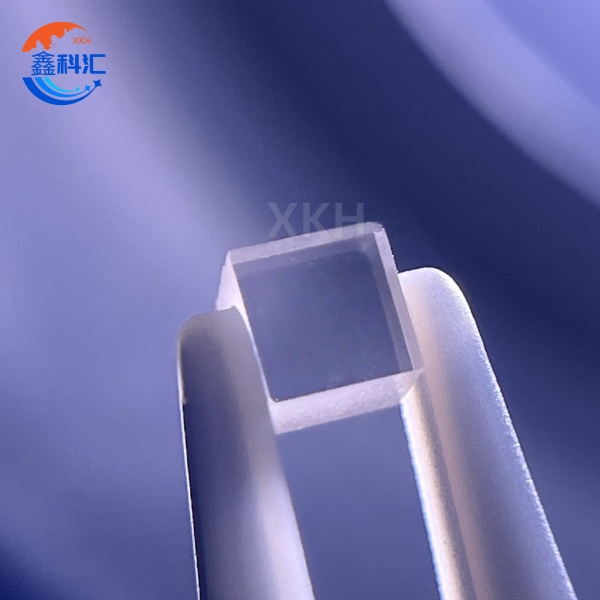

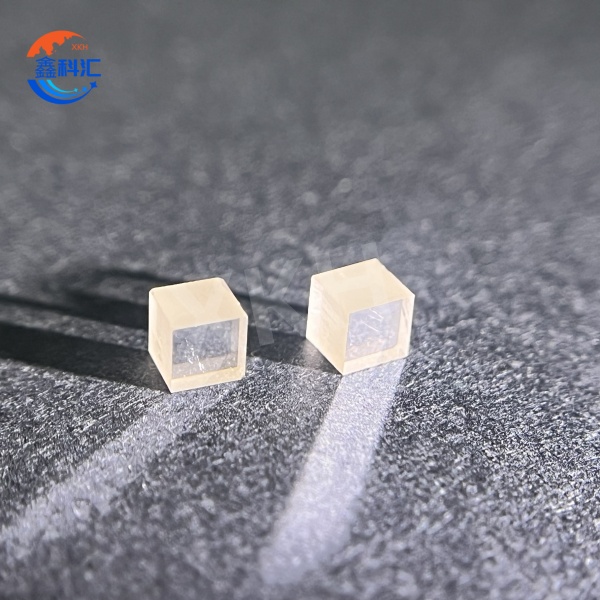

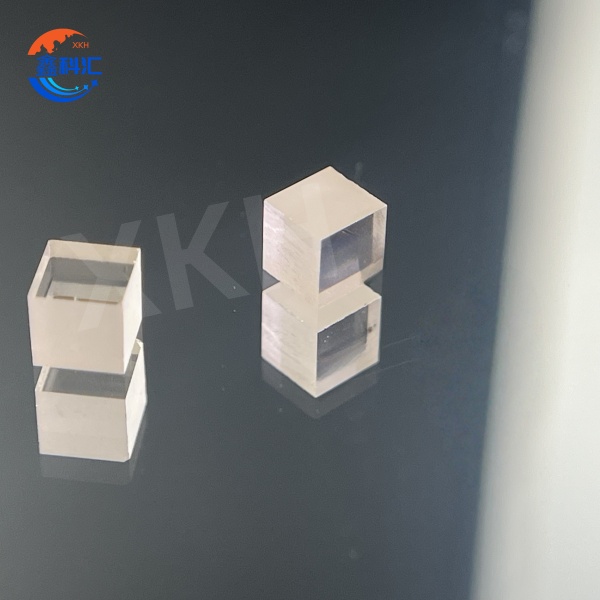

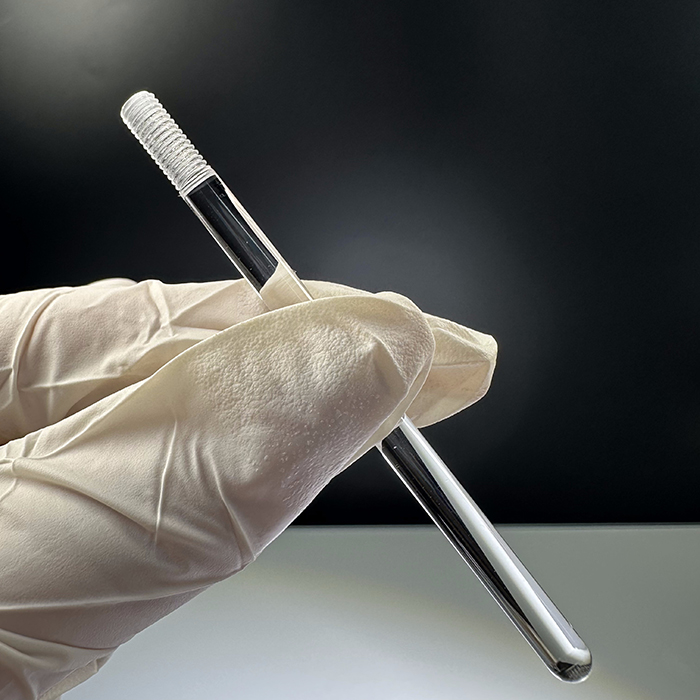

High Purity SiC Optical Lens Cubic 4H-semi 6SP Loj Customized

Cov yam ntxwv ntawm SiC Optical Lens

1. Cov khoom siv zoo tshaj

Ib puag ncig zoo Adaptability: Withstands kub> 1500 ° C, muaj zog acid / alkali corrosion, thiab high-zog hluav taws xob hluav taws xob, zoo tagnrho rau spacecraft thiab nuclear chaw.

