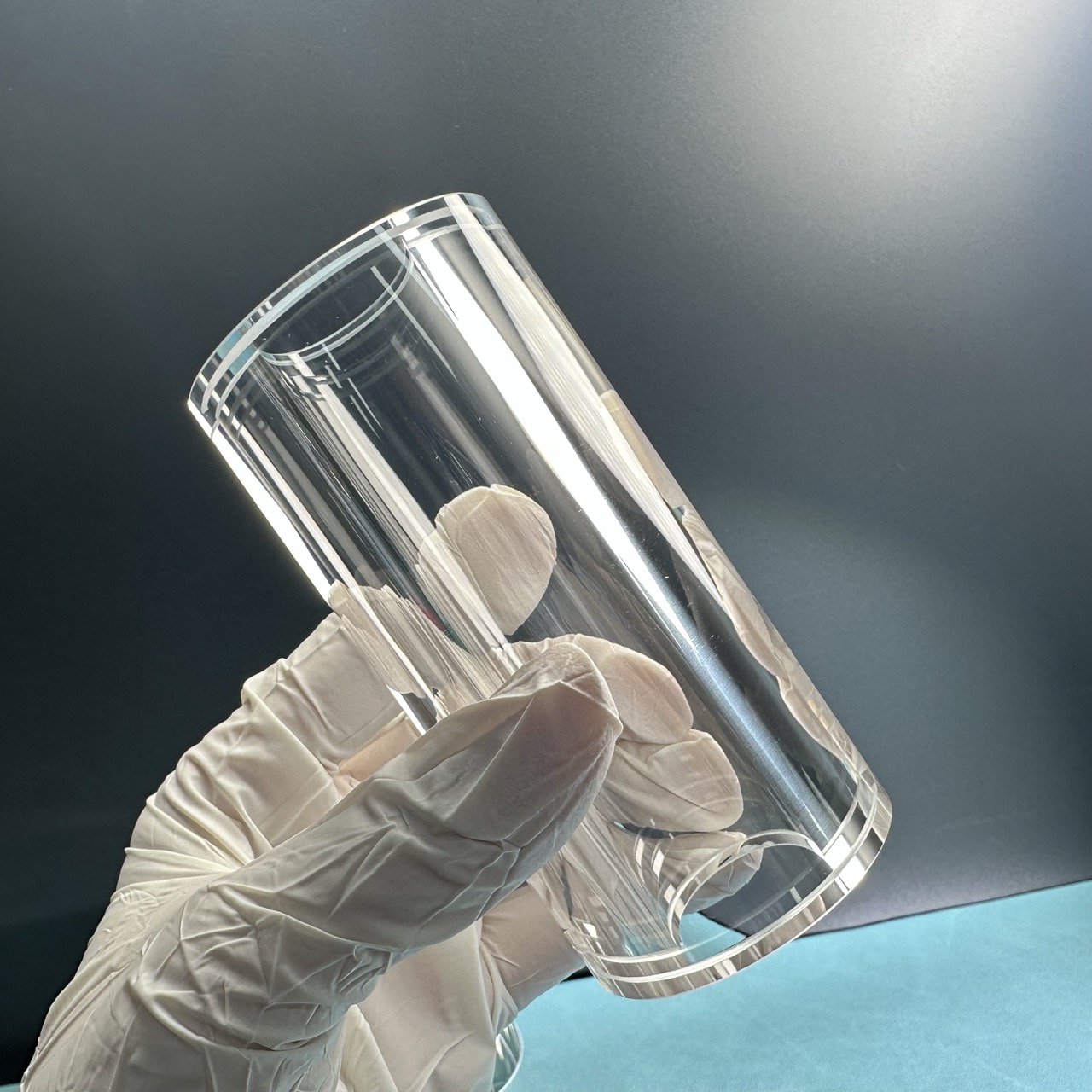

High-Purity Fused Quartz Wafers rau Semiconductor, Photonics Optical Applications 2 "4" 6 "8" 12 "

Daim duab qhia ntxaws

Txheej txheem cej luam ntawm Quartz iav

Quartz wafers tsim cov caj qaum ntawm cov khoom siv niaj hnub suav tsis txheeb uas tsav lub ntiaj teb digital niaj hnub no. Los ntawm kev taw qhia hauv koj lub xov tooj smartphone mus rau lub nraub qaum ntawm 5G lub hauv paus chaw nres tsheb, quartz ntsiag to xa cov kev ruaj ntseg, purity, thiab precision yuav tsum tau nyob rau hauv high-kev ua tau zoo electronics thiab photonics. Txawm hais tias txhawb kev hloov pauv hloov pauv, ua kom MEMS sensors, lossis tsim lub hauv paus rau quantum suav, quartz cov yam ntxwv tshwj xeeb ua rau nws tsis tuaj yeem nyob thoob plaws kev lag luam.

