Microjet laser tshuab cuab yeej wafer txiav SiC cov ntaub ntawv ua

Txoj haujlwm ua haujlwm:

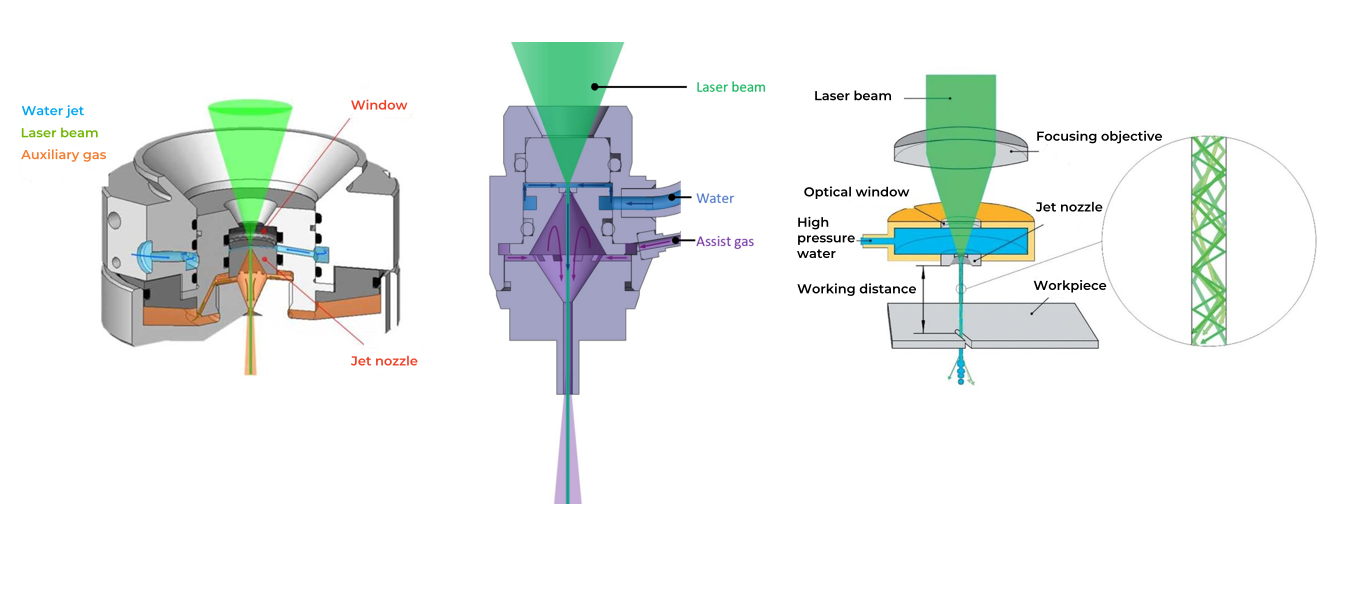

1. Laser coupling: pulsed laser (UV / ntsuab / infrared) yog teem rau hauv lub dav hlau ua kua los tsim ib tug ruaj khov zog kis tau tus mob channel.

2. Kev taw qhia ua kua: lub dav hlau ceev ceev (ntev tus nqi 50-200m / s) ua kom txias rau qhov chaw ua haujlwm thiab tshem tawm cov khib nyiab kom tsis txhob muaj cua sov thiab muaj kuab paug.

3. Kev tshem tawm cov khoom siv: Lub zog laser ua rau cov nyhuv cavitation hauv cov kua kom ua tiav cov txheej txheem txias ntawm cov khoom (tshav kub cuam tshuam cheeb tsam <1μm).

4. Dynamic tswj: real-time hloov ntawm laser tsis (lub zog, zaus) thiab dav hlau siab kom tau raws li qhov xav tau ntawm cov khoom sib txawv thiab cov qauv.

