Ion Beam Polishing Tshuab rau sapphire SiC Si

Daim duab qhia ntxaws

Product Overview ntawm Ion Beam Polishing Tshuab

Lub Ion Beam Figuring thiab Polishing Tshuab yog raws li lub hauv paus ntsiab lus ntawm ion sputtering. Hauv lub tshuab nqus tsev siab, ib qho ion qhov chaw tsim cov ntshav, uas yog nrawm rau hauv lub zog ion beam. Cov kab teeb no ua rau lub ntsej muag ntawm qhov muag pom, tshem tawm cov khoom ntawm qhov ntsuas atomic kom ua tiav qhov kev kho qhov tseeb thiab ua tiav.

Raws li cov txheej txheem tsis sib cuag, ion beam polishing tshem tawm cov kev ntxhov siab thiab tsis txhob muaj kev puas tsuaj rau subsurface, ua rau nws zoo tagnrho rau kev tsim cov khoom siv hluav taws xob zoo siv hauv astronomy, aerospace, semiconductors, thiab cov ntawv thov kev tshawb fawb.

Txoj Cai Ua Haujlwm ntawm Ion Beam Polishing Tshuab

Ion tiam

Inert gas (piv txwv li, argon) yog nkag mus rau hauv lub tshuab nqus tsev chamber thiab ionized los ntawm cov hluav taws xob tawm mus rau hauv plasma.

Acceleration & Beam tsim

Cov ions tau nrawm mus rau ntau pua lossis txhiab tus hluav taws xob hluav taws xob (eV) thiab zoo li mus rau qhov chaw ruaj khov, tsom teeb pom kev zoo.

Kev tshem tawm cov khoom siv

Lub ion beam lub cev sputters atoms los ntawm qhov chaw yam tsis muaj tshuaj tiv thaiv.

Kev kuaj pom yuam kev & Txoj Kev Npaj

Cov duab deviations yog ntsuas nrog interferometry. Kev tshem tawm cov haujlwm yog siv los txiav txim siab lub sijhawm nyob thiab tsim cov cuab yeej ua haujlwm zoo.

Kaw-Loop Kho

Cov voj voog ntawm kev ua thiab kev ntsuas txuas ntxiv mus txog thaum RMS / PV cov hom phiaj ua tiav.

Cov yam ntxwv tseem ceeb ntawm Ion Beam Polishing Tshuab

Universal Surface Compatibility- Cov txheej txheem tiaj tus, spherical, aspherical, thiab freeform nto

Ultra-Stable tshem tawm tus nqi- Pab kom sub-nanometer daim duab kho

Kev puas tsuaj-dawb ua- Tsis muaj subsurface defects lossis kev hloov ntawm cov qauv

Kev ua tau zoo ib yam- Ua haujlwm sib npaug zoo ntawm cov khoom sib txawv hardness

Low/Medium Frequency Kho- Tshem tawm qhov yuam kev yam tsis tau tsim cov khoom siv nruab nrab / siab zaus

Yuav Tsum Muaj Kev Kho Mob Tsawg- Kev ua haujlwm tsis tu ncua ntev nrog tsawg kawg downtime

Main Technical Specifications ntawm Ion Beam Polishing Tshuab

| Yam khoom | Specification |

| Txoj kev ua | Ion sputtering nyob rau hauv ib puag ncig high-vacuum |

| Hom kev ua haujlwm | Tsis sib cuag nto figuring & polishing |

| Max Workpiece Loj | Φ4000 hli |

| Motion Axes | 3-axis / 5-axis |

| Kev tshem tawm ruaj khov | ≥95% |

| Qhov tseeb | PV <10 nm; RMS ≤ 0.5 nm (tus qauv RMS < 1 nm; PV < 15 nm) |

| Muaj peev xwm kho tau | Tshem tawm qhov yuam kev tsawg-nruab nrab yam tsis qhia qhov yuam kev nruab nrab / siab zaus |

| Kev ua haujlwm tsis tu ncua | 3-5 lub lis piam tsis tu lub tshuab nqus tsev |

| Tus nqi kho mob | Tsawg |

Kev Ua Tau Zoo ntawm Ion Beam Polishing Tshuab

Txhawb hom nto

Yooj yim: tiaj tus, kheej kheej, prism

Complex: Symmetric / asymmetric asphere, off-axis asphere, cylindrical

Tshwj xeeb: Ultra-thin optics, slat optics, hemispherical optics, conformal optics, theem phaj, freeform nto

Cov ntaub ntawv txhawb nqa

Kho qhov muag iav: Quartz, microcrystalline, K9, thiab lwm yam.

