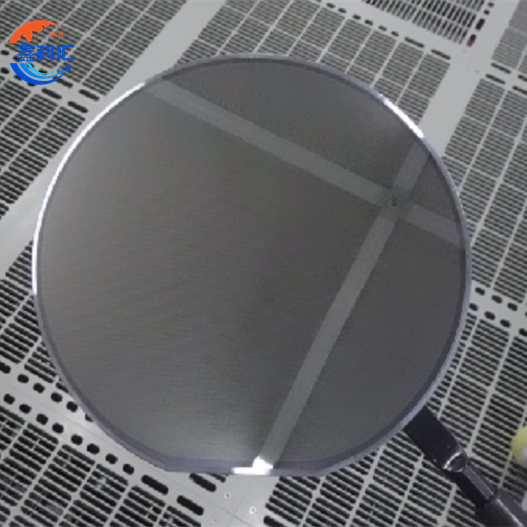

HPSI SiCOI wafer 4 6inch Hydropholic Bonding

SiCOI Wafer (Silicon Carbide-on-Insulator) Cov Khoom Txheej Txheem

SiCOI wafers yog ib tug tshiab tiam semiconductor substrate combining Silicon Carbide (SiC) nrog ib tug insulating txheej, feem ntau SiO₂ los yog sapphire, los txhim kho kev ua tau zoo nyob rau hauv lub hwj chim electronics, RF, thiab photonics. Hauv qab no yog cov ncauj lus kom ntxaws txog lawv cov khoom categorized rau hauv ntu tseem ceeb:

| Khoom | Kev piav qhia |

| Khoom siv | Silicon Carbide (SiC) txheej sib koom ua ke ntawm cov txheej txheem insulating (feem ntau SiO₂ lossis sapphire) |

| Crystal Structure | Feem ntau 4H lossis 6H polytypes ntawm SiC, paub txog kev siv lead ua zoo thiab sib xws |

| Cov khoom hluav taws xob | Siab tawg hluav taws xob (~ 3 MV / cm), dav bandgap (~ 3.26 eV rau 4H-SiC), tsis tshua muaj hluav taws xob tam sim no |

| Thermal conductivity | High thermal conductivity (~ 300 W / m·K), ua kom muaj cua sov zoo |

| Dielectric Txheej | Insulating txheej (SiO₂ lossis sapphire) muab hluav taws xob cais tawm thiab txo cov kab mob parasitic capacitance |

| Mechanical Properties | High hardness (~ 9 Mohs scale), zoo heev mechanical zog, thiab thermal stability |

| Nto tiav | Feem ntau ultra-nqus nrog tsawg qhov tsis xws luag, haum rau kev tsim khoom |

| Daim ntawv thov | Cov khoom siv hluav taws xob hluav taws xob, MEMS cov khoom siv, cov khoom siv RF, cov khoom siv hluav taws xob uas xav tau qhov kub thiab txias siab |

SiCOI wafers (Silicon Carbide-on-Insulator) sawv cev rau cov qauv txheej txheem semiconductor substrate, uas muaj cov txheej txheem zoo ntawm silicon carbide (SiC) sib raug zoo rau txheej txheej insulating, feem ntau silicon dioxide (SiO₂) lossis sapphire. Silicon carbide yog qhov dav-bandgap semiconductor paub txog nws lub peev xwm tiv taus qhov kub thiab txias, nrog rau cov thermal conductivity thiab superior mechanical hardness, ua rau nws zoo tagnrho rau high-power, high-frequency, thiab high-temperature electronic applications.

Cov txheej insulating hauv SiCOI wafers muab cov hluav taws xob sib cais zoo, txo cov kab mob cab thiab cov dej ntws tawm ntawm cov khoom siv, yog li txhim kho tag nrho cov cuab yeej kev ua tau zoo thiab kev ntseeg tau. Lub wafer nto yog precisely polished kom ua tiav ultra-smoothness nrog tsawg yam tsis xws luag, ua tau raws li qhov kev thov nruj ntawm micro- thiab nano-scale ntaus ntawv fabrication.

