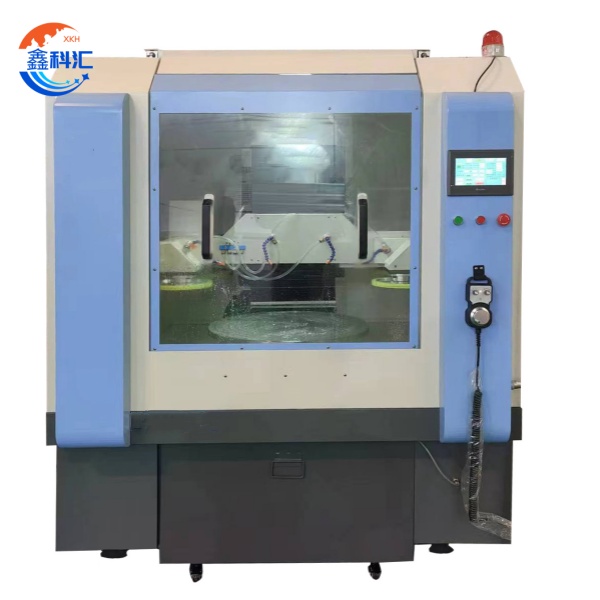

Tsis Siv Neeg Wafer Nplhaib-Txiav Cov Khoom Siv Ua Haujlwm Loj 8inch / 12inch Wafer Nplhaib Txiav

Technical parameters

| Parameter | Chav tsev | Specification |

| Qhov siab tshaj plaws workpiece loj | mm | Ø 12" |

| Spindle | Kev teeb tsa | Tib Spindle |

| Ceev | 3,000-60,000 rpm | |

| Tso zis zog | 1.8 kW (2.4 yeem) ntawm 30,000 min⁻¹ | |

| Max Blade Dia. | Ø 58 mm | |

| X-Axis | Txiav ntau yam | 310 hli |

| Y-Axis | Txiav ntau yam | 310 hli |

| Kauj ruam nce | 0.0001 hli | |

| Positioning raug | ≤0.003 hli / 310 hli, ≤0.002 hli / 5 hli (ib qho yuam kev) | |

| Z-Axis | Movement Resolution | 0.00005 hli |

| Rov ua dua | 0.001 hli | |

| θ-Axis | Max kev sib hloov | 380 deg |

| Spindle Hom | Ib leeg spindle, nruab nrog cov hniav txhav rau lub nplhaib txiav | |

| Nplhaib-txiav raug | ib m | ± 50 |

| Wafer Positioning raug | ib m | ± 50 |

| Ib leeg-wafer Efficiency | min / wafer | 8 |

| Multi-Wafer Efficiency | Txog li 4 wafers ua tiav ib txhij | |

| Khoom hnyav | kg | ≈3,200 |

| Khoom Dimensions (W × D × H) | mm | 2,730 × 1,550 × 2,070 |

Txoj Cai Kev Ua Haujlwm

Lub kaw lus ua tiav qhov tshwj xeeb trimming kev ua tau zoo los ntawm cov thev naus laus zis no:

1.Intelligent Motion Control System:

· High-precision linear tsav tsav (rov ua dua qhov tseeb: ± 0.5μm)

· Six-axis synchronous tswj txhawb txoj kev npaj txoj hauv kev

· Real-time vibration suppression algorithms kom ntseeg tau txiav kev ruaj ntseg

2.Advanced Detection System:

· Integrated 3D laser qhov siab sensor (qhov tseeb: 0.1μm)

· High-resolution CCD pom qhov chaw (5 megapixels)

· Online kev soj ntsuam zoo module

3. Cov txheej txheem ua haujlwm puv npo:

· Tsis siv neeg loading / unloading (FOUP txheem interface tau tshaj)

· ntse sorting system

· Kaw-loop tu chav tsev (kev huv: Chav 10)

Tej kev siv

Cov khoom siv no muab tus nqi tseem ceeb thoob plaws hauv kev tsim khoom semiconductor:

