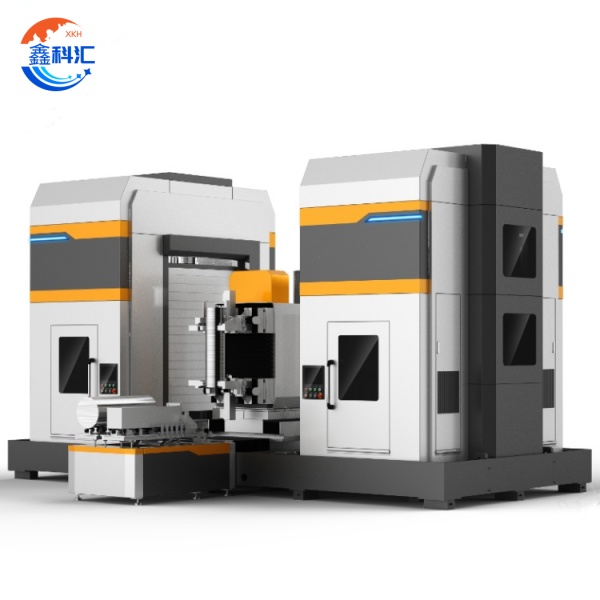

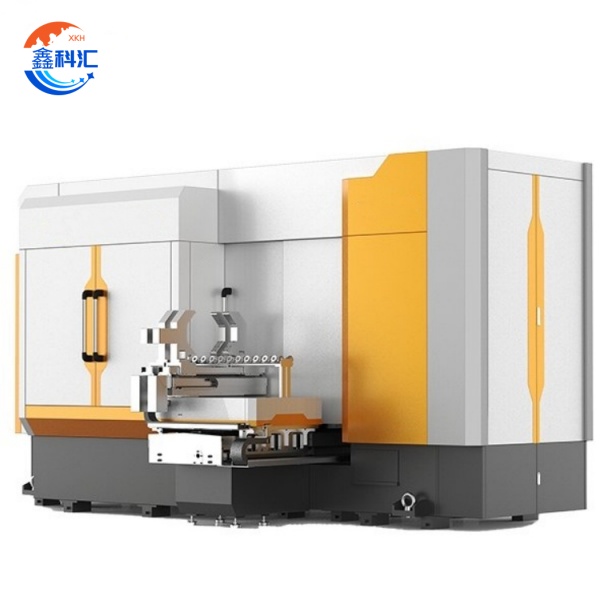

Ob chav chaw nres tsheb square tshuab monocrystalline silicon pas nrig ua 6/8/12 nti nto flatness Ra≤0.5μm

Khoom nta:

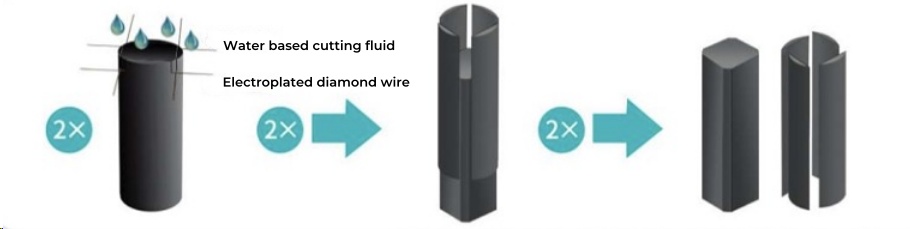

(1) Ob chav chaw nres tsheb synchronous ua

· Ob chav efficiency: Ib txhij ua ntawm ob lub silicon rods (Ø6 "-12") nce productivity los ntawm 40% -60% vs. Simplex khoom.

· Kev tswj hwm ywj pheej: Txhua qhov chaw nres tsheb tuaj yeem kho tus kheej ntawm qhov kev txiav txim siab (nruj, pub ceev) kom hloov mus rau qhov sib txawv silicon pas nrig specifications.