"Fused Silica" lossis "Fused Quartz" uas yog amorphous theem ntawm quartz (SiO2). Thaum sib piv rau borosilicate iav, fused silica tsis muaj additives; yog li nws muaj nyob rau hauv nws daim ntawv ntshiab, SiO2. Fused silica muaj ntau dua kis tau tus mob nyob rau hauv infrared thiab ultraviolet spectrum thaum piv rau ib txwm iav. Fused silica yog tsim los ntawm melting thiab re-solidifying ultrapure SiO2. Synthetic fused silica ntawm qhov tod tes yog tsim los ntawm silicon-nplua nuj chemical precursors xws li SiCl4 uas yog gasified thiab ces oxidized nyob rau hauv ib tug H2 + O2 cua. SiO2 hmoov av tsim nyob rau hauv cov ntaub ntawv no yog fused rau silica ntawm ib tug substrate. Cov fused silica blocks raug txiav rau hauv wafers tom qab uas cov wafers thaum kawg polished.

Cov yam ntxwv tseem ceeb thiab txiaj ntsig ntawm Quartz iav Wafer

-

Ultra-High Purity (≥99.99% SiO2)

Qhov zoo tshaj plaws rau ultra-clean semiconductor thiab photonics txheej txheem uas cov khoom siv yuav tsum raug txo kom tsawg. -

Dav Thermal Ua Haujlwm Ntau Yam

Ua kom muaj kev ncaj ncees ntawm cov txheej txheem los ntawm qhov kub thiab txias txog li 1100 ° C yam tsis muaj warping lossis degradation. -

Zoo tshaj UV thiab IR Transmission

Muab qhov zoo tshaj plaws kho qhov muag pom tseeb los ntawm kev sib sib zog nqus ultraviolet (DUV) los ntawm ze-infrared (NIR), txhawb kev siv kho qhov muag pom tseeb. -

Tsawg Thermal Expansion Coefficient

Txhim khu kev ruaj ntseg nyob rau hauv qhov kub thiab txias, txo kev ntxhov siab thiab txhim kho cov txheej txheem kev ntseeg tau. -

Superior Chemical Resistance

Inert rau feem ntau cov kua qaub, alkalis, thiab cov kuab tshuaj-ua rau nws zoo-tsim rau cov tshuaj lom neeg ua phem. -

Nto Finish Flexibility

Muaj nrog ultra-smooth, ib sab lossis ob sab polished tiav, sib xws nrog photonics thiab MEMS cov cai.

Kev tsim cov txheej txheem ntawm Quartz iav Wafer

Fused quartz wafers yog tsim los ntawm cov txheej txheem tswj thiab meej:

-

Kev xaiv raw khoom

Kev xaiv ntawm high-purity ntuj quartz los yog hluavtaws SiO₂ qhov chaw. -

Melting thiab Fusion

Quartz yog yaj ntawm ~ 2000 ° C nyob rau hauv hluav taws xob furnaces nyob rau hauv ib qho chaw tswj kom tshem tawm cov inclusions thiab npuas. -

Thaiv txoj kev

Cov molten silica yog txias rau hauv cov khoom blocks lossis ingots. -

Wafer Slicing

Precision pob zeb diamond los yog hlau saws yog siv los txiav cov ingots rau hauv wafer blanks. -

Lapping & Polishing

Ob qhov chaw yog flattened thiab polished kom tau raws li qhov tseeb kho qhov muag, thickness, thiab roughness specifications. -

Ntxuav & Tshuaj xyuas

Cov wafers raug ntxuav hauv ISO Class 100/1000 cleanrooms thiab raug soj ntsuam nruj me ntsis rau qhov tsis xws luag thiab kev sib haum xeeb.

