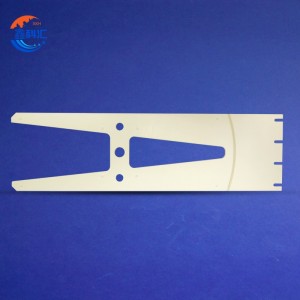

High-Performance Alumina Ceramic End Effector (Fork Arm) rau Semiconductor thiab Cleanroom Automation

Daim duab qhia ntxaws

Khoom Taw Qhia

Alumina Ceramic End Effector, tseem hu ua ceramic diav rawg caj npab los yog robotic ceramic tes, yog ib tug high-precision tuav tivthaiv tsim rau automated systems nyob rau hauv semiconductor, photovoltaic, vaj huam sib luag zaub, thiab high-purity kuaj ib puag ncig. Nws yog engineered los muab tshwj xeeb thermal stability, mechanical rigidity, thiab tshuaj tiv thaiv, muab huv si, txhim khu kev qha, thiab kev nyab xeeb thauj cov ntaub ntawv rhiab heev xws li silicon wafers, iav substrates, thiab hluav taws xob micro-components.

Raws li hom robotic kawg effector, cov khoom siv ceramic no yog qhov kawg ntawm kev sib txuas ntawm lub tshuab automation thiab cov khoom ua haujlwm. Nws ua lub luag haujlwm tseem ceeb hauv kev hloov pauv, kev sib dhos, thauj khoom / tshem tawm, thiab tso cov haujlwm hauv chav huv thiab qhov chaw nqus.

Khoom Txheej Txheem - Alumina Ceramic (Al₂O₃)

Alumina ceramic yog ib qho ruaj khov thiab chemically inert technical ceramic khoom paub txog nws cov khoom zoo heev thiab hluav taws xob. Lub high-purity (≥ 99.5%) alumina siv nyob rau hauv cov kawg effectors xyuas kom meej:

-

Siab hardness (Mohs 9): Thib ob tsuas yog pob zeb diamond, alumina muab kev hnav tsis kam.

-

Muaj peev xwm kub: Ua kom muaj kev ncaj ncees siab tshaj 1600 ° C.

-

Tshuaj inertness: Resistant rau acids, alkalis, kuab tshuaj, thiab plasma etching ib puag ncig.

-

Hluav taws xob rwb thaiv tsev: Nrog lub zog dielectric siab thiab qis dielectric poob.

-

Tsawg thermal expansion: Ua kom muaj qhov ruaj khov nyob hauv qhov chaw thermal cycling.

-

Tsawg particle tiam: Qhov tseem ceeb rau kev ua kom huv huv (Class 10 txog Chav Kawm 1000).

Cov yam ntxwv no ua rau alumina ceramic zoo tagnrho rau kev ua haujlwm tseem ceeb hauv kev lag luam sib kis-rhiab heev.

Kev siv ua haujlwm

Alumina ceramic kawg effector yog dav siv nyob rau hauv high-tech industrial processes, tshwj xeeb tshaj yog nyob rau hauv cov tsoos metallic los yog yas cov ntaub ntawv poob luv vim thermal expansion, paug, los yog corrosion. Cov ntawv thov tseem ceeb suav nrog:

- Semiconductor wafer hloov

- Photolithography loading thiab unloading systems

- Cov iav substrate tuav hauv OLED thiab LCD kab

- Crystalline silicon wafer hloov hauv lub hnub ci cell ntau lawm

- Automated optical lossis microelectronic tshuaj xyuas

- Kev thauj mus los hauv cov tshuaj ntsuam xyuas lossis biomedical labs

- Nqus ib puag ncig automation systems

Nws lub peev xwm ua tau yam tsis muaj kev qhia txog cov khoom siv lossis cov nqi zoo li qub ua rau nws tsis muaj qhov tseem ceeb rau kev ua haujlwm zoo neeg hlau hauv chav huv automation.

Tsim nta & Customization

Txhua tus ceramic kawg effector yog engineered kom haum ib tug tshwj xeeb robotic caj npab los yog wafer tuav system. Peb txhawb tag nrho customization raws li:

-

Wafer loj compatibility2 ", 4", 6", 8", 12" thiab ntau dua

-

Qhov geometry thiab qhov sib txawv: Ua raws li ntug tuav, sab nraub qaum, lossis cov qauv tsim wafer

-

Suction ports: Integrated lub tshuab nqus tsev qhov los yog raws rau kev tuav tsis sib cuag

-

Mounting configuration: Qhov, threads, slots tailored rau koj tus neeg hlau kawg cuab tam flange

-

Kev kho saum npoo: Polished, lapped, lossis zoo-av tiav (Ra <0.2 µm muaj)

-

Ntug tiv thaiv: Rounded fab los yog chamfering kom tsis txhob wafer puas

Los ntawm kev siv CAD kos duab lossis 3D qauv muab los ntawm cov neeg siv khoom, peb cov kws tsim khoom tuaj yeem ua kom zoo dua txhua lub diav rawg rau qhov hnyav, lub zog, thiab kev huv.