Infrared cov ntaub ntawv: Silicon, germanium, thiab lwm yam.

Hlau: Aluminium, stainless hlau, titanium alloy, thiab lwm yam.

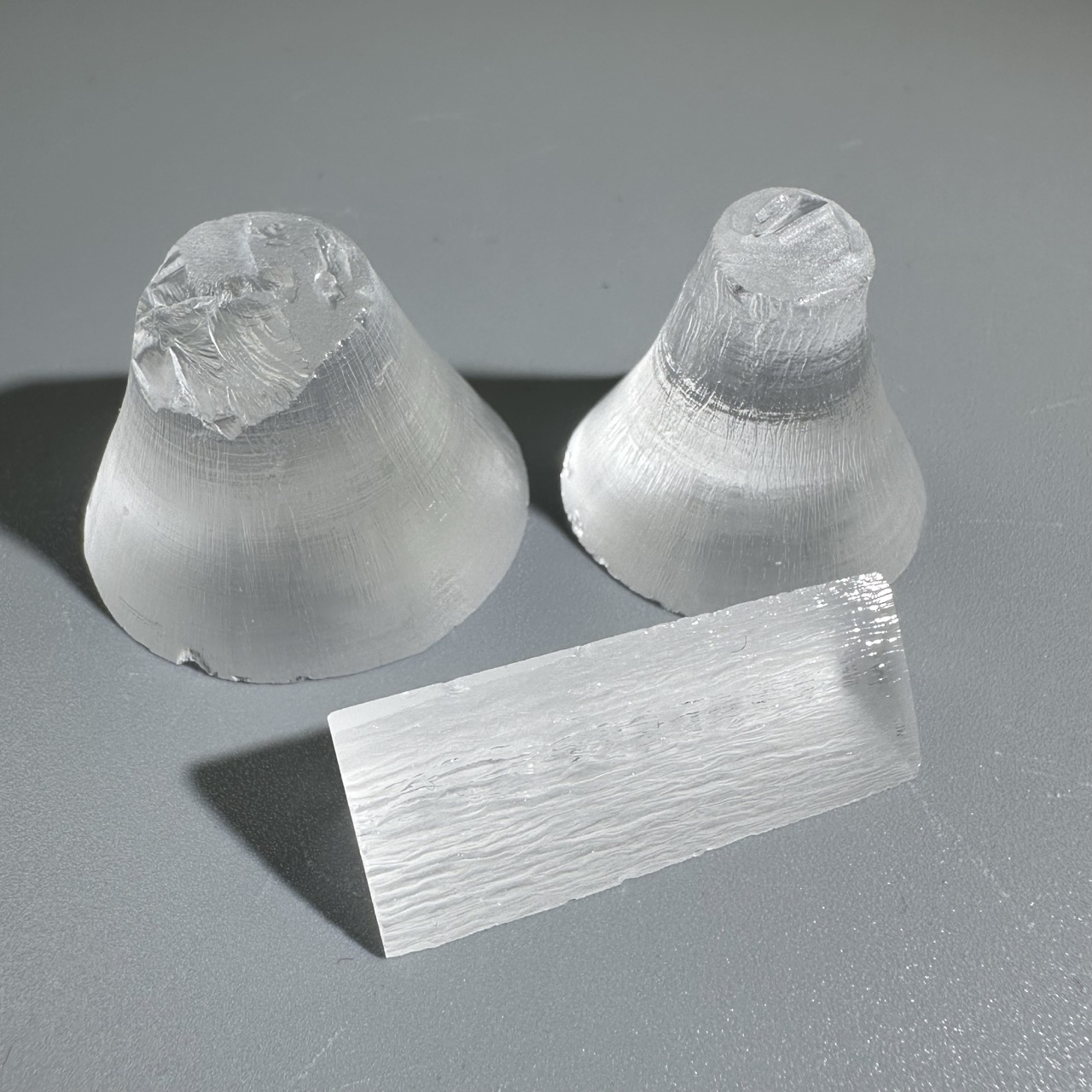

Crystals: YAG, ib leeg-crystal silicon carbide, thiab lwm yam.

Cov ntaub ntawv tawv / tawv: Silicon carbide, thiab lwm yam.

