Infrared Picosecond Dual-Platform Laser Tej cuab yeej rau Optical iav / Quartz / Sapphire ua

Main parameter

| Hom Laser | Infrared Picosecond |

| Platform Loj | 700 × 1200 hli |

| 900 × 1400 hli | |

| Txiav Thickness | 0.03-80 hli |

| Txiav ceev | 0-1000 hli (mm / s) |

| Txiav ntug tawg | 0.01 hli (mm) |

| Nco tseg: Platform loj tuaj yeem kho tau. | |

Cov yam ntxwv tseem ceeb

1. Ultrafast Laser Technology:

· Picosecond-theem luv pulses (10⁻¹²s) ua ke nrog MOPA tuning thev naus laus zis ua tiav lub zog siab tshaj plaws> 10¹² W / cm².

· Infrared wavelength (1064nm) nkag mus rau cov ntaub ntawv pob tshab los ntawm nonlinear absorption, tiv thaiv nto ablation.

· Proprietary multi-focus optical system generates plaub qhov kev ua haujlwm ywj pheej ib txhij.

2.Dual-Station Synchronization System:

· Granite-base dual linear tsav theem (qhov chaw raug: ± 1μm).

· Chaw nres tsheb hloov lub sij hawm <0.8s, ua rau tib lub sijhawm "kev ua haujlwm-loading/unloading" ua haujlwm.

· Kev tswj qhov kub thiab txias (23 ± 0.5 ° C) ib lub chaw nres tsheb ua kom lub sijhawm ua haujlwm ruaj khov.

3.Intelligent Process Control:

· Integrated khoom database (200+ iav tsis) rau tsis siv neeg parameter txuam.

· Real-time plasma xyuas dynamically kho laser zog (kho daws teeb meem: 0.1mJ).

· Cov ntaub thaiv huab cua minimizes ntug micro-cracks (<3μm).

Nyob rau hauv cov ntaub ntawv thov raug suav nrog 0.5mm-thick sapphire wafer dicing, lub kaw lus ua tiav kev txiav ceev ntawm 300mm / s nrog chipping qhov ntev <10μm, sawv cev rau 5x kev txhim kho kev ua haujlwm ib txwm muaj.

Kev ua tau zoo

1.Integrated dual-chaw nres tsheb txiav thiab splitting system rau kev ua haujlwm yooj yim;

2.High-speed machining ntawm complex geometries txhim kho cov txheej txheem conversion efficiency;

3.Taper-dawb txiav npoo nrog tsawg chipping (<50μm) thiab tus neeg teb xov tooj-kev tuav pov hwm;

4.Seamless hloov ntawm cov khoom specifications nrog intuitive ua hauj lwm;

5.Cov nqi khiav lag luam qis, tus nqi siab, cov txheej txheem siv tsis tau thiab tsis muaj kuab paug;

6.Zero tiam ntawm slag, pov tseg kua los yog dej khib nyiab nrog guaranteed nto kev ncaj ncees;

Qauv qauv

Tej kev siv

1.Consumer Electronics Manufacturing:

· Precision contour txiav ntawm smartphone 3D npog iav (R-lub kaum sab xis: ± 0.01mm).

· Micro-qhov drilling hauv sapphire saib lo ntsiab muag (qhov tsawg kawg nkaus aperture: Ø0.3mm).

· Kev ua tiav ntawm optical iav transmissive zones rau cov koob yees duab hauv qab.

2.Optical Component Production:

· Microstructure machining rau AR/VR lens arrays (feature size ≥20μm).

· Angled txiav ntawm quartz prisms rau laser collimators (angular kam rau ua: ± 15 ").

· Profile shaping ntawm infrared lim (txiav taper <0.5°).

3.Semiconductor Ntim:

· iav hla-via (TGV) ua ntawm wafer theem (nam piv 1:10).

· Microchannel etching ntawm iav substrates rau microfluidic chips (Ra <0.1μm).

· zaus-tuning txiav rau MEMS quartz resonators.

Rau automotive LiDAR optical qhov rais fabrication, lub kaw lus enables contour txiav ntawm 2 hli-thick quartz iav nrog txiav perpendicularity ntawm 89.5 ± 0.3 °, ua tau raws li automotive-qib vibration xeem yuav tsum tau.