Exceptional Mechanical Strength: Ze-pob zeb diamond hardness (Mohs 9.5), flexural zog> 400 MPa, thiab cuam tshuam tsis kam tshaj li cov pa iav optical.

Thermal Stability: Thermal conductivity 100 × siab dua fused silica, nrog CTE tsuas yog 1/10 ntawm cov iav zoo tib yam, ua kom ruaj khov nyob rau hauv lub thermal cycling ceev.

2. Optical Performance Advantages

Broad spectral kis tau tus mob (0.2-6 μm); Cov txheej txheem tshwj xeeb tuaj yeem ua kom zoo tshaj qhov xa mus rau> 95% hauv cov kab tshwj xeeb (xws li 3-5 μm nruab nrab IR).

Tsawg tawg poob (<0.5% / cm), nto tiav mus txog 10/5 khawb-dig qauv, thiab nto flatness λ/10 @ 633 nm.

High laser-induced kev puas tsuaj qhov pib (LIDT)> 15 J / cm² (1064 nm, 10 ns pulses), haum rau lub zog siab lub zog laser tsom.

3. Precision Machining peev xwm

Txhawb nqa qhov chaw nyuaj (aspheric, freeform) nrog daim ntawv raug <100 nm PV thiab centration <1 arcmin.

Muaj peev xwm ntawm kev nthuav dav SiC lo ntsiab muag (inch> 500 mm) rau astronomical telescopes thiab qhov chaw optics.

Cov ntawv thov tseem ceeb ntawm SiC Optical Lens

1. Chaw Optics & Kev Tiv Thaiv

Satellite tej thaj chaw deb sensing lo ntsiab muag thiab chaw telescope optics, leveraging SiC lub teeb yuag zog (density 3.21 g / cm³) thiab hluav taws xob tsis kam.

Missile seeker optical windows, enduring aerodynamic cua sov (> 1000 ° C) thaum lub sij hawm hypersonic ya davhlau.

2. High-power Laser Systems

Tsom tsom iav rau kev lag luam laser txiav / vuam cov cuab yeej, txhawb nqa ntev ntev rau kW-chav kawm txuas ntxiv lasers.

Beam shaping ntsiab nyob rau hauv inertial confinement fusion (ICF) systems, kom ntseeg tau meej high-zog laser kis tau tus mob.

3. Semiconductor & Precision Manufacturing

SiC daim iav substrates rau EUV lithography optics, nrog thermal deformation <1 nm nyob rau hauv 10 kW / m² kub flux.

Electromagnetic lo ntsiab muag rau e-nqaj tshuaj ntsuam cov cuab yeej, siv SiC cov conductivity rau active kub tswj.

4. Kev Tshawb Fawb & Lub Zog

Endoscope lo ntsiab muag rau lub qhov cub kub kub (1500 ° C ua haujlwm tas li).

Infrared optical Cheebtsam rau roj zoo loggging twj, tiv thaiv downhole pressures (> 100 MPa) thiab corrosive media.

Core Competitive Advantages

1. Kev ua thawj coj ua tau zoo

SiC lo ntsiab muag tshaj cov khoom siv kho qhov muag (fused silica, ZnSe) hauv thermal / mechanical / chemical stability, nrog lawv "siab conductivity + low expansion" zog daws cov thermal deformation cov nyom hauv optics loj.

2. Kev siv lub neej ua haujlwm tau zoo

Thaum cov nqi pib yog siab dua, SiC lo ntsiab muag 'ntev kev pab cuam lub neej (5-10 × cov iav ib txwm siv) thiab kev ua haujlwm tsis muaj kev saib xyuas ua rau txo tag nrho cov nqi ntawm cov tswv cuab (TCO).

3. Tsim Kev ywj pheej

Cov txheej txheem tiv thaiv kev sib raug zoo lossis CVD ua rau lub teeb yuag SiC cov qauv kho qhov muag (honeycomb cores), ua tiav qhov tsis sib haum xeeb nruj-rau-qhov hnyav.

XKH Service Capabilities

1. Kev Pabcuam Kev Tsim Khoom

Xaus-rau-kawg kev daws teeb meem los ntawm kev tsim kho qhov muag (Zemax / Code V simulation) mus rau qhov kawg xa khoom, txhawb nqa aspheric / off-axis parabolic freeform nto.