Surface Quality / Precision

PV <10 nm

RMS ≤ 0.5 nm

Txheej Txheem Kev Kawm ntawm Ion Beam Polishing Tshuab

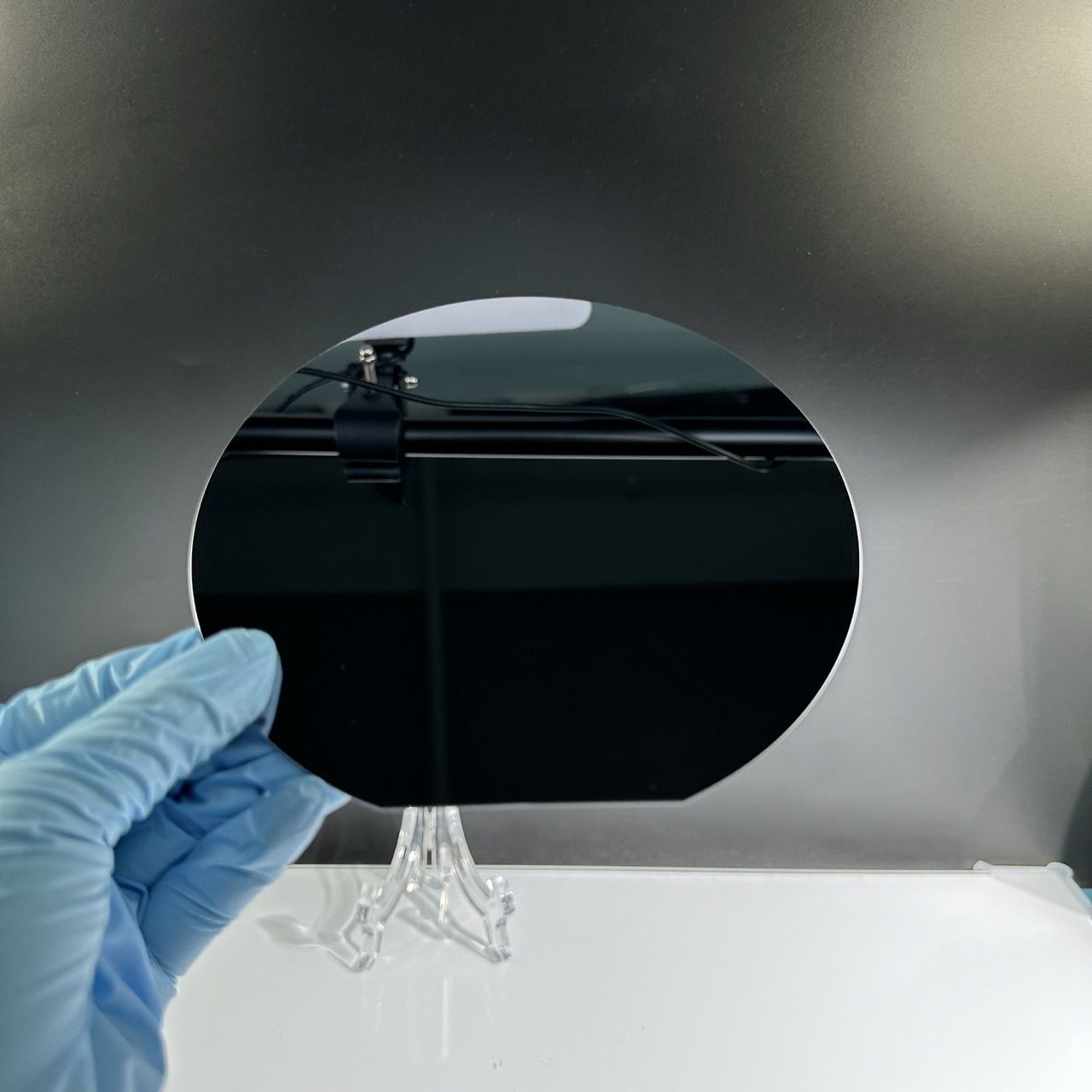

Case 1 – Standard Flat Mirror

Khoom siv: D630mm quartz tiaj tus

Qhov tshwm sim: PV 46.4 nm; RMS 4.63 nm

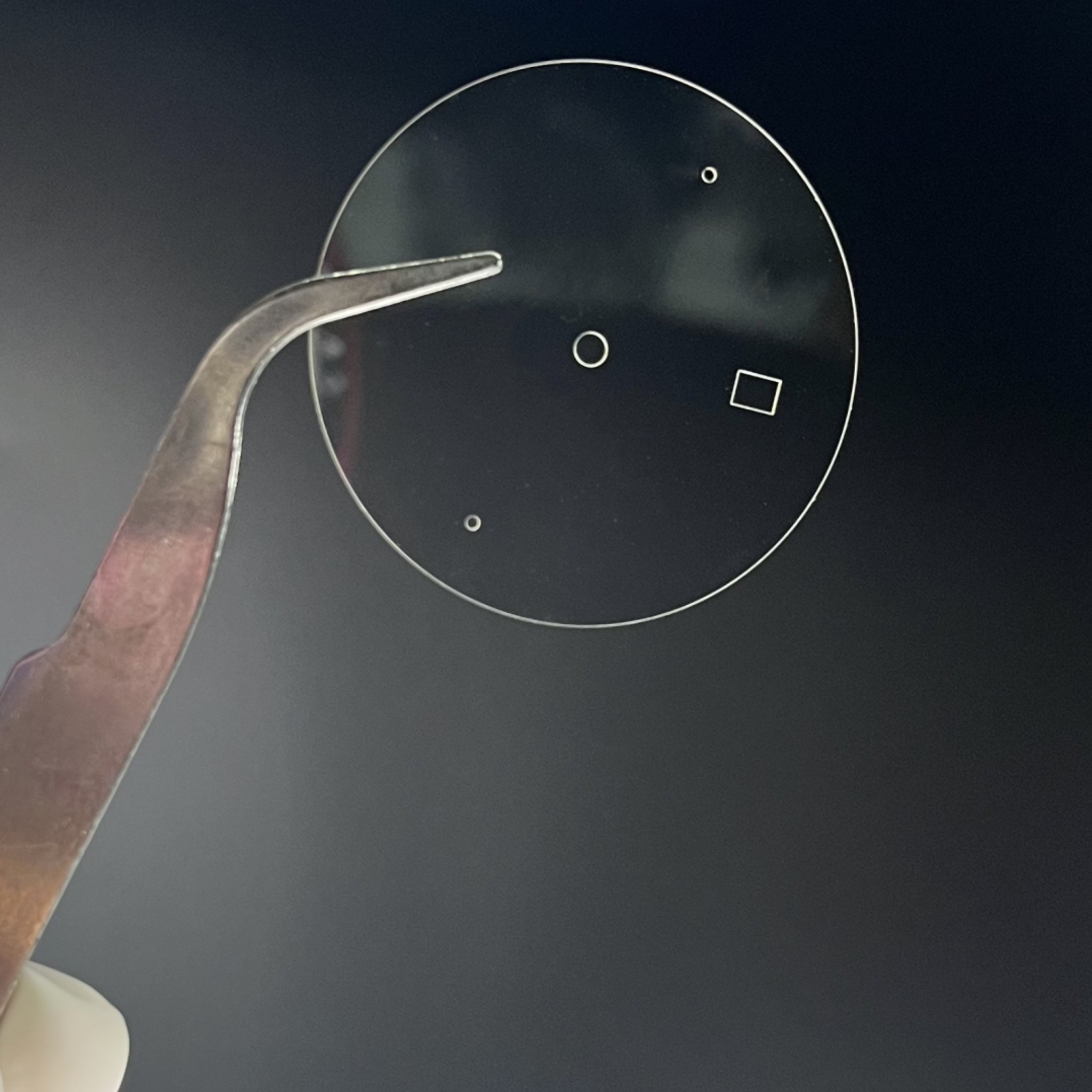

Case 2 – X-ray Reflective Mirror

Workpiece: 150 × 30 hli silicon ca

Qhov tshwm sim: PV 8.3 nm; RMS 0,379 nm; Qhov siab 0.13 µrad

Case 3 – Off-Axis Daim iav

Khoom siv: D326mm off-axis av daim iav

Qhov tshwm sim: PV 35.9 nm; RMS 3.9 Nm

FAQ ntawm Quartz Glasses

FAQ - Ion Beam Polishing Tshuab

Q1: Dab tsi yog ion beam polishing?

A1:Ion beam polishing yog txheej txheem tsis sib cuag uas siv lub teeb pom kev ntawm ions (xws li argon ions) kom tshem tawm cov khoom ntawm qhov chaw ua haujlwm. Cov ions tau nrawm thiab coj mus rau saum npoo, ua rau cov khoom siv atomic-theem tshem