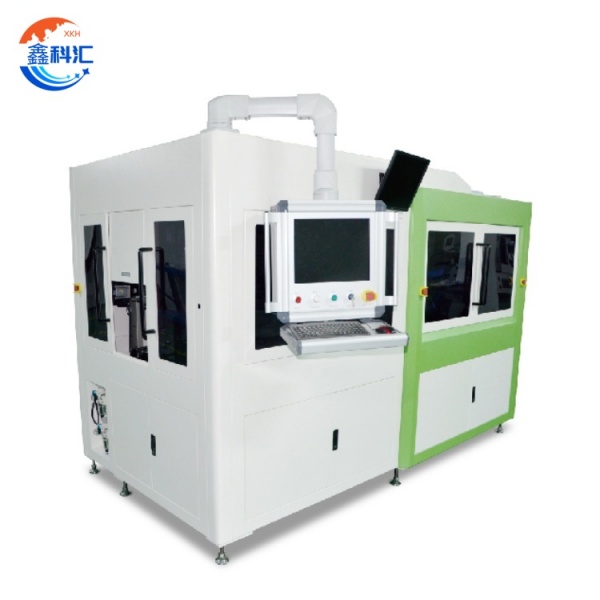

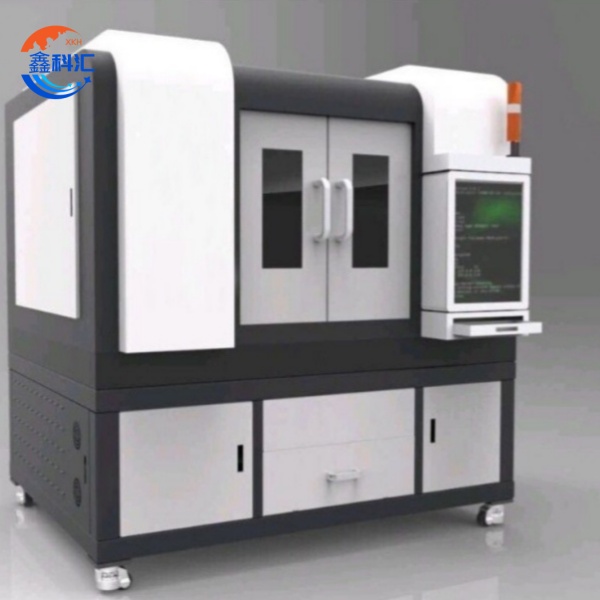

High precision laser drilling tshuab rau sapphire ceramic khoom lub pov haum bearing nozzle drilling

Khoom Taw Qhia

Cov ntaub ntawv siv tau: Haum rau cov hlau ntuj, polycrystalline steel, ruby, sapphire, tooj liab, ceramics, rhenium, stainless hlau, carbon steel, alloy steel thiab lwm yam superhard, kub kub resistant cov ntaub ntawv rau txawv duab, diameters, tob thiab taper drilling.

Cov xwm txheej ua haujlwm

1. Nws yog tsim rau kev khiav hauj lwm nyob rau hauv lub ambient kub ntawm 18 ℃ -28 ℃ thiab txheeb ze av noo ntawm 30% -60%.

2. Haum rau ob-theem fais fab mov / 220V / 50HZ / 10A.

3. Kho cov ntsaws ntsaws uas ua tau raws li qhov yuav tsum tau muaj ntawm cov qauv suav nrog. Yog tias tsis muaj lub ntsaws zoo li no, yuav tsum muab lub adapter tsim nyog.

4. Dav siv nyob rau hauv pob zeb diamond hlau daim duab tuag, qeeb hlau tuag, muffler qhov, koob qhov, lub pov haum bearing, nozzle thiab lwm yam perforating industries.

Technical parameters

| Lub npe | Cov ntaub ntawv | Muaj nuj nqi |

| Optical maser wavelength | 354.7nm los yog 355nm | Txiav txim siab lub zog faib thiab nkag tau lub peev xwm ntawm lub laser beam, thiab cuam tshuam rau cov khoom nqus thiab cov nyhuv ua haujlwm. |

| Nruab nrab tso zis zog | 10.0 / 12.0 / 15.0 w@40khz | cuam tshuam rau kev ua tau zoo thiab xuas nrig ntaus ceev, lub zog siab dua, ua kom nrawm dua. |

| mem tes dav | Tsawg dua 20ns@40KHz | Qhov luv luv mem tes dav txo qhov kub ntawm thaj tsam cuam tshuam, txhim kho qhov tseeb ntawm machining, thiab zam qhov thermal puas ntawm cov khoom. |

| Pulse repetition tus nqi | 10 ~ 200KHz | Txiav txim siab qhov sib kis ntau zaus thiab xuas nrig ntaus efficiency ntawm lub laser beam, qhov ntau dua qhov zaus, qhov punching ceev ceev. |

| optical beam zoo | M² <1.2 | Cov kab hluav taws xob zoo ua kom pom tseeb qhov tseeb thiab ntug zoo, txo qis zog. |

| Qhov chaw diam | 0.8 ± 0.1 hli | Txiav txim siab qhov tsawg kawg nkaus aperture thiab machining raug, qhov chaw me me, qhov me me ntawm qhov aperture, qhov tseeb dua. |

| beam-divergence angle | Ntau tshaj 90% | Lub peev xwm tsom thiab xuas nrig ntaus qhov tob ntawm lub laser beam raug cuam tshuam. Qhov me dua lub divergence Angle, lub zog muaj peev xwm tsom. |

| Beam ellipticity | Tsawg dua 3% RMS | Qhov me dua qhov ellipticity, qhov ze ntawm qhov zoo ntawm lub qhov yog rau lub voj voog, qhov siab dua qhov machining raug. |

