CVD txoj kev ua kom muaj siab purity SiC raw khoom hauv silicon carbide synthesis rauv ntawm 1600 ℃

Txoj haujlwm ua haujlwm:

1. Precursor mov. Silicon qhov chaw (xws li SiH₄) thiab cov pa roj carbon (xws li C₃H₈) gases yog sib xyaw ua ke thiab muab nkag rau hauv cov tshuaj tiv thaiv chamber.

2. Kev kub siab decomposition: Ntawm qhov kub ntawm 1500 ~ 2300 ℃, cov roj decomposition generates Si thiab C active atoms.

3. Cov tshuaj tiv thaiv nto: Si thiab C atoms tso rau ntawm lub substrate nto los ua ib txheej SiC siv lead ua.

4. Crystal kev loj hlob: Los ntawm kev tswj ntawm qhov kub thiab txias gradient, roj ntws thiab siab, kom ua tiav cov kev taw qhia kev loj hlob raws tus c axis lossis lub axis.

Cov ntsiab lus tseem ceeb:

Kub: 1600 ~ 2200 ℃ (> 2000 ℃ rau 4H-SiC)

· Siab: 50 ~ 200mbar (tsis tshua muaj siab los txo cov roj nucleation)

· Gas ratio: Si/C≈1.0 ~ 1.2 (kom tsis txhob Si los yog C enrichment defects)

Cov yam ntxwv tseem ceeb:

(1) Crystal zoo

Tsawg defect ceev: microtubule ntom <0.5cm ⁻², dislocation ceev <10⁴ cm⁻².

Polycrystalline hom tswj: tuaj yeem loj hlob 4H-SiC (mainstream), 6H-SiC, 3C-SiC thiab lwm yam siv lead ua.

(2) Cov khoom siv ua haujlwm

Kev ruaj ntseg kub siab: graphite induction cua sov lossis cua sov ua haujlwm, kub> 2300 ℃.

Kev tswj tsis sib xws: kub hloov pauv ± 5 ℃, kev loj hlob ntawm 10 ~ 50μm / h.

Gas system: High precision mass flowmeter (MFC), roj purity ≥99.999%.

(3) Kev siv technology zoo

High purity: Tom qab impurity concentration <10¹⁶ cm⁻³ (N, B, thiab lwm yam).

Loj loj: Txhawb 6 "/8" SiC substrate kev loj hlob.

(4) Kev siv hluav taws xob thiab nqi

Kev siv hluav taws xob siab (200 ~ 500kW·h ib lub cub tawg), suav txog 30% ~ 50% ntawm cov nqi tsim khoom ntawm SiC substrate.

Core applications:

1. Fais fab semiconductor substrate: SiC MOSFETs rau kev tsim hluav taws xob tsheb thiab photovoltaic inverters.

2. Rf ntaus ntawv: 5G puag chaw nres tsheb GaN-on-SiC epitaxial substrate.

3.Extreme ib puag ncig li: kub sensors rau aerospace thiab nuclear fais fab nroj tsuag.

Technical specification:

| Specification | Paub meej |

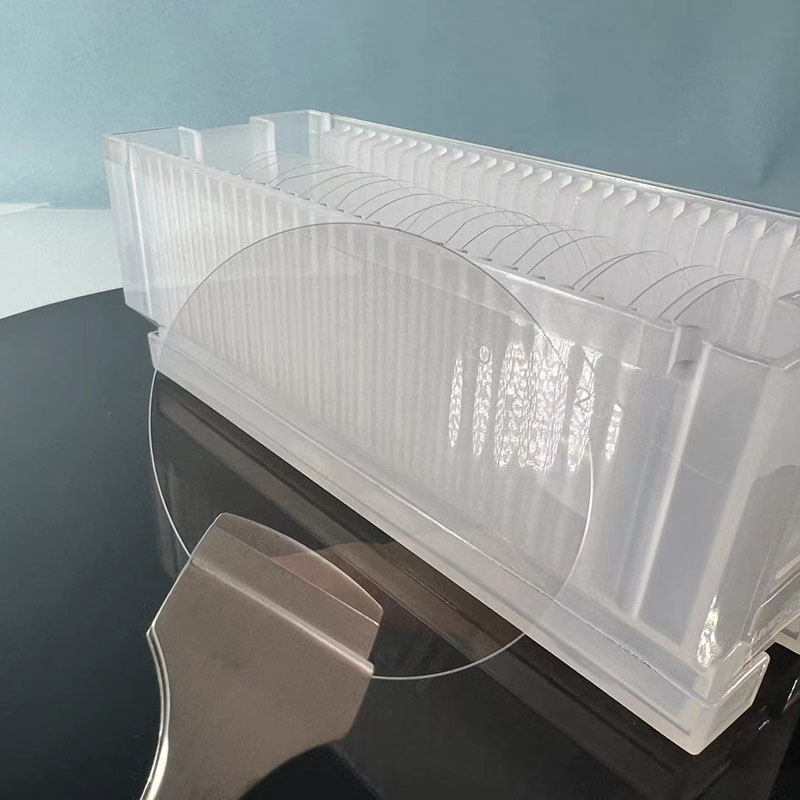

| Qhov Loj (L × W × H) | 4000 x 3400 x 4300 mm los yog kho |

| Rauv chamber diameter | 1100 hli |

| Chaw thau khoom muaj peev xwm | 50kg ua |

| Qhov txwv lub tshuab nqus tsev degree | 10-2Pa (2h tom qab lub twj tso kua mis molecular pib) |

| Chamber siab nce tus nqi | ≤10Pa / h (tom qab calcination) |

| Lower furnace cover lifting stroke | 1500 hli |

| Txoj kev cua sov | Induction cua sov |

| Qhov kub siab tshaj plaws hauv qhov cub | 2400 ° C |

| Cua sov fais fab mov | 2 x 40 kW |

| Kev ntsuas kub | Ob-xim infrared ntsuas kub |

| Qhov kub thiab txias | 900 ~ 3000 ℃ |

| Kub tswj qhov tseeb | ± 1 ° C |

| Tswj siab ntau yam | 1 ~ 700 hli |

| Siab tswj qhov tseeb | 1 ~ 5mbar ± 0.1mbar; 5 ~ 100mbar ± 0.2mbar; 100 ~ 700mbar ± 0.5mbar |

| Txoj kev thauj khoom | Kev thauj khoom qis; |

| Yeem configuration | Ob chav ntsuas qhov ntsuas kub, unloading forklift. |

XKH Services:

XKH muab cov kev pabcuam tag nrho rau silicon carbide CVD furnaces, suav nrog cov khoom siv kho kom haum (kub thaj chaw tsim, gas system configuration), txheej txheem kev txhim kho (crystal control, defect optimization), kev cob qhia (kev khiav hauj lwm thiab tu) thiab kev pab cuam tom qab muag (cov khoom seem ntawm cov khoom tseem ceeb, kev kuaj xyuas tej thaj chaw deb) los pab cov neeg muas zaub ua tau zoo ntau lawm SiC substrate. Thiab muab cov txheej txheem hloov kho cov kev pab cuam txuas ntxiv txhim kho siv lead ua yield thiab kev loj hlob efficiency.