Cov txheej txheem siv

Tshwj xeeb engineered rau precision txiav ntawm brittle / tawv cov ntaub ntawv xws li:

1.Standard iav & optical iav (BK7, fused silica);

2. Quartz muaju & sapphire substrates;

3. Tempered iav & optical lim

4. Daim iav substrate

Muaj peev xwm ntawm ob qho tib si contour txiav thiab precision sab hauv qhov drilling (tsawg kawg Ø0.3mm)

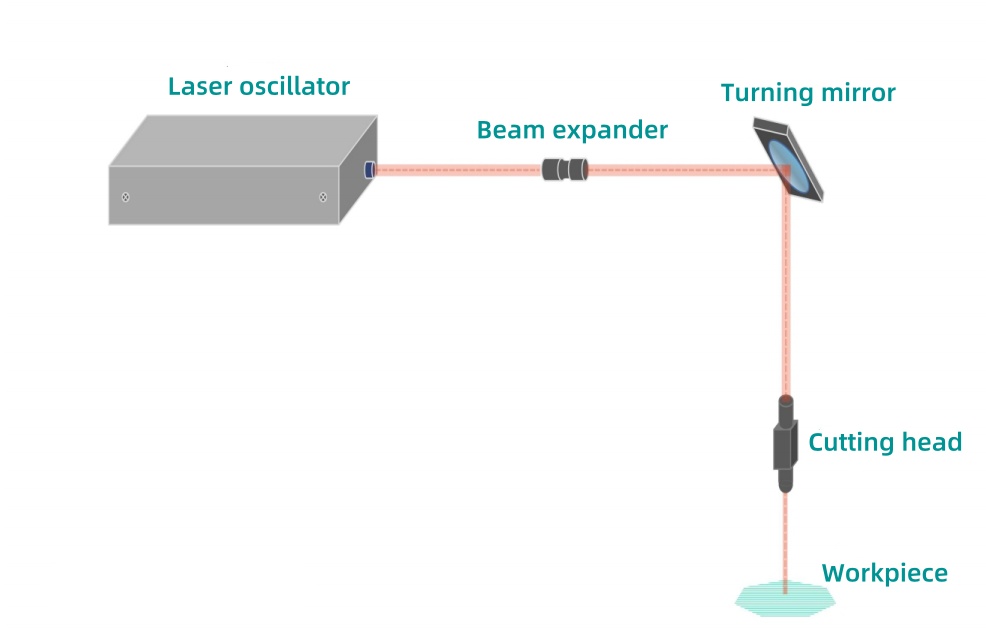

Laser Txiav Txoj Cai

Lub laser generates ultrashort pulses nrog lub zog siab heev uas cuam tshuam nrog workpiece hauv femtosecond-to-picosecond timescales. Thaum nthuav tawm los ntawm cov khoom siv, lub nqaj cuam tshuam nws cov qauv kev ntxhov siab los tsim cov micron-scale filamentation qhov. Optimized qhov sib nrug generates tswj micro-cracks, uas ua ke nrog cleaving technology kom ua tiav precision sib cais.

Laser txiav qhov zoo

1.High automation kev koom ua ke (ua ke txiav / cleaving functionality) nrog tsawg zog noj thiab yooj yim ua hauj lwm;

2.Kev ua tsis sib cuag ua rau muaj peev xwm ua tsis tau zoo los ntawm cov txheej txheem ib txwm ua;

3.Consumable-free lag luam txo cov nqi khiav thiab txhim khu ib puag ncig sustainability;

4.Superior precision nrog xoom taper lub kaum sab xis thiab tshem tawm cov kev puas tsuaj thib ob workpiece;

XKH muab cov kev pabcuam customization rau peb cov tshuab laser txiav, suav nrog cov txheej txheem tsim kho, tshwj xeeb cov txheej txheem kev txhim kho, thiab cov kev daws teeb meem tshwj xeeb kom tau raws li cov cai tsim khoom tshwj xeeb thoob plaws ntau yam kev lag luam.