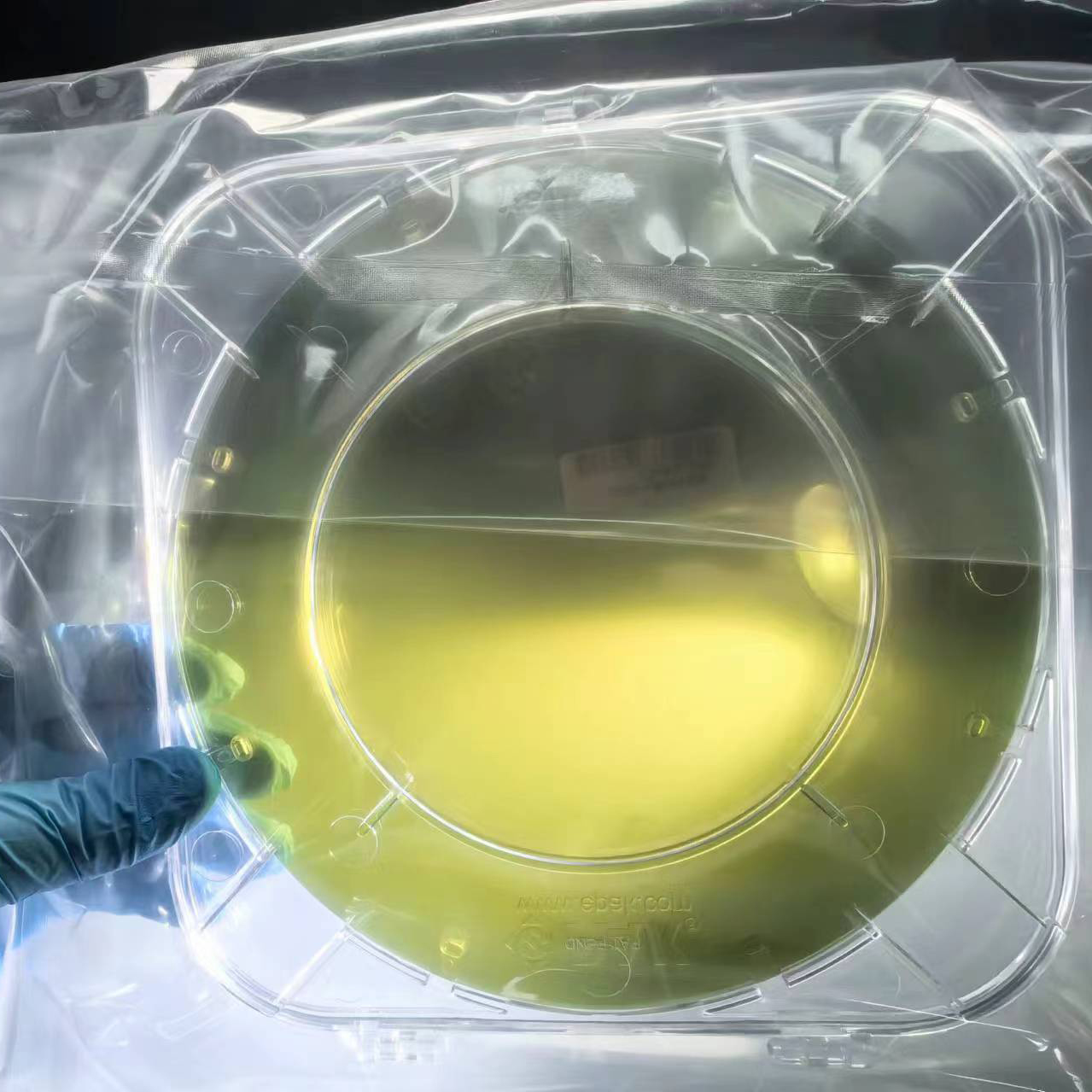

(2) High-precision txiav

· Dimensional raug: square bar sab nrug kam rau ua ± 0.15mm, ntau yam ≤0.20mm.

· Nto zoo: txiav ntug tawg <0.5mm, txo qhov sib tsoo tom ntej.

(3) Kev txawj ntse tswj

· Adaptive cutting: real-time saib xyuas ntawm silicon pas nrig morphology, dynamic hloov ntawm txoj kev txiav (xws li kev khoov silicon pas nrig).

· Cov ntaub ntawv traceability: sau cov kev ua tsis tau ntawm txhua tus pas nrig silicon los txhawb MES system docking.

(4) Tsawg tus nqi siv tau

· Pob zeb diamond hlau noj: ≤0.06m / mm (silicon pas nrig ntev), hlau txoj kab uas hla ≤0.30mm.