| Daim ntawv thov teb | Cov ntaub ntawv txheej txheem | Technical Advantage |

| IC Manufacturing | 8/12 "Silicon Wafers | Txhim kho lithography alignment |

| Cov khoom siv fais fab | SiC/GaN Wafers | Tiv thaiv ntug tsis xws luag |

| MEMS Sensors | SOI Wafers | Ua kom cov cuab yeej ntseeg tau |

| RF Devices | GaAs Wafers | Txhim kho kev ua haujlwm siab |

| Advanced Ntim | Reconstituted Wafers | Ua kom ntim cov khoom tawm |

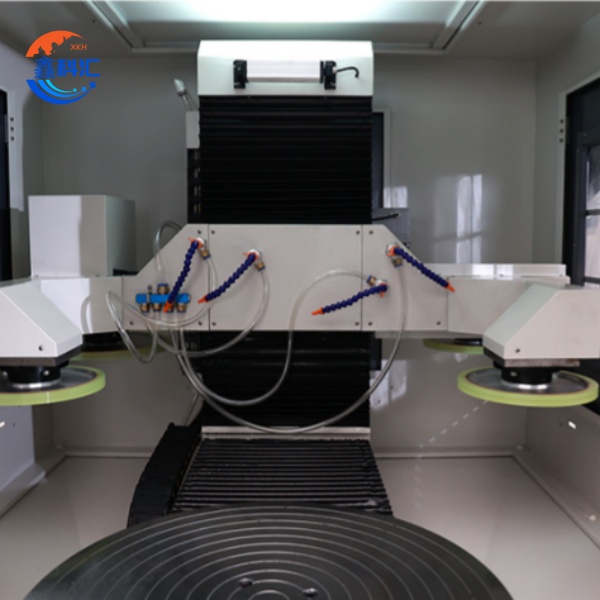

Nta

1.Four-chaw nres tsheb configuration rau siab ua efficiency;

2.Stable TAIKO nplhaib debonding thiab tshem tawm;

3.High compatibility nrog cov khoom tseem ceeb;

4.Multi-axis synchronous trimming thev naus laus zis ua kom paub tseeb ntug txiav;

5.Txoj kev ua haujlwm puv ntoob ntws tau txo cov nqi zog;

6.Customized worktable tsim ua kom ruaj khov ntawm cov qauv tshwj xeeb;

Muaj nuj nqi

1.Nplhaib-nplaum detection system;

2.Automatic worktable tu;

3.Intelligent UV debonding system;

4.Operation cav kaw;

5.Factory automation module kev koom ua ke;

Kev cog lus rau kev pabcuam

XKH muab cov kev pabcuam dav dav, tag nrho lub neej txhawb nqa tsim los ua kom cov cuab yeej ua haujlwm tau zoo thiab ua haujlwm tau zoo thoob plaws hauv koj txoj kev tsim khoom.

1. Kev Pabcuam Customization

· Cov Khoom Siv Kho Kom Zoo: Peb pab pawg engineering koom tes nrog cov neeg siv khoom kom ua kom zoo dua cov txheej txheem (txiav ceev, xaiv cov hniav, thiab lwm yam) raws li cov khoom siv tshwj xeeb (Si / SiC / GaAs) thiab cov txheej txheem yuav tsum tau ua.

· Kev Txhawb Txhawb Kev Txhim Kho: Peb muab cov qauv ua piv txwv nrog cov ntaub ntawv qhia ntxaws ntxaws suav nrog kev ntsuas ntug roughness thiab qhov tsis xws luag.

· Consumables Co-Development: Rau cov ntaub ntawv tshiab (xws li, Ga₂O₃), peb koom tes nrog cov tuam txhab tsim khoom siv los tsim cov ntawv tshwj xeeb cov hniav / laser optics.

2. Kev txhawb nqa kev tshaj lij

· Dedicated On-Site Support: Muab ntawv pov thawj engineers rau qhov tseem ceeb ramp-up theem (feem ntau 2-4 lub lis piam), npog:

Khoom calibration & txheej txheem fine-tuning

Kev cob qhia tus neeg ua haujlwm muaj peev xwm

ISO Class 5 Cleanroom integration kev taw qhia

· Kev Saib Xyuas Kev Noj Qab Haus Huv: Kev kuaj xyuas kev noj qab haus huv peb lub hlis twg nrog kev soj ntsuam kev vibration thiab servo motor diagnostics los tiv thaiv kev poob qis.

· Kev Saib Xyuas Chaw Taws Teeb: Cov cuab yeej siv sijhawm tiag tiag taug qab los ntawm peb lub platform IoT (JCFront Connect®) nrog cov lus ceeb toom tsis txaus ntseeg.

3. Kev Pabcuam muaj nqis ntxiv

· Txheej Txheem Kev Paub: Nkag mus rau 300+ daim ntawv qhia txiav cov ntaub ntawv siv tau rau ntau yam (hloov kho peb lub hlis twg).

· Technology Roadmap Alignment: Cov ntaub ntawv pov thawj yav tom ntej koj cov peev txheej nrog kho vajtse / software txhim kho txoj hauv kev (xws li AI-raws li kev kuaj xyuas qhov tsis zoo).

· Teb Thaum Muaj Xwm Ceev: Tau lees paub 4-teev kev kuaj kab mob chaw taws teeb thiab 48-teev kev cuam tshuam ntawm qhov chaw (kev pabcuam thoob ntiaj teb).

4. Kev Pabcuam Infrastructure

· Kev Ua Haujlwm Zoo: Daim ntawv cog lus cog lus rau ≥98% cov khoom siv uptime nrog SLA-rov qab lub sij hawm teb.

Kev txhim kho txuas ntxiv

Peb ua kev tshawb fawb txog kev txaus siab rau cov neeg siv khoom ib xyoos thiab siv Kaizen cov phiaj xwm los txhim kho kev xa khoom. Peb pab pawg R & D txhais cov kev nkag siab ntawm cov khoom siv hloov kho tshiab - 30% ntawm kev txhim kho firmware pib los ntawm cov neeg siv khoom tawm tswv yim.