Cov txheej tshwj xeeb: tiv thaiv kev cuam tshuam (AR), pob zeb diamond zoo li carbon (LIDT> 50 J / cm²), conductive ITO, thiab lwm yam.

2. Cov Txheej Txheem Ua Haujlwm Zoo

Cov cuab yeej siv hauv xov tooj suav nrog 4D interferometers thiab dawb-lub teeb profilers kom ntseeg tau λ/20 nto qhov tseeb.

Khoom-theem QC: XRD crystallographic orientation tsom xam rau txhua SiC dawb paug.

3. Kev Pabcuam Ntxiv

Thermo-structural coupling analysis (ANSYS simulation) rau kev kwv yees kev ua tau zoo.

Integrated SiC lens mounting qauv optimization tsim.

Xaus

SiC lo ntsiab muag yog redefining kev ua tau zoo txwv ntawm high-precision kho qhov muag tshuab los ntawm lawv cov khoom tsis sib xws. Peb lub peev xwm sib xyaw ua ke ntsug hauv SiC cov khoom sib txuas, kev ua kom zoo, thiab kev sim xa cov kev hloov kho kho qhov muag rau aerospace thiab kev tsim khoom siab heev. Nrog rau kev nce qib hauv SiC siv lead ua kev loj hlob, kev txhim kho yav tom ntej yuav tsom mus rau qhov loj dua apertures (> 1m) thiab ntau qhov chaw geometries (freeform arrays).

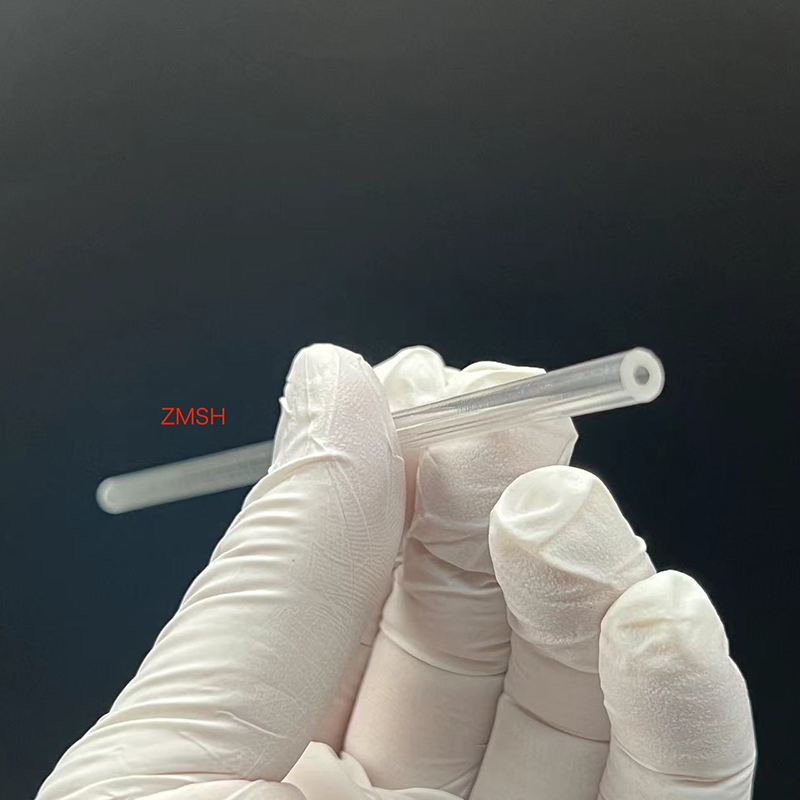

Raws li lub tuam txhab ua lag luam ntawm cov khoom siv kho qhov muag siab heev, XKH tshwj xeeb hauv cov ntaub ntawv ua tau zoo xws li sapphire, silicon carbide (SiC), thiab silicon wafers, muab cov kev daws teeb meem kawg-rau-kawg los ntawm cov khoom siv raw rau kev ua tiav. Peb cov kev txawj ntse spans:

1. Kev Cai Fabrication: Precision machining ntawm complex geometries (aspheric, freeform) nrog tolerances rau ± 0.001mm

2. Cov khoom siv ntau yam: Kev ua cov sapphire (UV-IR qhov rais), SiC (high-power optics), thiab silicon (IR / micro-optics)

3. Kev Pabcuam Ntxiv:

Anti-reflective / durable txheej (UV-FIR)

Metrology-backed quality assurance (λ/20 flatness)

Cleanroom sib dhos rau kev sib kis-sensitive daim ntaub ntawv

Ua haujlwm rau aerospace, semiconductor, thiab laser industries, peb muab cov ntaub ntawv tshawb fawb kev txawj ntse nrog kev tsim khoom siab heev kom xa cov khoom siv kho qhov muag uas tiv taus qhov chaw huab cua thaum ua kom pom kev ua haujlwm zoo.