Pob zeb diamond hlau peb-chaw nres tsheb ib-hlau txiav tshuab rau Si Wafer / Optical iav khoom txiav

Khoom Taw Qhia

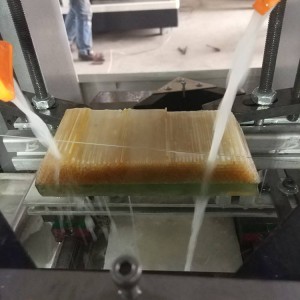

Lub pob zeb diamond hlau peb-chaw nres tsheb ib leeg-xaim txiav tshuab yog cov cuab yeej ua haujlwm siab thiab ua haujlwm siab tsim los rau cov ntaub ntawv nyuaj thiab nkig. Nws siv cov pob zeb diamond hlau raws li qhov nruab nrab ntawm kev txiav thiab tsim nyog rau kev ua tiav ntawm cov ntaub ntawv hardness xws li silicon wafers, sapphire, silicon carbide (SiC), ceramics, thiab optical iav. Featuring ib tug peb-chaw nres tsheb tsim, lub tshuab no enables ib txhij txiav ntawm ntau workpieces ntawm ib tug ntaus ntawv, ho txhim kho efficiency ntau lawm thiab txo cov nqi tsim khoom.

Txoj Cai Ua Haujlwm

- Pob zeb diamond hlau txiav: Siv electroplated los yog resin-bonded pob zeb diamond hlau los ua kev sib tsoo-raws li txiav los ntawm kev kub ceev reciprocating tsab ntawv tsa suab.

- Three-Station Synchronous Cutting: Nruab nrog peb qhov chaw ua haujlwm ywj pheej, tso cai rau kev txiav ib txhij ntawm peb daim los txhim kho cov khoom siv.

- Kev Tswj Kev Nyuaj Siab: Koom nrog lub siab-precision nro tswj system kom ruaj khov pob zeb diamond hlau nro thaum txiav, ua kom raug.

- Txias & Lubrication System: Ua haujlwm dej deionized los yog tshwj xeeb coolant kom txo thermal puas thiab ncua pob zeb diamond hlau lifespan.

Khoom nta

- High-Precision Txiav: Ua tiav qhov tseeb ntawm ± 0.02mm, zoo tagnrho rau kev ua haujlwm ultra-thin wafer (xws li photovoltaic silicon wafers, semiconductor wafers).

- High Efficiency: Peb-chaw nres tsheb tsim tsim tau ntau tshaj 200% piv rau ib-chaw nres tsheb tshuab.

- Cov Khoom Siv Tsawg: Kev tsim cov kerf nqaim (0.1–0.2mm) txo cov khoom pov tseg.

- High Automation: nta tsis siv neeg thauj khoom, sib dhos, txiav, thiab tshem tawm cov tshuab, txo cov kev cuam tshuam ntawm phau ntawv.

- High Adaptability: Muaj peev xwm txiav ntau yam khoom tawv thiab nkig, suav nrog monocrystalline silicon, polycrystalline silicon, sapphire, SiC, thiab ceramics.

Technical Advantage

| Qhov zoo

| Kev piav qhia

|

| Multi-Station Synchronous Txiav

| Peb qhov chaw tswj hwm tus kheej ua rau kev txiav cov khoom ua haujlwm nrog cov thicknesses sib txawv lossis cov khoom siv, txhim kho kev siv cov khoom siv.

|

| Intelligent Tension Control

| Kaw-loop tswj nrog servo motors thiab sensors ua kom cov hlau nro tas li, tiv thaiv kev tawg lossis txiav kev sib txawv.

|

| High-Rigidity Structure

| High-precision linear qhia thiab servo-tsav tshuab kom ruaj khov txiav thiab txo qis kev vibration.

|

| Zog Efficiency & Eco-Friendliness

| Piv nrog rau kev txiav slurry tsoos, pob zeb diamond hlau txiav yog tsis muaj kuab paug, thiab cov dej txias tuaj yeem rov ua dua, txo cov nqi kho cov khib nyiab.

|

| Kev soj ntsuam ntse

| Nruab nrog PLC thiab kov-screen tswj tshuab rau kev saib xyuas lub sijhawm ntawm kev txiav ceev, nro, kub, thiab lwm yam, txhawb nqa cov ntaub ntawv traceability. |

Technical Specification

| Qauv | Peb qhov chaw nres tsheb pob zeb diamond ib kab txiav tshuab |

| Qhov siab tshaj plaws workpiece loj | 600 * 600 hli |

| Hlau khiav ceev | 1000 (MIX) m/min |

| Pob zeb diamond hlau diam | 0.25-0.48 hli |

| Kab cia muaj peev xwm ntawm cov khoom siv log | 20km ua |

| Txiav thickness ntau | 0-600 hli |

| Txiav raug | 0.01mm ib |

| Vertical lifting stroke ntawm workstation | 800 hli |

| Txiav txoj kev | Cov khoom yog nyob ruaj ruaj, thiab pob zeb diamond hlau sways thiab nqis |

| Txiav pub ceev | 0.01-10mm / min (raws li cov khoom thiab thickness) |

| Lub tank dej | 150 L |

| Txiav kua | Anti xeb high-efficiency txiav kua |

| Lub kaum sab xis | ± 10 ° |

| Swing ceev | 25 ° / s |

| Qhov siab tshaj plaws txiav nro | 88.0N (Teeb yam tsawg kawg nkaus unit 0.1n) |

| Txiav qhov tob | 200 ~ 600 hli |

| Ua kom sib txuas daim hlau raws li tus neeg siv khoom txiav | - |

| Chaw ua haujlwm | 3 |

| Fais fab mov | Peb theem tsib xaim AC380V / 50Hz |

| Tag nrho lub zog ntawm lub tshuab cuab yeej | ≤ 32kw |

| Main lub cev muaj zog | 1 * 2 kWm |

| Lub cev muaj zog | 1 * 2 kWm |

| Workbench viav vias motor | 0.4 * 6kw |

| Tension tswj lub cev muaj zog | 4.4 * 2kw |

| Hlau tso tawm thiab sau lub cev muaj zog | 5.5 * 2.5 hli |

| Sab nraud qhov ntev (tsis suav nrog rocker arm box) | 4859 * 2190 * 2184 hli |

| Sab nraud qhov ntev (nrog rau lub thawv rocker caj npab) | 4859 * 2190 * 2184 hli |

| Tshuab hnyav | 3600 ua |

Daim ntawv thov teb

- Kev lag luam photovoltaic: Slicing ntawm monocrystalline thiab polycrystalline silicon ingots los txhim kho wafer tawm los.

- Kev lag luam semiconductor: Precision txiav ntawm SiC thiab GaN wafers.

- Kev lag luam LED: Txiav sapphire substrates rau LED nti tsim.

- Advanced Ceramics: Tsim thiab txiav cov khoom siv ua haujlwm siab zoo li alumina thiab silicon nitride.

- Kho qhov muag iav: Precision ua ntawm ultra-nyias iav rau lub koob yees duab lo ntsiab muag thiab infrared qhov rais.