Cov khoom siv no tsis yog tsuas yog txhim kho cov yam ntxwv ntawm cov khoom siv hluav taws xob ntawm SiC tab sis kuj tseem txhim kho kev tswj xyuas thermal thiab kev ruaj ntseg zoo. Raws li qhov tshwm sim, SiCOI wafers tau siv dav hauv cov khoom siv hluav taws xob hluav taws xob, xov tooj cua zaus (RF) Cheebtsam, microelectromechanical systems (MEMS) sensors, thiab high-temperature electronics. Zuag qhia tag nrho, SiCOI wafers muab cov khoom tshwj xeeb ntawm lub cev ntawm silicon carbide nrog cov txiaj ntsig hluav taws xob cais tawm ntawm cov txheej txheem insulator, muab lub hauv paus zoo tshaj plaws rau tiam tom ntej ntawm cov khoom siv hluav taws xob semiconductor.

SiCOI wafer daim ntawv thov

Fais fab Electronics Devices

High-voltage thiab high-power switches, MOSFETs, thiab diodes

Tau txais txiaj ntsig los ntawm SiC qhov dav bandgap, siab tawg voltage, thiab thermal stability

Txo lub zog poob thiab txhim kho kev ua haujlwm hauv lub zog hloov pauv

Xov tooj cua zaus (RF) Cheebtsam

High-frequency transistors thiab amplifiers

Tsawg parasitic capacitance vim insulating txheej txhim khu kev ua haujlwm RF

Haum rau 5G kev sib txuas lus thiab radar systems

Microelectromechanical Systems (MEMS)

Sensors thiab actuators ua haujlwm nyob rau hauv ib puag ncig hnyav

Mechanical robustness thiab chemical inertness ncua lub neej ntawm cov cuab yeej

Xws li lub siab sensors, accelerometers, thiab gyroscopes

Cov Khoom Siv Hluav Taws Xob Kub Kub

Electronics rau automotive, aerospace, thiab industrial applications

Ua haujlwm ruaj khov ntawm qhov kub siab uas silicon tsis ua haujlwm

Photonic Devices

Kev koom ua ke nrog optoelectronic Cheebtsam ntawm insulator substrates

Ua kom muaj cov khoom siv hluav taws xob ntawm lub chip nrog kev txhim kho thermal tswj

SiCOI wafer's Q&A

Q:SiCOI wafer yog dab tsi

A:SiCOI wafer sawv cev rau Silicon Carbide-on-Insulator wafer. Nws yog ib hom semiconductor substrate uas nyias txheej ntawm silicon carbide (SiC) yog sib koom ua ke rau ib txheej insulating, feem ntau silicon dioxide (SiO₂) lossis qee zaum sapphire. Cov qauv no zoo ib yam li lub tswv yim rau cov paub zoo Silicon-on-Insulator (SOI) wafers tab sis siv SiC es tsis txhob siv silicon.

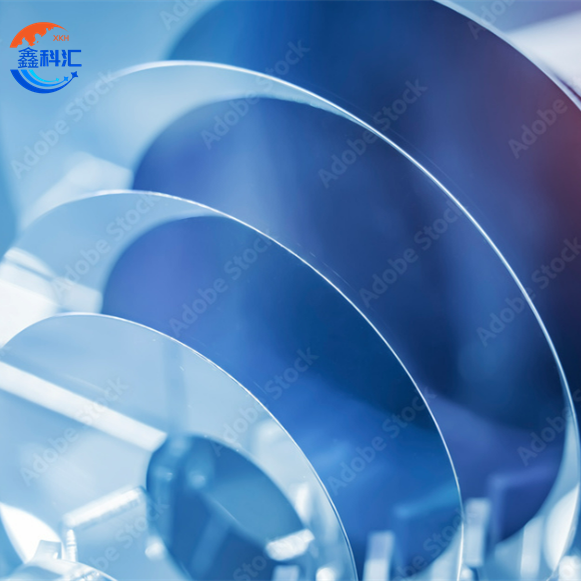

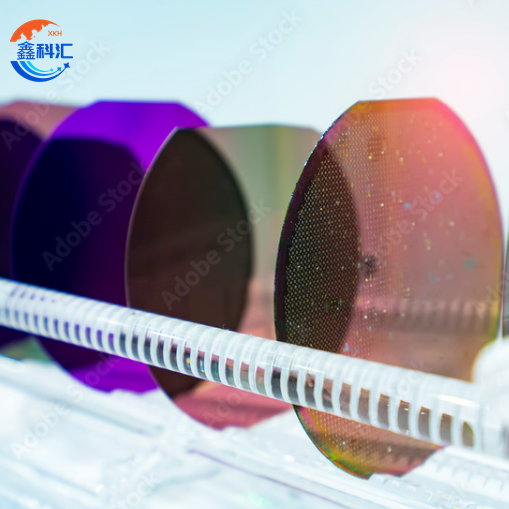

Duab