Cov ntsiab lus tseem ceeb:

1. Laser hwj chim: 10-500W (adjustable)

2. Dav dav dav: 50-300μm

3.Machining raug: ± 0.5μm (txiav), qhov tob rau qhov dav piv 10: 1 (drilling)

Technical zoo:

(1) Yuav luag xoom kub puas tsuaj

- Lub dav hlau ua kua txias tswj lub tshav kub cuam tshuam cheeb tsam (HAZ) rau **<1μm**, zam micro-cracks los ntawm cov pa laser ua (HAZ feem ntau> 10μm).

(2) Ultra-siab precision machining

- Txiav / tho qhov raug mus txog ** ± 0.5μm **, ntug roughness Ra<0.2μm, txo qhov xav tau rau polishing tom ntej.

- Txhawb nqa txoj kev ua haujlwm 3D (xws li conical qhov, zoo li lub qhov).

(3) Cov khoom siv dav siv tau

- Cov ntaub ntawv nyuaj thiab nkig: SiC, sapphire, iav, ceramics (cov txheej txheem ib txwm ua tau yooj yim tawg).

- Cov khoom siv hluav taws xob kub: polymers, cov ntaub so ntswg lom (tsis muaj kev pheej hmoo ntawm thermal denaturation).

(4) Kev tiv thaiv ib puag ncig thiab kev ua haujlwm zoo

- Tsis muaj plua plav paug, kua tuaj yeem rov ua dua thiab lim.

- 30% -50% nce hauv kev ceev (vs. machining).

(5) Kev txawj ntse tswj

- Integrated pom qhov chaw thiab AI parameter optimization, adaptive khoom thickness thiab tsis xws luag.

Technical specifications:

| Countertop ntim | 300 * 300 * 150 hli | 400 * 400 * 200 hli |

| Linear axis XY | Linear lub cev muaj zog. Linear lub cev muaj zog | Linear lub cev muaj zog. Linear lub cev muaj zog |

| Linear axis Z | 150 | 200 |

| Positioning raug μm | +/-5 | +/-5 |

| Rov ua qhov tseeb qhov tseeb μm | +/-2 | +/-2 |

| Acceleration G | 1 | 0.29 ib |

| Tus lej tswj | 3 axis / 3 + 1 axis / 3 + 2 axis | 3 axis / 3 + 1 axis / 3 + 2 axis |

| Tus lej tswj hom | DPSS Nd:YAG | DPSS Nd:YAG |

| Lub wavelength nm | 532/1064 ib | 532/1064 ib |

| Rated zog W | 50/100/200 | 50/100/200 |

| Dej dav hlau | 40-100 | 40-100 |

| Nozzle siab bar | 50-100 | 50-600 |

| Dimensions ( tshuab cuab yeej) (dav * ntev * qhov siab) mm | 1445 * 1944 * 2260 | 1700 * 1500 * 2120 |

| Loj (tswj txee) (W * L * H) | 700 * 2500 * 1600 hli | 700 * 2500 * 1600 hli |

| Qhov hnyav (cov khoom siv) T | 2.5 | 3 |

| Qhov hnyav (tswj txee) KG | 800 | 800 |

| Kev muaj peev xwm ua tau | Nto roughness Ra≤1.6um Qhib ceev ≥1.25mm / s Txiav txiav ≥6mm / s Linear txiav ceev ≥50mm / s | Nto roughness Ra≤1.2um Qhib ceev ≥1.25mm / s Txiav txiav ≥6mm / s Linear txiav ceev ≥50mm / s |

| Rau gallium nitride siv lead ua, ultra-wide band gap semiconductor cov ntaub ntawv (pob zeb diamond / Gallium oxide), aerospace tshwj xeeb cov ntaub ntawv, LTCC carbon ceramic substrate, photovoltaic, scintillator siv lead ua thiab lwm yam ntaub ntawv ua. Lus Cim: Kev ua haujlwm muaj peev xwm txawv nyob ntawm cov khoom siv