tawm, ua rau cov khoom ua kom zoo nkauj. Cov txheej txheem no tshem tawm txhua yam kev ntxhov siab thiab kev puas tsuaj subsurface, ua rau nws zoo tagnrho rau precision optical Cheebtsam.

Q2: Dab tsi ntawm qhov chaw tuaj yeem ua tus txheej txheem Ion Beam Polishing?

A2:CovIon Beam Polishing Tshuabtuaj yeem ua tau ntau yam ntawm qhov chaw, nrog rau cov khoom siv kho qhov muag yooj yim xws liflats, spheres, thiab prisms, as well as complex geometry nyiamaspheres, off-axis aspheres, thiabfreeform nto. Nws yog tshwj xeeb tshaj yog zoo rau cov ntaub ntawv xws li kho qhov muag iav, infrared optics, hlau, thiab cov ntaub ntawv nyuaj / brittle.

Q3: Cov ntaub ntawv dab tsi tuaj yeem Ion Beam Polishing Tshuab ua haujlwm nrog?

A3:CovIon Beam Polishing Tshuabtuaj yeem polish ntau yam khoom, suav nrog:

-

Kho qhov muag iavKhoom siv: Quartz, microcrystalline, K9, thiab lwm yam.

-

Cov ntaub ntawv infrared: Silicon, germanium, thiab lwm yam.

-

Hlau: Aluminium, stainless hlau, titanium alloy, thiab lwm yam.

-

Cov khoom siv Crystal: YAG, ib leeg-crystal silicon carbide, thiab lwm yam.

-

Lwm cov ntaub ntawv nyuaj / nkig: Silicon carbide, thiab lwm yam.

Txog Peb

XKH tshwj xeeb hauv kev tsim cov thev naus laus zis, tsim khoom, thiab muag cov iav tshwj xeeb kho qhov muag thiab cov ntaub ntawv siv lead ua tshiab. Peb cov khoom siv kho qhov muag khoom siv hluav taws xob, khoom siv hluav taws xob, thiab tub rog. Peb muab Sapphire optical Cheebtsam, xov tooj ntawm tes lens npog, Ceramics, LT, Silicon Carbide SIC, Quartz, thiab semiconductor siv lead ua wafers. Nrog cov kws tshaj lij thiab cov cuab yeej siv niaj hnub, peb ua tau zoo hauv kev ua cov khoom lag luam uas tsis yog tus qauv, aiming los ua ib qho khoom siv optoelectronic high-tech enterprise.