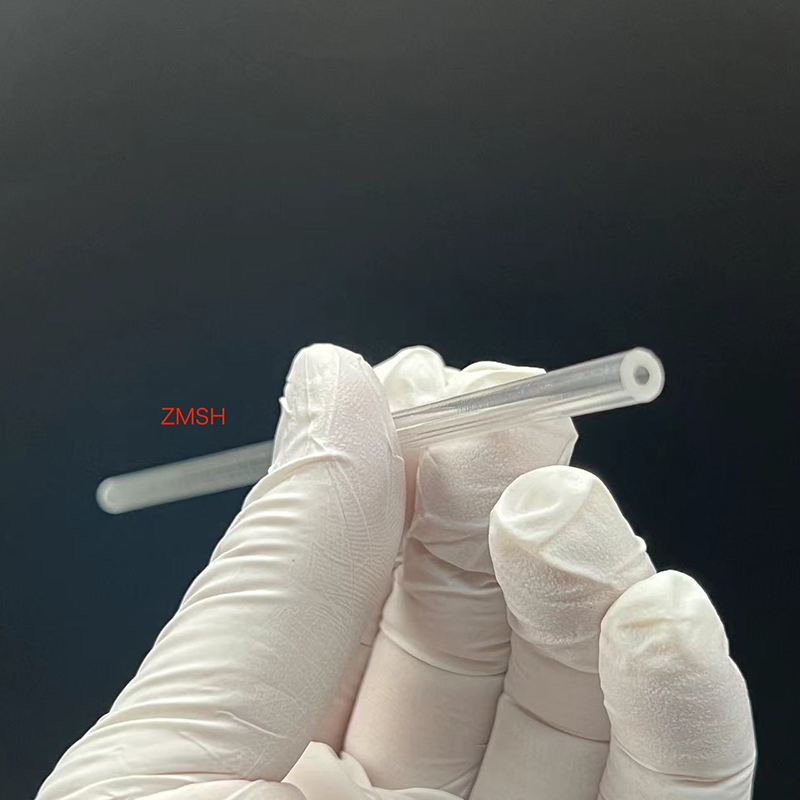

· Heteroepitaxy: SiC-on-Si (sib haum nrog 8-nti silicon kab) thiab SiC-on-Piamond (thermal conductivity> 2,000 W / m·K).

· Kev txo qis: Hydrogen etching thiab annealing kom txo cov micropipe / ntom qhov tsis xws luag, txhim kho wafer tawm los rau> 95%.

3. Kev Tswj Xyuas Zooua

· Kev Xeem Kawg-rau-End: Raman spectroscopy (polytype pov thawj), XRD (crystallinity), thiab SEM (kev tshuaj xyuas tsis raug).

· Cov ntawv pov thawj: Ua raws li AEC-Q101 (automotive), JEDEC (JEDEC-033), thiab MIL-PRF-38534 (qib tub rog).

4. Ntiaj teb no Supply Chain Supportua

· Muaj Peev Xwm Ntau Lawm: Cov zis txhua hli> 10,000 wafers (60% 8-nti), nrog rau 48-teev thaum muaj xwm txheej ceev.

· Logistics Network: Kev pab them nqi hauv Europe, North America, thiab Asia-Pacific ntawm huab cua / hiav txwv freight nrog kub tswj ntim.

5. Kev Tsim Kho Kev Lag Luamua

· Sib koom R&D Labs: Sib koom ua ke ntawm SiC fais fab module ntim optimization (xws li, DBC substrate integration).

· IP Daim Ntawv Tso Cai: Muab GaN-on-SiC RF epitaxial loj hlob daim ntawv tso cai los txo cov neeg siv khoom R&D cov nqi.

Cov ntsiab lus

SiC (silicon carbide) noob siv lead ua substrates, raws li cov khoom siv tswv yim, tab tom hloov kho thoob ntiaj teb kev lag luam chains los ntawm kev tawg hauv kev loj hlob siv lead ua, kev tswj tsis raug, thiab kev sib koom ua ke ntau yam. Los ntawm tsis tu ncua kev nce qib wafer tsis xws luag, scaling 8-nti ntau lawm, thiab nthuav heteroepitaxial platforms (xws li, SiC-on-Piamond), XKH xa high-reliability, nqi-zoo daws rau optoelectronics, tshiab zog, thiab advanced manufacturing. Peb qhov kev cog lus rau kev tsim kho tshiab ua kom cov neeg siv khoom ua tau zoo hauv cov pa roj carbon nruab nrab thiab cov tshuab ntse, tsav lub sijhawm tom ntej ntawm cov khoom siv hluav taws xob dav dav.