| ||

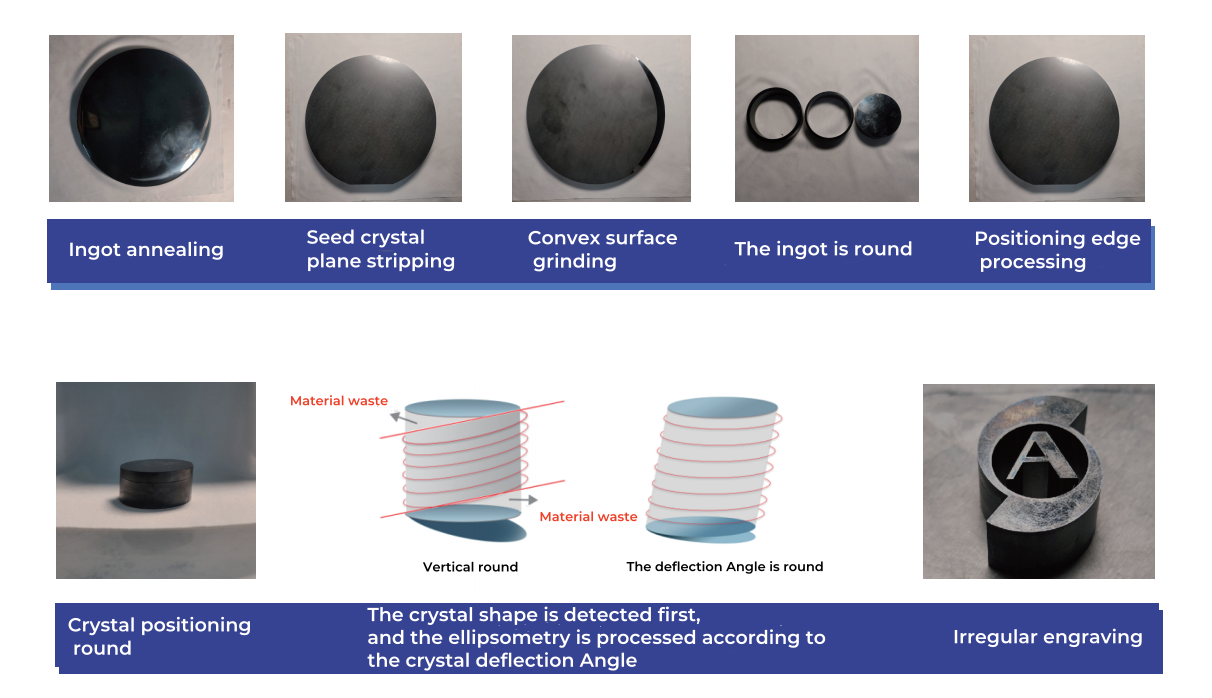

Txheej txheem:

XKH cov kev pabcuam:

XKH muab tag nrho cov kev pab cuam lub neej tag nrho rau microjet laser tshuab cuab yeej, los ntawm cov txheej txheem thaum ntxov txoj kev loj hlob thiab kev xaiv cov cuab yeej kev sab laj, mus rau nruab nrab-lub sij hawm customized system kev koom ua ke (xws li tshwj xeeb txuam ntawm laser qhov chaw, dav hlau system thiab automation module), mus rau tom qab kev khiav hauj lwm thiab txij nkawm kev cob qhia thiab tas mus li txheej txheem optimization, tag nrho cov txheej txheem yog nruab nrog kev pab neeg kev pab txhawb nqa; Raws li 20 xyoo ntawm precision machining kev paub, peb muaj peev xwm muab ib-nres kev daws teeb meem nrog rau cov khoom pov thawj, kev qhia ntau lawm thiab tom qab-muag cov lus teb sai (24 teev ntawm kev pab txhawb nqa + tseem ceeb spare qhov chaw cia) rau txawv industries xws li semiconductor thiab kev kho mob, thiab cog lus 12 lub hlis ntev warranty thiab lub neej kev pab cuam thiab txawj tej yam ntxiv. Xyuas kom meej tias cov neeg siv khoom ib txwm tswj hwm kev lag luam ua cov kev ua tau zoo thiab ruaj khov.

Daim duab qhia ntxaws