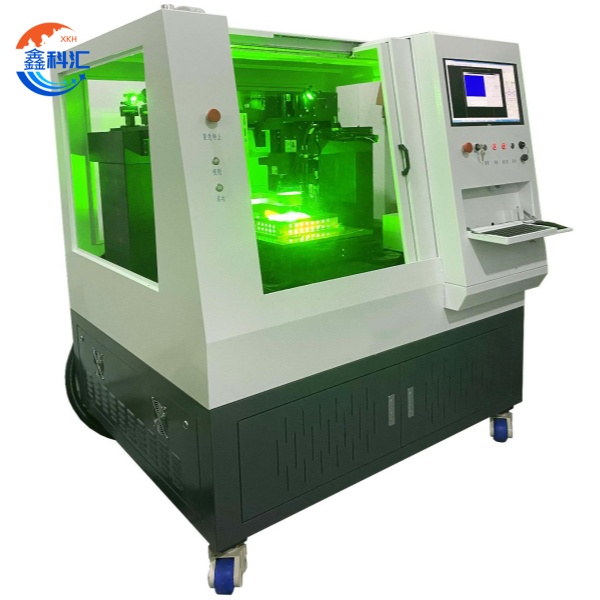

Infrared Nanosecond Laser Drilling khoom rau iav Drilling thickness≤20mm

Main parameter

| Laser hom | Infrared nanosecond |

| Platform loj | 800 * 600 hli |

|

| 2000 * 1200 hli |

| Drilling thickness | ≤ 20 (mm) |

| Drilling ceev | 0-5000 (mm / s) |

| Drilling ntug breakage | <0.5 (mm) |

| Nco tseg: Platform loj tuaj yeem kho tau. | |

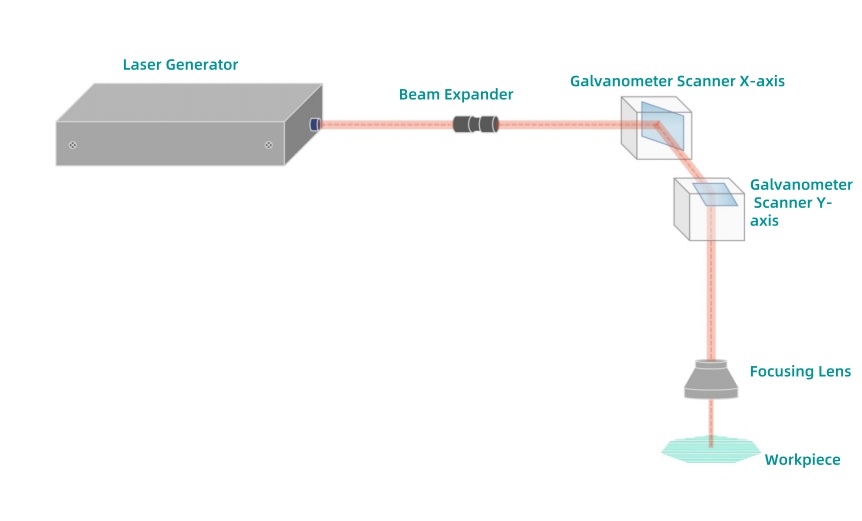

Laser Drilling Txoj Cai

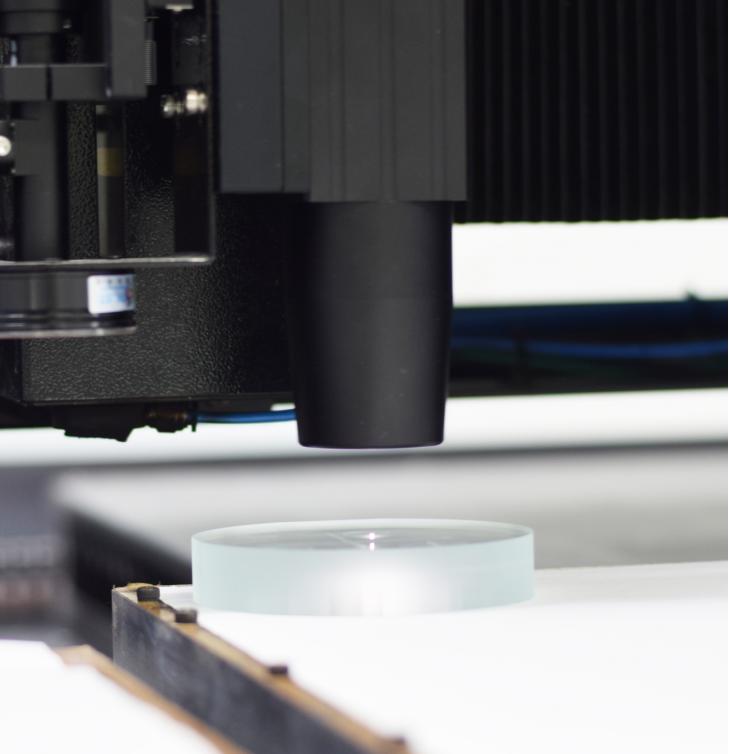

Lub laser beam yog teem rau ntawm ib qho kev pom zoo nyob rau hauv lub workpiece thickness, ces scans raws predefined paths ntawm kev kub ceev. Los ntawm kev sib cuam tshuam nrog lub zog loj laser beam, lub hom phiaj cov khoom raug tshem tawm txheej txheej los ntawm txheej los ua cov kab txiav, ua tiav cov perforation meej (lub voj voog, square, lossis complex geometries) nrog kev tswj cov khoom sib cais.