Kev muaj peev xwm ua tau

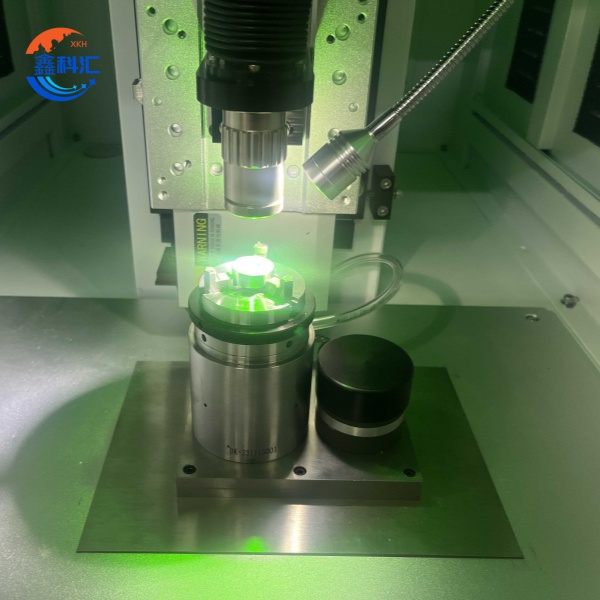

High-precision laser drilling tshuab muaj peev xwm ua tau zoo thiab tuaj yeem laum qhov los ntawm ob peb microns mus rau ob peb millimeters inch, thiab cov duab, qhov loj me, txoj hauj lwm thiab lub kaum sab xis ntawm lub qhov tuaj yeem tswj tau qhov tseeb. Nyob rau tib lub sijhawm, cov cuab yeej txhawb nqa 360-degree tag nrho-txhim kho qhov drilling, uas tuaj yeem ua tau raws li qhov xav tau ntawm drilling ntau yam duab thiab cov qauv. Tsis tas li ntawd, lub siab precision laser xuas nrig ntaus tshuab kuj muaj cov ntug zoo thiab nto tiav, qhov ua tiav yog burr dawb, tsis muaj ntug melting, thiab lub qhov nto yog du thiab tiaj tus.

Daim ntawv thov ntawm high precision laser punching tshuab:

1. Kev lag luam Electronics:

Printed Circuit Board (PCB) : siv rau kev ua microhole kom tau raws li qhov xav tau ntawm kev sib txuas siab.

Semiconductor ntim: Punch qhov nyob rau hauv wafers thiab ntim cov ntaub ntawv los txhim kho pob ceev thiab kev ua tau zoo.

2. Aerospace:

Cav hniav txias qhov: Micro txias qhov yog machined ntawm superalloy hniav los txhim kho cav efficiency.

Composite ua: Rau high-precision drilling ntawm carbon fiber composites kom paub meej lub zog.

3. Khoom siv kho mob:

Minimally invasive surgical instruments: Machining microholes in surgical instruments los txhim kho qhov tseeb thiab kev nyab xeeb.

Drug delivery system: Punch qhov hauv cov khoom xa tshuaj los tswj cov tshuaj tso tawm.

4. Automobile Manufacturing:

Roj txhaj tshuaj system: Machining micro-qhov ntawm cov roj txhaj nozzle kom optimize cov roj atomization nyhuv.

Sensor manufacturing: Drilling qhov nyob rau hauv lub ntsiab sensor los txhim kho nws rhiab heev thiab teb ceev.

5. Cov khoom siv kho qhov muag:

Optical fiber connector: Machining microholes ntawm optical fiber connector los xyuas kom meej qhov zoo ntawm cov teeb liab kis tau tus mob.

Optical filter: Punch qhov hauv qhov kho qhov muag kom ua tiav qhov kev xaiv wavelength tshwj xeeb.

6. Precision machinery:

Precision pwm: Machining microholes ntawm cov pwm los txhim kho kev ua haujlwm thiab kev pabcuam lub neej ntawm pwm.

Micro qhov chaw: Punch qhov ntawm micro qhov kom tau raws li qhov xav tau ntawm kev sib dhos siab.

XKH muab ntau yam ntawm high-precision laser drilling tshuab cov kev pab cuam, suav nrog cov khoom muag, kev txhawb nqa, kev daws teeb meem, kev teeb tsa thiab commissioning, kev cob qhia kev ua haujlwm thiab kev saib xyuas tom qab muag, thiab lwm yam, kom ntseeg tau tias cov neeg siv khoom siv kev tshaj lij, kev txhawb nqa thiab kev txhawb nqa.

Daim duab qhia ntxaws