· Coolant ncig: Lub kaw lus pom txuas ntxiv lub neej kev pabcuam thiab txo cov kua dej pov tseg.

Technology thiab kev loj hlob zoo:

(1) Txiav tshuab optimization

- Ntau kab txiav: 100-200 pob zeb diamond kab yog siv nyob rau hauv parallel, thiab txiav ceev yog ≥40mm / min.

- Kev tswj nruj: kaw lub voj kev hloov kho (± 1N) kom txo tau txoj kev pheej hmoo ntawm cov hlau tawg.

(2) Compatibility extension

- Cov khoom siv hloov pauv: Txhawb P-hom / N-hom monocrystalline silicon, sib xws nrog TOPCon, HJT thiab lwm cov roj teeb uas muaj txiaj ntsig zoo silicon rods.

- Saj zawg zog loj: silicon pas nrig ntev 100-950mm, square pas nrig sab nrug 166-233mm adjustable.

(3) Automation hloov tshiab

- Neeg hlau thauj khoom thiab tshem tawm: tsis siv neeg thauj khoom / tshem tawm ntawm cov pas nrig silicon, tuav ≤3 feeb.

- Kev tshuaj ntsuam xyuas ntse: Kev saib xyuas kwv yees kom txo qis kev poob qis.

(4) Kev ua thawj coj hauv kev lag luam

- Kev them nyiaj yug Wafer: tuaj yeem ua tiav ≥100μm ultra-thin silicon nrog square rods, fragmentation tus nqi <0.5%.

- Kev siv hluav taws xob kom zoo: Kev siv hluav taws xob rau ib chav tsev ntawm silicon pas nrig yog txo los ntawm 30% (vs.

Technical Parameters:

| Lub npe parameter | Index tus nqi |

| Tus naj npawb ntawm cov tuav tau ua tiav | 2 pcs / teev |

| Kev ua bar ntev ntau yam | 100 ~ 950 hli |

| Machining margin ntau yam | 166-233 hli |

| Txiav ceev | ≥40mm / min |

| Pob zeb diamond hlau ceev | 0 ~ 35m / s |

| Pob zeb diamond txoj kab uas hla | 0.30mm los yog tsawg dua |

| Linear noj | 0.06m / mm los yog tsawg dua |

| Tau tshaj round pas nrig txoj kab uas hla | Tiav square pas nrig txoj kab uas hla + 2mm, Xyuas kom polishing dhau tus nqi |

| Txiav ntug breakage tswj | Raw ntug ≤0.5mm, Tsis muaj chipping, zoo nto zoo |

| Arc ntev uniformity | Projection ntau yam <1.5mm, Tsuas yog silicon pas nrig distortion |

| Tshuab qhov ntev (ib lub tshuab) | 4800 × 3020 × 3660mm |

| Tag nrho cov nqi zog | 56 kW ua |

| Cov khoom hnyav tuag | 12t ib |

Machining qhov tseeb Index Table:

| Yam khoom Precision | Tolerance ntau |

| Square bar margin kam rau ua | ± 0.15 hli |

| Square bar ntug ntau yam | ≤0.20mm |

| Lub kaum sab xis ntawm txhua sab ntawm square pas nrig | 90 ° ± 0.05 ° |

| Flatness ntawm square pas nrig | ≤0.15mm |

| Robot rov ua qhov tseeb | ± 0.05 hli |

XKH cov kev pabcuam:

XKH muab cov kev pabcuam tag nrho rau mono-crystalline silicon dual-station tshuab, suav nrog cov khoom siv kho kom haum (sib haum nrog cov silicon rods loj), cov txheej txheem commissioning (txiav parameter optimization), kev cob qhia kev ua haujlwm thiab kev txhawb nqa tom qab muag (qhov tseem ceeb ntawm cov khoom siv, kuaj cov chaw taws teeb), kom ntseeg tau tias cov neeg siv khoom tau txais txiaj ntsig siab (> 99%) thiab kev tsim khoom siv qis qis (AI) kev tsim khoom thiab kev txhim kho cov nqi qis. Lub sijhawm khoom xa tuaj yog 2-4 lub hlis.

Daim duab qhia ntxaws