Q: Dab tsi yog cov thev naus laus zis tseem ceeb siv hauv SiC wafer slicing thiab ua?

A:Silicon carbide (SiC) muaj qhov hardness thib ob tsuas yog pob zeb diamond thiab suav tias yog cov khoom siv tawv heev thiab nkig. Cov txheej txheem slicing, uas cuam tshuam nrog kev txiav cov noob qoob loo rau hauv nyias wafers, yog lub sij hawm siv thiab ua rau chipping. Raws li thawj kauj ruam hauvSiCib leeg siv lead ua ua, qhov zoo ntawm slicing ho cuam tshuam tom qab sib tsoo, polishing, thiab thinning. Slicing feem ntau qhia txog cov kab nrib pleb thiab subsurface, nce wafer breakage tus nqi thiab cov nqi tsim khoom. Yog li ntawd, kev tswj xyuas qhov tawg tawg puas tsuaj thaum hlais yog qhov tseem ceeb rau kev nce qib SiC ntaus ntawv.

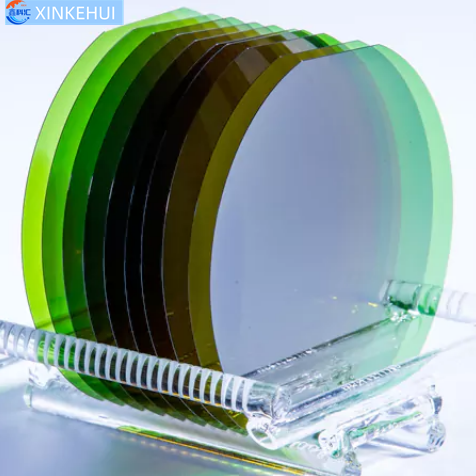

Tam sim no qhia SiC slicing txoj kev suav nrog ruaj-abrasive, dawb-abrasive slicing, laser txiav, txheej hloov (txias sib cais), thiab hluav taws xob slicing. Ntawm cov no, reciprocating multi-wire slicing nrog taag pob zeb diamond abrasives yog feem ntau siv txoj kev ua SiC ib leeg muaju. Txawm li cas los xij, raws li qhov loj me mus txog 8 ntiv tes thiab siab dua, tsoos hlau sawing ua haujlwm tsawg dua vim cov khoom siv siab, cov nqi, thiab kev ua haujlwm tsawg. Muaj kev xav tau ceev ceev rau cov nqi qis, qis qis, ua haujlwm siab slicing technologies.

Q: Dab tsi yog qhov zoo ntawm laser slicing dua tsoos multi-wire txiav?

A: Ib txwm xaim sawing txiav covSiC kevraws ib qho kev taw qhia mus rau hauv slices ob peb puas microns tuab. Cov hlais yog tom qab ntawd siv cov pob zeb diamond slurries tshem tawm cov cim pom thiab kev puas tsuaj hauv av, ua raws li tshuaj lom neeg polishing (CMP) kom ua tiav lub ntiaj teb kev npaj, thiab thaum kawg ntxuav kom tau txais SiC wafers.

Txawm li cas los xij, vim SiC lub siab tawv thiab brittleness, cov kauj ruam no tuaj yeem yooj yim ua rau warping, cracking, nce breakage tus nqi, ntau dua cov nqi, thiab ua rau siab roughness thiab paug paug (plua plav, dej khib nyiab, thiab lwm yam). Tsis tas li ntawd, hlau sawing yog qeeb thiab muaj qhov tawm los tsawg. Kev kwv yees qhia tau hais tias ib txwm siv ntau cov hlau slicing ua tiav tsuas yog li 50% cov khoom siv, thiab txog li 75% ntawm cov khoom ploj tom qab polishing thiab sib tsoo. Cov ntaub ntawv tsim tawm txawv teb chaws thaum ntxov tau qhia tias nws tuaj yeem siv sijhawm kwv yees li 273 hnub ntawm kev tsim khoom 24-teev tas li los tsim 10,000 wafers-lub sijhawm siv ntau heev.

Hauv tsev, ntau lub tuam txhab siv lead ua SiC tau tsom mus rau kev ua kom muaj peev xwm ua kom sov. Txawm li cas los xij, tsis yog tsuas yog nthuav tawm cov khoom tsim tawm xwb, nws tseem ceeb dua los xav txog yuav ua li cas txo qhov poob - tshwj xeeb tshaj yog thaum cov khoom siv lead ua loj hlob tsis tau zoo.

Cov khoom siv laser slicing tuaj yeem txo cov khoom poob thiab txhim kho cov txiaj ntsig. Piv txwv li, siv ib leeg 20 mmSiC kev: Hlau sawing tuaj yeem tawm los ntawm 30 wafers ntawm 350 μm thickness.Laser slicing tuaj yeem tawm tau ntau dua 50 wafers.Yog tias wafer thickness txo mus rau 200 μm, ntau tshaj 80 wafers tuaj yeem tsim los ntawm tib lub ingot.While hlau sawing yog dav siv rau 6 ntiv tes thiab wafers. ingot yuav siv sij hawm 10-15 hnub nrog cov txheej txheem ib txwm siv, xav tau cov khoom siv high-end thiab ua rau cov nqi siab nrog kev ua haujlwm tsawg. Nyob rau hauv cov xwm txheej no, laser slicing qhov zoo ua kom pom tseeb, ua rau nws lub ntsiab lus yav tom ntej rau 8-nti wafers.