Cov khoom ntawm Quartz iav wafer

| spec | chav tsev | 4" | 6" | 8" | 10" | 12 " |

|---|---|---|---|---|---|---|

| Txoj kab uas hla / qhov loj (los yog square) | mm | 100 | 150 | 200 | 250 | 300 |

| Kev kam rau siab (±) | mm | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Thickness | mm | 0.10 los yog ntau tshaj | 0.30 los yog ntau tshaj | 0.40 los yog ntau tshaj | 0.50 los yog ntau tshaj | 0.50 los yog ntau tshaj |

| Cov ntaub ntawv tseem ceeb | mm | 32.5 ib | 57.5 ib | Semi-notch | Semi-notch | Semi-notch |

| LTV (5mm × 5mm) | ib m | <0.5 | <0.5 | <0.5 | <0.5 | <0.5 |

| TTV | ib m | <2 | <3 | <3 | <5 | <5 |

| Hneev | ib m | ± 20 | ± 30 | ± 40 | ± 40 | ± 40 |

| Warp | ib m | ≤ 30 | ≤ 40 | ≤ 50 | ≤ 50 | ≤ 50 |

| PLTV (5mm × 5mm) <0.4μm | % | ≥95% | ≥95% | ≥95% | ≥95% | ≥95% |

| Ntug Rounding | mm | Ua raws li SEMI M1.2 Standard / xa mus rau IEC62276 | ||||

| Hom nto | Ib Sab Polished / Ob Chav Sab Polished | |||||

| Polished sab Ra | nm | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| Cov Txheej Txheem Rov Qab | ib m | dav 0.2-0.7 lossis customized | ||||

Quartz vs. Lwm cov ntaub ntawv pob tshab

| Khoom | Quartz iav | Borosilicate iav | Sapphire | Standard iav |

|---|---|---|---|---|

| Max ua haujlwm Temp | ~ 1100 ° C | ~ 500 ° C | ~ 2000 ° C | ~ 200 ° C |

| Kev xa tawm UV | Zoo heev (JGS1) | pluag | Zoo | pluag heev |

| Tshuaj tiv thaiv | Zoo heev | Nruab nrab | Zoo heev | pluag |

| Purity | Siab heev | Tsawg rau nruab nrab | Siab | Tsawg |

| Thermal Expansion | Tsawg heev | Nruab nrab | Tsawg | Siab |

| Nqi | Nruab nrab mus rau siab | Tsawg | Siab | Tsawg heev |

FAQ ntawm Quartz iav Wafer

Q1: Dab tsi yog qhov txawv ntawm fused quartz thiab fused silica?

Thaum ob qho tib si yog amorphous cov ntaub ntawv ntawm SiO₂, fused quartz feem ntau yog los ntawm ntuj quartz qhov chaw, whereas fused silica yog synthetically tsim. Functionally, lawv muaj kev ua tau zoo sib xws, tab sis fused silica tej zaum yuav muaj me ntsis siab dua purity thiab homogeneity.

Q2: Cov fused quartz wafers puas tuaj yeem siv rau hauv qhov chaw nqus tsev siab?

Yog lawm. Vim tias lawv cov khoom qis qis thiab kev ua haujlwm siab thermal, fused quartz wafers yog qhov zoo heev rau lub tshuab nqus tsev thiab kev siv aerospace.

Q3: Cov wafers no puas haum rau kev sib sib zog nqus-UV laser ntawv?

kiag li. Fused quartz muaj kev xa tawm siab mus txog ~ 185 nm, ua rau nws zoo tagnrho rau DUV optics, lithography qhov ncauj qhov ntswg, thiab excimer laser systems.

Q4: Koj puas txhawb kev cai wafer fabrication?

Yog lawm. Peb muab tag nrho customization nrog rau txoj kab uas hla, thickness, nto zoo, flats / notches, thiab laser patterning, raws li koj cov kev thov tshwj xeeb.

Txog Peb

XKH tshwj xeeb hauv kev tsim cov thev naus laus zis, tsim khoom, thiab muag cov iav tshwj xeeb kho qhov muag thiab cov ntaub ntawv siv lead ua tshiab. Peb cov khoom siv kho qhov muag khoom siv hluav taws xob, khoom siv hluav taws xob, thiab tub rog. Peb muab Sapphire optical Cheebtsam, xov tooj ntawm tes lens npog, Ceramics, LT, Silicon Carbide SIC, Quartz, thiab semiconductor siv lead ua wafers. Nrog cov kws tshaj lij thiab cov cuab yeej siv niaj hnub, peb ua tau zoo hauv kev ua cov khoom lag luam uas tsis yog tus qauv, aiming los ua ib qho khoom siv optoelectronic high-tech enterprise.