Qhov zoo ntawm Ceramic End Effectors

| Feature | Tau txais txiaj ntsig |

|---|---|

| High Mechanical Rigidity | Txhim kho qhov ntev precision nyob rau hauv robotic loading rog |

| Zoo heev thermal Performance | Ua tau zoo nyob rau hauv high-temperature los yog plasma ib puag ncig |

| Zero Metal Contamination | Tsis muaj kev pheej hmoo ntawm ion contamination nyob rau hauv tseem ceeb semiconductor ua |

| Kev sib txhuam qis | Txo txoj kev pheej hmoo khawb ntawm wafer lossis iav substrates |

| Anti-Static thiab Non-Magnetic | Tsis nyiam plua plav lossis cuam tshuam rau cov khoom sib nqus-rhiab |

| Lub neej ua haujlwm ntev | Superior hnav tsis kam nyob rau hauv repetitive high-speed automation cycles |

| Ultra-Clean Compatibility | Haum rau ISO 14644 chav huv (Class 100 thiab hauv qab) |

Piv nrog rau cov yas los yog txhuas caj npab, alumina ceramic muab cov tshuaj lom neeg thiab lub cev ruaj khov nrog kev saib xyuas tsawg heev.

| Khoom | Hlau caj npab | Plastic Arm | Alumina Ceramic caj npab |

|---|---|---|---|

| Hardness | Nruab nrab | Tsawg | Siab heev (Mohs 9) |

| Thermal stability | ≤ 500 ° C | ≤ 150 ° C | ≥1600 ° C |

| Tshuaj tiv thaiv | Nruab nrab | pluag | Zoo heev |

| Cleanroom Suitability | Nruab nrab | Tsawg | Siab heev |

| Hnav Resistance | Nruab nrab | Tsawg | Zoo heev |

| Dielectric zog | Tsawg | Nruab nrab | Siab |

| Custom Machining Precision | txwv | Nruab nrab | Siab (± 0.01mm ua tau) |

Technical Specifications

| Parameter | Tus nqi |

|---|---|

| Khoom siv | High-purity Alumina (≥99.5%) |

| Ua haujlwm kub | Txog li 1600 ° C |

| Nto Roughness | Ra ≤ 0.2 µm (yeem) |

| Tau tshaj Wafer Sizes | 2 "mus rau 12" los yog kev cai |

| Flatness kam rau ua | ± 0.01 hli (nyob ntawm daim ntawv thov) |

| Nqus Suction Support | Yeem, customizable channels |

| Mounting Options | Bolt-dhau, flange, slotted qhov |

Cov lus nug nquag nug (FAQ)

Q1: Qhov kawg effector puas tuaj yeem koom ua ke rau hauv cov tshuab robotic uas twb muaj lawm?

A1:Yog lawm. Peb txhawb customization raws li koj tus neeg hlau interface. Koj tuaj yeem xa peb daim duab CAD lossis flange qhov ntev rau kev hloov pauv.

Q2: Cov caj npab puas puas tawg yooj yim thaum siv?

A2:Thaum cov ceramic yog nkig los ntawm qhov xwm txheej, peb cov qauv tsim siv qhov zoo tshaj plaws geometry kom txo qis kev ntxhov siab. Raws li kev siv kom raug, lawv muab kev pab cuam lub neej ntev dua li hlau lossis yas.

Q3: Nws puas tuaj yeem siv qhov no hauv lub tshuab nqus tsev siab lossis cov plasma etching chamber?

A3:Yog lawm. Alumina ceramic yog non-outgassing, thermally ruaj khov, thiab corrosion resistant - zoo kawg nkaus haum rau high-vacuum, reactive gas, los yog plasma ib puag ncig.

Q4: Cov khoom no puas raug ntxuav lossis tswj xyuas li cas?

A4:Lawv tuaj yeem ntxuav tau siv DI dej, cawv, lossis cov tshuaj ntxuav hauv chav huv. Tsis muaj kev saib xyuas tshwj xeeb yog xav tau vim lawv cov tshuaj lom neeg ruaj khov thiab inert nto.

Txog Peb

XKH tshwj xeeb hauv kev tsim cov thev naus laus zis, tsim khoom, thiab muag cov iav tshwj xeeb kho qhov muag thiab cov ntaub ntawv siv lead ua tshiab. Peb cov khoom siv kho qhov muag khoom siv hluav taws xob, khoom siv hluav taws xob, thiab tub rog. Peb muab Sapphire optical Cheebtsam, xov tooj ntawm tes lens npog, Ceramics, LT, Silicon Carbide SIC, Quartz, thiab semiconductor siv lead ua wafers. Nrog cov kws tshaj lij thiab cov cuab yeej siv niaj hnub, peb ua tau zoo hauv kev ua cov khoom lag luam uas tsis yog tus qauv, aiming los ua ib qho khoom siv optoelectronic high-tech enterprise.