Nrog laser txiav, lub sij hawm slicing ib 8-nti wafer yuav nyob rau hauv 20 feeb, nrog rau cov khoom poob ib wafer nyob rau hauv 60 μm.

Hauv cov ntsiab lus, piv rau ntau cov hlau txiav, laser slicing muaj kev ceev dua, cov txiaj ntsig zoo dua, cov khoom siv qis dua, thiab kev ua kom huv.

Q: Dab tsi yog cov teeb meem tseem ceeb hauv SiC laser slicing?

A: Cov txheej txheem laser slicing suav nrog ob kauj ruam tseem ceeb: kev hloov kho laser thiab wafer sib cais.

Lub hauv paus ntawm kev hloov kho laser yog beam shaping thiab parameter optimization. Cov tsis xws li laser fais fab, qhov chaw txoj kab uas hla, thiab scan ceev txhua yam cuam tshuam rau qhov zoo ntawm cov khoom ablation thiab kev vam meej ntawm kev sib cais wafer tom ntej. Lub geometry ntawm thaj chaw hloov kho txiav txim siab qhov roughness thiab qhov nyuaj ntawm kev sib cais. High deg roughness complicates tom qab sib tsoo thiab ua rau kom cov khoom poob.

Tom qab kev hloov kho, kev sib cais wafer feem ntau ua tiav los ntawm kev sib tsoo, xws li kev sib tsoo txias lossis kev ntxhov siab. Qee lub tshuab hauv tsev siv ultrasonic transducers los txhawb kev vibrations rau kev sib cais, tab sis qhov no tuaj yeem ua rau chipping thiab ntug tsis xws luag, txo qis qhov kawg tawm los.

Txawm hais tias ob kauj ruam no tsis yog qhov nyuaj, qhov tsis sib xws hauv cov khoom siv lead ua zoo-vim cov txheej txheem kev loj hlob sib txawv, qib doping, thiab cov kev ntxhov siab sab hauv-tshwj xeeb cuam tshuam rau kev txiav nyuaj, tawm los, thiab cov khoom poob. Tsuas yog txheeb xyuas thaj chaw teeb meem thiab kho qhov chaw laser scanning tej zaum yuav tsis ua kom tau txais txiaj ntsig zoo.

Tus yuam sij rau kev saws me nyuam thoob plaws yog nyob rau hauv kev tsim cov txheej txheem tshiab thiab cov cuab yeej siv uas tuaj yeem hloov mus rau ntau hom siv lead ua zoo los ntawm ntau lub tuam txhab, txhim kho cov txheej txheem tsis zoo, thiab tsim cov tshuab laser slicing nrog universal applicability.

Q: laser slicing tshuab puas tuaj yeem siv rau lwm yam khoom siv semiconductor ntxiv rau SiC?

A: Laser txiav tshuab muaj keeb kwm tau siv rau ntau yam khoom siv. Nyob rau hauv semiconductors, nws tau pib siv rau wafer dicing thiab txij li thaum nthuav mus rau slicing loj loj ib leeg muaju.

Tshaj SiC, laser slicing kuj tseem siv tau rau lwm cov ntaub ntawv nyuaj lossis nkig xws li pob zeb diamond, gallium nitride (GaN), thiab gallium oxide (Ga₂O₃). Cov kev tshawb fawb ua ntej ntawm cov ntaub ntawv no tau pom qhov ua tau thiab qhov zoo ntawm laser slicing rau semiconductor daim ntaub ntawv.

Q: Puas muaj tam sim no paub tab hauv tsev laser slicing khoom khoom? Koj qhov kev tshawb fawb nyob rau theem twg?

A: Loj-inch SiC laser slicing khoom yog dav suav hais tias yog cov cuab yeej tseem ceeb rau yav tom ntej ntawm 8-nti SiC wafer ntau lawm. Tam sim no, tsuas yog Nyiv tuaj yeem muab cov tshuab zoo li no, thiab lawv kim heev thiab raug txwv rau kev xa tawm.

Kev thov hauv tsev rau laser slicing / thinning tshuab yog kwv yees nyob ib ncig ntawm 1,000 units, raws li SiC cov phiaj xwm tsim khoom thiab muaj peev xwm pom cov hlau uas twb muaj lawm. Cov tuam txhab loj hauv tsev tau nqis peev ntau hauv kev txhim kho, tab sis tsis muaj kev paub tab, cov khoom lag luam muaj nyob hauv tsev tseem tsis tau mus txog kev xa tawm.

