LNOI Wafer (Lithium Niobate ntawm Insulator) Telecommunications Sensing Siab Electro-Optic

Daim duab qhia ntxaws

Txheej txheem cej luam

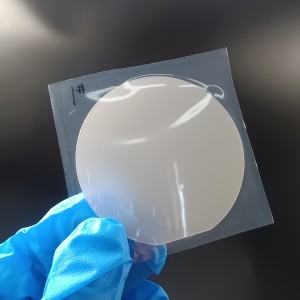

Nyob rau hauv lub thawv wafer muaj symmetrical grooves, qhov ntev ntawm uas yog nruj me ntsis sib xws los txhawb ob sab ntawm lub wafer. Lub thawv siv lead ua feem ntau yog ua los ntawm cov khoom siv yas PP uas tiv taus kub, hnav thiab hluav taws xob zoo li qub. Cov xim sib txawv ntawm cov khoom siv ntxiv yog siv los paub qhov txawv ntawm cov txheej txheem hlau hauv cov khoom siv semiconductor. Vim yog qhov loj me me ntawm cov khoom siv hluav taws xob, cov qauv ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom cov qauv tsim, thiab cov txheej txheem nruj heev ntawm cov khoom siv hauv kev tsim khoom, lub thawv wafer yuav tsum tau lees paub qhov chaw huv si txuas mus rau microenvironment lub thawv tshuaj tiv thaiv kab noj hniav ntawm cov tshuab ntau lawm.

Fabrication Methodology

Kev tsim ntawm LNOI wafers muaj ob peb kauj ruam meej:

Kauj ruam 1: Helium Ion ImplantationHelium ions tau nkag mus rau hauv ib qho LN siv lead ua siv lub ion implanter. Cov ions no nyob ntawm qhov tob tshwj xeeb, tsim lub dav hlau tsis muaj zog uas yuav pab txhawb kev ua yeeb yaj kiab.

Kauj ruam 2: Base Substrate TsimIb qho sib cais silicon lossis LN wafer yog oxidized lossis txheej nrog SiO2 siv PECVD lossis thermal oxidation. Nws saum npoo yog planarized rau kev pom kev sib raug zoo.

Kauj Ruam 3: Bonding ntawm LN rau SubstrateLub ion-implanted LN siv lead ua yog flipped thiab txuas mus rau lub hauv paus wafer siv ncaj wafer bonding. Hauv cov chaw tshawb fawb, benzocyclobutene (BCB) tuaj yeem siv los ua cov nplaum kom yooj yim rau kev sib txuas hauv cov xwm txheej tsis tshua muaj zog.

Kauj Ruam 4: Kev kho cua sov thiab kev sib cais zaj duab xisAnnealing activates npuas tsim ntawm qhov tob implanted, ua kom sib cais ntawm nyias zaj duab xis (sab saum toj LN txheej) los ntawm tej. Mechanical force yog siv los ua kom tiav qhov exfoliation.

Kauj Ruam 5: Nto PolishingChemical Mechanical Polishing (CMP) yog siv los ua kom du saum npoo LN, txhim kho kho qhov muag zoo thiab cov khoom tawm los.