Qhov zoo ntawm Laser Drilling

· High automation kev koom ua ke nrog tsawg zog siv thiab ua haujlwm yooj yim;

· Kev ua haujlwm tsis sib cuag ua rau tsis muaj kev txwv cov qauv geometry tshaj li cov qauv siv;

· Consumable-free lag luam txo cov nqi khiav lag luam thiab txhim khu ib puag ncig sustainability;

· Superior precision nrog tsawg ntug chipping thiab tshem tawm ntawm lwm yam workpiece puas tsuaj;

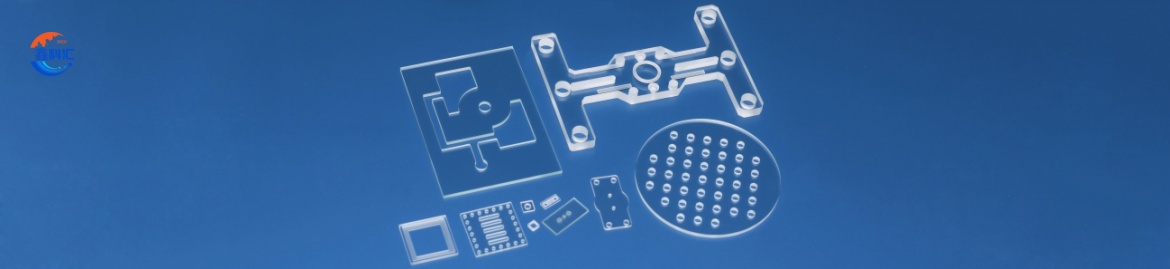

Qauv qauv

Cov txheej txheem siv

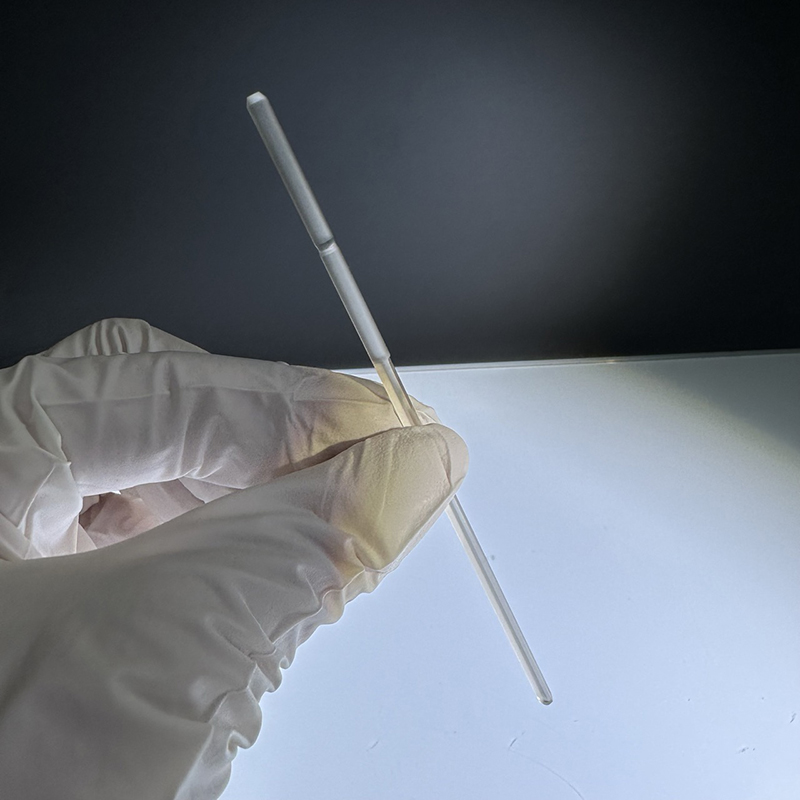

Lub kaw lus yog engineered rau precision ua ntawm nkig / tawv cov ntaub ntawv xws li drilling, grooving, zaj duab xis tshem tawm, thiab nto texturing. Cov ntawv thov ib txwm muaj xws li:

1. Drilling thiab notching rau da dej qhov rooj Cheebtsam

2. Precision perforation ntawm cov khoom siv iav panels

3. Hnub ci vaj huam sib luag ntawm drilling

4. Hloov/socket npog phaj perforation

5. Daim iav txheej tshem tawm nrog drilling

6. Kev cai nto texturing thiab grooving rau cov khoom tshwj xeeb

Kev ua tau zoo

1. Loj-hom platform haum cov khoom sib txawv ntawm qhov ntev ntawm kev lag luam

2. Complex contour drilling ua tiav hauv kev ua haujlwm ib zaug

3. Tsawg ntug chipping nrog superior nto tiav (Ra <0.8μm)

4. Seamless hloov ntawm cov khoom specifications nrog intuitive ua hauj lwm

5. Kev ua haujlwm raug nqi zoo nrog:

· Cov nyiaj tau los siab (> 99.2%)

· Consumable-free processing

· Zero pa phem emissions

6.Kev ua haujlwm tsis sib cuag ua kom muaj kev ruaj ntseg ntawm qhov chaw

Cov yam ntxwv tseem ceeb

1. Precision Thermal Management Technology:

· Siv cov txheej txheem ntau-pulse nce qib drilling nrog adjustable ib leeg-pulse zog (0.1-50 mJ)

· Kev tsim kho tshiab ntawm cov kab hlau thaiv kab hlau thaiv kev tiv thaiv qhov cua sov ua rau thaj tsam li ntawm 10% ntawm lub qhov taub

· Real-time infrared kub saib xyuas module cia li them nyiaj rau lub zog tsis muaj zog (± 2% stability)

2. Intelligent Processing Platform:

· Nruab nrog high-precision linear motor theem (rov ua dua qhov tseeb: ± 2 μm)

· Integrated vision alignment system (5-megapixel CCD, paub qhov tseeb: ± 5 μm)

· Preloaded txheej txheem database nrog optimized tsis rau 50+ hom iav ntaub ntawv

3. High-Efficiency Production Design:

· Dual-chaw nres tsheb alternating ua hauj lwm hom nrog cov ntaub ntawv hloov lub sij hawm ≤3 vib nas this

· Standard processing voj voog ntawm 1 qhov / 0.5 sec (Φ0.5 hli los ntawm-qhov)

· Modular tsim ua kom muaj kev sib hloov ceev ceev ntawm kev tsom iav tsom iav (kev ua haujlwm ntau: Φ0.1-10 hli)

Brittle Hard Material Processing Applications

| Hom khoom | Daim ntawv thov Scenario | Txheej txheem txheej txheem |

| Soda-lime iav | Da dej qhov rooj | Mounting qhov & cov kav dej |

| Cov khoom siv tswj vaj huam sib luag | Dej qhov arrays | |

| Tempered iav | Qhov cub saib qhov rais | Qhov cua qhov arrays |

| Induction cooktops | Angled txias channels | |

| Borosilicate iav | Hnub ci vaj huam sib luag | Mounting qhov |

| Laboratory glassware | Kev cai tso dej raws | |

| iav-ceramic | Cooktop nto | Burner positioning qhov |

| Induction cookers | Sensor mounting qhov arrays | |

| Sapphire | Cov cuab yeej ntse npog | Qhov cua qhov |

| Industrial viewports | Txhim kho qhov | |

| Coated iav | Cov iav da dej | Mounting qhov (txheej txheem tshem tawm + drilling) |

| Ntaub phab ntsa | Low-E iav zais qhov dej qhov | |

| Ceramicized iav | Hloov/socket npog | Kev ruaj ntseg slots + hlau qhov |

| hluav taws teeb meem | Emergency Pressure Relief qhov |

XKH muab kev txhawb nqa dav dav thiab cov kev pabcuam ntxiv rau cov khoom siv infrared nanosecond laser iav drilling kom ntseeg tau tias kev ua haujlwm zoo thoob plaws hauv lub neej ntawm cov cuab yeej siv. Peb muab cov txheej txheem tsim kho raws li cov kev pabcuam uas peb pab pawg engineering koom tes nrog cov neeg siv khoom los tsim cov khoom siv tshwj xeeb cov tsev qiv ntawv, suav nrog cov kev pabcuam tshwj xeeb drilling rau cov ntaub ntawv nyuaj xws li sapphire thiab tempered iav nrog thickness variations ntawm 0.1mm txog 20mm. Rau kev ua kom zoo tshaj plaws, peb ua cov khoom siv hauv tsev calibration thiab kev ntsuas kev ua tau zoo, ua kom cov kev ntsuas tseem ceeb xws li lub qhov taub qhov siab (± 5μm) thiab ntug zoo (Ra <0.5μm) ua tau raws li cov qauv kev lag luam.