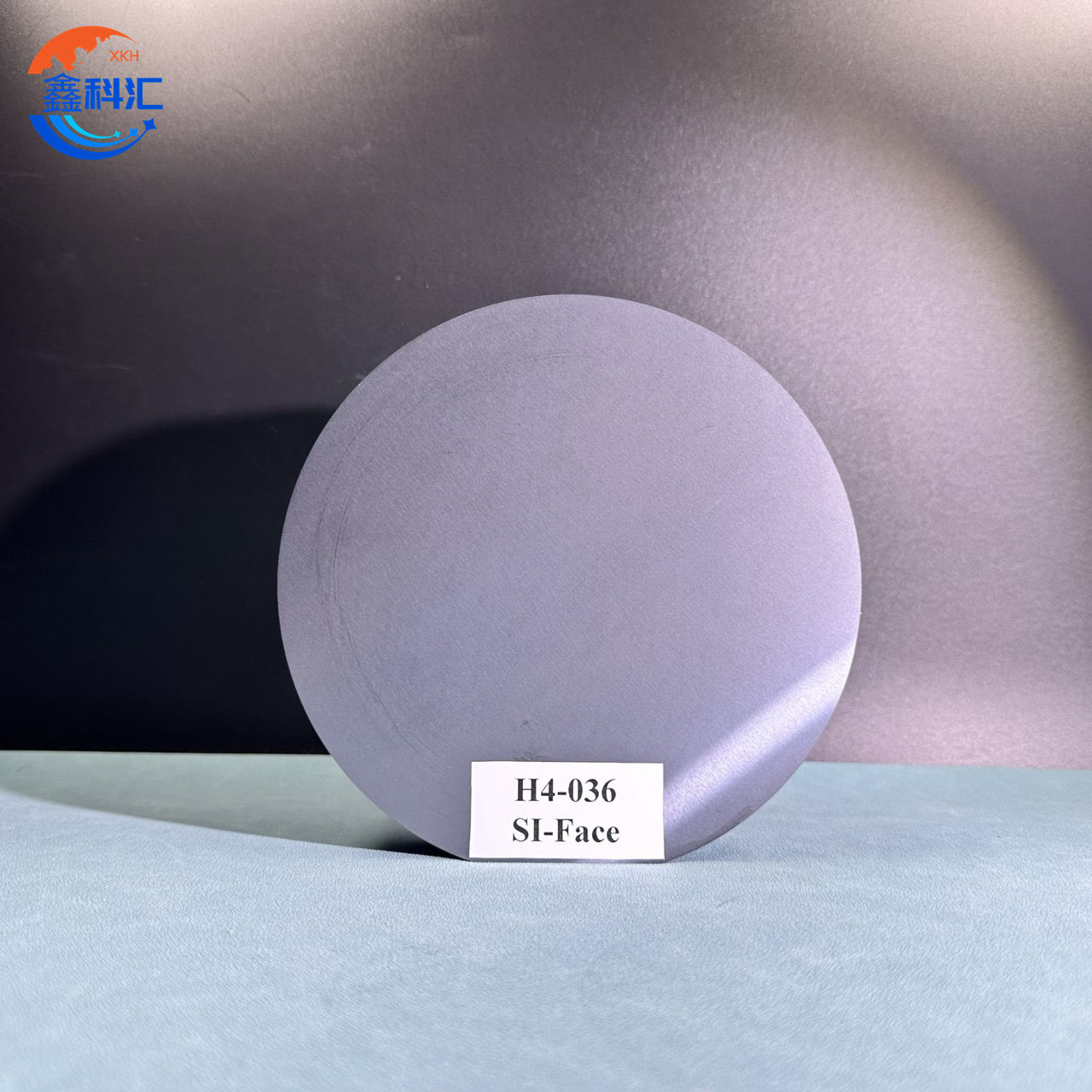

Cov pab pawg tshawb fawb tau tsim cov cuab yeej laser nqa tawm tshuab txij li xyoo 2001 thiab tam sim no tau txuas ntxiv qhov no mus rau qhov loj-inch SiC laser slicing thiab thinning. Lawv tau tsim cov qauv qauv thiab cov txheej txheem slicing muaj peev xwm ntawm: Txiav thiab thinning 4-6 nti semi-insulating SiC wafersSlicing 6-8 nti conductive SiC ingotsPerformance benchmarks: 6-8 nti semi-insulating SiC: slicing lub sij hawm 10-15 feeb / wafer; cov khoom poob <30 μm6-8 nti conductive SiC: slicing lub sij hawm 14-20 feeb / wafer; cov khoom poob <60 μm

Kwv yees wafer yield tau nce ntau dua 50%

Tom qab txiav, cov wafers ua tau raws li lub teb chaws tus qauv rau geometry tom qab sib tsoo thiab polishing. Cov kev tshawb fawb tseem qhia tau tias laser-induced thermal teebmeem tsis cuam tshuam kev ntxhov siab lossis geometry hauv wafers.

Cov cuab yeej siv tib yam kuj tau siv los txheeb xyuas qhov ua tau rau kev txiav pob zeb diamond, GaN, thiab Ga₂O₃ ib leeg muaju.

Post lub sij hawm: May-23-2025