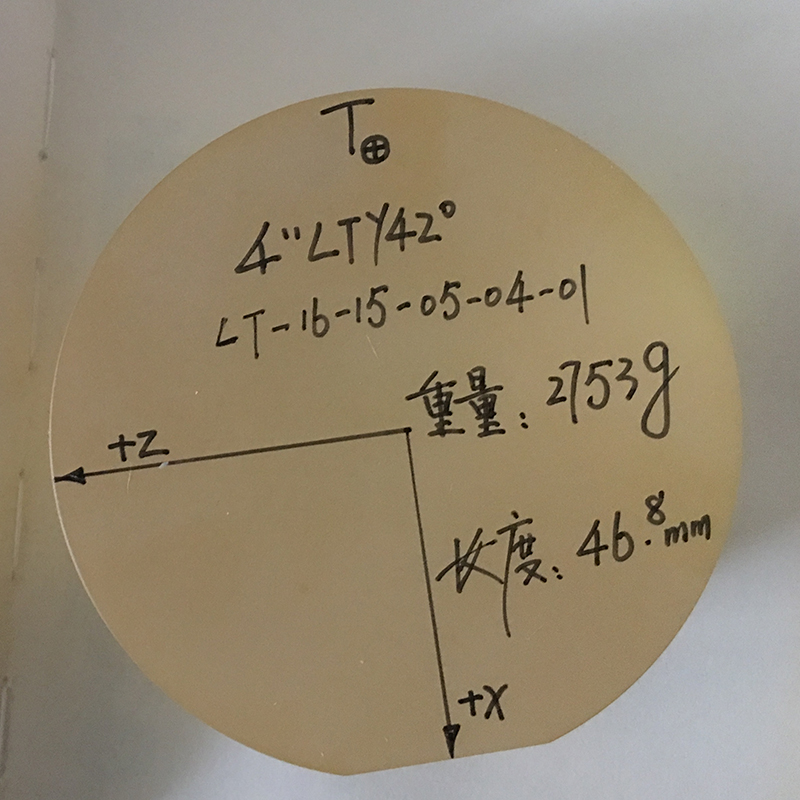

Technical Parameters

| Khoom siv | Kho qhov muag Qib LIB 3 wafes (White or Dub) | |

| Curie Temp | 1142 ± 0.7 ℃ | |

| Txiav Lub kaum sab xis | X / Y / Z thiab lwm yam | |

| Txoj kab uas hla / qhov loj | 2 "/ 3" / 4" ± 0.03mm | |

| Tus nqi (±) | 0.20mm ± 0.005mm | |

| Thickness | 0.18 ~ 0.5mm lossis ntau dua | |

| Thawj Pav ca | 16mm / 22mm / 32mm | |

| TTV | <3m | |

| Hneev | -30 | |

| Warp | <40 m os | |

| Kev taw qhia Pav ca | Txhua yam muaj | |

| Nto Hom | Ib Sab Polished (SSP) / Ob Chav Sab Polished (DSP) | |

| Polished sab Ra | <0.5nm | |

| S/D | 20/10 | |

| Ntug Cov txheej txheem | R = 0.2 hli C-hom or Bullnose | |

| Zoo | Dawb of tawg (npuas thiab suav nrog) | |

| Kho qhov muag doped | Mg/Fe/Zn/MgO lwm rau kho qhov muag qib LN wafers rau thov | |

| Wafer Nto Cov txheej txheem | Refractive Index | Tsis yog = 2.2878 / Ne = 2.2033 @ 632nm wavelength / prism coupler method. |

| Kev kis kab mob, | Tsis muaj | |

| Cov khoom c> 0.3m m | <=30 | |

| Scratch, Chipping | Tsis muaj | |

| Tsis zoo | Tsis muaj ntug tawg, khawb, pom cov cim, stains | |

| Ntim | Qty / Wafer box | 25 pcs rau ib lub thawv |

Siv Cases

Vim nws muaj ntau yam thiab kev ua tau zoo, LNOI tau siv thoob plaws ntau qhov kev lag luam:

Photonics:Compact modulators, multiplexers, thiab photonic circuits.

RF/Acoustics:Acousto-optic modulators, RF lim.

Quantum Computing:Nonlinear zaus mixers thiab photon-pair generators.

Kev Tiv Thaiv & Aerospace:Tsawg-poob optical gyros, zaus hloov khoom siv.

Cov cuab yeej kho mob:Optical biosensors thiab high-frequency signal probes.

FAQ

Q: Vim li cas LNOI nyiam tshaj SOI hauv cov tshuab kho qhov muag?

A:LNOI nta superior electro-optic coefficients thiab wider transparency ntau yam, ua kom muaj kev ua tau zoo dua hauv photonic circuits.

Q: Puas yog CMP yuav tsum tau ua tom qab sib cais?

A:Yog lawm. Qhov raug LN nto yog ntxhib tom qab ion-slicing thiab yuav tsum tau polished kom tau raws li qhov ntsuas qhov ntsuas qhov ntsuas.

Q: Dab tsi yog qhov siab tshaj plaws wafer loj muaj?

A:Kev lag luam LNOI wafers feem ntau yog 3 "thiab 4", tab sis qee tus neeg muag khoom tab tom tsim 6 "variants.

Q: LN txheej puas tuaj yeem rov siv dua tom qab sib cais?

A:Lub hauv paus siv lead ua tuaj yeem rov ua polished thiab rov siv dua ob peb zaug, txawm hais tias qhov zoo yuav degrade tom qab ntau lub voj voog.

Q: Puas yog LNOI wafers sib haum nrog CMOS ua?

A:Yog lawm, lawv tau tsim los ua kom haum nrog cov txheej txheem semiconductor fabrication, tshwj xeeb tshaj yog thaum siv silicon substrates.